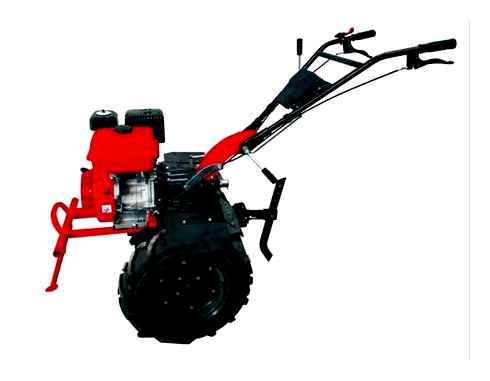

How to assemble the starter on a power tiller. How to use. Typical errors.

Starters for power tillers: repair, replacement with your own hands

Motoblocs are known for their design features. In particular, the fact that they use two starters at once. The auxiliary or spring starter helps the main starter to start properly and quickly. But if the auxiliary starter suddenly fails, then we have to think about how to repair the manual starter. It is possible, even with your own hands.

Speaking of which, the spring option is not the only. The manual starter on a single-axle tractor is quite common, it is common in Russia. It is much easier to use. It is easier to install, even if the user does it with his own hands. It has quite an uncomplicated design:

- drum housing;

- coil;

- Spring, or rather, the whole two: large and small;

- washer;

- cord;

- tongues;

- bolts and nuts, without which it is impossible to assemble either mechanical or electric starter.

When assembled, it looks as follows: the cord is attached to the spool, and it is fixed to the core of the drum housing. Inside the drum there is a special space, where a large spring is located around the axis. It is responsible for ensuring that after cranking the starter returns to its previous position.

Arrangement of the starter

Planning to find out how to assemble the starter on a motor-block, it is necessary to become more familiar with the features of this element and its construction. Motoblocks provide for the presence of two such devices at once. the main and additional, which guarantees the successful start of the engine even in low temperatures.

Studying the device of the starter motor-block, it is advisable to allocate several important nodes at once:

The design provides that in the center of the body of the unit there is a coil with a wrapped cord. On the axis of the body of the product there is a large circular spring, which is responsible for returning the product to its original position when rotating.

The starter is responsible for starting the engine

The principle of operation of such an element is extremely simple and reliable. the user pulls the cord, resulting in the rotation of the coil. Thanks to this element feeds the engine revolutions, which contributes to its confident start.

Types of mechanisms

Before finding out how to repair the starter with their own hands, as well as the most common faults of this unit, it is necessary to get acquainted with the varieties of the part. On sale there are various types, which differ significantly from each other in their technical characteristics and principle of operation.

The most popular appear to be:

- spring devices. a classic version, characterized by the ease of installation and efficiency in use;

- electronic models. provide the presence of the battery for a successful start of the engine, the power is determined by the battery charge;

- The manual mechanism is a simple but less effective option, involving the use of a special handle to start the engine.

When planning to buy a manual starter for a power tiller or its other variety, it should be noted that for most models of equipment, the spring elements are excellent, because their energy will be enough to start the engine. The more advanced electronic devices require a battery charge, so they cannot be used if there is no access to electricity.

How the manual starter works

When the user of the power tiller sharply pulls the starter handle, the entire mechanism installed on the machine comes into motion. The initial rotation is transferred to the single-axle tractor, or rather to the engine, and it starts. Usually to start the engine you need to pull the starter grip a few times to get it to start properly.

Block: 4/18 | Number of characters: 350

Repair of motor-block starter with your own hands

Let’s consider the step-by-step instructions of the procedure:

- Before proceeding directly to the repair of this mechanism, you should find the manual for the power tiller, it contains a scheme of construction.

- Next, you need to prepare a wrench and take a picture of the mechanism, so that later you can assemble it correctly.

- Then you need to unscrew the washer, it is placed inside the housing.

- Then open the cover. Carefully examine the condition of all the elements, there may be damage.

- Basically, the repair of the structure is to replace the worn-out part.

- If you notice damage on the large spring, it should be removed from the drum. In this case, the spring can be restored to functionality, but it is still better to replace the part with a new one.

In addition to the main starter, there is a spring device, which has a simpler design. It can be replaced on your own.

The electric starter is connected to the battery from which it is powered. The machine is started with the start button. The battery determines how long the part will last and its power.

The installation of the device is carried out according to the scheme. A power tiller with an electric starter is reliable, durable and sturdy. However, not all models with a manual start can be converted. Therefore it is essential to read the operating instructions and find out if the battery can be replaced before carrying out any work.

All owners of power tillers need to know that in the beginning of operation all units work properly, but over time, various components can fail.

To extend the longevity of the unit and its parts, you need to regularly inspect the single-axle tractor.

This is interesting: how to assemble a single axle tractor with their own hands.

Starter on a single axle tractor. the device, the nuances of repair, prevention

Motor-block starters are known for their design features. In particular, by the fact that for their use two starters are used at once. Auxiliary or spring starter helps the main one to start properly and quickly. But if the auxiliary starter suddenly fails, then we have to think about how to repair the manual starter. Perhaps even with your own hands.

By the way, the spring option is not the only one. The manual starter on a single-axle tractor is quite common, it is common in Russia. It is much easier to use. It’s easier to install, even if the user does it with his hands. It has quite an uncomplicated design:

bike engine to Power Tiller how-to make power weeder use for bike engine

- drum housing;

- spool;

- a spring, or rather, as many as two: large and small;

- washer;

- cord;

- reeds;

- Bolts and nuts to assemble neither mechanical nor electric starter.

When assembled, it looks as follows: the cord is attached to the spool, and it is fixed to the core of the drum housing. There is a special space inside the drum, where a large spring is located around the axle. It is she is responsible for ensuring that after cranking the starter returns to its previous position.

How the manual starter works

When the user of the power tiller sharply pulls the starter knob, the entire mechanism installed on the machine is set in motion. The initial rotation goes to the single-axle tractor, or rather to the engine, and it starts. As a rule, to start the engine, you need to pull the starter handle a few times sharply to properly accelerate it.

Small nuances on repair

As already mentioned, the manual starter is the least fanciful. In most cases, the repair of the starter is to fix the places where the springs are attached. They sometimes unbend. Or, perhaps, the repair of the starter will be to replace some parts for new. Sometimes you need to replace the starter cord.

In order to determine the specific malfunction, you will need to disassemble the area of the power harvester where the starter is mounted. In what order the repair should take place:

- First, you need to arm yourself with the manufacturer’s schematic diagram. There is a description of how and where all of the parts are attached to the power harvester. You will also need a wrench, with which you will unscrew and remove the nuts.

- Next you need to disconnect the starter. It is better to take a picture and write down everything about its mounting scheme. Otherwise you might not be able to put it back together again.

- In the center of the drum you see a washer that needs to be unscrewed. This is the top washer. When you take it off, disassemble everything you find inside and check for damage to any element.

What breaks most often?

The easiest thing to fix is something that can simply be replaced. For example, if you have a torn cord for your power tiller, you can exchange it for a new one. As for the large spring, here everything is also simple: study the places where it is attached. At its ends there are two hooks. If one of them is not available, it is worth to heat the spring, bend its end in the form of a hook and it will be ready to serve again. However, if the hook is broken due to metal fatigue, it will be more appropriate to replace the spring.

Spring mechanism

Manual design is simple, but it can be improved to save effort and time. For example, put an electric starter for a power tiller. So you don’t have to pull the handle every time. But keep in mind: this design will not suit all starters with manual starting. And the circuit you choose to install may not fit every engine.

In these cases, you should consider a third option: a spring-loaded engine start mechanism. After installing it on the engine, you just need to move the handle of the power tiller, and it will start immediately. This kind of kickstarter is based on semi-automatic spring action

It accelerates the engine mounted on the single axle tractor without having to pull the handle with your hands. It can take about two hours to change from a fully manual starter to a mechanical one

This type of kickstarter is based on semi-automatic spring operation. It accelerates a single-axle tractor-mounted engine without having to pull the handle with your hands. To change from a full manual starter to a mechanical starter can take around two hours.

Preventive maintenance will prevent repairs

There’s one more important thing to keep in mind. New things work great at first and starters are no exception. The factory starter is quite capable of starting a new single-axle tractor with one jerk. And this excellent state of affairs will last for about the first year of operation. To avoid hassle, always check that there is sufficient lubricant before each start. Also commensurate with the force of the jerk when pulling the handle. This will help reduce the likelihood of breakage.

Design modification

Are there options to improve engine starting? You can replace the mechanical component with an electric starter, then the need to pull the handle with all its force will simply disappear. But this modification is not available for all models of power tillers with manual start.

In addition, the electrical circuitry selected for installation will not fit every engine, so it is worth looking at other varieties of motorblock starter. One solution can be a mechanical spring mechanism.

Some stores sell a conversion kit for the Zubr power tiller. The old manual starter on the single axle tractor is no longer needed, so it is simply removed. The installation of an analogue with a spring starting mechanism is suitable for replacement. Once installed, just change the position of the lever and the engine will start almost immediately. The mechanical starter, thanks to the work of the spring, begins to accelerate the engine shaft without a constant jerking motion. Replacement process takes no more than an hour.

The original starter on a single-axle tractor starts the engine with just one pull. Such smooth operation of the mechanism can last a year, but the more often it is used, the faster the breakdown will occur. To avoid this as long as possible, it is worth checking the amount of lubricating fluid before starting, as well as not pulling hard on the handle of the cord. This will only reduce the likelihood of failure, but will not avoid it completely.

Self-repair starter. the algorithm in detail

Over time, the manual starter of the used power tiller often fails. In that case you need to remove the mechanism to repair or fully replace the broken parts. In order not to make mistakes when removing the starter, you will need to use the diagram from the manufacturer of the power tiller.

Repair of the motor-block starter is performed in this sequence:

- In the central part of the starter drum is a washer. You will need to unscrew it first;

- Carefully detach the cover of the starter housing, then you need to inspect all parts of the mechanism for breakage;

- The kickstarter consists of a mass of small parts. it is very important not to lose them during repair. To do this, all the elements should be placed on a piece of old newspaper or cloth;

- Most often, the repair of the starter involves replacing worn parts. The length and width of the new parts are of great importance. If they are too large, the housing cover will not close and the single axle tractor will not start;

- Often to be replaced by existing in the construction of the starter a large spring. At its ends there are special hooks, with which the part clings to other elements of the mechanism. When replacing the spring, you must be extremely careful not to damage the hooks.

Replacing the failed parts of the starter is not a complicated procedure. The main thing when repairing. do not try to restore the original shape and functionality of severely worn parts, otherwise the use of a power tiller with such parts will lead to accelerated wear of other important mechanisms of the agricultural machine.

Removing and disassembling the starter, replacing broken parts

To make repairs to the grass trimmer starter, you will need to first disassemble it, and then assemble it. This process is not a particularly difficult undertaking. You will need a screwdriver with a tip of the right shape.

Everything should be done carefully, observing safety precautions, mainly to ensure that the spring, if accidentally flying out, does not injure the master.

Disassembly of the starter unit

Disassemble the starter mechanism in order to install new parts in place of the broken ones in the following sequence:

- unscrew the screw that secures the pulley with the starter cover using a screwdriver;

- take out the spring and tendons;

- Remove carefully the pulley (it is necessary to unscrew the head or to work, wearing previously goggles and gloves);

- determine why the triggering mechanism is broken;

- If the spring is almost completely destroyed, it has to be replaced;

- if the spring is out of the hook, it is installed in its original place, having bent before (the photos show the process of laying);

after the spring plate installed inside the groove, carefully perform its twisting. To change the spring, you must work carefully and carefully: it can, under the influence of the force caused by installing it in place, accidentally burst

Even if the roller is carefully removed, the spring band quickly comes off the coil and can injure your hand with its sharp edges

To change the spring, you should work carefully and carefully: it can, under the influence of the force caused by installing it in place, accidentally burst

even if the roller is carefully removed, the spring band quickly comes off the coil and can injure your hand with its sharp edges

It is not always possible to put the spring plate back in its place immediately. It often slips, so the attempts must be repeated until the desired result.

Assembly of the starter

Assembly of the starter unit is carried out in a series of steps:

turn the coil over so that the spring bend fits into the slot in the housing exactly as shown in the photo below;

When performing the above manipulations, be sure to put two washers. If this is not done, the spring will eventually damage the plastic cup, and when it is tightened, it will begin to cinch. Because of this there is a feeling as if the spring is loose. To eliminate this defect, you need to install this part of a longer or additional washer.

When such spare parts are missing, you can just unscrew the screw a little, and the starter unit will start to work without jamming. But this option is temporary. it is better to repair quality as soon as possible.

Spring tensioning

After the spring is installed, it should be tensioned. To do this, carry out the following steps:

- remove the handle from the starter cord;

- then the rope is inserted into the bobbin slot;

- Make tensioning of the spring, rotating the spool in the opposite direction of the clockwise direction (winding);

- Make the required number of revolutions specified in the instruction manual for the grass trimmer model used and corresponding to the length of the cord used;

- at the very end, the rope is put through the hole designed for this purpose, located in the starter cover

- put the handle back in place, fixing it with a knot.

Kubota #Power tiller PEM 140DI

If the spring keeps coming off after repair, you can get rid of it in the following ways:

- Squeeze an appropriately sized piece of plate into the groove where the spring hook is located;

- drill holes on both sides of the groove in the coil, into which the spring catch should be inserted and fixed with a wire.

Replacing a torn cord

The torn cord is replaced in this sequence:

- The old cord is removed;

- choose a rope suitable in size (thickness and length);

- After passing it through a special hole, located in the spool, tie a knot;

- Wind up the spring, producing the desired number of revolutions;

- fix the handle.

It is better to tension the spring plate with a partner so that the edge of the cord does not wind up inside the starter mechanism.

Assemble the starter on the trimmer and wind the spring is not difficult, but you should do it carefully and with care. For different models of chain saws, the breakdowns of starting mechanisms are the same, so they are repaired in the same way

There are some nuances associated with their design features.

What other types of starters are suitable for power tillers??

Every owner of power tillers should understand that at first absolutely all starters work perfectly and can please their owners with this state of affairs for about a year. But without periodic lubrication of parts, their testing and commensurate force jerk, this joy does not last long. Take good care of your starter, and it will pay you back in return with high performance and long service life.