How To Cut A 45 Degree Ceiling Plinth

How to properly trim the corners of the skirting board

Since it is hard plastic skirting boards that are increasingly used during repairs, it is about them that will be discussed. Their installation is inevitably associated with the need to cut and form beautiful joints in the corners. The quality of all work and the appearance of the room where the repair is being made will depend on how the plinth will be docked, in general.

How to cut a plastic skirting board

If the angle in the room where it is planned to finish the joints of the walls and the floor with a plinth is 90 degrees, which happens extremely rarely, then the cuts of the plinths should have an angle of 45 degrees each. Such a cut is the easiest to make, especially with the use of a miter box. It is enough to insert the plinth into the miter box, then select a groove at 45 degrees and make a cut.

However, such angles of 90 degrees in rooms are extremely rare, usually they differ by several values in one direction or another. And in some rooms, the corners may even be larger. Then the cutting is done differently: a marking is drawn on the floor with a pencil, where the border of the location of the plinth is drawn on one and the other side of the corner. you get a small rhombus. The diagonal of this rhombus will be the very cutting line of the product. Next, a plinth is applied to the marking, on which the marking is performed in accordance with the diagonal of the rhombus. If you draw a straight line from this mark to the corner of the plinth, then you get the very necessary cutting line.

Cutting the corner on the skirting board

The outer corners of the skirting boards are formed a little differently, or rather, in a room with ideal geometry, you can also cut products at an angle of 45 degrees (but in a different direction) and, after joining, close the edges with a plug. Non-standard corners are cut like this: one of the skirting boards is applied to one of the walls, its borders are marked with a pencil. The same procedure is performed with another product. again a rhombus flaunts on the floor, the diagonal of which will become a guideline for cutting products.

Decoration of the outer corner of the plastic skirting board

Methods for cutting plastic skirting boards

Cutting skirting boards is seemingly simple, but responsible. If the corners are cut incorrectly, they will not fit correctly and all the work will go down the drain, since the product will no longer have a beautiful appearance. there will be gaps between two sections of the plinth and decorative inserts (corners, connecting elements, etc.).

Most often, an ordinary metal hacksaw, which has fine teeth, is used to cut the plinth. However, it will not work for thin skirting boards, since the product will simply tear under the influence of this tool.

Plastic skirting board cutting angle grinder

Sometimes the plinth is cut with metal scissors. But the method also has its drawbacks, because the product can crumple under the pressure of the blades. Less commonly, but still used is an angle grinder. However, the cutting line after cutting can be inaccurate, as the tool often “tears” soft plastic. Especially often this method turns out to be unsuccessful for beginners in the world of repair, who still do not know how to fully control the work. So the angle grinder can be attributed to rather specific methods.

Metal scissors

The most important thing in the procedure for cutting skirting boards is observing the required geometry. The procedure is never performed “by eye”, here the accuracy of measurements and accuracy are important. Therefore, there are other methods for cutting skirting boards.

The absence of fittings suggests the use of other methods of connecting skirting boards. This is an option with and without clipping templates.

Stencil cutting

The method is recommended for cutting products intended for installation in non-standard-shaped rooms with angles that differ from the standard mark of 90 degrees. Stencils for the desired angle can be made from paper or thin cardboard. First, strips are cut from the rough material, which have exactly the same width as the skirting board. Then they are applied to the corner and fixed, after which they are cut to the shape of the corner. Then, according to the stencils received, the skirting board itself is cut at the required angle.

Stencil cutting of plastic skirting boards

The main types of floor skirting boards

The wooden skirting board is a classic. It is a natural product, as it is made from solid wood. This type is distinguished by high strength and durability. the skirting boards, installed back in the days of the USSR, still serve faithfully in some apartments and houses. Now they are made mainly of pine wood, but there are also products from walnut, oak, ash and other species. However, due to this, the cost of products increases. not everyone can afford such skirting boards.

Wooden floor plinth

Because of this, veneered skirting boards have appeared on the market. their are an order of magnitude lower. However, outwardly, they practically do not differ from products made of expensive wood. The fact is that their upper part, which plays a decorative role, is made of a thin layer of expensive wood. Without certain knowledge and experience, it is almost impossible to distinguish veneered skirting from ordinary wood.

It is convenient to cut wooden skirting boards with a hacksaw for metal

The most popular now is the plastic skirting board, that is, made of PVC. It has partially displaced conventional wood products from the market, as it has a number of advantages:

- Looks nice and neat. it is able to imitate products made from natural wood;

- Easy to install, flexible and very easy to cut;

- Can serve as a cable channel for wiring;

- Not afraid of exposure to water, and also does not rot, mold does not start on it;

- Inexpensive compared to wood or veneer.

Plastic skirting board is made of polyvinyl chloride, which is passed through special forms under high pressure. After the mass has solidified, a neat plastic product is obtained.

Plastic skirting board

Plastic skirting boards are of several types. for example, used for carpet (they have a special shape in the form of the letter G, fix the material) or for linoleum. There are also universal products that can be installed on any type of flooring. They can be classified and depending on the hardness.

Table. Types of plastic skirting boards depending on hardness.

Flexible plastic skirting boards

Useful Tips

Experienced craftsmen recommend starting the installation of the skirting board from the inner corner. At the junction of two walls, which form the inner corner, the cut on the skirting boards will be 45 degrees (in a room with correct and accurate geometry). It is recommended to cut with a miter box. this is the only way to achieve a perfectly even cut.

Cutting floor and ceiling plinths with a miter box

In general, in any case, the cut edges of plastic skirting boards should be sanded. this way it will be possible to get rid of sharp edges, and it will be easier to work. And the skirting boards with cable channels are cut only after the product has been disassembled. the decorative strip designed to hide the wires and attachment points of the skirting board is cut separately.

The plinth is cut to the desired size

It is recommended that immediately before installing the plinth, cut the segments to the required length and arrange the corners so as not to be distracted by this procedure during the assembly of the plinth. You should not neglect the use of additional elements. plugs, corners and other products for the baseboard. With their help, it will be possible to give the finished work a complete and harmonious look.

It is very easy to cut skirting boards at any angle with this device

Using a ruler and pencil without a miter box

If you don’t have a miter box at hand, and you don’t want to make stencils, then you can try to apply the necessary markings on the plinth with a pencil. In the case of the formation of an internal corner, the width of the product is measured with a ruler, then the obtained value is deposited on the end of the plinth, and a fishing line is drawn from its corner to this marked point with a pencil, along which the cut will be made. The second plinth, which will form a corner together with the first, is simply cut off according to the first attached to it.

Floor plinth in non-standard corners

Cutting the skirting board with a miter box

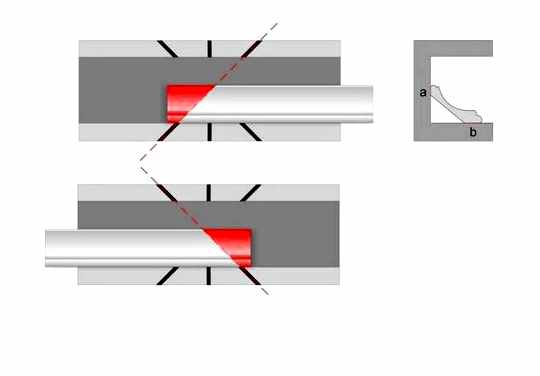

For the correct trimming of the plinth, a special device was invented, which was called the miter box. It is a small block with a notch for the skirting board and with gaps located at different angles. for the cutting tool.

With the help of a miter box, you can get neat and even cuts. The plinth is fixed inside the product, then the angle and direction of cut required in a particular case are selected.

We make a miter box with our own hands

When working with a miter box, it is important to ensure that the edges of the skirting board protrude a short distance beyond the edges of the selected slot. If the trimming tool is wider than the plinth itself, it is recommended to securely fix the product inside the miter box before trimming. Otherwise, the skirting board may move inside, the cut angle will constantly change, because of which it (cut) will turn out to be incorrect and incorrect.

Making cuts for joining skirting boards using a miter box

Cutting with a rotary miter

How to cut off a plastic skirting board: how to cut and how to cut it correctly, cutting methods

A skirting board is an essential element for decorating a room and giving it a complete and neat look. It can be made of various materials, but plastic skirting boards are especially popular now. It is easy to install, but even in this process there are some subtleties that are important to know about. How to cut a plastic skirting board correctly so that you can neatly dock it in the corners?

Choosing the corner shaping tool

The most economical option is to buy a simple plastic miter box. It is a plastic block with eight working slots. Such a device is designed for only two operations: trimming at 45, 90 and 22.5 degrees. An angle of 90 degrees is useful, for example, if you need to embed a socket in the middle of the molding.

Some fixtures come with eccentric clamps included. They are preferable, since it is easier to work with it. the plinth is clamped in the desired position and does not move during the cutting process. Accordingly, if flaws happen, then they are minimal and it will not be difficult to adjust the angle.

How to cut a plastic skirting board: a simple plastic miter box

If you have to renovate your own home, then it may make sense to purchase a more serious tool. a rotary single-plane miter box. It is designed for cutting at 15, 22.5, 30, 36, 45 and 90 degrees. The design of such a miter box includes 2 clamps. for clamping in the horizontal and vertical planes, as well as a stopper that will allow you to cut the workpieces by one length. The hacksaw will be built in here. If it is not clear how to cut the ceiling plinth. the review below will help you.

How to trim a skirting board in a corner: a swivel miter box

How to saw down a ceiling plinth: contains a detailed description of the swivel miter box and information on how to use this tool.

How to cut the corners of a skirting board without a miter box

If you are wondering how to properly saw down a ceiling plinth without a miter box, then the following information will be useful to you. We take the right segment of the ceiling plinth made of polystyrene, apply it to the installation site and draw a line on the ceiling along its upper edge. It should go beyond the points of the vertices of the corners by about 5 cm. Do the same with the left segment and put points at the intersection of the lines. We put the ceiling plinths in place one by one and transfer the resulting marks to them.

We figured out the upper part of the ceiling moldings, now we move on to the bottom. Everything is simple here, the marks we need are the tops of the corners. Mark their location with dots on the lower edges of the left and right ceiling plinths. Next, you need to connect the points on the moldings. this will be the trim line. This method will help to cope with even the most crooked corners. Adjustment is most likely not needed, and if it does, it will be minimal.

How to cut a ceiling plinth without a special tool: the photo shows the marks for the intersecting point method

Important: the jobs described here require marking on the surfaces. Therefore, first you need to start cutting and adjusting the ceiling plinth, and only then think about how to glue the wallpaper. Or, if you want to fix the skirting board over the wallpaper, markup and trimming are done before finishing, and gluing after it.

How to cut a ceiling plinth at 45 degrees with your own hands, how to cut a plastic fillet: instructions, photos and

How to cut a ceiling plinth for perfect corners

In the corners of a room, when installing a ceiling plinth, for example, from polystyrene, small inconsistencies can often occur that spoil the overall appearance of the room. This, of course, can and should be avoided. So, how to cut the plinth with your own hands exactly? The first assistant in this matter will be such a tool as a miter box. But buying such one for a one-time repair is not always advisable. Although, if you decide to help all relatives and neighbors with repairs, and in the future also make money on this, then you need this device.

An example of ideal angles

If you are still limited to one installation of the plinth at home, then such a carpenter’s tool is not necessary. You can do without it. In order to consider all the ways how to properly cut the ceiling plinth, we will find out what it consists of.

Inner corner

- We make the right measurements.

- We install the plinth strip in the miter box so that this position exactly coincides with the placement on the ceiling.

- The plinth should be firmly pressed against the opposite wall of the miter box. Hold and press with your free hand.

- We put a hacksaw at an angle of 45 ° in a special hole and cut off the part.

When cutting soft materials (PVC, expanded polystyrene), use a hacksaw for metal or an ordinary construction knife. Then the work will be neat and with smooth edges.

Some helpful tips to make your work and preparation easier

Next, we will talk about the tool with which you can trim. This section also contains useful information on joining skirting boards at corners.

Outside corner

- Measure the length of the plinth from the nearest wall to the outer corner, leave the fishing line on the wrong side with a pencil, indicating the desired length. It should be noted that the edge (its upper part) should extend slightly outward.

- The plinth is moved to the miter box and cut off.

- The adjacent bar also needs to be measured with a margin and cut off in a mirror image to the first part.

Trying on the ceiling plinth: the joining of the parts should be perfectly flat. If the result is not achieved and there are irregularities at the joints, you can trim the edges with an ordinary knife to a perfect fit.

Checking the smooth docking

All the nuances are well described:

other methods

With a good eye and accuracy of hand action, you can use a homemade template that resembles an imitation of a miter box. To do this, take a thin board or thick plywood and draw a layout in the form of a horizontal rectangle. Using a protractor, mark 45 ° on the right and left sides of the rectangle. Draw the mowing lines connecting the opposite edges. You can now cut off the ceiling plinth using this layout. The actions are simple and similar to the description above in the first option. Only the ceiling parts should not be inserted, but superimposed on the drawing and combined with the hacksaw layout.

Description of methods for gluing ceiling skirting boards (cornices) to the ceiling. Method of gluing with glue, putty and sealant. How to make even corners on the ceiling.

Composition and features of the material

To understand how to properly cut the baseboard, you need to understand its composition. This will help you choose the right tool and cutting technology.

- Styrofoam. The price and strength of this material are the lowest. But since we create decorative ceiling decoration, strength is not particularly required.

- Styrofoam ceiling skirting board is denser. Than regular foam. The most common knife is used to cut such material.

Tip: sharpen the knife well before use. This will eliminate the presence of torn edges at the cut.

How to cut a skirting board straight

- Tree. Here you have to put more effort into processing. Use only a hacksaw for wood.

Tip: The smaller and more frequent the saw tooth, the smoother the edges will be. You can even use a sheet for metal.

- Plastic. How to cut off a plastic skirting board? The same method is suitable here as with a tree. a saw, a hacksaw. Alternatively, you can also use an angle grinder.

Using a regular hacksaw blade

Indoor ceiling

Interior ceiling corner view

By analogy with the outer corner, we cut off the inner one. We only cut the inner left and right edges respectively.

It is important to remember: the product is always mounted upside down on the ceiling. Therefore, insert it upside down into the miter box. This will help you cut the skirting board correctly.

How to cut a 45 degree ceiling plinth

Cutting without miter box

If you do not have such a device, and you are not going to purchase it for one-time use, then you can use the following methods, how to cut the plinth at 45 degrees.

- The first way is to make this simple carpentry tool yourself. To do this, knock down the most ordinary wooden tray. Then we measure the cut line with a protractor or school square. We cut the grooves and we have a primitive device ready.

- Second way. How to cut a skirting board at an angle is even easier. It is especially painless to use it in cases where the corners of the room are not even.

We don’t need a tray. Two boards knocked down at 90 degrees and a cardboard stencil with a line drawn for orientation is enough.

- Third way. In this case, we do not knock anything down at all, but simply use a table set against the wall or any other similar structure.

We mark the future joints directly on the product itself, on the wall and on the ceiling. We apply the skirting board the way we are going to mount, and cut according to the marked marks.

The simplest way without the use of special tools

Remember: hold the tool vertically while cutting to get a right angle.

External floor

External floor corner view

In this case, using a miter box, we are not a mode of internal, but external edges. The rest of the operation is similar.

other methods

With a good eye and accuracy of hand action, you can use a homemade template that resembles an imitation of a miter box. To do this, take a thin board or thick plywood and draw a layout in the form of a horizontal rectangle. Using a protractor, mark 45 ° on the right and left sides of the rectangle. Draw the mowing lines connecting the opposite edges. You can now cut off the ceiling plinth using this layout. The actions are simple and similar to the description above in the first option. Only the ceiling parts should not be inserted, but superimposed on the drawing and combined with the hacksaw layout.

Description of methods for gluing ceiling skirting boards (cornices) to the ceiling. Method of gluing with glue, putty and sealant. How to make even corners on the ceiling.

Cutting with a miter box

What is a miter box? This is a special tray made of wood, aluminum or plastic with provided grooves to guide the saw at the desired angle.

Here is a quick guide to using such a carpentry tool:

- Training. We take the product and put it in the tray. Align in the position in which it will be installed on the ceiling.

- Cutting. With the other hand, insert the cutting tool into the groove. It can be a knife or a hacksaw. And we cut it boldly. The device will not allow you to miss the intended place.

You should know: a blade for metal is also suitable for cutting foam.

- Treatment. Wood skirting boards may need to be filed to level the cut edges. Plastic or foam can be tweaked with a knife, the main thing is that it is sharp enough.

Tip: Do not press down on the product when cutting. Polyfoam can crumble, and the tree can split altogether.

It’s so easy and simple to use the miter box

The first way is with a miter box

Professional miter box with rotary hacksaw

The miter box usually looks like a tray with vertical holes for a hacksaw. It can be made of wood, metal or plastic. This tool is the oldest and simplest carpenter’s tool for cutting wood pieces at 90 ° and 45 °. There are types of such a device for professional work, with a rotary mechanism, in which the cutting tool can be rotated and fixed in any position.

How to cut a ceiling plinth correctly

Ceiling corners are divided into internal and external, the method of joining on them is slightly different.

If necessary, you can make a miter box with your own hands. To do this, you will need three trims from plywood or boards of the same size. First, they are applied in the form of an inverted letter “P” and the corners are marked. Then, according to the marking, slots are cut out for a hacksaw almost to the very bottom, and the boards are twisted.

Cutting wood floor molding with a miter box

It is necessary to measure the distance from the edge of the skirting board already glued to the wall to the top of the corner of the wall. Now we take a new piece of molding and set aside a length equal to this distance on its lower edge. We put a point with a pencil or stick a piece of electrical tape. We do this procedure for both the outer and inner corners. In the miter box, place the skirting boards from left to right for the left side of the corner and from right to left for the right. In this case, they should be pressed as in the figure. to the side of the miter box closest to you.

How to cut a corner of a ceiling plinth. laying a workpiece in a miter box:

- For the outer left, match the mark on the skirting board with the extreme left slot. For the outer right. from the far right.

- For the inner left, match the mark on the skirting board with the extreme right slot. For the inner right. from the far left.

Clarification: the notch refers to the one on the side closer to you.

Cutting skirting boards at an angle: the red line marks where you saw the cut

How to cut the corners of a skirting board without a miter box

If you are wondering how to properly saw down a ceiling plinth without a miter box, then the following information will be useful to you. We take the right segment of the ceiling plinth made of polystyrene, apply it to the installation site and draw a line on the ceiling along its upper edge. It should go beyond the points of the vertices of the corners by about 5 cm. Do the same with the left segment and put points at the intersection of the lines. We put the ceiling plinths in place one by one and transfer the resulting marks to them.

We figured out the upper part of the ceiling moldings, now we move on to the bottom. Everything is simple here, the marks we need are the tops of the corners. Mark their location with dots on the lower edges of the left and right ceiling plinths. Next, you need to connect the points on the moldings. this will be the trim line. This method will help to cope with even the most crooked corners. Adjustment is most likely not needed, and if it does, it will be minimal.

How to cut a ceiling plinth without a special tool: the photo shows the marks for the intersecting point method

Important: the jobs described here require marking on the surfaces. Therefore, first you need to start cutting and adjusting the ceiling plinth, and only then think about how to glue the wallpaper. Or, if you want to fix the skirting board over the wallpaper, markup and trimming are done before finishing, and gluing after it.