How to cut mineral wool knauf. Is it true that Minvat needs to be protected from moisture and wind?

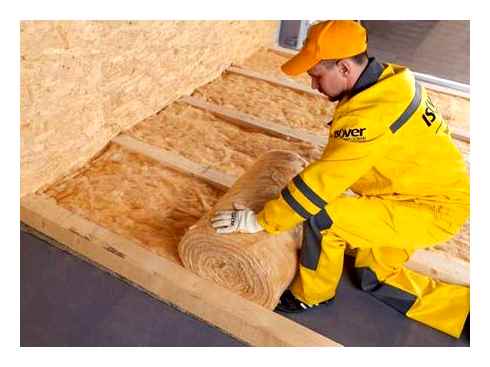

How to cut a mineral wool insulation

Mineral wool is popular and effective thermal insulation used for internal and external work when arranging residential and household buildings. A feature of the material is its unique spatial structure that provides high operational qualities. Violation of the location of the fibers leads to an increase in thermal conductivity of the product, which requires the choice of a special technology for cutting plates.

Characteristics and properties of mineral wool

Cut the insulation with tools that are best suited to its type and technical characteristics.

For thermal insulation work, such varieties of mineral wool are used:

- Stone. Consists of integrated fibers of mountain dolomite rocks. Basalt, characterized by high strength, is mainly used for manufacturing. The material is used as a heater for the manufacture of acoustic panels. Cutting stone cotton wool is easy, as it is soft and suppleted.

- Slag. It is made from waste of the steel industry. It is used more in the decoration of outbuildings, as it contains impurities of toxic materials, has a sharp unpleasant odor. It is difficult to cut mineral wool in the slabs, as it is fragile and unstable to the pressure.

- Glass. Raw materials for production are fiberglass, lime and stone baby. Consists of many intertwined glass fibers that easily break. On sale is delivered in tightly twisted rolls. It is easy to cut glass wool, as the material lends itself to any sharp tool.

The convenience of its styling and the quality of the final result depends on the quality of cutting the insulation.

Proper transportation of the material

Since the material is characterized by porosity, fragility and hygroscopicity, you need to handle it accordingly.

When transporting and storing mineral wool, it is recommended to follow the following rules:

- During loading and unloading, do not throw packaging, but gently lay, avoiding their falls and strong compression.

- Transport bales in covered trucks, laying them horizontally on a flat bottom. Fix the insulation so that it does not beat on the walls of the body.

- Store products in dry closed rooms. If this is not possible and it is stored on the street, cover with a film or tarpaulin to protect against precipitation.

- Take the slabs from the pack right before their laying. This will prevent moisture absorption and reduce the risk of random damage to the material.

The technology of insulation involves the installation of dispersal slabs, with compression for 1-2 cm on each side. Based on this, it is necessary to cut mineral wool with an error in size of not more than 0.5 cm.

Cutting tools

In the production process, to cut the material into fragments of the desired configuration, special stationary equipment is used.

At home, you can use the following tools:

- Stationery knife. Simple and inexpensive device with interchangeable blades that are easy to change as it is abrasion. Thin steel is well included in the basalt and glass material, but almost powerless in front of slag slabs. The downside is that such a product can only be cut by mineral wool up to 50 mm thick.

- Kryazuvka for metal. A great solution if you need to cut slag or stone wool with a thickness of up to 100 mm. On sale there are unilateral and bilateral canvases with small and large teeth. You can easily choose the most convenient option.

- Special knives. Products have narrow blades up to 34 cm long with teeth without wiring. The handles are specially adapted for sawing at the optimal angle. In various models, the canvases are made of cold stainless or carbon steel.

- Bukhankaya knife. The device is a good analogue of a special tool. For work, you need to choose knives with a gear, not a wavy edge. The length of the blade should be more than 15 cm.

- Cutting machine. The equipment is quite expensive, but productive. Allows you to make accurate and even cuts. Buying a machine makes sense if there is a large amount of insulation work.

The choice of a device for cutting mineral wool is determined by its own priorities, building skills and financial capabilities.

How to cut mineral wool

The main technical condition for the process is the preservation of the structure of the material. the fibers should remain intact and maintain their position in the space. In order for the division lines to be accurate and even, you should first mark with a marker using a tailor’s meter or rule. Cut the plates you need to put them on the table so that the fishing line for the cutting is on weight. After that, it should, avoiding excessive pressure, make progressive movements with the tool.

You need to finish the sawing, holding the cut fragment by weight so that it does not break under his own weight.

Safe working conditions

The main component of mineral wool are thin and sharp fibers. In the process, they come off the base and rise into the air. The ingress of these particles on the body causes a burning skin, the carving in the eyes and irritation of the respiratory mucosa.

In order to prevent harm to your own health, it is necessary to create the following conditions for work:

- exclusion of accidental penetration to the place of work of outsiders;

- removal of people and animals to a safe place if cutting is carried out on the street;

- the use of overalls, masks, respirator, hermetic glasses and rubberized gloves;

- high.quality ventilation in the room, the exclusion of flying substances in the neighboring rooms;

- cutting across the fibers in order to reduce the number of volatile compounds;

- wet cleaning with pre.cleaning surfaces with a vacuum cleaner;

- Closing the insulation by plaster, vapor.permeable or windproof film with the aim of complete isolation.

Mineral wool. multifunctional material with unique properties

Mineral wool is a fibrous material that is obtained from rocks of rocks, as well as metallurgical slags and their mixtures. Most often, global manufacturers of mineral wards use rocks as raw materials. Thanks to this, the mineral wool is of high quality, it can be operated for a long time. Когда необходима долговечная и надежная работа зданий и строений, применяют именно ее.

Mineral wool, which is obtained from domain slag, is not enough durable in conditions of temperature changes, the action of loads and deformations, increased humidity. Therefore, it is successfully used in summer cottage construction, as well as in the construction of temporary structures.

Mineral wool has unique properties:

Fire resistance. Minvata is achieved due to the use of non.combustible silicate melts of rocks in the production of non.combustible. Even at high temperatures, there is no deformation of mineral wool plates, all properties are preserved. The material resists the spread of combustion in a fire, which is why mineral wool is used for insulation of rooms where various fire hazardous substances are stored. It is used even in conditions of prolonged contact with high temperature, however, without further mechanical exposure. This property is obtained due to the difference in the melting temperature of the stone fibers and used in the binder.

Biological and chemical resistance to various aggressive substances, immunity to fungi and the effects of rodents. In this case, mineral wool is fully consistent with the current sanitary and hygienic standards and quality standards.

Insignificant degree of thermal, as well as natural shrinkage. The dimensions and form of materials from mineral wool do not change for the entire time of operation. This helps to exclude the passage of the cold in the butt places. This happens when the material is seated over time.

Negigroscopicity. The ability of the material to prevent moisture penetration is quite high. So the water absorption level is about 0.5%, which is much lower than that of other materials. To reduce the risk of moisture penetration into the material to a minimum, it is produced and stored in dry rooms or impregnated with water.repellent substances.

Vapor permeability. This property is indispensable when creating a microclimate in the room and regulating humidity level. Due to the vapor permeability of the material, unhindered removal of water vapor and condensate is possible. Stability of volume and shape in any conditions.

Low thermal conductivity. This material is characterized by high thermal resistance. So to ensure the same value as in 10 cm of mineral wool with a density of 100 kg/m.cube. It will take 25 cm of dry wood, 200 cm of silicate brick, 117 cm of hollow ceramic. This property helps to save money in repair.

The thermal conductivity of mineral wool depends on the geometry of the fibers of the material. The direction of the fibers also affects the strength. An ideal choice is material with randomly directed fibers.

High sound insulation. Mineral wool is a strong barrier for sound waves.

High strength and corrosion stability. High.quality mineral wool is a chemically inactive environment and does not cause corrosion of metals in contact with it. The more vertical fibers in the material, the higher its strength. In the presence of a large number of fibers of this type, you can use a less dense coating.

Environmental friendliness. The material is absolutely safe and harmless to a person.

Easy installation. It is easy to cut any mineral wool to give the desired shape: soft. with a knife, and a denser. a hacksaw. It can be easily placed on any surface with different configuration, since it easily acquires any form.

Durability. The service life of mineral wool, provided that the proper operation is at least 70 years. Such durability is achieved through the use of rocks of basalt stone.

Mineral cotton wool from techno.nicob: some advantages

A huge number of positive properties of the material make it one of the most popular insulation in the building materials market. It is not easy to compete with such inexpensive material with a huge list of advantages.

The company “Technonikol” offers a wide selection of heat and soundproofing materials from mineral eco-friendly cotton wool. Our experts are ready to help you with the selection of the insulation that is suitable for you.

You can buy thermal insulation for cash and non.cash calculation. We provide an individual approach to each client. In addition, we have a flexible system of discounts for regular and wholesale customers.

Remember: the right choice of insulation will solve many problems for many years, save your time and money, create comfort and comfort in your home. Do not save on professional consultation and installation: the spent funds will definitely justify themselves.

What will we cut

On an industrial scale, special machine equipment is used for cutting mineral insulation. Consider how to cut insulation from mineral wool yourself at home.

Often for cutting, mineral wools use a mounting knife. But he has one drawback. a short blade that is not suitable for working with thick insulation plates. In addition, the blade is quickly blurred and requires replacement.

Sometimes a special hacksaw for wood or metal is used, and the craftsmen found how to cut mineral wool at home. a kitchen.pledged knife for cutting Bukhankaa.

Stainless steel knife

A knife for cutting insulation with a long blade made of strong stainless steel is suitable for working with mineral wool of any thickness. For cutting the insulation of different stiffness on each side of it, the teeth of larger and smaller are located. Such a blade easily enters the thickness of the stove, allowing you to make even figured cuts thanks to a sharp tip.

Carbon steel knife with a blade

A knife for cutting mineral wool with carbon steel blade has high cutting quality and easily sharpened. However, it requires more careful care compared to a stainless steel blade, as it is subject to rust. It must be wiped dry after each use and lubricate.

For example: Mora knife for cutting mineral wool

The Swedish company Mora produces tools for cutting mineral insulation. A stainless steel blade knife is used for cutting stone and glass mineral wool. The blade is made of special cold.rolled stainless steel and has a serrated sharpening. Ergonomic and comfortable plastic handle is suitable for working in gloves. Its characteristics:

A carbon steel blade knife is used for cutting mineral insulation of different types. It has a smooth, made of high.quality carbon steel blade 350 mm long. Plastic handle provides good capture in working gloves.

How to cut mineral wool

Mineral wool in structure. fibers, and, accordingly, with its cutting, small particles of these fibers fall into the air. So that they do not get into the respiratory tract and on the skin, it is important to create safe working conditions:

- provide good ventilation in the working room;

- use overalls and protective equipment. overalls, gloves, mask or respirator, protective glasses;

- Immediately after the end of the work, thoroughly wash your hands with cold water, and then the face.

To minimize the amount of harmful dust in the air, cutting mineral wool should be carried out with tools with a well.sharpened, acute working edge. Better to cut fibers across the fibers.

To obtain lanes of the same width, the mineral insulation produced in rolls is recommended first cut right in the roll, without unfolding, and mineral wool slabs cut one at a time.

To ensure even and accurate cuts, you must first mark the material or cut right along the ruler.

Recommendations on how to work with insulation

Before starting work, they study the instruction manual. It is required to cut and lay the layers correctly to improve thermal insulation, maintain safety for the user.

When working with insulation components, the following recommendations are used:

- Prior to use, the product is stored in a dry place without direct sunlight;

- packaging is removed only before the work;

- Professional tools are used for cutting, in their absence, you can use sharp, not blunt objects, for example, knives;

- If the product has a fibrous structure, it is additionally put on protective gloves so as not to cause allergic reactions, irritation and other dermatological problems;

- They pre.measurements do not make a mistake with the cut, otherwise it will be impossible to return the pristine type of product;

- If a part of the material remains after the work, it is placed back in the package, especially if mineral wool is used, since its fibers may fall out.

The listed rules will help make work better and easier.

Neat execution

It is important to create safe conditions

If you adhere to safety rules, you can save the health of the employee and the people around.

- It is forbidden to have cutting tools in free form, especially with direct access for children;

- If the mineral wool is used, a protective suit, gloves, glasses, a respiratory mask are pre.prepared;

- To use other products, only gloves may be required, inside which rubber spraying is applied, and fingertips are covered with silicone;

- Cutting tools should be sharpened if dumb devices are used, the cut will be uneven, when pressed, the user can damage the limbs;

- It is recommended to cut the surface in the open air, the balcony and in other non.residential premises;

- Small surpluses are immediately thrown away so that their fibers do not spread through the air, floor;

- the cut is made carefully so as not to accidentally cut the fingers or other parts of the body.

If you do not observe safety precautions, you can not only cut, but also harm the body. For example, the penetration of mineral wool into the respiratory tract can cause athletes, bronchial asthma, halflenosis and other deviations.

Safe slicing

Cutting tools

To understand how to cut the insulation of mineral wool, foam, other products, preliminarily reveals their structure and thickness. It is best to adhere to the advice of manufacturers, as they take into account these components.

In the presence of thin materials with a thickness of not more than 5 cm, you can use recommendations than cut the basalt insulation:

- a kitchen knife that has cloves at the edges (usually it is intended for loaf);

- construction knife for installation work;

- A knife for the office.

The listed items are suitable in cases where the user is trying to find out how to cut mineral wool in a stove 50 mm. They successfully cut the structure, do not cause laying, completely penetrate the thickness of 5-10 cm.

Preliminary measurements play an important role

If the thickness of the product exceeds 50 mm, more serious cutting tools are required.

- Knives for cutting insulation with a thickness of more than 30 mm. Most often they can be found in construction stores, sellers recommend that they be purchased together with the purchased material for insulation. This is a good option, since the manufacturers have already made a check for the quality and the ability to cut such a thickness.

- Saw. Before buying, they carefully inspect it, as only a tool with undamosed teeth is suitable.

- Cutting machines. They are required for professional masters. The machines are designed to cut complex shapes, for example, circles, ovals, various figures.

It is easier to cut sheets of foam or extruded polystyrene foam. For this enough kitchen or stationery knife. The situation is more difficult for users who have purchased rolled heaters (mineral wool).

How to cut a mineral plate: a review of knives and drank

To figure out how to cut to mineral wool, find out its thickness. The tool used depends on it.

- Stationery knife. Suitable only for products with a thickness of not more than 5 cm. It is better to break off the upper part of the blade to use the sharp area. The blades should be enough for it to penetrate through the entire structure, it goes out another 2-3 cm.

- Kitchen knife. Suitable products with zazubins, which are usually used for bukhankaa. Even if the tool has dulled a little, the little calls will successfully cut the material.

- Construction knife. This is a universal tool that is suitable for different products, including rolls or mats of mineral wool with a thickness of more than 10 cm.

- Kryazuvka for metal, hand saw. It has similar qualities, like a kitchen knife, as it also has a zabina.

- Stab for heater cutting. The set contains different blades that are suitable for thickness up to 30 cm.

- Professional tools. This includes machines, batteries with a cost of 3,000 more often they are used only by professional builders, masters.

Having found out the advantages and disadvantages, you can successfully select the required tools that will be needed in the future.

An example of a special knife

Rules for use

Before starting work, it is necessary to familiarize yourself with the guide to use the knife and ensure the safety of installation in order to prevent both gross and small errors, and harm to your health. There are several fundamental rules.

The insulation should be cut at low ambient temperatures. to safely start cutting mineral wool, you will have to dress in a special durable suit that will not allow the skin contact with toxic material and its irritation.

To protect your hands from getting cuts and abrasions with careless cutting, it is necessary to cover them with gloves with rubber or silicone coating.

The respiratory system must be closed with a strong respirator, and the eyes are protected with special professional glasses, since glass particles of foam or mineral wool can fall into the respiratory tract or into the mucous membrane of the eyes.

During the installation work, it is necessary to arrange small breaks and open the windows to ventilate the room. If possible, it is better to immediately work indoors with good ventilation.

So that the thermal insulation material does not break off, and particles fly less from it, the cutting tool must be technically working and well sharpened. To reduce the amount of dust in the air, the insulation should be cut along the location of the fibers.

In the process of cutting, you need to count on the remainder of a small layer about 2 cm long in order to ensure a dense overlap of the insulated space.

Minvata is better to cutting before expanding.

Mineral wool panels should be removed from the packaging box and cut one at a time, so as not to accidentally damage its shape when transferring the material from one to another place and when they are located on each other.

Already cut pieces of insulation can not simply be thrown onto the floor or on another piece, since a huge number of polystyrene fibers will immediately begin to rise into the air. The material should be shifted with special accuracy.

In addition, with independent installation work, the best option would be to consult with specialists, since, perhaps, it will have to cut pieces of complex shape. Professional recommendations will help to avoid unjustified material consumption. Manufacturers also advise you to start cutting cotton wool before expanding the roll, and to ensure even and accurate cuts, it is necessary to mark the material in advance by the ruler.

The remains of thermal insulation material do not have to throw away. They will remain suitable for insulation of pantries, garage, barn or other utility rooms. In addition, they can be processed and sold at a low price for subsequent use.

At the end of the work, it is recommended to thoroughly rinse the face and hands with soap under cool water.

average cost

The basalt plate in the regions costs from 450 for a package of 0.288 m3 (sometimes you can buy with a discount of 20%), a product in rolls: 150 1 kg. 1 m3. Packaging 0.3 m3, with foil coating from 295 1 m2.

What will we cut

You can do this with different devices, depending on the thickness of the mineral wool.

- a kitchen.bukhank knife with a gear edge;

- mounting construction knife;

- stationery knife.

- Special knives about 300 mm long. Often they are offered by manufacturers of warming materials. Such a tool has teeth of different sizes for cutting mineral wool of different thickness and density;

- saws with undamosed teeth;

- Kryzuvka for metal;

- Cutting machines. Used when cutting elements of complex shape. However, for independent construction of your own home, that is, for single use, it is impractical to purchase such expensive equipment. you will have to adapt to the possibilities of other tools.

The better cutting mineral wool?

For dividing paintings and rolls, specialists use a specialized machine. But most people ask themselves: “The better to cut mineral wool in the boards of the house to save money?””

Important! To cut, mineral wools use a hacksaw for metal or wood.

In household tasks and goals, to cut the canvas, a knife for installation work is involved. This tool has the only minus, because of a small blade, it is difficult for them to cut thick plates. Thanks to this, use the knife of the office advisable exclusively for thin sheets. If this condition is not fulfilled, then the canvases may fail.

Tools that are much better suitable for cutting mineral material for insulation:

Knauf Insulation. Rock Mineral Wool Production Process

- A knife whose blade is made of carbon steel. It is quite easy to cut this product, also, its blade is perfectly sharpened and quickly sharpened. This knife needs careful care to avoid rust. An important rule of care is to wipe the blade after washing.

- A knife whose blade is made of stainless steel. On any side, teeth of various lengths are taken into account, thanks to this it is quite easy to make cutting of mineral material for insulation of a variety of size and thickness. The blade quickly plunges into the stove and cuts it qualitatively. A sharp tip can perform not indirect cuts.

- Special machines. Such tools are able to draw canvases along a flat line and bending. A similar function is very appreciated in industry. If you need to cut cotton wool 1 time, then it makes no sense to buy expensive equipment. the tool that is in the house is suitable.

Cutting min. Vata with a specialized saw

It is worth paying attention! Scissors for cutting cotton wool cannot be applied.

To cut wool, it is best to use a specialized hacksaw for heat insulators or metal. It is used to cut the material, its thickness does not exceed 5 cm.

The blades of the tool that you use to cut cotton wool are always required to be perfectly sharpened. In this version, fibers from cotton wool will be stretched minimally. Manufacturers recommend cutting cotton wool before turning the roll.

How to cut mineral wool

Mineral wool in structure. fibers, and, accordingly, with its cutting, small particles of these fibers fall into the air. So that they do not get into the respiratory tract and on the skin, it is important to create safe working conditions:

- provide good ventilation in the working room;

- use overalls and protective equipment. overalls, gloves, mask or respirator, protective glasses;

- Immediately after the end of the work, thoroughly wash your hands with cold water, and then the face.

To minimize the amount of harmful dust in the air, cutting mineral wool should be carried out with tools with a well.sharpened, acute working edge. Better to cut fibers across the fibers

To obtain lanes of the same width, the mineral insulation produced in rolls is recommended first cut right in the roll, without unfolding, and mineral wool slabs cut one at a time.

To ensure even and accurate cuts, you must first mark the material or cut right along the ruler.

How to cut KNAUF sheet. Types of GSL for the floor: the main types of marking, which it means

Gypsum is in itself the material of the hygroscopic, so lay the gvlvltes on the floor, if the room is exposed to humidity, is not recommended. For rooms with constant high humidity, for example, for kitchens, bathrooms, bathrooms, pools and saunas, it is better to purchase a gypsum.fiber slab, that is, moisture.resistant plates. Outwardly the sheets do not differ from each other, so it is important to pay attention to the marking.

For the design of the flooring, special elements of GVL gender are produced, marking “EP”. Most often the material is produced. which is the main supplier of leaf products in the domestic market. All products are not only of high quality, but also by increased strength characteristics.

Some prefer to lay ordinary GVL stamps on the floor, but for this it is not one, but two elements that are located with a displacement relative to each other. This distance most often does not exceed 3-5 mm. If special sheets of GVL are used for Knauf Paul, they fit into one layer, because they have sufficient strength.

Products intended for the floor are produced with the labeling “EP”

In addition, products are classified by type of edge. If the sheets differ in a straight edge, they are marked “PC”. Plates with a folding edge are also produced, which allows minimizing the visual perception of joints. The size of the fold usually varies in width from 2.8 to 3.2 mm, depth-1.7-2.3 mm. It is appropriate to arrange the floor with both one and the other type of material, but due to the fact that the price of GSL for the floor with the folded edges is higher, many prefer to purchase sheets with a direct edge.

As already indicated, the process of production of plates is regulated by GOST standards. Based on this, such options for standard sizes are distinguished:

It is not always possible to adhere to these indicators, so a width is possible, but not more than 3-4 mm. As for the length, here the retreat should not exceed 2-3 mm. In rare cases, if the plates are long, this indicator reaches 4 mm.

The thickness of the gulists can vary within 12.5-20 mm

In order not to make a mistake when buying material, you should know what this or that marking means, for example, GVV-PC 2000x1000x12.5. Here you can see that a regular plate is represented that does not have moisture resistant qualities, characterized by a straight edge. If the labeling is the abbreviation “VGLV-FC”, this means that the slab is moisture-resistant with the folding edge.

Popular materials

Home:

- Uneven ceiling, how to disguise. How to fix a low and curved ceiling

- Select the bedroom curtains

- Ergonomic arrangement of furniture in the residence

- Covering the frame of the board. Tools and materials

- A room with a niche that it is. Alcove in the apartment is not a mistake, but a pearl of the interior. Ideas for organizing the gazebo

- Breeding the foundation for a wooden house. The technology of filling the foundation for a standing wooden house

- Transformer staircase. Universal chair or two items in one

- How to cut a gypsum.fiber plate knauf. Features of gypsum fiber sheets

- How to cut the surface of Knauf. How to cut gvl: how to cut sheets at home

- Advantages of GVL

- Tools necessary for working with GVL

- The process of cutting gypsum

- The front side of GVL. How to determine the front side?

- Grout for grouting. Do you need putty drywall?

- Like gvl knauf putty. Make a frameless installation

- GVL cutting knife. Hand tool

- Khvl hacksaw. Why not use a regular hack for cutting gvl

- Features of GVL

- GVL tools

- GVL cutting technology

- Video cutting sheets GVL

The better to cut mineral wool?

Professionals use a special machine to separate paintings and rolls. But many are wondering: “The better to cut to mineral wool in the boards of the house to save money?””

Important! For cutting, minvates use a hacksaw for metal or wood.

In everyday life, to cut the canvas, a mounting knife is involved. This tool has one drawback, due to a small blade, it is difficult for them to cut thick plates. Therefore, I recommend applying a chancellery knife only for thin sheets. If this condition is not observed, then the canvases may become unusable.

Cutting mineral wool with a knife

Tools best suitable for cutting mineral insulation:

- A knife whose blade is made of carbon steel. It is very easy to cut such a product, in addition, its blade is well and quickly sharpened. This knife needs careful care to avoid rust. The main rule of care is to wipe the blade after washing.

- A knife whose blade is made of stainless steel. On each side there are teeth of different lengths, so it is very easy to do cutting of mineral insulation of different sizes and thicknesses. The blade quickly plunges into the stove and cuts it qualitatively. A sharp tip can make not indirect cuts.

- Special machines. Such tools are able to draw canvases along a flat line and bending. Such a function is very appreciated in industry. If you need to cut cotton wool once, then it makes no sense to purchase expensive equipment. a tool that is in the house is suitable.

Cutting mineral wool with a special saw

note! Scissors for cutting wool cannot be used.

To cut a cotton wool, it is advisable to use a special hacksaw for insulation or metal. It is used to cut material, the thickness of which does not exceed 5 cm.

The blades of the tool that you use to cut cotton wool should always be well sharpened. In this case, fibers from cotton wool will be stretched minimally. Manufacturers advise cutting cotton wool before turning the roll.

How to transport insulation correctly

Mineral wool is one of the best, simple and common materials for insulation and sound insulation of walls and ceiling today, and is also known in some other areas of application. In addition, it is easy to mount, that is, you can independently insulate the premises. Many people do not know how to cut mineral wool correctly without violating its structure, in this material we will consider all methods of proper cutting of mineral wool, as well as advise tools that are best suited for this.

It is customary to classify mineral wool according to the principle of material from which it is made. This follows that the mineral wool made of different source materials differs in structure. fibers, and, accordingly, and according to the type of cutting. So there are the following types of mineral watches:

Mineral wool in a studio | Part 1 | Absorption Coefficient

- Glass minvata. Consists of glass melts.

- Stone Minvata. It is most often made from various melts of rocks.

- Slag Minvata. Source material. domain slag.

In fact, you should pay attention to the fact that sometimes mineral wool is harmful. This is due to the fact that it has dust and phenol.formaldehyde resins in it. Therefore, it is necessary to refer to this material selectively, although mineral wool cannot be attributed to carcinogens for humans.

Mineral wool cutting can be carried out both independently at home and using various equipment. Equipment for cutting mineral wool plates can be different. The question is in scale. Mineral wool cutting machine is suitable for serious and large scale. for enterprises, manufacturers, etc.D. But a knife for cutting mineral wool will become an indispensable assistant in cutting insulating materials at home.

It is important that the cutting of mineral wool does not damage the fibers, so the equipment should be selected carefully. The cut should be even. At home, cutting mineral wool rolls (the so-called “50-ka”) will be convenient using a cutting knife, but for large (“100-ki”) a special hacksaw for heater will be convenient.

If you do not know how to cut mineral wool at home, we can advise you with excellent tools best suitable for cutting mineral wool.

So, for cutting mineral wool, a good, sharp chancellery knife or a hacksaw for metal is best suited, carefully cut the mineral wool in the right directions, for greater accuracy you can draw a pencil or cut right along the ruler. The process of cutting mineral wool is somewhat similar to the cutting of paralon, only you need to make a little more effort, pressing a little more on the tool for cutting mineral wool.

Today, manufacturers offer a sufficient number of heater. Each of these materials is used in certain conditions and has its own price. However, insulation is most popular that provide optimal heat conservation and have a long service life. The second no less important point is the cost that should be acceptable.

Roofing Pie system insulation scheme.

- Thermal insulation and hydrophobilization. The first parameter is from 0.042 to 0.048 W/mk. Other well.known insulation materials (for example, polystyrene foam, polyurethane foam) have approximately the same characteristics). Minvat is not able to accumulate moisture (hygroscopicity. less than 1%), which makes its weight unchanged. A distinctive feature can be called vapor permeability, which guarantees insulation and at the same time intensive moisture exchange between the external environment and the walls of the building;

- Density, strength. The insulation has a sufficient density (from 30 to 100 kg/cube. m), which guarantees high thermal insulation properties with optimal strength. The rigidity of the material is provided by the direction of the fibers; They are located in a horizontal and vertical direction;

- soundproofing. Good characteristics of noise protection are achieved due to the porous structure of cotton wool;

- resistance to aggressive environment. Cotton wool “indifferent” to alkali, acids; does not rot, is not affected by the fungus. Rodents also bypass this insulation;

- fire resistance. Basalt wool can withstand heating up to 700 ° C. This protects the structure from complete destruction during fire and gives time to evacuate the residents;

- Health safety. In production, resins containing harmful substances (formaldehyde, phenol) are used). However, compliance with the technology involves their introduction to the insulation in a chemically related state. Substances become completely neutral in relation to the environment and do not pose a danger to humans.

However, if the mineral wool is produced by a artisanal method, then the health danger exists. Therefore, it is more advisable to purchase material from trusted manufacturers.

A distinctive feature of mineral insulation is a structure consisting of fibers, which should be solid to ensure thermal insulation. In this regard, special attention should be paid to the cutting process. You can not use scissors for cardboard or fabric for cutting material, or ordinary dining rooms.

On an industrial scale, special machine equipment is used for cutting mineral insulation. Consider how to cut insulation from mineral wool yourself at home.

Often for cutting, mineral wools use a mounting knife. But he has one drawback. a short blade that is not suitable for working with thick insulation plates. In addition, the blade is quickly blurred and requires replacement.

Sometimes a special hacksaw for wood or metal is used, and the craftsmen found how to cut mineral wool at home. a kitchen.pledged knife for cutting Bukhankaa.

How to cut Knauf Minvatu. How to cut mineral wool in a roll

Mineral wool is an artificial building material that is made for heat and sound insulation of residential buildings and industrial premises. The material is not afraid of fire resistant to various weather conditions. For convenience, they are produced in rolls and mats. It is not enough to purchase a heater, it is still important to know how to work with it, this will be discussed below.

Recommendations how to work with insulation

Insulation of the attic premises of effective ways to reduce the body of loss as a result of the house you need to heat less, and you mean, you can save on electricity. Mineral wool insulation is a universal version with high technical characteristics for thermal and acoustic characteristics, as well as fire resistance.

The insulation consists of fibers. During work with the material, a large number of harmful particles fly out into the air. Small dust is dangerous for human breathing and skin. Therefore, when working with it, the precautions observe.

- work in a well.ventilated room.

- For work, use personal protective equipment: mask, glasses, respirator.

- They work in overalls: well.fastened overalls, headdress, building gloves.

- After work, the hands and face are thoroughly washed under cold water. Overalls shake off from dust.

How to cut mineral wool in a roll

To insulate the house with mineral wool, it is cut, covered with material along and across. Each type of cut has its own rules, observing which work is much easier to do.

Longitudinal cut of the material

Mineral cotton wool in rolls is cut in an unpooked form. Roll on a hard, even surface. Roulette measure the required length. Put tags in three places in a package circle. The place of cut, for accuracy, is wrapped with molar tape.

Then they take the saw and cut the mineral wool roll in a circle. After the cut.off piece is separated, the packaging film is removed.

Important. Maslar tape is wound on a roll on the opposite side of the workpiece, so that after cutting the rest of the roll does not unwind.

Transverse cutting material

For transverse cutting, mineral wool roll is unpacked. Make markings on both sides. Then apply a flat bar: a ruler, a piece of profile or a beam.

With a knife or hacksaw are carried out along the bar. If it is not possible to cut off the insulation in one motion, the cut is repeated several times. The material is cut to the end, so that you do not have to tear off, in this case the geometry will be violated. We’ll have to equalize the insulation.

Important. When cutting the insulation, put the board so that the knife does not stop.

Than cutting the insulation

In production, the material is cut on machines, special disk saws. At home, the insulation can be cut using a stationery knife, wood saw and special insulation knives.

- The stationery knife is used only for transverse cut, since it does not have a large size of the blade. The cutting part is quickly stupid, because of this they often change the blade. Chancellery knife is used for cutting not a large amount of insulation.

- To cut mineral wool along the roll, use wood saw. The hacksaw has a long canvas that cuts out a roll. The disadvantage is that after such a cut there is a lot of waste from the insulation. When carving, the teeth of the hacksaw is pulled out pieces of insulation.

- Bukhankaa knife with a long blade of 200. 300 mm comfortable tool. to cut off the insulation along and across the roll. The blade with cloves easily sail the insulation fiber does not leave much waste. The disadvantage of the kitchen knife is that it is quickly stupid. If there is a lot of work, for an even cut, the knife will have to be periodically tightened.

- For professional cutting, the wools make special knives. The length of the tool with a handle is 500 mm, the length of the blade is 330 mm. Knives are made of stainless and cold.rolled steel, a special wavy gear sharpening of the tool allows you to cut the material evenly.

The right choice of tool for work and compliance with recommendations will help make insulation of the house a pleasant and useful activity that will not bring unnecessary troubles.

How to cut KNAUF Profile. Profile cutting tools

We will figure out how to cut profiles for drywall (guides, racks, etc.It is important to know what tools are needed for this, as well as take into account the features and methods of cutting.

There are several main types of metal profile:

They are used for partitions. Remain even, carry the weight of drywall plates.

Are placed vertically and fixed inside the channels of the guides.

Usually installed in the lower and upper part of the frame.

Depending on the specific task, arched, angular, beacon, ceiling types of profiles can be used.

In the process of assembling the frame, all types of profile have to be cut into several pieces to achieve the necessary design. This can be done in several ways and tools. The main thing is that some requirements are observed:

- The chosen tool must match the work on metal

- The surface of the profile should save the shape and do not deform

- Ease of operation of the selected tool

Before cutting a metal profile for drywall, you need to prepare a set of tools:

Consider some of them, and you will make a choice yourself.

Scissors for metal

Do not require special dexterity in work and are inexpensive. You can cut any kind of profile. There is no dependence on electricity. The amount of garbage and the noise level. minimal. Is the most common cutting tool in construction work with drywall slabs.

Metal saw and electrician

The cut place is even, smooth. With this method, the noise level is higher and the garbage (metal shavings) remains after work. The costs of buying power tools increase.

Kryazuvka for metal

Can be attributed to the most unsuccessful choice of cutting method. You can cut off the metal profile, but it is inconvenient (due to the subtlety of the metal, the knife canvas will stick).

Cutting machine

It is convenient to cut the metal profile, to work with the machine just.

Disadvantages. the high cost of the machine, takes up a lot of space, noise when working.

Corner grinder

Noisy way, with flying sparks. With special caution, use in rooms where wallpaper and/or covered on the floor is already glued, in order to avoid sparks and burning the surface.