How to cut sewer pipes in an inaccessible place. What disk to use for wood

How to cut a sewer plastic pipe

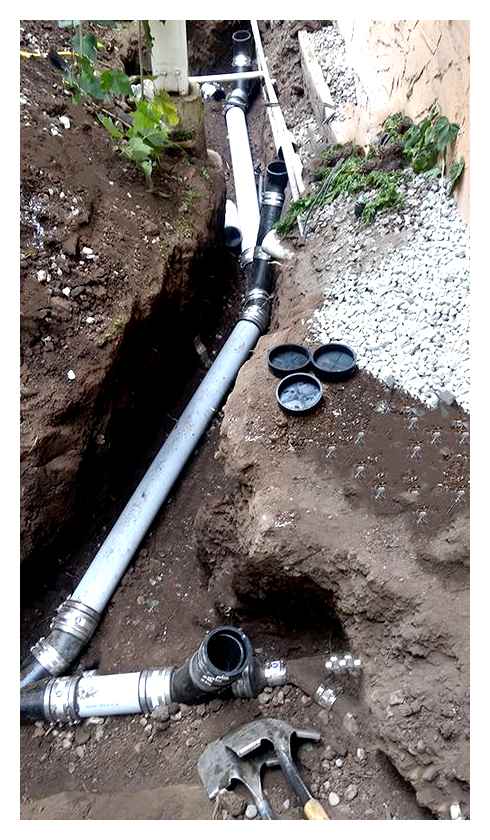

In order to lay sewer pipes, you can not resort to the services of specialists, but do everything with your own hands.

With your own hands, laying sewer pipes is carried out according to certain rules, the outer sewage system has its own characteristics.

First of all, it is necessary to cut them into areas of the desired length, then they need to be interconnected by style elements. After the assembly of the pipeline is completed, it is mounted in the wall.

Connection of sewage elements

Before laying the pipes, it is necessary to transport and store them. In order to avoid pipes deformation, you need to prepare a smooth surface. When laying sewer pipes, it is sometimes necessary to cut them in order to ensure accurate styling.

Kaya work can be done with your own hands, a special tool is used for this that forms a chamfer on a cut edge, but you can use a regular hacksaw for this purpose. After the edge is cut off, it is cleaned and mowed at an angle of 150 degrees. This is done so that the sealing ring is not damaged and to make installation in a short time. It is very important to know that accessories and shaped parts cannot be cut. After that, you should check whether the bevel is made correctly on the cut edge, and then proceed to the direct connection of the parts.

To lay sewer pipes to the smooth ends of the elements, apply a lubricant on a silicone basis. This is done in order to:

- A light connection was provided during assembly;

- The coefficient of friction was reduced, which occurs between the sealing ring and the pipe during operation, when temperature fluctuations occur;

- eliminate the possibility of sticking and reduce the degree of internal stress of the system;

- Rubber sealing for longer maintained operational and technical qualities.

It should be remembered that the inside of the bell is not lubricated!

After that, the smooth section of the sewage elements is pushed into the bell to the stop (the place of their contact should be marked). The smooth edge is extended from the bell (distance up to 10 mm) and is left for fixation. In view of this, a gap is formed, which will ensure compensation for changes in the length of the pipe when temperature changes occur and the internally voltage of the system will be prevented.

General course of work

To decide how to disconnect the cast.iron pipes of sewage, you need to carefully examine them and draw up a small work plan. If there is a complete replacement of the pipes, the old ones can simply be broken with a hammer and take out the garbage. To do it is easy, t. to. cast iron is very fragility. If you need to disassemble and replace only part of the pipes, you will have to work carefully and slowly. It is necessary to turn off the supply of water into the apartment, otherwise the drains will fall into the sewer. The next work is carried out in several stages:

- Part of the riser below the connection is cut off with an angular grinder;

- The cut off the piece is disconnected from the bell;

- If you fail to pull out a piece, you need to warm up the joint.

Work with cast iron is injured, therefore it is necessary to use personal protective equipment: mittens or gloves, protective glasses, special clothing.

Tools necessary to remove pipes

To remove old pipes, you need to prepare some tools and materials. Regardless of the methods of connecting the pipes will be needed:

- corner grinder for cutting individual elements of the pipeline;

- cuts and grinding wheels;

- gas burner or soldering lamp for warming up joints;

- hammer and screwdrivers;

- chisel;

- pipe key;

- respirator and glasses for disassembling the flooded sulfur joints;

- Peorator;

- pipeline;

- nail;

- steel wedge or chisel;

- Passatigi;

- Water bucket.

After their preparation, you can start dismantling the system.

Other tools for cutting plastic pipes

They are rarely used when there is no pipeline at hand:

- Corner grinder. for cutting pipes, a cutting disk for metal will be required. The main point in the operation of the corner grinder is the exact regulation of the effort, it is impossible to crush too much on the tool.

- Electricity is the most convenient way in the absence of special scissors. It is likely to get an oblique cut, so for greater accuracy during operation, the pipe must be turned several times.

What is categorically not recommended to cut pipes:

- Ribbon saw. its blade moves too slowly and if it is not insufficient enough, the probability of damage to the internal diameter of the pipe is great, which leads to chips and cracks.

- Circular machine. Since plastic pipes are flexible, pushing them into the machine often causes a pipe displacement and blow, which is dangerous for a person producing a cut.

Pipe cutting tools

FACCOSNITER. designed to improve the quality of welding of plastic pipes. With its help, the edge or upper layer of plastic pipes in diameter is removed.

On sale, you can find FACCOSHERS of various designs designed to work with pipes of different diameters. When buying, it is necessary to decide on the volume of work and the material of the pipes. The tool happens with both manual and automatic supply. It allows you to configure the required diameter of the pipe and wall thickness.

Caliber. necessary for working with metal.plastic pipes. With its help, before soldering the pipes, the aluminum layer on the pipe cut is cleaned. In addition, the caliber allows you to remove the burrs and uneven cuts, as well as remove the chamfer if necessary.

If the pipe during cutting slightly wrinkled and the cut acquired an oval shape, the calibrator leveles the end, making it again perfectly round. For each specific diameter of the pipes, a separate calibrator is required.

When planning the device of a plastic pipeline, it is necessary to prepare in advance the entire tool necessary for the full work cycle. The set of the tool depends on the length and complexity of the pipeline, pipe material and their diameters. 2015-10-08

Today I will tell you about evolution. Not in the sense of evolution on the theory of Darwin, but about the evolution of plumbing. There are such sewer pipes well.known. fifties. I want to talk about the evolution of how their plumbing is being cut.

How to disconnect the cast.iron pipes of sewage

First of all, you should get rid of the cement castle (sealing of the bell. the camber of the packley and the device of the castle). The work is not easy-it requires almost tenderness due to the structure of cast iron, scattering from gross treatment, despite its strength. The cement castle is destroyed by a screwdriver or chisel.

The circuit of disconnecting the toilet

Cast iron is cut with a corner grinder. First dismantle the pipe. Then, in the unit remaining in the bell, two cuts are carefully made (at a distance of 100 mm from each other) with a small circle. Pieces are knocked out of the bell with a chisel (they knock on it with a hammer. pounding with a hammer directly on the cast iron is strictly prohibited).

Important! Do not use gross power. break the entire system. Cast iron is fragile. You need to act very carefully.

Even if the bell on the tee, which goes to replace, should be carefully so as not to damage the lower pipe included in the same tee (unless, of course, you are going to replace everything from the neighbors). Having removed all the fragments, the bell is thoroughly cleaned of rust, dirt, etc.

A Crazy Way To Fix Pipes

Cast iron risers were once massively put in apartment buildings (the designs have been preserved to this day). Certain details were produced at the factory. They also performed the clogging. Used sulfur for this. Such a system can be disassembled only with the use of open fire. At the same time, sulfur allocates toxic pairs. the respirator is necessary. We do not advise doing such work independently. it is actually dangerous.

Moments of disassembly of cast iron

With a complete replacement of the structure with a plastic one, you can not do excess work and just break everything with a hammer. This is quite easy to do, because cast iron is considered a fragile material. However, if only part of the pipeline must be disassembled, the work should be performed more carefully.

Before dismantling the cast.iron sewer, it is necessary to inspect the entire system in order to determine the area that will be repaired. Then necessarily disconnect the water supply so that the drains do not get into the sewer. Further disassembly is performed in stages:

- The part of the pipe located below the connection is cut off.

- The pipe is separated from the bell. Calculation methods will be discussed in more detail.

- If you just do not get out the connection, use a soldering lamp or the surrounding incisions are made a length of 20 mm.

When carrying out procedures, it is necessary to use all means of protection due to the injuries of this work.

Calculation of the pipeline with a sulfur connection

Regardless of what a cast.iron sewage system was connected, before replacing it is necessary to carry out some standard preparatory work:

- turn off the water;

- disconnect the hose leading to the toilet;

- remove the toilet itself by unscrewing the bolts;

- Clean the bathroom of equipment and furniture.

To determine whether the sulfur was used when connecting the pipes, it is necessary to bring a soldering lamp to the seam. Under the influence of high temperatures, the sulfur melts, accompanying this process with an unpleasant odor.

When analyzing cast.iron sewer pipes, work begins from the farthest corner. The element must be broken with a hammer. It is better to use a tool with a plastic or polymer base, because due to metal nozzles, sewage. Finding the cross.polling to the riser, it is necessary to shake it as much as possible.

Then you need to prepare a soldering lamp or gas burner. At least two people should be engaged in heated formations. While one warms and melts sulfur, the other must shake the structure. At the same time, it is necessary to use gloves and other protective means.

Когда соединительное вещество полностью расплавится, из стояка можно достать крестовину. At the same time, it is worth being very neat, you need not to forget to remove the remaining sulfur, and then let the riser cool well. If the cast.iron structure turned out to be too strong, you can always make several incisions near the pipe that must be removed. This will facilitate the extraction procedure.

Calculating the pipeline with cement connection

Dismantling of iron pipes that were connected by cement is practically no different from the aforementioned option with gray, but it is much safer. All because when melting sulfur, a lot of carbon monoxide is released.

To start dismantling, you need to cut off part of the pipe. At the same time, it is worth retreating at least 30 cm from the connection site. The frozen cement is removed with a hammer, which must be beaten on a screwdriver or a chisel inserted into the hole. All procedures should be performed as accurately as possible so as not to damage the bell.

When the joints are freed from cement, you need to try to shake the main pipe. In order not to process the sewer with a soldering lamp or burner, you need to withdraw a cabin, however, if you can not do without it, it is necessary to heat it strongly or use a specialized key. For example, for a 50 mm pipe, tools No. and 4 are used.

The cross is located from below on the main riser. To extract it, you can just use a hammer with a screwdriver. At the same time, for some time, you need to lightly tap the tee of the most to form a small gap between him and the pipe. Then you need to penetrate this opening, give the tee and remove it. It will take a lot of time to carry out these manipulations, in addition, this method is ineffective.

The following option is to use a solder lamp or burner. Dismantling is much faster, but an unpleasant odor becomes a payment for this, which is disappeared for a long time. First of all, it is necessary to cut the cubs of the cross. Then a heating device is placed in the pipe. A metal shield is applied to the upper part of the pipe to get the ability to adjust the traction inside the riser. When heated, you need to start swing the pipe and, as soon as the opportunity arises, remove the dismantled tee.

You can also use a corner grinder. To do this, first cut off parts of the tee, leaving a small piece in the pipe. Then put a medium.sized disk that could freely get inside, and cut out the corner grinder residual parts of the structure, knocking them out with a hammer.

How to cut a cast.iron pipe

Cutting of cast.iron pipes can be carried out using corner grinders and pipelines. In addition, to saw off a cast.iron pipe is possible using a chisel and a hacksaw for metal. Also for cutting pipes made of cast iron, special gas installations can be used.

How to saw off the pipe with a hacksaw on metal and chisel

Cutting cast iron pipes using a hacksaw or chisel is as follows:

First of all, you should measure the pipe and put a mark where the cut will be made.

After that, a wooden block must be placed under the pipe at the cutting site.

Then strictly according to the mark made on a cast.iron pipe, you need to make.

Combiles are best done in sections of 20 millimeters.

Using a chisel at the mark, you need to beat off a cast.iron pipe.

How to cut the pipe using a pipeline

Teen Titans GO! To The Movies Exclusive Clip | Time Cycles | @DC Kids

A pipeline for cutting cast.iron pipes is used if other cutting methods are impossible. You can cut off the cast.iron pipe using a pipeline by doing the following:

First you need to install a cutter on a pipeline.

Then you need to work with the chipper handle until the cast.iron pipe is tightly burned, and only then carefully cut.

Device and the capabilities of the corner grinder

Arranged an angle grinder (corner grinder) is quite simple. The electric motor through the angular gearbox transfers rotation to the shaft, on which interchangeable nozzles are fixed. The area of use of corner grinding. It is used for cutting, stripping, peeling, grinding and sharpening. The type of work performed is determined by the functional purpose of the shift disks. Each nozzle for angular grinder has its own purpose.

Such an instrument is used during construction work, in mechanical and repair shops, during rescue work and in other fields of activity. Corner grinder is indispensable both in everyday life and production. We also recommend this

Wood disks for corner grinding

The angle.grinder is used to work with solid materials and is not a specialized tool for processing wood. But you can use it for this purpose, although you will have to observe some conditions. It is strongly recommended to use standard equipment, t.to. It is not safe.

The industry produces a number of specialized wood discs recommended for angular grinding:

- The cuts of a special shape and expanders located on the cutting part have detachment, which allow you to prevent the instrument jamming.

- Chain discs are intended for modeling, milling and cleaning wood. They are a high.alive steel disk, on the outer edge of which a chain from a chainsaw is installed.

- Special petal petals are designed to align irregularities and cleaning. Such a nozzle consists of several layers of sandpaper laid radially one on the other so that they block each other.

- The disc disk is used for black wooden processing, for example, in the construction of a log house. This nozzle replaces Plotnitsky ax.

- Wood mills allow for coarse milling work.

- End discs are used to align the end surface.

- Grinding disk for wood with interchangeable sandpaper circles of various granularity.

Device and the capabilities of the corner grinder

Arranged an angle grinder (corner grinder) is quite simple. The electric motor through the angular gearbox transfers rotation to the shaft, on which interchangeable nozzles are fixed. The area of use of corner grinding. It is used for cutting, stripping, peeling, grinding and sharpening. The type of work performed is determined by the functional purpose of the shift disks. Each nozzle for angular grinder has its own purpose.

Such an instrument is used during construction work, in mechanical and repair shops, during rescue work and in other areas of activity. Corner grinder is indispensable both in everyday life and production. We also recommend this

Wood disks for corner grinding

The angle.grinder is used to work with solid materials and is not a specialized tool for processing wood. But you can use it for this purpose, although you will have to observe some conditions. It is strongly recommended to use standard equipment, t.to. It is not safe.

The industry produces a number of specialized wood discs recommended for angular grinding:

- The cuts of a special shape and expanders located on the cutting part have detachment, which allow you to prevent the instrument jamming.

- Chain discs are intended for modeling, milling and cleaning wood. They are a high.alive steel disk, on the outer edge of which a chain from a chainsaw is installed.

- Special petal petals are designed to align irregularities and cleaning. Such a nozzle consists of several layers of sandpaper laid radially one on the other so that they block each other.

- The disc disk is used for black wooden processing, for example, in the construction of a log house. This nozzle replaces Plotnitsky ax.

- Wood mills allow for coarse milling work.

- End discs are used to align the end surface.

- Grinding disk for wood with interchangeable sandpaper circles of various granularity.

How to cut cast.iron pipes?

It all depends on what place the pipe is and which equipment can be used. So here are some options for cutting a cast.iron pipe:

- Saw for metal. This is a manual method of cutting, for it there is no need to have any certain conditions, just have access to the pipe itself. Tool. hacksaw for metal and metal canvas. The pipe is drunk with a motion with a crusty from itself and a return to idle.

- File. Do not be surprised and this method can live. There are no conditions, only the tool is the file itself, preferably triangular. The cut occurs as follows. with movements from ourselves throughout the circumference we make deepening, until the entire thickness of the pipe breaks out.

- Cutting disk. It is necessary to have a network of 220 volts or another with which the power tool, or compressed air works, if it is a pneumatic tool. Tool. a cutting tool (angular grinder or its analogues) and a cutting disk. We fill the disk into the tool and saw the pipe around the circle. There are both universal metal disks and cast iron disks in various versions.

- Autogen or analogues. Special equipment is needed, which cuts metal, mainly a mixture of oxygen and gas, but there are also options for using other gases. This method is not attached to the place and can be used autonomously. Cutting principle. melting metal at high temperatures.

- Electro or electric gas welding. Need electric current and special equipment. The principle of cutting is electric shows that appears in the contact of the phase and earth, which, using electrodes or gas, creates a high melting point.

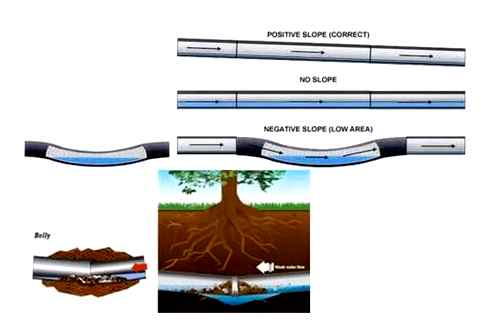

General internal sewage device

The sewer system is a network of pipelines through which waste fluids are removed from the premises and sent to treatment facilities. Distinguish between internal and external sewage. The first is located inside the building, performs the functions of collecting and removing effluents from household appliances or plumbing. The second (external) part provides the movement of drains to treatment facilities. Most of the problems that happen with water disposal systems occur in internal areas. This is due to the high probability of blockages and frequent mechanical loads. Before repairing the sewer pipe, it is necessary to study its design. Inside the room, the pipeline consists of two sections:

- Horizontal wiring (sunbed). These are the elements of the production of plumbing, connected to the horizontal pipe, its diameter is usually 50 mm;

- riser. This is a vertical pipeline, the task of which includes the removal of effluents to the outer sections of the system, as well as ventilation of the internal cavity of pipelines.

The horizontal pipe joins the tee with a diameter of 110 mm. It serves to connect the toilet. Connection to the riser is made using another tee of the same size.

Modern pipes used to assemble sanitation systems are made of plastic. Most often it is PVC. This is cheap, quite durable, light material. The assembly and repair of the plastic pipes of the sewage system is not difficult and can be performed with their own hands. The only problem when performing repair work may be disassembling the line of pipes. The design of plastic elements is such that to remove and replace the defective part, you have to disassemble the entire system from the starting point. It is inconvenient and difficult to work. In addition, if an expensive repair is made in the apartment, the full disassembly of the system becomes impossible. It is required to repair sewage pipes without dismantling the remaining elements. This is an accomplished task, but it requires an understanding of the specifics of the system. Incorrectly completed work causes blockages.

Jokes jokes, and the method of applying beautiful Metochki with the help of a thread masterpiece, as well as the mounting of the cutter in a wooden block.

Now you know not only how to cut along a plastic sewer pipe, but also why do it. We offer to frolic with pipes in this context, and in the event of sewage failures, contact specialists.

Reasons for the course

To eliminate the investigation, you need to find the cause. Often the sewer pipe flows at the junction or leakage begins as a result of pipe damage.

If the cause of damage has become a mechanical effect on the design, the degree of deformation must be assessed. Perhaps a difficult repair with the replacement of pipes will be needed. Often the problem is associated with poor.quality installation, improper structural solution or careless operation.

It is easy to cope with such problems. It will be possible to quickly replace the cuffs or light the damaged element without resorting to the help of plumbing.

Ways to eliminate leaks

Before performing work, it is necessary to warn the residents that they do not use the sewer. Then you should turn off the entire equipment that uses water, for example, washing machine. After overlapping the flowing area, you should thoroughly dry the place of the leakage with a hairdryer.

Before starting work, it is worth dealing with the material from which the sewer system is made. Today it is metal (steel, cast iron) or polymeric materials. polyvinyl chloride or polyethylene. How to cover the joint of the sewer pipe depends on the material.

The flowing joint must be thoroughly cleaned of the residues of the cementing display. Then treat the cement and PVA glue with an aqueous solution. In this case, be sure to use gloves. The solution will dry about a day. Accordingly, it is impossible to use the sewer at this time.

To perform work, it is advisable to use the repair coupling.

We seal the joints with the help of the tape

A self.adhesive tape is a modern and reliable waterproofing material that allows you to quickly and efficiently seal sewing joints. The strength of the tape is given by the basis made of polyethylene. Additionally, the product provides corrosion protection and good dielectric properties. With a tape, various parts of the plumbing system can be sealed, such as taps, inserts and plugs.

The plumbing of the toilet involves the use of various sealing tools, and a self.adhesive tape is the first way to wrap the flowing joint (but far from the only one).

We use to eliminate the leak of sealant

Silicone or rubber sealants are a great option for waterproofing sewer structures. The high level of adhesion with the surface of the elements is explained by excellent adhesion. over, sealing of pipes can be carried out without pre.processing with primitive agents and primers.

The type of hardener used in sealants imposes restrictions on use in different conditions. The cheapest, acidic acid cannot be used everywhere due to a possible chemical reaction with acids. Neutral sealants are universal.

You can safely recommend the use of such a sealant for most types of pipes. For reliability after work, it will be necessary to smear with silicone all joints and places of possible leaks.

How can we cut sewer pipes?

Plastic sewer pipes are easily cut by a knife.haired wood with a small tooth.

You can also cut with a hacksaw on metal.

Personally, I use a corner grinder (corner grinder) with a cutting circle for metal. It is very convenient for her after cutting off to remove the chamfer for a lighter joining of pipes.

Burrs on the cut edge of the pipe must be cleaned with a knife or sandpaper. Otherwise, hair and thread will subsequently cling to them.

Cast iron sewer pipes, as well as the plastic companies of Rehau (reinforced with minerals), it is best to cut the same corner grinder with a circle of metal.

Find out the rules for laying sewer pipes here.

- How to open bags with a bellow

- How to protect against spray when kneading

- How to save time and nerves on filling the garbage bag

- How to correct the wire on a power tool correctly

- How to tighten the cartridge drill without a key

Stanislav Timchkin was with you. I will help save strength, time, money and nerves!

4 Комментарии и мнения владельцев

Very sensible tips. Just in the subject, t.to. I am making repairs.

I hope something will come in handy from the selection!

Good afternoon! Need your advice. How to cut a tee in a riser from a PVC? Apartment new building, you need to bring the drain to the washing machine.

Hello! The main point in this case is where the bell is below the alleged tee, and whether there is access to it. If there is access, then you will need the tee itself, a piece of the pipe from the tee to this bell, and such a detail as the “elongo” (see. a photo). To cut off the pipe of the riser, you need to ensure the lack of water flow. block hot and cold water. But you need to remember that the neighbors from above can drain water from the toilet or bath. You need to be ready for this. It can be difficult to cut off the pipe of the riser, due to lack of access. You can do this with a corner grinder, cutting the window in the pipe, or you can use a metal cable. Throwing it through the pipe, make several sawing movements, the pipe will heat up and cut. Be sure to tear the edge with a knife or sandpaper and make a chamfer. Next, we put on it an extension cord, a tee and a piece of pipe to the bell. We insert the pipe into the bell, tighten the elongator to the desired level. Ready. If there is no access to the lower bell, it’s better not to take risks and not pull the pipe out of it. Then you can not insert. Representatives of the management company, t, will not allow the pipe cut of the pipe or using the connecting coupling.to. This is prohibited by SNiPs.