How to cut threads with a dick properly. Rules for use

Cutting threads with dies

Dies are used to cut on the outer surface of the mounting thread of the triangular profile with a step of 2 mm. The dick is a nut made of instrumental carbon steel and having such a thread, for which it is intended for cutting. In this nut (dick), the side holes are drilled depending on the size. There may be about 3. 8 holes depending on the diameter of the dick, these holes intersects with thread form threaded combs. The dick is fixed in the dress holder and the thread is cut. At the end of the dick, the size of the thread and the material of the dick is marked.

The threaded strip is attached in a manual plane.holder. the goal. After cutting two, three turns with pressure, the further feed of the dick is self.tightening. There are conical holes on the dick, they are provided for attaching a trash in a dress holder. When cutting the thread with a dick manually, the rod is fixed in a vice so that its end, protruding above the level of the sponge, is 20. 25 mm larger than the length of the chopped part. To ensure cutting at the upper end of the rod, remove the chamfer. Then, a dick fixed in the plane.holder is applied to the rod and rotate with a slight pressure so that the plate crashes into about one, two threads. When cutting the thread with a dick, it is necessary to use machine oil, cooling fluid and even when cutting the threads, one revolution is made forward and half a turn back so that the thread is according to the standard and the dick is not dull.

Inner thread cutting with taps

Inner threads are cut with taps. The tap is a screw of the same diameter, step and angle, thread profile, as they rifled thread. The tap is made of carbon. instrumental steel and quickly cutting steel. The tap has longitudinal grooves, at the intersection of grooves with turns, combs are formed. Before cutting the threads, lubricate with butter and cooling liquid the internal part of the workpiece and tap, in which the height of cutting teeth, the combs are constantly increasing. Behind the fence part of the tap there is a caliber part. After the tap is blown away, it can be sharpened. The number of feathers distinguishes three.pill and four.pill taps, depending on the diameter of the tap, they are usually used by a set of two or three pieces, between which the processing allowance is distributed, for example: for a set of two meters, 70 % of the load falls on the first meter, and 30 % in the second one in the second. Perhaps cutting threads with one machine tap.

one.10 Kleka

Rivet. This is an operation with which inexhaustible compounds of parts are obtained. It is often used in the manufacture of art products. The riveting process consists of drilling holes in the details, installing rivets in them and rummageing the protruding end of the rivet with the formation of a second head. The rivet connection can be mobile and motionless.

The fixed connection is used in most cases for various metal structures, starting from gratings, fences and ending with jewelry. Moving compounds are used in the manufacture of tools (forceps, scissors) and other products (loops, hinges) to obtain articulated joints, in them rivets are installed with a gap.

Rivets are made of metals with viscosity and plasticity in a cold state (steel, copper, brass, aluminum, silver, etc.). They consist of a rod with one head called a mortgage head, the second. Closing head, formed when rummaging.

The most common rivets with a semicircular and secret head (flat) are. The rod along its length is taken based on the sum of the thickness of the crumple parts and the protruding part of the rod necessary to form a closing head. For the formation of a flat, secret, head, the protruding end should be 0.5 diameters of the rod, and for the semicircular head-1.5 diameter of the rivet rod rod. The protruding end of the rivets is made slightly conical, so that it is easier to enter it into the hole.

The diameter of the rivet rod is best taken depending on the thickness of the cluttered sheets or details: D = 2S, where D. The diameter of the rivet rod, and S. The smallest thickness of the cluttered parts (sheets).

Riveting tools are stretching and squeezing. The stretch serves to compress the closed parts. It is a steel rod with a hole on the end part, the diameter and depth of which should be slightly larger than the protruding part of the rivet. The compression serves to decorate the closing head and has the same design as the stretch, but instead of the hole in it there is a hole in the shape of the head.

In the process of riveting, the following operations are performed:

Correct the details. Edit, supplies, removal of burrs.

Mark the holes for rivets and tap the centers. At the same time, the distance from the center of the rivet to the edge of the crossed part should be at least 1.5 diameters of the rivet, and between the centers of rivets in a row from 3 to 4 diameters.

Drill (or break through) holes. The diameter of the drilling holes is taken by 0.1-0.2 mm larger than the diameter of the rivet rod. This facilitates the insertion of rivets into the holes.

Remove the chamfers or unscrew the holes under the secret heads. The rivet is inserted into the holes, starting it from below, and under it they put support (a special rod with a moon under the head, strengthened in a vice) or a stove.

Haming with a hammer with a hammer, tightly squeezed the crossed parts.

Rive rivets rivets. At the same time, they strive to ensure that the number of shocks is minimal, since the metal is bombed and loses its plasticity.

Preparation for manually thread execution

Cutting threads on pipes at home can be carried out when using improvised tools. The basic rules of preparation are in the points below:

- At the place of cutting of the turns, dirt and rust are removed, other pollutants. This recommendation is due to the fact that extraneous elements can worsen the quality of the turns.

- If there is a chamfer on the pipe, then it is carefully removed with a file. In some cases, this process is carried out by an angular grinder, but the quality of the resulting chamfer can be low. Therefore, if there is no need to hurry, then it is best to work as a file.

- At the time of operation, the surface should be well lubricated with oil. Only in this case can a smooth course of the applied mechanism can ensure.

If the above recommendations regarding the preparatory stage are not followed, then the working part can be quickly worn out, and the process itself becomes more complicated. In some cases, a strong effect may lead to a pipe breakdown.

Step.by.step instructions for cutting threads using a dick

The most common can be called a dick of various types. It is one of the necessary tools for cutting turns. Among its features, we note the points below:

- The dick looks like a nut made of hardened steel. Holes made in the form of a flower are set on the end sides. To ensure the mechanical processing of the face are represented by sharp cutting edges. Due to the petal form, the ficteration of the chips from the cutting zone is ensured.

- The housing has holes designed to install the handle. They are located on the side sides, due to which an uniform exposure is ensured.

The dick was widespread due to the fact that it is quite simple to use. The recommendations for its use look as follows:

- At the time of processing, the pipe must be vertically located. over, it is fixed using a vice.

- It is recommended to clean the surface, as well as the creation of a chamfer.

- Oil should be applied to the pipe, which will simplify the stroke of the dick on the pipe.

- It should be borne in mind that the dick should be strictly vertically. Even with a deviation of only 10 degrees, it will lead to a decrease in the quality of the received turns.

- The handle should be rotated clockwise.

- In order to improve the quality of the resulting surface, you should do one reverse after two turns, due to which the removal of the remains of the metal from the cutting part is ensured.

During the work, you should periodically lubricate the working part and pipe with oil. Lubricated substances make the cutting process more simple and smooth.

Interchange cutting tap

With a tap, cut the inner thread in the pre.drilled opening. The hole should be less than the size of the coil (the size of the coil is indicated on the tap). Something like in the table:

The diameter of the hole for the inner thread with a tap

It is worth remembering that the drill will not give an absolutely accurate diameter, it will be more on some shares of mm. This is especially noticeable in diameters up to 3 mm. This should be taken into account and taken less for the tenth share of mm.

As well as with dies, there is a meteen holder.

Taps are black and finished. Sometimes they cut first black, then with a final tap, but basically the finish are used immediately.

Manual cutting of the inner thread with a tap

The process is practically identical to cutting the thread. The tap is attached to the holder and installed perpendicular to the hole. The part with the hole should be reliably fixed.

The tap and hole are lubricated and this is done periodically, after several turns. As well as with a dick, you need to do 1-2 turns and 0.5 turns back to remove chips.

A square is used to check the accuracy of cutting threads, checking the verticality of the tap after several turns.

DIY cutting on a metal pipe with your own hands

When installing metal pipes for the water supply or heating, you have to cut the thread. The threaded connection of the pipes is quite reliable and withstands significant pressure (if you do it correctly), so let’s see how to cut the thread for meters. DIY pipe.

First of all, we cut off the desired segment with the help of corner grinding or hacksaw for metal, be sure to control the evenness of the cut so that one part of the pipe is not more than the other. the cut should be perpendicular to the walls of the pipe.

The pipe should be cleared of rust, old paint, etc.P., If something is on it. Next, cut the chamfer from the pipe (internal or external, depending on which thread you cut) for a lighter course of the cutting tool. The chamfer can be cut off with a corner grinder with a metal disk (→ How to work with a corner grinder) or a petal disk or a file.

Metal pipes with cut cham

External thread cutting on a pipe with a dick (KVPP)

Everything is the same as with the rods, which were written above, but now more with a diameter, which most likely requires some practice and you should practice or be extremely careful for the first time. Also, to obtain high.quality threads and the subsequent good connection of the pipes, you need to work first with a black dick, then finish (such sets are sold).

The selection of metal metal is also important. To work with solid alloys, the appropriate dies from certain alloys should be used, clarify this when buying.

But, the dick is not such a good and powerful tool for cutting the threads on the pipes with your own hands, it is much more convenient to use the cups.

Klupp is almost the same plane.holder, only with a guide for an even passage and cutting threads. The dwarf is dressed on a pipe of this particular guide.

We dress and make a duck on the pipe, screwing it a little with our hands, then you need to use either a special tool. a crack that is convenient to twist the dwarf, but for household needs, a large divorce or gas key is suitable for both household needs.

One part of the pipe should be, of course, fixed in the vice. If the pipe is cut in place, then look so that it does not vomit somewhere from the effort applied to the karta. The pipe can be fixed using the second gas key, but it is better to do this to the second person, t.to. Cut the thread with one hand problematic.

Interior cutting on the pipe tap

Sometimes you have to cut. pipes and inner thread. This is done in the same way with the help of a tap, only already larger diameter.

To cut good threads, use a minimum of 2 taps. draft and finishing. It is important to choose the right tap for the diameter of the pipe. So, the internal diameter of the pipe should be larger by the length of the coil of the tap (if more accurately, then for the thickness of the cut), this is indicated on the tank itself.

The cut is carried out first with one tap, then the second. The main thing is to strictly observe the perpendicularity of the tap stroke and control it. That’s all, success in cutting threads!

Tutorial: Unity & Multithreading

Leave your advice and Комментарии и мнения владельцев below. Subscribe to the newsletter. Success to you, and good to your family!

How to cut thread with a dick

With amateur construction, it is sometimes necessary to cut an external or internal thread into any part. To quickly and efficiently conduct this operation, you need to know the basic rules for its implementation.

The internal thread is cut with a tap, the outer. a dick. As a rule, it is more often necessary to cut the external thread. To do this, you will need a rod on which you will cut the thread, the dick and the basin for it.

Remember that the diameter of the bar should be equal to the diameter of the future thread. Reliably fix the part in a vice, preferably vertically. Insert the desired dick into the cart and fix it. Now attach the dick by the end of the rod, making sure that there are no distortions, it is very important.

The right thread is cut by rotation of the gate clock, the left is against the sentry (for such a thread there should be the corresponding dick). The dick should be rotated evenly, without jerks. Be sure to lubricate its working surface with machine oil.

When cutting the thread, chips form, it must be regularly removed, slightly turning the dick in the opposite direction. As a rule, after the dick has cut several turns of the thread, further work is already going quite simply.

If there is no groove for a dick, you can clamp it with a regular gas key. But in this case, it is much more difficult to start cutting threads without distortions, so observe the exact position of the dick, do not allow the key tilts. The slightest skew can ruin all the work.

What if the blank diameter is more than the required thread size? In this case, the bar must be trotted on a lathe to the required diameter. If you do not work out the part in the current machine, you can cease it on a regular electric tochil, but this work requires great accuracy. Control the diameter of the bar with a caliper, make sure that it is strictly cylindrical. The reliability of the future thread depends on the quality of processing of the workpiece.

Sometimes it is not possible to start the correct cutting the first time, the thread turns out to be distorted. In this case, remove the dick and stand the already chopped section of the thread with a hammer, then repeat the cut again. Since the beginning of the thread is usually not its loaded working area, this is quite acceptable.

Design description

The teeth are located at such angles that when the Lerk is rotated, the turns are formed. The cutting edge of the tool has the shape of a cone, with the thickness of the leerka in 8-10 turns (teeth).

In most cases, manual cutting of thread on the pipe is carried out using a whole round leerka.

The device for the formation of turns is attached in a special holder, and its surface can have up to five grooves.

Lerka with a set of dies

These grooves make up the working part, which stands from three zones. In the upper and lower part there are conical areas. cutting areas with which cutting is made.

A device for the manufacture of round turns can be used for cutting pipe, metric or inch threads.

Such tools have one predominant feature. during the formation, all three edges of the working area work, this allows you to create a thread on a pipe for one passage.

Types and differences

The thread for cutting threads is classified taking into account not only the shape, but also the structure of the case.

Pipe thread cutting

The formation of round.type turns is carried out using the tool with GOST 13536–68, cutting the cylindrical thread on the pipes is performed by the tool corresponding to GOST 9740–71.

Conquered cutting on pipes is used by a tool manufactured according to GOST 6211–81. It is recommended to perform turns using the most common round leerka.

This thread.cutting tool allows you to form turns that differs with a large step with a metric dimension, or a pipe thread with a small step in an inch dimension.

However, if the thread on the pipe requires special accuracy, then the round Lerka will not work. This is due to the fact that its cutting edge in the manufacture is not subjected to grinding after heat treatment.

Cutting the thread of Lerke

Another feature is the dependence of the size of the chopped thread on the external diameter of the tool. The larger the diameter of the opening of the Lerka, the better the outlet of the chips will be performed and the better the thread will be made on the pipe.

Whole and sliding lerka

A whole.type threaded.cutting tool allows you to achieve good quality causes on the pipe. Using a whole leerka, you can form both a metric and an inch thread.

Cutting the thread with a whole leerka occurs quite quickly, and a good result is achieved due to high indicators of the stiffness of the metal from which the tool is made.

The only significant drawback of the thread.cut whole leerka is a low level of wear resistance.

Such models can be used in cases where there are no special requirements related to accuracy on the thread.

The thread.cutting tool in the process can be a little spring, which will lead to minor changes in the diameter of the thread.

The difference can be 0.1-0.3 mm. Another drawback of a whole leerka is its low degree of stiffness, due to which cutting of the thread is not always clean and accurate.

Cutting process

The sliding type tool is equipped with special guides, which significantly facilitate the cutting of the thread.

This model consists of two parts that are attached in the frame using special screws. Screws help with high accuracy to adjust the parameters of the turns that are cut on the pipe.

For the most effective work, it is recommended to get a whole set of dies. this will create a cutting of the desired diameter without much effort and difficulties. Before cutting the thread on the pipe, it is important to fix the sliding leerka with locking screws.

Also, thread.cut cartridges can be used for this, for fastening of which recesses with conical shape and special grooves of the angular type are used. Grooves help to regulate the accuracy of the future connection.

Special Lerki

In addition to ordinary flap for cutting threads on pipes, special tools can be used. They can be:

Before cutting the thread on the pipe, you need to pay attention to the features of the product marking.

The process of cutting with a lirka

So, for example, a metric tool makes turns in millimeters, and can be designated as M8, M10 and so on. Accordingly, such a lick can be cut on a pipe thread with a diameter of 8 or 10 mm.

In addition, cutting with this tool is cut step by step, and each individual step corresponds to the distance between new turns.

Metric Lerka can possess not only the main, but also an additional turn of the turn. Such threads for cutting threads can be indicated by marking M 12-1.5, m 12-0.75 or m 12-0.5. The distance between the turns will decrease in proportion to a reduction in the step.

It is especially worth highlighting the leerka with the left thread. Already by the name it is clear that the presented tool ensures the cutting of the left thread.

Such a variety is not as often as a traditional one, but a special threaded tool will be required to perform them.

As a rule, a device of this type is used to cut threads on such tube joints that will subsequently rotate. This variation is characterized by a special marking, which is designated as LN.

Pipe Lerka provides the creation of cylindrical threads on small tubes, hairpins and rods. Conical Lerka is indispensable when creating heating and water supply systems. The product has a marking “K”.

The purpose of the dick

The tool under consideration is quite simple, characterized by the following features:

- The main purpose is the formation of a threaded surface on a different outer surface. In most cases, the strip for cutting threads is used to obtain grooves on pipes or shafts, various rods.

- Mechanical processing is provided due to the complex surface of the inner surface. It is represented by a combination of several cutting edges located in a certain sequence. When rotating, they remove metal in order to form turns.

- The design has a blank and a gate hole through which an effort will be transmitted.

The distinctive features of inch are the location of the cutting edges. To ensure the removal of shavings from the cutting area, the hole has a rather complex shape in which the tool can be found almost immediately.

Types of dies

There are simply a huge number of different options for the performance of the tool, which is associated with the variety of threaded connections. They all have their certain advantages and disadvantages.

Types of dies are taken into account for selecting the most suitable execution option for cutting thread. The main features of the classification are as follows:

In addition, do not forget that there is a metric and inch dick. Metric threads are more widespread, but inch are used to create various mechanisms.

Metric thread trim for cutting

Classification of dicks for cutting threads in the form is carried out as follows:

Several types of tools are distinguished by constructive signs:

- The whole dick of the left, the thread can be with a different step, is represented by a non.vegetable cast body, which has several holes. This version of execution was widely used, as it is characterized by reliability and ease of use, a long service life. However, with frequent work with various diameters, you have to have a whole set of this tool with you.

- Clushes greatly simplify the process of cutting the turns, which is also associated with the design features of the body.

- Sliding options for execution have the most complex body, which can be adjusted in a certain diameter range. Having one similar tool in stock, you can cut the threaded surface on the blanks of various diameters.

With the left thread, you can work when using all the common tools for execution of the tool. For the purpose, the following classification can be distinguished:

Production is carried out in accordance with the established standards in GOST.

How to cut the outer thread with a dick

To cut the outer thread manually, a special tool is used. a dress holder with dies of various diameters.

Player holder with dies for different diameters

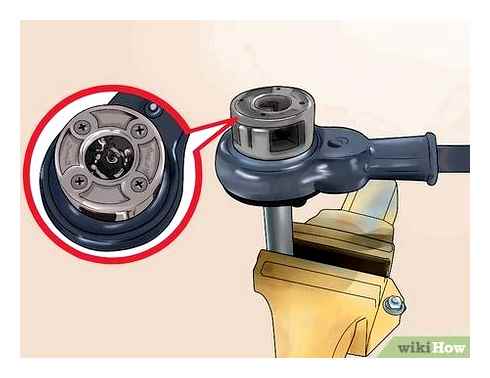

In hard.to.reach places, for example, near the walls, a dress holder with rattle is used.

Selection of a dick

Nominal thread diameter. diameter in the tops of the triangles of thread. The dick cuts the metal, forming the hollows and leaving the peaks untouched, thereby both the rod and the dick should be the same diameter. The thread of the thread, for example. M3 is “M”. a metric thread, and the number is the nominal diameter of the thread in mm. Accordingly, to cut the thread 3 mm rod, take the dick m3. The measurements of the rod are performed by a caliper.

So that the dick is better crashed into the rod from its end cut the chamfer.

The principle of cutting threads with a dick

For fastening the workpiece, you will need a vice. The workpiece is firmly fixed in a vice and lubricated with machine oil for a lighter stroke of the dick, reducing friction and wear of the tool.

Machining Tapered Threads for a Steam Locomotive Try-Cock Repair

When cutting the threads, a large accumulation of chips in the chipholate holes should be avoided.

The dick is installed on the end of the details perpendicular. With a little pressure, the plane holder begin to rotate clockwise, if the thread is right, respectively, if the left, then against the sentry.

- First make 2-3 turns.

- Then half a turn back to remove chips.

- We light up after every 3-4 turns, you can use a syringe.

- And t.D.

Pipe dies

On the water pipe, the thread is slightly different from the usual, primarily in size. This is due to the fact that the binding comes from inch. There is only one catch. If the pipe has 10 inches, then this does not mean that its diameter is 2.5410 = 25.4 mm. Its diameter will be 33 millimeters. This is due to the fact that the transfer to the metric system is accompanied by the addition of two wall thicknesses.

Pipe dies

So that such confusion does not occur with the dies, they began to be released separately for water pipes. It is quite easy to distinguish them from standard. on the case there is a marking in the form of a Latin letter “G”.

Thus, it turns out that there are lerks on G1/2, g ¾, and so on.

In general, pipe tools allow you to make a cut on a pipe with dimensions from G1/8 to G2.

External thread cutting

An integral part of any threaded connection is a component with external thread. It is he who screws into the hole with the inner thread. The external threaded surface is equipped with the bodies of rotation, that is, the shafts. This type of thread is characteristic of bolts, studs, running screws, all kinds of couplings and adapters.

A special tool is used to cut the outer thread:

As clear, the dick is inserted into the dress holder. The plate fixed in the holder is planted on the tip of the shaft with a chamfer. Next, the dick is crushed and wound on the shaft.

The height of the dicks depends on the diameter of the chopped thread. On average, the dick has 8 screw grooves. If we consider the dies for cutting metric threads, then industry offers dies from M3-M6 to M52. In addition to the dicks for cutting a traditional metric thread, there are dies for pipe (inch) threads, which can be both cylindrical and conical.

A variety of dies is Lerka. The key difference of Lerok from the dies is the design. Lerka is represented by a whole product. The dick can have a dislocated or sliding structure.

- Clushed dies have a cut on one side, which makes a threaded product with a spring. Dressing sections are usually used to update clogged or licked threaded surfaces.

Of course, a scrap dick can also be used for direct thread cutting. But due to the springing design, the accuracy of the threaded surface will be far from the ideal. As a rule, the first, the so.called “draft”, the passage is made by a split dick.

- Sliding dies have a collapsible design. If in the cut dies the incision is made only on one side of the product, then in sliding analogues the plug is cut into 2 equal parts.

Sliding.type dies usually have a prismatic form. To work with such dies, you should use a dwarf with a clamping mechanism.

There are 6 typical dimensions of Kulapp.

Sliding dies are characterized by increased durability. Due to the collapsible design, cutting edges can “play” during critical loads. This avoids the appearance of chips and cracks on rifled grooves.

Of course, the collapsible design of the dies affects the accuracy of cutting threads. Usually, with the help of a collapsible prismatic dick, it is possible to achieve 6-7 qualities of accuracy, while indifferent analogues provide the possibility of obtaining a thread of 8-9 qualifications.

- Solid leerks. cast uneven dies. The main advantage of Lera is the ability to cut threads with an increased degree of accuracy. Good quality of the resulting thread is due.

Regarding weaknesses, in Lerah they are. High stiffness of the structure makes such dicks subject to chips and cracks. Rifled edges are often painted in lerah. Lera is significantly inferior in durability by split and sliding analogues. When using Ler, it is recommended to use abundant lubricant. Cooling will not hurt.

Additional thread cutting methods

Regarding handmade, the threads of only the initial standard size are cut independently. The larger the diameter of the thread is cut, the more efforts must be applied to the cutting tool.

In the past, serial and mass production of metal products did not exclude manual labor in the manufacture of threaded surfaces. Today, the threads are almost completely cut by specialized equipment. Revolutionary and threaded units are widely used.

There are even compact machines that make it possible to cut the thread machine in place.

If we talk about the production of large threaded joints, screw.cutting machines cope well with such work. Of course, you can entrust the creation of threaded surfaces to an ordinary tokar machine. When using machine turning technology, dies and taps for manual cuts are often used. But the thread, internal and external, it is possible to make even an ordinary turning cutter.