How To Cut Wooden Skirting Corners

Come in handy

How to cut a skirting board in the corners for a neat fit

During renovation work in the premises, the skirting boards play a decorative role, they are the finishing touch of the design. They are also designed to close the blemishes between different surfaces. Correct gluing of ceiling and floor skirting boards is an easy task, but a responsible one.

In this regard, the issue of their installation becomes especially important.

PVC foam, plastic, available with and without cable ducts for wiring.

Wooden, made of various types of wood, solid or laminated; Installing a wooden plinth is no different from installing plastic fillets.

Metal, steel and aluminum, with cable channels and flat.

Included with plastic or metal products are various connections and ends, with which it is easy to carry out installation. Therefore, the question of how to cut plastic skirting boards at the joints almost never arises. Wooden ones do not have such connecting elements. They need to be trimmed for a nice connection.

Important. Before installation, wooden fillets must be kept in the room for which they are intended for at least a day. Like any wood product, it must adapt to temperature and humidity.

For work we need the following:

miter box;

a hacksaw with a fine tooth;

sandpaper.

Consider how the pruning process is carried out.

To connect the planks when going around corners, the question arises, how to cut the plinth at 45 degrees? This is done very simply, but it is desirable to have a special device called a miter box.

It doesn’t matter if you purchase a professional metal tool or simpler options for plastic or wooden fixtures, they will all help you do this work with your own hands without unnecessary problems.

In this case, the price of a professional device is justified if you have to do this kind of work often. For small volumes, you can limit yourself to simpler and cheaper options.

Important. The height of the walls at the machine should overlap the height of the trim to be trimmed to obtain an even cut.

Device for sawing molded products, arrows show technological slots for work in accordance with the instructions.

Instructions for sawing inside corners:

prepare two pieces of the river for docking;

we take the first piece, insert it into the miter box from right to left so that it lies on the base, like on the floor and leaned against the wall of the device farthest from us, like against a wall;

saw down the product from the left end, passing the saw through the holes numbered 1;

the second segment is inserted into the device from left to right, precisely observing the orientation along the floor and wall;

we saw it from the right end, passing the saw through the holes numbered 2.

Instructions for sawing outside corners:

prepare two pieces of plinth for joining;

take the first segment, insert it into the tool from right to left so that it lies on the base. as on the floor and leaning against the wall of the instrument farthest from us, as against a wall;

we saw it from the left end, passing the saw through holes numbered 2;

insert the second segment into the tool from left to right, precisely observing the orientation along the floor and wall;

we cut it from the right end, passing the saw through the slots numbered 1.

Advice. In the joints along the walls, it is advisable to cut the strips at 45 degrees, as a result of such a joint, the joint will be practically invisible. The trimmed strips are inserted into the tool from both sides, as if leaning against the wall, trimming occurs through one technological gap. First, they cut off one, then slide the second towards him, push the first away from the gap, and cut the second.

We have figured out how to cut a floor plinth. as you can see, this is not such a difficult process.

Ceiling fillets for cutting are applied to the side of the tool closest to the working person.

Let’s analyze now how to cut ceiling skirting boards, in what this process is fundamentally different from cutting floor products.

The main rule to remember is that the ceiling fillets are applied for cutting to the side of the miter box, which is closer to the person working with it. In this case, the side of the plinth, which should lie on the ceiling, will lie on the base of the tool.

Instructions for cutting the inner corners of the ceiling plinth:

prepare two pieces of fillets for joining;

we take the first piece, turn it over and put it into the miter box from right to left so that it lies on the base of the miter box, like on the ceiling and leaning against the wall of the device closest to us, like a wall;

we cut the rail from the left end, passing the saw through the slots numbered 2;

we put the second piece into the miter box from left to right, accurately observing the orientation;

we saw it from the right end, through the slots numbered 1.

Outside corner trimming instructions:

prepare two pieces of fillets for joining;

we take the first segment, insert it into the tool from right to left so that it lies on the base of the machine, as on the ceiling and leans against the wall of the tool closest to us, as against a wall;

we saw it from the left end, through the slots numbered 1;

we put the second piece into the miter box from left to right, accurately observing the orientation;

we cut it from the right end, through the hole numbered 2. # useful

How to join a floor plinth in the corners

What kind of floor skirting boards are and with what tool they are installed, the rules for the formation of neat inner, outer and non-standard corners.

- Main varieties

- Installation tools

- How to cut the corners of a skirting board

- Internal

- Outdoor

- Non-standard

- Installation instructions

Docking the floor plinth in the corners is a responsible process, which is important to carry out with high quality, since precisely defined, clear corners delight the eye and give the floor covering a complete look. To connect the products and get a neat joint, you need to know the technology for cutting them and the existing methods of fixing. Before cutting the floor plinth, read the instructions and recommendations below.

Installation instructions for plastic skirting boards

We start the installation from the middle of the wall. To do this, we cut the butt end at an angle of 90 degrees and carefully grind it with sandpaper. This will allow for better grip between the two parts.

To prevent the skirting boards from moving away, it is recommended to use special glue or sealant for fixing. We also use special fasteners. self-tapping screws, dowel-nails.

If you have sockets at the bottom, then you should carefully cut out a recess for them with a jigsaw. We carefully process the resulting surface with sandpaper.

If you need to dock the skirting board with the casing of the doorway, then it is worth calculating the length of the canvas in such a way that only the side plug can be accommodated between the end and the door jamb.

How to cut the corners of a skirting board. see

Before cutting the corners of the plinth for the floor, you need to prepare a suitable tool, depending on which product you are using. The procedure for installing products and forming beautiful and neat corners is not difficult, but it requires care and patience. With a little practice, you can carry out these finishing works on your own quickly and without problems.

Did you like the article? Share it with your friends via social! Spending only 10 seconds of your time on two clicks on the social network button, you will help our project. thank!

Corner overlays

For outside and inside corners

- there is a fairly simple way to connect the ceiling plinth in the corners. you can use special fittings in the form of overlays, as in the top photo;

- mainly, these are internal or external corners, but in addition, such accessories are produced as h-joints for joining two strips along a straight mowing line, as well as left and right end caps;

- such elements, depending on the fillets themselves, can be made of plastic, wood or gypsum, but plastic is used for two types of planks. polyurethane and foam;

The difference in the cross-section of the ceiling plinth in size and configuration

How to install laminate flooring beading

- the selection of such overlays is made exclusively according to the size and configuration of the cross-section of the fillet itself, since such parameters can differ greatly from each other and suitable fittings are produced for each line of such products;

- fixing the linings is mainly done on the same fasteners as the fillet itself (glue or putty), but in some cases (usually for plastic) the lining has inner ears for hidden fasteners and in such cases it is screwed with self-tapping screws;

- in some cases, two types of fasteners can be used, since it is difficult to adjust the corners of the ceiling plinth when they are heavy. For example, gypsum corners for wide fillets cannot stay on the putty and will slide under their own weight, so they are additionally fixed with nails or self-tapping screws, and after the mixture has solidified, this fastener is dismantled, and the holes are sealed.

Note. Whether you need overlays for the ceiling plinth, you decide for yourself, but at the same time it should be said that the price of finishing the perimeter will increase, since such accessories may cost more than the fillet itself.

With what and where you can work

The easiest way is to work with plastic, and there is a wire where to hide.

Currently, the most purchased products for work are:

- Wooden skirting boards. These are, as a rule, solid wood products with an embossed outer surface. In some cases, grooves are prepared in such skirting boards to hide the wires. The skirting boards are fixed to the wall with self-tapping screws in the dowels, fixation by other methods, for example, with sealants, is allowed, but this technique has proven itself poorly, there is nothing more reliable than self-tapping screws;

- Plastic products. By and large, this is not only the simplest, but also the most thoughtful constructor. In this case, everything is thought out: there are designs of external and internal corners, side plugs right and left, for them there are even special fasteners that are fixed to the wall, and the plinth is simply inserted into them. In addition, the plinth itself is hollow and can perfectly hide the wiring and cables communication. Working with them is simple and will be discussed by us immediately in the next section;

About plastic more

You can choose almost any color scheme.

Something, but plastic products do not need introduction, it is difficult to imagine lighter and more varied designs in terms of color. Plastic skirting boards are most often selected in a single color scheme with the floors.

At the same time, it does not matter at all what kind of covering you have on your floor: laminate, linoleum or simply painted fiberboard, for all of them there is a plinth of a suitable color. And working with him is a pleasure.

In this case, you need to do the following:

- Using a tape measure, specify the dimensions of the perimeter of the room or several rooms in which you are going to install this plinth. Calculate the number of internal and external corners, since it is on them that there are ready-made corner elements, as well as the number of docking elements;

- After the purchase, you cut out the material and cut the skirting board itself, remembering to make corrections for the size of the docking groove in the finished corners. The products themselves are perfectly sawn with a saw with small teeth on the miter box with ordinary cross-cuts, in case of the appearance of small plastic shavings, it can be removed with an assembly knife;

- Fixation of finished fragments occurs either with screws to the wall, or to clips, which are initially marked and fixed to the wall with the same screws;

Pay attention! The docking of the skirting boards in the corners does not require additional fixation, however, if you have animals or small children in the house, then in order to be sure of their safety, the integrity of the structure, as well as the normal aesthetic appearance of the entire ensemble, it is better however, secure the joints in the outer corners with glue for the ceiling or floor plinth.

In general, full minced meat.

- Docking with already exposed elements. These are, as a rule, door frames, which can be made of wood and with absolutely different parameters, both width and pattern. There is nothing to worry about. The junction of the door casing and the skirting board is designed as follows: the skirting board is brought to the already installed casing in such a way that the minimum possible distance between the casing and the product with the side cap is, best of all, end-to-end.

About plastic more

You can choose almost any color scheme.

Something, but plastic products do not need introduction, it is difficult to imagine lighter and more varied designs in terms of color. Plastic skirting boards are most often selected in a single color scheme with the floors.

At the same time, it does not matter at all what kind of covering you have on your floor: laminate, linoleum or simply painted fiberboard, for all of them there is a plinth of a suitable color. And working with him is a pleasure.

In this case, you need to do the following:

- Using a tape measure, specify the dimensions of the perimeter of the room or several rooms in which you are going to install this plinth. Calculate the number of internal and external corners, since it is on them that there are ready-made corner elements, as well as the number of docking elements;

- After purchasing, cut out the material and cut the skirting board itself, remembering to make corrections for the size of the docking groove in the finished corners. The products themselves are perfectly sawn with a saw with small teeth on the miter box with ordinary cross cuts, in case of the appearance of small plastic shavings, it can be removed with an assembly knife;

- The fixation of finished fragments occurs either with screws to the wall, or to clips, which are initially marked and fixed to the wall with the same screws;

Pay attention! The docking of the skirting boards in the corners does not require additional fixation, however, if you have animals or small children in the house, then in order to be sure of their safety, the integrity of the structure, as well as the normal aesthetic appearance of the entire ensemble, it is better however, secure the joints in the outer corners with glue for the ceiling or floor plinth.

In general, full minced meat.

- Docking with already exposed elements. These are, as a rule, door frames, which can be made of wood and with absolutely different parameters, both width and pattern. There is nothing to worry about. The junction of the door casing and the skirting board is designed as follows: the skirting board is brought to the already installed casing in such a way that the minimum possible distance between the casing and the product with the side cap is, best of all, end-to-end.

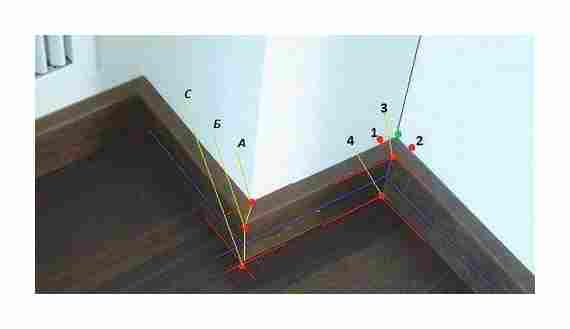

Working with inside corners straight and not very

Full photo report.

Whether you are working with wood on the floor or Styrofoam skirting board on the ceiling, there is no escape from the docking questions. Here you will have to dock and dock with minimal gaps, and for this you have to work hard.

So, we are considering all the options for work:

- The first option is right angles. 90 degrees is the dream of a builder and repairman, in this case everything is simple:

- The product is placed in the miter box so that the floor part of the product is placed on the base, and the side part (which will be fixed to the wall) to the side of the device;

- On the side scale, we find a groove with a mark of 45 degrees in the direction we need and start cutting with a hacksaw with small teeth;

- If necessary, the cut and the front of the skirting board can be lightly cleaned with sandpaper;

Advice! How to join a wooden skirting board? This question will surely arise, since even with a very clear fit, a gap will remain. In this case, you will need a special putty for wood. It is easy to apply, and after drying it is easy to remove the excess with sandpaper, especially since the wooden skirting board it will still be either stained and varnished, or painted.

Above as below.

- Not right angles. option two. Unfortunately, not always, not always, you will meet right angles, especially in houses that have already passed a certain age. Therefore, in this case, the question of how to dock the plinth in the corners will come to the fore.

In this case, we do the following:

- A lot depends on the correct measurement. The plinth is brought to the corners from both sides, and the outer genital border is outlined with a pencil or other marker, which can then be easily removed. As a result, you get a rhombus, the diagonal of which is drawn from the corner outward and will be the cutting line;

- Transfer the cutting line to the material and also perform the necessary manipulation with a hacksaw;

Interesting to know! Some craftsmen advise cutting to make a few with an indent in the direction of increasing, so that it is possible to adjust the joint manually. We can advise you. try. Experiments are always useful, the more the risk is minimal, if you succeed, very good, no, there is always putty for small defects.

- The joint between the plinth and the platband is carried out in the same way as described earlier;

- Working with ceiling skirting boards follows the same rules as with flooring.