How to Disassemble a Husqvarna Chainsaw. Algorithm and description of Husqvarna carburetor tuning

Husqvarna 142 chainsaw repair with your own hands video

The key role in any chainsaw is played by a two-stroke carburetor power unit. Its power directly depends on the chosen model and purpose. The second major mechanical component is the saw unit, which is made up of the bar, the cutting chain, and the sprocket wheel. The parameters of these components can vary.

Treatment with lubricating compounds is carried out with a special oil, which is poured into a specialized tank, it is located on the hand unit. It should be noted that the volume of oil and fuel tanks are calculated in such a way that their contents, as a rule, ends at the same time.

Fault options and troubleshooting

Whether you have a Champion, Husqvarna 236, or Patriot chainsaw, the causes of poor performance are identical. There are a lot of options as to why a STIHL chain saw won’t start, but the most common are.

The chainsaw does not start well in the cold

If the saw does not start well when cold, it means there is no compression in the saw. This is due to ring abrasion due to prolonged use. It turns out that when the user tries to start the Champion 137 in a cold state, the compression for this manipulation will not be enough.

In this case, it is not recommended to systematically jerk the knob. Eventually the unit will still start, but it may break other mechanical components. In this case you need to replace the worn rings with new ones.

The chain saw does not start when cold

Here the causes lie in the priming of the engine and wetting of the spark plugs. Here is what to do in such a situation:

- move the choke to the middle position;

- Blow out the component parts well;

- start the machine for 10 seconds;

- put it in idle mode;

- On a Kalibr chainsaw or other model, to fully open the flap.

Next, simply idle the engine by pulling the knob. If the engine does not overheat, it will start easily.

If this variant of troubleshooting did not help, it means that the motor has already cooled down considerably. Fix the half throttle according to the recommendations in the manual and repeat the operation.

Part 3 How to Tune Carburetor Husqvarna 235e Chainsaw

You should also try spinning the cold stroke screw in the clockwise direction. The higher the speed of rotation in the equipment, the easier it is to start it. Be aware that the chain must remain in the stationary position when idling.

The chain saw does not start well and shuts down immediately

In this situation, the reason is the flooding of the plugs with gasoline at the moment when the user tried to start the machine. A small amount of fuel accumulates under the spark plug electrodes, due to which there is no spark in the equipment.

The problem can be solved by removing the plug and drying it thoroughly. the system has been designed to be able to use the air cleaner as an aid to combustion. But this should only be done with a gas torch. Otherwise there may be a small amount of soot in the area of the electrodes. After the spark plugs are completely dry, you need to drain the excess fuel and leave the equipment itself to dry.

Chinese saw doesn’t start

It should be noted at once that Chinese machines have no distinguishing features from other analogues. They are just as reliable and productive, and cost less. The only thing that is necessary individually for this unit is to use only branded oil and fuel.

Most units do not work well on domestic fuel, gasoline clogs the channels and as a result the fuel does not come to the motor. Use fuel of high quality or from the manufacturer of the saw.

Why the new saw doesn’t work

New equipment should have no problems with wear and tear of functioning mechanical parts, since the model just came out of the assembly line. Such untidiness may occur in the case of purchase of demonstration equipment, which is not once used to promote the company. It may also be caused by improper operation of the machine, which does not comply with the recommendations from the manual.

The first thing to check is whether all parts and components are installed in their places. Also, for example, Husqvarna will not start if it has been filled with a fuel mixture prepared without taking into account the correct proportions.

But if all the recommendations are followed, every detail is carefully fixed in its place and the equipment was not purchased from the stand, the buyer probably got a defective device.

The fuel in the tank is insufficient or of poor quality

This is one of the most common reasons. Gasoline equipment users, in order to save money, often use the budget fuel. The unit will operate properly for the first time, but the problem is bound to appear after a few months of operation.

The chainsaw does not start when hot

In cases where the chainsaw does not start on hot, you need to carry out a visual inspection of all the main nodes of the chainsaw. The inspection should start with the spark plug. Check the spark, inspect the surface of the spark plug electrode, these actions will help establish the direction in which to look for the problem.

Trouble in the ignition system

If when inspecting the spark plug, it is found that it is wet and spark formation on the contacts does not occur, it means that the problem should be sought in the ignition system, inspect the coil, check the gap between the flywheel and the coil contacts. You may also check how firmly the spark plug wire cap is seated on the spark plug and the spark plug itself. Try replacing it with a new one.

Read also What soil to plant geraniums in

Problems in the fuel system

If inspection reveals that the spark is present and the spark plug is dry, it means that there is a problem in the fuel system. Start by checking the fuel filter. Next, you need to inspect the fuel hose and its attachment to the carburetor, pay attention to fuel leaks from the carburetor and the presence of gasoline in the air filter housing. Proceed to the removal of the carburetor is advisable only if a visual inspection did not allow to determine the cause of the failure.

A typical sign of a problem in the fuel system is an excessive amount of fuel in the engine cylinder. This is usually indicated by an excessively wet spark plug and the presence of spark on the spark plug contacts. In this situation, you need to turn the chainsaw so that the spark plug hole was directed downward. If there is petrol leaking from the cylinder, it means that the reason why the chainsaw will not start is the fuel overflow into the engine.

“Pouring” fuel, sometimes due to improper carburetor adjustment, or its malfunction.

You can learn how to adjust the carburetor on Champion 254 by watching this instruction video.

Classic layout

Classic Husqvarna design makes chain saw repair easy. Chain guide bar is on the right and side of the saw, and there is an emergency brake. Engine housing covers the auxiliary crank from left to right. The on/off button is located at the rear and is oriented under the thumb, the gas pedal button is on the handle.

Drum and starter handle on left side, above cooling grid. Bottom left. fuel tank cap.

All machine components are hidden under the housing cover.

Design and Operating Principle of a Carburetor

A carburetor serves to prepare a combustible mixture in an operator-determined proportion of gasoline and air.

Excessively enriched, as well as excessively lean, the mixture will lead to unstable engine operation, can cause overheating and accelerate wear of the piston system.

Correct adjustment and adjustment of the throttle body is essential for the proper functioning of the device.

And for this you need to know the principles of the carburetor of a Husqvarna chainsaw.

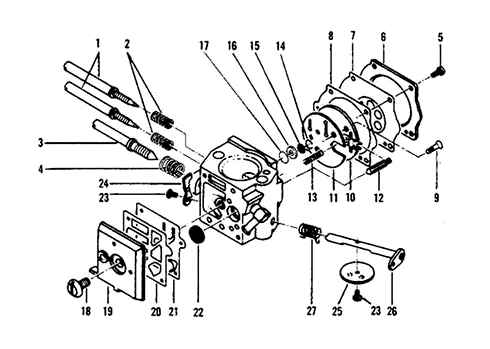

Its construction consists of the following elements:

- housing with clamping bolts and a set of gaskets;

- The fuel pump is the device that pumps the gasoline-oil mixture into the carburetor;

- diaphragm. designed to limit the flow of the fuel mixture into the engine;

- float chamber. it collects fuel, the level is regulated by the float, the mixture is supplied to the main chamber for mixing with air as necessary;

- the main chamber. air flows through it, and fuel is injected there as well, the amount of mixture supplied to the engine is regulated by the throttle valve located here;

- diffuser. it is a part of the narrowing of the air supply pipe at the point of fuel injection;

- needle valve. a device that regulates the fuel supply;

- jets. screws that regulate the mixture at high and low speeds, as well as the idle speed screw.

Also in the structure of the carburetor, in addition to the throttle, there is a valve, located at the inlet from the air filter. It artificially reduces the air supply, making the mixture more saturated to make it easier to start a cold engine.

For fuel injection into the main chamber is responsible for the nozzle valve, it also prevents the ingress of air. When setting up the carburetor on your Husqvarna chain saw special attention must be paid to this valve. к. its condition has a direct effect on engine operation. Valve can become jammed if stored for too long. This will restrict the fuel supply and prevent the engine from starting.

Also, either from prolonged use or from a factory defect, the valve can let air into the main chamber. In this case, the only way to fix the problem is to replace it.

Operation of the carburetor occurs as follows: the air flow, falling into the diffuser, mixes with injected fuel, the resulting mixture is fed to the engine. The amount of mixture is adjusted by the throttle valve. Higher mixture results in higher RPM.

How and when to adjust the ignition on the Husqvarna saw

Users of Husqvarna chain saws often have a question: how and when do I adjust the ignition? The answer is simple. Husqvarna chain saws have an electronic ignition coil and flywheel that cannot be adjusted. The only thing that can be adjusted is the gap between the coil and the flywheel.

To adjust the gap at home, you need to cut the feeler from a plastic bottle, and then loosen the screws that secure the coil. Further, the dipstick is installed between the coil contacts and the flywheel. The screws are tightened.

It is necessary to adjust the gap during maintenance or if you find scuffing on the flywheel surface. Such scoring indicates that there is no gap at all.

If after the clearance between the coil and flywheel is set, and the parts continue to come into contact, the crankshaft bearings should be checked for wear. It’s possible that they are badly worn out and need to be replaced.

Husqvarna chain saw. diagnostics and repair

Today almost every owner of a private house or an advanced dacha owner uses a chainsaw which has high mobility, unpretentiousness in operation and repair. Among the many models of gasoline equipment and tools on the market the Swedish brand Husqvarna is worth mentioning. Founded 400 years ago, the company Husqvarna initially produced guns, and in 1959, due to the need to expand its product line established the production of chain saws. Unlike competitors, this manufacturer has sought to improve the layout of the saw. In order to reduce the noise emitted by engine the famous designer from Sweden Sixten Sazon using as an example a motorcycle muffler was used in Husqvarna chainsaw.

Almost all professional and amateur chain saws are equipped with air-cooled two-stroke gasoline motors.

This includes at least one cylinder with heat dissipating ribs. The fuel supply system (carburetor) performs the function of a gasoline-air mixer. Dirt, dust and shavings must not enter the working chamber together with the fuel mixture; to clean the air inlet, the chain saw is equipped with filters. Manufacturers recommend changing the filter once a season. In between replacements at intervals of once in 10-15 refuelings it should be cleaned.

For convenience and ease of starting the engine in any chainsaw starter, which is a coil with a wound cable and a handle. Even the most powerful Husqvarna chain saw has a clever start mechanism.

To reduce the vibrations transmitted to the hands of the sawmill operator, the tool is equipped with a special device. This mechanism also prevents the tire from “rolling” while you’re sawing wood.

Carburetor tuning and repair

Since there is not always the time, opportunity and means to turn to professionals to repair equipment, users are often interested in how to adjust the carburetor of a Husqvarna chain saw 137. It is worth noting that this component is calibrated by the manufacturer, but if the operating conditions were violated or improper intervention was made, malfunctions may follow. To make adjustments to the settings, you will need to follow the instructions of the Husqvarna 137 chainsaw and perform the following manipulations:

- Warm up the engine, then turn off the device for about ten, fifteen minutes.

- Inspect and flush the filter system.

- Turn the low and high revolutions control screws clockwise until they reach the limit.

- After the maximum is reached, turn them in the opposite direction, one and a half turns.

- It will be necessary to turn on the engine at medium speed, in this state it will warm up for seven to ten minutes.

- Turn the idle speed screw clockwise. Release it when the engine starts to run steadily.

- At that moment the chain must be stationary.

- Check the chainsaw at maximum rpm.

- If the gas pedal is giving out little acceleration the L screw can be corrected by turning it counterclockwise.

- In the final part of the adjustment, the check is carried out at idle speed.

Husqvarna 137 chainsaw carburetor repair should be performed in strict accordance with the manufacturer’s instructions and using certified parts.

How to disassemble your Husqvarna chain saw

The process of disassembling a Husqvarna chain saw is simple. In order to do everything correctly and not to break parts of the housing or the gas cylinder, it is necessary to disassemble in the following order:

- Top Cover.

- Chain and chain brake cover.

- Starter.

- Handwheel and clutch.

- Front handle.

- Carburetor.

- Oil pump.

- Engine.

Depending on the Husqvarna model, the disassembly procedure may differ slightly.

Important: Before you start to dismantle the chainsaw you have to clean it. The saw produces a lot of chips and wood dust, which can get into the internal parts of the Husqvarna chain saw when it is disassembled.

Removing side cover and chainsaw headset

The side cover, also called the saw chain brake cover, is held in place by two thirteen-nut nuts.

After unscrewing the nuts, the cover is removed from the guide rods and the guide bar and chain can be removed from the chainsaw. Some Husqvarna saws have a special tool-less mechanism for removing the cover and the saw headset.

Starter

The starter is located on the right side of the Husqvarna and is held by several screws. Unscrewing that, you can easily remove the starter and thus gain access to the flywheel and ignition coil.

Flywheel and clutch removal

To undo the flywheel nut, unscrew the spark plug and put the piston lock in its place.

If you don’t have a special stopper, you can use an old chain saw starter cord instead. You must tie knots at a distance of 2-3 cm on the string and then, using a screwdriver, insert it through the spark plug hole into the cylinder. The string will limit the piston stroke and thus prevent the crankshaft from turning and protect the piston from damage.

Once the piston retainer is installed in the cylinder, the flywheel nut can be unscrewed. After the nut is unscrewed, you must use a hammer and a mallet of soft material to make a sharp blow, setting the mallet on the flywheel mounting shaft. This is necessary to remove the flywheel from the shaft, i.e. к. the design involves installing and tightening this element with a lot of force.

To learn more about how to remove the flywheel from a Husqvarna chain saw, as well as how to completely disassemble the saw, watch this video. The wizard explains the whole process step by step and demonstrates all the necessary tools:

To unscrew the clutch, you’ll need a special wrench. If you do not have a wrench, it can be made from an old head of the twenty-two, grinding it in a certain way with an emery.

The clutch has a left hand thread and should be unscrewed in a clockwise direction.

Do not try to unscrew the clutch with a hammer and chisel, as some craftsmen advise. If you use such tools, you risk breaking the clutch housing and increasing the repair costs. It can also damage the crankshaft bearings.

Front handle

Removing the front handle of the Husqvarna is fairly easy, t. к. It is attached to the shock absorbers with screws.

Air filter and carburetor

To remove the carburetor it is necessary to disconnect the fuel hose and flap pulls from it, it is convenient to do this after the air filter is dismantled, which is installed immediately behind the carburetor and is held by two nuts for 10. Once the air filter is removed and the fuel hose and linkages are disconnected, simply pull the carburetor toward you and remove it from the studs.

Use tweezers and medical clamps to remove carburetor.

Oil pump

On the Husqvarna, the oil pump is installed on the right side of the chainsaw. It can be removed only after unscrewing the clutch. No special tools are needed for removal, t.к. fixing screws are made for a common Phillips screwdriver. After the screws have been unscrewed, it is necessary to lift the pump and disconnect the oil hoses from it.

Engine

To remove the engine on a Husqvarna chain saw, after removing the carburetor, clutch, flywheel, and muffler, you need to remove the four screws that secure it to the housing.

After the engine is removed, you can unscrew the ignition coil from it, remembering to first disconnect the wires running from it to the ignition switch. The coil can also be removed after the starter has been removed.

Reassembly of the chain saw Husqvarna should be carried out in reverse order, while tightening the flywheel nut and the clutch should be tightened with a force whose value is specified in the instruction manual chain saw.

Husqvarna

Husqvarna 137 Specifications

Cylinder capacity. 36.3 cm3 Power. 1.6 kW (2.2 л.с.) Recommended maximum engine speed. 13,000 rpm Fuel tank capacity. 0.41L Oil tank capacity. 0.2L oil pump type. fixed flow Chain pitch. 0.325″ Recommended tire length. 13-15″ (33-38 cm) Sound level. 98dB(A) Noise level. 118 dB(A) Vibration, front/rear handle. 4.9 m/s2 / 7.7 m/s2 Weight (without guide bar and chain). 4.6 kg

Vibration damping and handles isolated from the motor.

Как правильно отрегулировать карбюратор на бензопиле Husqvarna

Centrifugal air cleaning system for long filter cleaning intervals, smooth operation and reduced wear.

Curved front handle for better grip and natural working posture.

The narrow body, high center of gravity and flat bottom make the chainsaw exceptionally easy to handle.

Dual-action chain brake, right hand guard, and chain limiter increase sawing safety.

Forged three-piece crankshaft forged to maximize wear life in the toughest conditions.

The low weight of all moving motor parts allows for quick acceleration.