How to fix the drill vertically to the table. The device of the machine

What is a guide for a drill, how to make a vertical holder

To get a hole with a minimum of burrs and strictly vertical walls, a high.quality tool is required, but the result does not depend on one of it and the skills of the employee. To facilitate the process of vertical drilling will help a drill guide, a rigidly fixing tool and changing its position exclusively in a given range. The holder of the drill for vertical drilling will significantly expand the functionality, and to make this device for a drill is completely easy with your own hands. The placement of the tool on the rack, which can be rotary, will turn the ordinary drill into a drilling machine, on which a wide range of technological operations is performed.

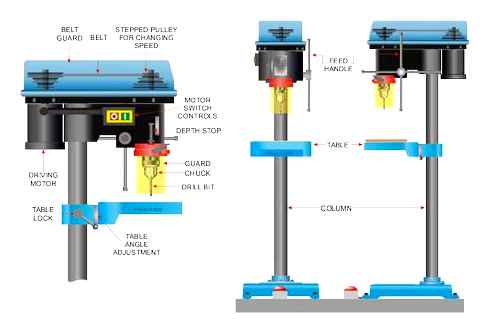

The device consists of parts connected by screws. The lower part plays the role of support. On this metal platform, the upper structure and the drill itself are stably held. With the help of the screws in the support, fixing the rack on the desktop is ensured. The bar is perpendicular to him. There is an equipment on the top rack for fixing a motionless bracket, whose clamping flanges securely attach the tool. The device has a drive handle, which is lowering and lifting the supporting bracket. Additionally, racks can have limiters of drilling depth and vise.

Main characteristics

The diameter sets the size of the length of the drill, which can be clamped on the rack. The standard range is 45–65 mm, but there are specialized flanges and adapters that allow you to expand this corridor. Fastenary equipment is more often calculated on work with a specific tool.

The working length determines the course of movement. If the device has a large range of movement, this allows you to drill large blanks. The standard move is 20-30 cm, but in professional racks this value reaches 50 cm.

How is the simplest drill holder arranged

Durable clamping type of clamp, holds the device on any flat surface (table, workbench, stool, vertical rack wall). Based on the clamp, in which the power tool is fixed. The joint can be tough, that is, the position of the drill cannot be changed.

Some models are equipped with a turning mechanism of the clamp. Rotation is carried out in one plane (table plane). In addition, if you remove the clamp (clamp), you can fix the holder of the holder stationary. True, for this you will have to drill a hole in the table. So this method is only suitable for a workshop in a workshop.

By installing the drill in this holder, you get at least a sharpener machine.

A disk for sandpaper (Velcro) is inserted into the cartridge, and you can not only sharpen the knives for the spouse, but also process the harvesting of a complex shape.

And if you fix the emphasis opposite the disk, you can polish fairly solid materials: metal, stone, and pr. If your holder is reliable enough, you can organize a mini circular saw.

Important! No manufacturer of saw discs provides for such a use. Working with a homemade circular is potentially dangerous.

One of the popular applications of such a holder is a mini.turning machine from a drill.

- simplicity (respectively, low cost).

- reliable fixation (less joints. more stable design).

- the device is able to hold a fairly heavy tool.

Holder with two degrees of freedom

The device has two articulated joints between the clamp (clamp) and the clamp for fixing the drill. The axes of the rotation of the hinges are located at an angle of 90 °, and allow the tool to position the tool at any angle to the working plane of the workbench. This can be seen in the illustration.

Of course, such a holder will no longer be fixed directly on the workbench (stationary), it works only with a clamp. It will not work to quickly direct the axis: for security purposes, first one hinges are fixed, then the second.

Nevertheless, this device makes it possible to use a drill as a milling cutter, with an arbitrary location of the shaft. Or you just have a rotation axis as you are convenient at the moment.

- Unknown setting of position, you have to fix the hinges in turn. In addition, there are certain restrictions on the size of the power tool (a large drill in such a holder cannot be fixed).

- There are questions for reliability: the more hinged compounds, the lower the accuracy and strength of the fastening.

How to make a bed?

Home.made drift holders must be installed on stable beds. For the manufacture of this assembly, you can use a steel plate 1 cm thick or a strong wooden board, the thickness of which should be at least 2 cm. Also, a thick piece of woody plate, plywood or textolite are suitable for this purpose. The massiveness of the bed depends on the power of the power tool. The higher it is, the thicker the reason should be. It is desirable that the width of the bed is 200 mm, and the length is 500-750 mm. To the bed located horizontally, using screws or screws, the main vertical rack and support should be attached. It is recommended to screw these parts of the machine from below through the bed.

DRAMEDROM holders will be stronger if their racks are additionally connected to supporting metal corners.

How the stand is made?

DRASE holders must be equipped with racks. It is on the quality of manufacture of this unit that the quality of drilling work will depend in the future. So that the drill does not deviate, but, therefore, does not spoil the workpiece and did not break, it is important for the master in the manufacture of the rack to observe a strict vertical in relation to the bed. You can make a guide vertical rack from a bar, a plywood plate, pipes or a metal profile. It all depends on the imagination and the availability of the right material.

Holder for a drill. This is a simple device for those who do not have emery. Will be useful to any master.

The process of manufacturing a rack

From a pipe with a diameter of 40-50 mm, it is necessary to cut off a ring of 20 mm wide.

It is cut along, and nuts are welded to its edges.

As a result, a clamp is obtained for squeezing the drill housing. He will pinch her in place of a removable regular handle. In one of its nuts, the thread should be drilled.

The clamp through the spacer from the plate is welded to the piece of a profile pipe 20×20 mm. The latter must definitely hinder the inner weld.

Next, it is required to cook the hem-shaped rack. Its sole is made of a profile pipe 40×40 mm 100 mm long. The ends of the latter must be brewed with plugs.

A piece of pipe 15×15 mm long 300 mm long is welded to the edge of the sole at right angles. The open end of the rack is also brewed with a plug.

On the rack you need to apply a scale on the ruler. To do this, tags are first put, and then tiles are performed on them.

From a 20×20 mm pipe, it is necessary to make limiters on a sliding mount of the drill. For this, 2 narrow rings are cut.

They are drilled from the side, and nuts m6 are welded in them.

Limiters will fix the lower position of the drill mount, and the upper so that it is not removed. Their clamp will be performed by lamb bolts.

For the convenience of fixing the soles of the rack itself, you need to cook a stand under it. It is made from a metal plate 100×100 mm and a channel of 50 mm wide.

The segment of the latter is welded on the plate. Then it drilled, and a nut m8 is welded into it.

You also need to make holes in the corners of the plate. Thus, you can fasten the stand on any surface and install the stand in it is stationary.

As a result, we get a mobile rack, which you just need to fasten on any even working surface with self.tapping screws. Then the drill is clamped in the clamp, and the prefix is used for its intended purpose.

It is also suitable for drilling with emphasis in the walls, or to the floor without the use of a stand.

Particularly interesting

“Make yourself. with your own hands”. A site of interesting self.liveings made from improvised materials and items at home. Step-by-step master classes with photo and description, technology, life hacks. Everything that is needed for needlework to a real master or just craftsman. Crafts of any complexity, a large selection of directions and ideas for creativity.

VERTICAL GLASS DRILLING MACHINE VSV100

Magnetic bed

A drill on a magnetic bed has an original design. it is created for drilling, cutting threads, and can make a zenkovka and scan of old holes in the most unpredictable conditions. Its distinguishing feature lies in the fact that it is clearly kept on any metal surface, therefore the main sphere of use of such mobile machines is installation and construction using metal structures, industrial engineering and shipbuilding, the construction of prefers from metal, laying pipelines, installing and repairing large reservoirs.

The base of the unique machine is securely attached to the surface of the metal with a force up to 5 tons due to a powerful magnet, allowing you to work in any position, even on the ceiling of the ship’s hold.

The main advantage is the diameter of the drilling, which is in the range of 1-150 mm, small holes are made by spiral drills, and larger ones. coronal drill. The mass of the machine varies from 9 to 25 kg, depending on the model.

Other fixation devices

So that the tool does not deviate from the direction of drilling, in practice, special devices called the conductor are often used. this is a system of holes of a few more necessary diameter. For professional use, conductors from steel are produced, and for use in everyday life. from durable plastic.

Many masters from garage cooperatives are not satisfied with the quality of factory structures, so they make a bed for a drill with a handicraft and with their own hands. Some craftsmen make clips for a drill completely of wood and multilayer plywood. an example is presented in the photo.

Drill holder with ball joint

This “third hand” allows you to direct the tool at the required angle in one motion. Freedom of movement is limited by a hemisphere, that is, a position in space can be any.

This design is familiar to many: car holders for smartphones and DVRs work on the same principle. But the drill is not a mobile phone, therefore, special strength requirements are imposed on the ball clar.

He should not weaken the “grip” with strong vibration, and at the same time, the effort to unwind the nut should not be too high. Otherwise, the main trump card is lost: the promptness of the movement.

- With one movement of the hand, you set the drill in any position.

- With such a holder, you can use only a light tool.

- The cost of this device is the highest.

Based on homework, you can either choose the type of holder from our review, or make it yourself (taking responsibility for safety).

Drill stand: buy or do it with your own hands?

Drilling with drilling machines made woodworking comfortable and simple. Drills pass through a mechanism that uses a rotating spindle fixed on a vice lying on the desktop. The drilling press is often clamped in a cartridge and three conical jaws, which are easily placed in a narrow hole.

There are many drilling presses on the market, and if you already have such, you may have felt the need for good quality rack for a drilling machine. The drilling stand is important for fixing the position of the drilling press. This will work with additional safety.

Production of additional nodes

The modernization of the structure will allow you to get a multifunctional machine on which you can mill small parts and drill holes at an angle.

To milling the part, it must be shifted to the side. For this, an additional horizontal rack is fixed to the plate. It is fixed on it, moving on a carriage with furniture guides. The control handle can be made similar on the spring or put a screw mechanism.

For drilling holes at an angle of 30, 45 and 60 О, an additional plate is installed. It is made a rotary, for which the holes are drilled along the arc. Fix the plate to the main strut of the machine, where it will rotate along the axis. A carriage with a supply mechanism is attached to an additional plate.

The transportation will help to measure the location of the holes. The central hole for the axis is taken as the basis and the points are measured from it at the desired corners.

During turning and even drilling, the additional plate has horizontally. To perform drilling at an angle, the plate is turned to the desired hole. Fixation of an additional plate is performed with screws from the back of the rack.

The simplest design allows you to get a multifunctional machine at home, on which you can mill small parts and drill holes from different angles.

The mechanism of resistance control

As already mentioned, the author proposed two ways to control the counter. Both of them are quite effective, but in practice they showed themselves differently.

What practice has shown: such a mechanism is convenient to manage, but does not give the desired pressure on the drill, the stand moves jerking. This is not the best option of existing ones, although you can adopt it to it. The second version of the device was much more convenient in practice.

Practice of working with a homemade counter

The device is primitively simple, collects without welding, which is very convenient. The most difficult thing in all work is to cut the profile into the desired segments. Everything else will take a few minutes.

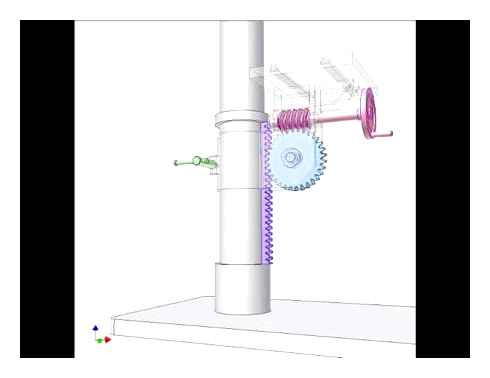

The mechanism of movement of the drill is vertically

Structural elements of the node:

- The handle with which a carriage with a drill fixed on it is brought to the surface of the processed part.

- A spring returning a carriage with a tool to its original position.

The mechanism can be made using two design schemes:

The first option involves the following scheme:

- Two metal plates are fixed on the machine’s rack with screws, and the axis is installed between them, where the handle is placed.

- On the other side of the rack, the plates and the axis are installed on which one end of the spring is fixed, the second end is connected to the handle.

- The pin with which the handle connects to the carriage is located in the longitudinal frame of the carriage.

If the springs are located in the lower part of the return mechanism, the handle is also fixed using two plates and axis, which provides its movement. The springs in this scheme are located in the lower part of the grooves of the guides, finalized with the help of metal corners, which limit their movement.

The principle of operation of the drilling machine, where the springs are located at the bottom of the carriage, is quite simple: dropping down when drilling, a carriage with a tool mounted on it presses on the springs and compresses them; After the cessation of this mechanical exposure, the springs are unclenched and raised a carriage with a drill to its original position.

Additional equipment of the machine

Additional prefixes will allow the use of a machine for drilling holes at an angle and perform simple turning and milling technological operations.

An automatic, vertical glass drilling machine for flat glass sheets

To carry out milling work on this equipment, you need to ensure horizontal movement of the processed part, for which a mobile horizontal table is used with a grip to fix the processed part. The best drive of this table will be a screw gear, which is set in motion with a handle.

With the help of a home.made drilling machine, where the hand.headed drill plays the role of the work head, holes at an angle are drilled if the machine is equipped with a rotary plate with holes in the arc. On this plate capable of rotating on the axis, which is fixed on the machine stand, is a carriage and a drill. The holes on the rotary plate are made at angles of 30 °, 45 ° and 60 °. Mechanism manufacturing procedure:

- A hole for the axis is drilled in the center of the machine and the rotary plate in the center.

- Using the transporter on the rotary plate, the axes of holes located at the most common corners are planned, and holes are drilled.

- Using axial holes on the rack and plate, two of these elements are combined and fixed with bolts.

- Three holes are drilled on the rack to fix the rotary plate with pins.

The rotary plate is rotated to the desired angle with the tool mounted on it and is fixed with three pins connecting the motionless and rotary part of the rack.

Machines with a rotary plate can also be used to perform simple turning work. For these operations, a drill using a rotary plate is located horizontally.