How to remove a broken coil from a mower. Lack of sparking

Repair of a trimmer coil for the grass with your own hands: how to remove, disassemble, change a fishing line for a trimmer, assemble and install back

If the fishing line for the trimmer is not lengthened by a light blow of the trimmer button for grass on the ground, the prerequisites for this usually the following.

Option 1. snack, t.E. Clamping cord between turns. This problem usually occurs if the user wraps a fishing line for a trimmer to a coil unevenly, crossing the windings or wrapping it without tension. In the latter case, when the mower rotates at high speeds under the influence of centrifugal force, the cord begins to drag on, under the influence of which the interspersonal clamp of the braid fishing line may occur. To eliminate obstacles, you need to disassemble the coil on the trimmer and correctly rewind the cord, in other words, even rotates with good tension.

Option 2.4. very short ends stick out of the head. When hitting the ground, the rod may not fall out if its ends protruding from the head are not long (short). Then centrifugal force is not enough to stretch the fishing line for the trimmer. Therefore, it is necessary to hang the unit (turn off the engine in another way, disconnect the electric trimmer for grass from the network) and pull the fishing line for a trimmer manually, after pressing the button.

Option 3. Fishing line for a trimmer to be sealed inside a mower. This makes the coil stop and do not even rotate when you press the button. This is mainly happening for several reasons: low quality of the cord, overheating of the coil during prolonged operation of the machine and the effect of a mowing fishing line on hard objects.

- First, the cord of third.party manufacturers that you like is made of low.quality and fusible materials that do not withstand mechanical and thermal loads. Therefore, it is necessary to give preference to “branded” fishing.

- If you have a fishing line for a trimmer of an unknown owner, and it is often soldered during operation, then, of course, follow the example of some users who, after filling the cord in the coil, moisten it or silicone lubricant (from a spray can) or mineral oil). This procedure significantly reduces the possibility of soldering turns of the mowing fishing line.

- A fishing line for a trimmer can also be soldered if during a mowing it falls into a solid object (stone, fence, dry branch, etc. D.). During this time, it stretches a little and stretches to the head at high speed. The cord heats up from friction, and its coils stick together. The only thing that will be done to eliminate this problem is to open a trimmer coil for grass and rewind a fishing line for a trimmer.

There are situations when a user of a trimmer for grass notices very quick fishing line consumption. Here he never clicked the button button to lengthen the fishing line for the trimmer. A prerequisite for spontaneous lengthening of the fishing line by cutting a special knife on the machine body is a lack of spring in a mowing head. Often beginner users of mowers, trying to load a fishing line for a trimmer into a coil, forget to install a compressed spring in the head, in other words, they completely lose it when opening the lid, and then they do not even suspect its existence.

The trimmer fishing line also expands without using the button if the spring is weakened. If the spring check confirmed this fact, then you need to insert several goals under it to increase the characteristics of the pressing.

The owners of the trimmers, mostly beginners, in confusion, next to the panic, when the coil has to change the cutting tool or fishing line for the trimmer. Often, when trying to unscrew the lawn mowing head, users simply make it unsuitable for use, not suspecting that it is unscrewed in the opposite direction to prevent this if you need to change the tool, we recommend that you join the step.by.step annotation below.

- Before pouring the rod into the coil, turn off the engine bureau, as it is also called, de.energize the electric trimmer for the grass to avoid injuries that occur when a cutting tool is accidentally rotated.

- Unscrew the attached nozzle of the transfer shaft. To do this, it is necessary to fix the shaft by leaving the opening on the puck and inserting an iron bar there or a screwdriver there.

- Unscrew the nozzle. You should know that the thread on the shaft remains. Therefore, turn the coil of the trimmer for the grass to the right, in other words, clockwise.

- Disassemble the mowing head. In most cases, the main cover is attached on the clips. To remove it, you will need to lower these clamps onto the case, squeezing the edges of the lid. If you have a pass, if your trimmer for grass has an automatic mower with a button below, then the nozzle should be disassembled carefully, since there is a chance of a spring loss, which sometimes flies away when removing the lid. ,

- Cut the required amount of fishing. Usually its length is 5 meters. Use the cord of the same diameter that is indicated in the note to the tool. It is not recommended to exceed the largest diameter of the mowing fishing line, as this will increase the load on the engine and increase gas mileage.

- Find the middle of a piece of cord, folding it in half. You will get a loop.

- The coils are cut special grooves inside (there are holes). Insert the loop of the fishing line into this groove.

- Wind a fishing line for a trimmer to a coil, turning it counterclockwise. The cord must be filled very evenly, the turns you need to put it in a non.overlap and with good tension. After the winding is completed, leave the free ends of the fishing line about 20 cm long and fix them in grooves on the sides of the coil.

- Collect the mowing head. Do not forget to completely assemble the nozzle spring and washer (if available). Insert the coil into the housing and pass the ends of the cord through the holes or eyes.

- Put on the lid and fix it with latches.

- Screw the nozzle back to the gear shaft, also fixing it with a screwdriver. Turn the coil of the trimmer for the grass to the left (counterclockwise).

Problems with fishing line

The users of trimmers, both gasoline and electronic, from time to time there are difficulties with the cord. The “advanced” owners of the braids without effort are controlled in the difficulties that have appeared, understanding why this is happening, and for beginners it is an inconsistent that does not have the best clarification. But in fact, everything is solved quite easily. The most frequent obstacles that happen to the fishing line, subsequent.

The cord is not served, the coil does not spin

Automatic or automatic head should serve a fishing line for a trimmer without stopping the unit. But if it does not come out, then the prerequisites can be subsequent:

- The fishing line for a trimmer in a coil is incorrectly wound, which is why the latter does not revolve;

- The cord is wound unevenly, and the thread can get stuck between the turns (the thread should be neat carefully, a turn to the turns, without distortions);

- Very short.term ends of the thread come out of the holes, as a result of which there is not enough centrifugal force to extract them, and the fishing line is not served for the trimmer (it is recommended to always adjust the length of the cord before starting the unit, pulling it down a little);

- The fishing line for the trimmer is sticking together (it will be considered further).

a fishing line for a trimmer flies out

The prerequisite that the cord after starting the unit is unwound, can also be a weakening of the spring of the head of the head. In addition, there are times when a mowing head

, and the spring installed in it disappears. Inexperienced users do not notice the absence of a spring and collect this knot without it. Therefore, the cord does not hold, and under the influence of centrifugal force flies out.

Option

To remove the head of the trimmer for the grass, it will need to have a complete disassembly.

- To remove the lid covering the inside of the head, you need to press on the latches (latches) located on 2 of its sides.

- Removing the lid, you will see the rogue that needs to be removed from the body. In some coils under the bobbin, a spring is installed, which must be carefully removed so as not to lose it in the grass.

- Removing the bobbin, in the center of the case you will see a screw with a slot under a cross.shaped or flat screwdriver. It is possible that there may be a bolt under the hexagon or nozzle “Asterisk”.

- Using a screwdriver, choosing the desired bat (nozzle), you need to unscrew the bolt (counterclockwise).

- After extracting the fasteners, take up the part of the part and, shaking it in different directions, remove it from the gear shaft.

Large cord consumption

In the main thing, the cord is rapidly ending, if you often knock on the ground with an automatic head or press it very down very much. The coil unlock occurs, and the fishing line for the trimmer, lengthening, is cut off by a knife. Another reason that the cord is rapidly ending is the incorrect operation of the device with an automatic head: the user with kosbe often drops the engine speed. But as we recall, the automatic head is arranged so that exactly with each reduction in the revolution the brand new portion of the fishing line is supplied, therefore it is rapidly consumed.

The thread does not hold

It happens that the thread is unwound if the spring weakened in an automatic head. The fishing line for the trimmer is put forward and cut off by the knife installed on the casing all the time, which increases its consumption. To check this, remove the casing and turn on the unit. If the fishing line for the trimmer “climbed”, then you will need to replace the spring.

Option

In this version, the head is twisted onto the gear shaft. To remove it, It will be needed

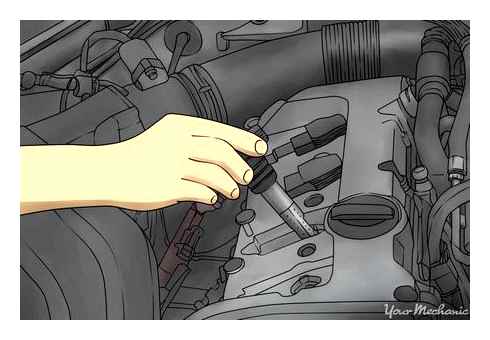

Fix this shaft. To do this, in similar trimmers, for example, in Huter and Champion devices, a hole is foreseen, through which you can stick either a narrow screwdriver or an iron rug.

So, to remove the bobbin, take 2 ordinary steps.

- Shine the screwdriver in the hole and stall the shaft.

- Take the head of the head and start twist it clockwise. It should be twisted in this direction for the reason that the thread cut on the shaft is left.

https: // yotools.ru/trimmeri/kak-namotat-lesku-na-katushku-trimmera-klyuchevye-momenty.html https: // obinstrumente.RU/Sadovyj-Instrument/Kak-Pomenyat-Slesku-V-Trimmera.html https: // tehnika.Expert/Dlya-Sada/Trimmer/Kak-Pravilno-Namotat-Slesku.HTML

The choice of fishing line

In order for the dressing of the fishing line to the trimmer head to be successful, it is important not to fail to choose the consumer material. The thicker the cord you refuel, the more thick and hard grass it can cut. A universal fishing line for a trimmer is often used, the diameter of which is 2 mm. You can choose the diameter suitable for the mower in the following ways:

- See the information about the thickness of the fishing line in the instructions attached to the trimmer.

- Pay attention to the squash itself. Sometimes information is applied on it about possible fishing line diameters.

- Another option is to try to insert the cord into the output. If it easily passes into it, then the selected fishing diameter is suitable for use.

A coil for a trimmer for grass can choose a cord thread by type of engine. If the fishing line for the trimmer is too thick, then the resistance to rotation will increase. the engine in this case will overheat and will soon fail. Useful recommendations:

- For an electric device with an engine of less than 500 in, a thread of 1.3 mm thick is suitable. If this was not found, then you can use a fishing line for a trimmer by 1.6 mm. If the power is more than 1 kW, then select a cord with a diameter of 2 mm.

- The gasoline trimmer for grass has a shaft mower. For the bent version, the cord for 2 mm is often used. If the shaft is straight, then set the thread 2.4–2.5 or 3 mm. The thickest fishing line for a trimmer is installed on powerful devices. from 1.3 kW.

Pay attention to the type of cross section of the cordry thread. Some popular options:

- The most common fishing lines with a round section. They mow fresh herbs well, but they cope worse with shrubs, drows.

- Twisted (spiral) cord does not differ in high strength, but well suitable for thin young grass.

- The jagged thread with sharp edges is ideal for a large weeds in a neglected area.

- You can mow the lawn in a rectangular, starry or square fishing line for a trimmer for grass, but they are not very durable.

- The most durable is a two.component cord with an internal core and a round section.

Types of fishing line for a trimmer for grass, keep in mind that it is impossible to use wire, metal strings and cables, as well as an ordinary fishing thread instead. The device will be dangerous for both the user and for others. So the cable or similar products will gradually begin to shut down, as a result, their ends will be reacted, and small pieces will scatter at high speed.

Necessary materials and tools

The indestructible nozzle for a trimmer for grass can be purchased at Aliexpress. But you can not overpay and make the same, and maybe better detail, with your own hands. This homemade coil for a lawn mower is suitable not only for fishing line, but also for a cable. This is very convenient and profitable, since the fishing line for the trimmer is heavily coping with thick plant stems and is consumed faster.

The presentation is based on the mechanism with the tape of the Bobin tape recorder. Many at home have old tape recorders, so problems with the search for spare parts should not arise. It will also require a protective casing from a car rack, which will act as a cover, a metal washer and a hexagonal nut with left thread.

For work, such tools and materials will be required:

Additionally, you will need a ruler, nippers, a key and some other auxiliary tools.

Repair of mechanical parts of lawn mowers of all types

Regardless of the type of engine, the mechanical part of the braid braid includes knives, a device for scattering or storing grass and a transmission mechanism. Most often knives fail or end with fishing line.

Cleaning the mechanical part of the BOSH mower

Broken or bent knives are visible to the naked eye. Depending on the material and the degree of damage, the knives are replaced or restored by simple flexion to the initial state. With strong wear, the cutting part can be blown up. Home.made lawmaker from a trimmer for grass may fail for many reasons. Most often this is an excess of the maximum permissible load for torque and engine, because instead of fishing line they use a knife.

Restoration of a gas trimmer handle for grass

During the inspection, check the condition of the grass supply channel in the container and, if necessary, clean it. complex mechanical malfunctions require complex tools, special equipment, professional skills, and it is better to trust specialists to eliminate problems.

Is it possible to make a coil for a trimmer for the grass with your own hands

Such a homemade mowing nozzle is fixed on the shaft with a nut. Twist or unscrew the nut without fixing the shaft will not work. To replace the cord, it will be enough to release the screws, insert a segment of the fishing line of the required length and press it again.

Also, a mowing nozzle for fixing the fishing line on it can be made from a metal sheet. How to do this can be understood from the next video.

Preliminary preparation

First of all, to wind the fishing line, it is required to remove the coil (bobbin, spool) from the trimmer for the grass. specific actions will depend on the complexity of the configuration and the type of product itself:

- Small electric trimmers for grass with a working location of the engine and coils in the lower part, as a rule, have side keys on both sides of the bobbin. With the simultaneous press on them, the upper part of the coil, along with the internal contents for winding the fishing line, is disconnected, while the lower remains on the trimmer. It is advisable to analyze the bobbing in an even smooth place, so that the spring does not jump out and not be lost;

- Electric and gasoline trimmers for grass with a curved rod without the ability to install a knife, as a rule, have coils with a special lamb: in such structures, you should hold the spool in a fixed position with one hand, and rotate the fixing bobbin on the bar with a barack’s baracks. After disconnecting the nut, the whole bobin is removed.

- Electric and gasoline trimmers for grass with the ability to install a knife on a straight rod (for example, trimmers for STIHL grass) have a hole. For the immobility of the bar, a screwdriver or another suitable object is inserted into this hole and, with slow rotation, such a mutual arrangement is achieved when the screwdriver enters the hole and the bob is fixed. After that, the coil body is scrolled clockwise (with the left thread) and removed from the trimmer for the grass.

For the second and third cases, the coil, depending on the design, are versed in various ways. In the bobbins with a lamb, lamb is twisted, in the reels with latches, latches-fixers are pressed and one part of the coil is freed from the other. If the halves of the spool are connected by thread, then it is enough to turn them with your hands in the opposite directions until they are completely developed.

Determination of the causes of the malfunction

If the trimmer engine for grass does not start or stalls immediately after starting, when overheating or during the functioning of the device, extraneous noises are heard and vibration is clearly felt, it is important to perform a visual inspection and identify a non.working node

To optimize preparatory measures before repairing, a simple diagnosis should be carried out and checked in stages:

- the presence of fuel in the tank and lubrication in the main nodes;

- serviceability of the spark plug and its performance;

- the purity of the fuel and air filter motorcycles;

- Cutting of the exhaust channel and the device’s saepun;

- The quality of the used fuel and lubricants.

To determine the functional performance of the ignition of the lawn mower, you should determine whether the candle works by testing the appearance of a spark in contact with the body of the functional device.

The spark plug itself can be changed to a new one, after driving the candle canal, if necessary, the old element is also dried, cleaned with special devices and returned to place.

What is needed to replace the cord

With the constant use of a trimmer for grass for grass, the discs are blunting, but they can be sharpened and continued to work. Lines for a trimmer

The coil tends to end, therefore there is a need to refuel the latest, why you need to find the type of head and prepare the cord of the desired thickness and length.

So, the mowing head is a cylindrical case, in which the rogue and a fishing line are located for a trimmer. Such a part is located both on electronic trimmers and on gasoline braids of all brands, whether it be Bosch, Makita, Stihl or another brand. There are three types of heads depending on the method of refueling and feeding the fishing line.

- The mechanism of operation of the heads of the automatic group is that without the help of others they feed a fishing line for a trimmer, when the mower reduces the speed of the motor. Such designs are comfortable when working in huge areas, but have a defect. Large cord consumption.

- Automatic group heads are comfortable in operation. Automatic fishing is carried out at the highest revolutions of the motor. To remove clogging of the cord, carefully tap on the ground with the inventory, after which the unlocked thread will push out of the reel. The segment to the desired length is made by a knife attached to the protective cover.

- Trammers for grass with manual supply of the cord must first be turned off, and then without the help of others remove the fishing line for the trimmer.

No spark on lawn mower engine. Ignition coil replacement

Coils for electronic and gasoline binders can be with one or 2 threads. The 1st is used for haircuts of low grass, 2. for cutting the highest grass and small shrubs.

Trimmer coil device for grass

Cassyle heads for trimmers come in different designs. both simple and complex. The figure below shows a semi.automatic trimmer head from the Husqvarna motorcycle (Husqvarna).

This type of head is present in the configuration of most benzocosyles and electrimmers such as Stihl (Stihl), Patriot (Patriot), Champion (Champion), Bosch (Bosch), Huter (Huter) and others. The device of the braid head is quite simple. It includes the following details:

- the base of the mowing head;

- button for semi.automatic supply of the cord;

- Spulk (coil), into which a fishing line for a trimmer is refuel;

- spring;

- eyes. through them a fishing line for a trimmer goes outside;

- trimmer head cover;

- Trimmer fishing line (cord).

Instructions

In order to change the fishing line for the trimmer, it is necessary to extract the old one (if it was).

The coil is part of the design of the trimmer for the grass, which is located inside the head of the motorcosa, drum or bobbin. Depending on the manufacturers of the head can be different. But this article discusses only Patriot, although their mechanism is used by many other companies.

Instructions on how to promote a hand head on a trimmer is described below.

How To Install A Spark Plug Boot On Chainsaws, Leaf Blowers, Weed Whackers Etc.

- First of all, you need to clean the head of dirt and adhering grass if it is contaminated. To do this, you need to raise a motorcycle head up and, holding the casing, remove a special protective cover dressed on the drum.

- The next step needs to remove the reel from the drum. The coil is easily removed even with one hand, because it is not fixed inside the drum.

- The drum itself is fixed in the trimmer with a bolt. This bolt must be unscrewed, after which you can easily pull out the drum. To do this carefully, you should support the drum with a coil, while twist the screw counterclockwise.

- Now you can pull the coil out. As mentioned above, it is not fixed in anything except a hook with a metal shaft, so it does not need to be torn off with force. Neatly, in a circular movement you should pull the coil from the drum.

- Now it remains to extract an old fishing line for a trimmer and follow the following instructions.

Installation of the coil and drum in its former place is performed according to the opposite algorithm.

Before the process of refueling the fishing line, it is worth making sure that the thread suitable for a trimmer was bought. In the case when the thread is not suitable, the fuel or energy consumption increases, as well as the load on the motor motor.

In order to replace the thread itself directly, you need to prepare a piece of thread of the required size. Most often, this requires about 4 m fishing line. A specific figure will depend on the parameters of the thread, for example, its thickness, as well as on the parameters of the coil itself. If it is not possible to accurately determine the length, it can be done as follows: insert and wind the thread to such a state that the coil is completely charged (the level of the fishing line will be compared with protrusions in the sides of the coil). It is necessary to ensure that the fishing line for the trimmer sits in the coil exactly.

The instructions for refueling the fishing line in the coil is described below.

The prepared thread must be taken and turned in half. It should be ensured that one edge is longer than the other by 0.1-0.15 m. Now you need to take the ends in different hands. The one that is smaller must be pulled to more, so that it becomes 2 times shorter. When bending, the indentation should be maintained at 0.15m. Find the slot inside the coil partition. Carefully prick the loop that turned out earlier in this slot. To continue work, it is necessary to determine the direction of winding the thread in the coil. To do this, just examine the coil. there should be an arrow on it. If the gunner could not be found, it is quite possible that there is a written designation. An example is given in the photo below. It is necessary to inspect the head of the coil. It has a direction indicator. However, this is the direction of the coil movement. To get the direction of winding, you need to wind in the opposite direction. Now you need to season the reel with a fishing line

It is worth noting that there are special guide grooves inside the coil. When wrapping a thread, you need to follow these grooves, otherwise you can damage a trimmer for grass

At this stage, you need to charge the coil very carefully. When the user winds up almost the entire thread, you should take the short end (do not forget about the protrusion of 0.15m) and stretch it into the hole located in the coil wall. Now you need to repeat this action similarly with another end (on the other hand). Put the coil itself in the coil head, before that, extinguishing a fishing line for a trimmer through the holes inside the drum. Now is the time to return the drum to your place. After that, you need to take with both hands by the ends of the fishing line and pull them to the sides. Then you need to put the lid in place (here you can safely make efforts until a characteristic click is heard). Remained to perform “cosmetic work”. You need to see if the thread has come out too long. You can start a trimmer for the grass and check in practice whether everything is comfortable. If the thread came out a little long, you can cut it with scissors.

Preparation for replacement

For clarity, a mowing head was removed from the motorcycles (Spool). To replace the fishing line you do not need to remove it, everything is done in place. It doesn’t take much time.

We disassemble the rogue of the trimmer for the grass-it holds on the clan locks. Remove the lid, pressing on the latches. If you do not have enough effort with your hands, then use the screwdriver.

The principle of action is as follows. By clicking on the button, the coil presses on the spring and leaves the fixing grooves in the lid of the spray. Holding the coil in this state, you can twist, thereby adjusting the length of the fishing line. When the button is released, the housing spring returns the coil to the original fixed state.

Which line for trimmer is used for a trimmer for grass?

There are several types of fishing line:

- Stronger round;

- For mowing soft vegetation curly;

- For mowing narrow toothed grass;

- Especially suitable for certain trimmers.

A cutting cut section should correspond to a plant plant that needs to be cut.

If you need to change the fishing line for the trimmer, then you need to choose exactly the type that the manufacturer of this particular trimmer for the grass of the model recommends, that is, the thickness of the cutting thread

must correspond to the engine power and the size of the unit.

It is better to choose a specialized cutting thread. It is worth for a while to soak a fishing line for a trimmer if you plan to change it in a coil.

After soaking, it acquires elasticity and becomes stronger.

The cutting thread can be made of various components. Often found in their middle nylon.

This material is characterized by a high degree of wear resistance, the ability to withstand various temperatures and high loads.

A nylon fishing line for a trimmer can be stored for a long time, it does not dry out and does not lose its strength.

Therefore, its service life can be quite long.

Coils or haircut heads have a different structure:

Is it possible to make a coil for a trimmer for the grass with your own hands

On sale there are a large number of trimmer heads (not automatic), which have a low price and good quality. But sometimes situations arise, for example, in the country, when the trimmer coil broke, and its repair is impossible, the store is far away, and you need to mow. In this case, you can quickly, literally in a few minutes, make a simple trimmer nozzle to fix the fishing line from ordinary plywood 10-12 mm thick.

- Take a piece of plywood or textolite and draw a circle with a diameter of about 14 cm on it.

- Cut the disk with a jigsaw or hacksaw for metal.

- Drill a hole in the center of the disk, suitable in diameter to the gear shaft. Do not forget before installing a disk on the shaft, put a puck on it.

- You can fasten small corners along the edges of the disk or make 1-2 holes on the opposite sides. They will serve for refueling fishing lines in them.

- To fix the fishing line for a trimmer, you can screw several screws into the plywood.

Such a homemade mowing nozzle is fixed on the shaft with a nut. Twist or unscrew the nut without fixing the shaft will not work. To replace the cord, it will be enough to release the screws, insert a segment of the fishing line of the required length and press it again.

Also, a mowing nozzle for fixing the fishing line on it can be made from a metal sheet. How to do this can be understood from the next video.

Prevention of the problem

Often, the breakdown of the ignition coils are associated with the closure or cliff of windings and mechanical damage to the magneto body. This is due to strong blows, fluid and oxidation, as well as overheating. If you avoid such incidents, you can not worry about the integrity of the ignition coil.

Important! To prevent regular failure, one of the most important components of the ignition system, you need to refuel high.quality fuel. Bad fuel spoils these details.

One of the nodes of Magneto, which regularly suffer when using, are high.voltage wires through which current from the ignition module enters the candles. They have a high service life, but the damage to them is caused by users by an inaccurate circulation when replacing candles, carefully pulling the wire itself, and not for the tip. Another problem that can happen to them is moisture and oxidation or damage to isolation. If you carefully pull out the candle and avoid the penetration of the liquid into the device, these problems can be avoided.

So, the repair of the ignition coil is not very complex and can be carried out by the user independently, but subject to the above procedure for disassembling and replacing the magneto or contacts of the interrupt.

Why is the ignition adjustment

In some cases, when the engine does not start, the ignition adjustment will be required. Of course, first you need to check the serviceability of a candle and a high.voltage cable with a cap.

It is necessary to adjust the ignition on a two.stroke engine in order to ensure timely ignition of fuel in the engine combustion chamber. Below is a scheme from which you can understand the principle of operation of the internal combustion engine.

The spark in the candle should appear at the time of compression of the fuel with a piston, when it does not reach the upper dead point (VMT) at least a little. Когда поршень проходит ВМТ, происходит возгорание топливной смеси, в результате чего поршень под действием энергии взрыва уходит вниз.

Therefore, if for some reason (mainly this is due to the shift of the flywheel to the shaft relative to its original position), the fuel fire occurs earlier than the piston passes, then it returns back, and the crankshaft scrolls in the opposite direction. Such a movement can damage the starter knot, cut off the launch cord, etc.D. In this case, an early ignition of fuel occurs.

There may also be a later ignition on the trimmer: the piston after compression of the fuel, which does not ignite, goes down, and at that moment a spark appears. In this case, the engine will either not start or significantly lose power and will be poorly gaining momentum.

But such problems with early or late ignition on two.stroke ICE are quite rare, since the flywheel with magnets is already established in the correct position, which is perfectly synchronized with the movement of the piston. In addition, the flywheel is fixed on the shaft using a key and nut. Therefore, the wrong installation of the part is excluded.

Basically, the ignition adjustment is to set the correct clearance between Magneto and the flywheel.

Replacing Magneto

To correctly purchase Magneto for replacement, you need to contact a specialized store or service center and name the brand and model of a trimmer for grass.

Advice! Another good decision will be the provision of an old ignition coil, according to which the seller will be able to choose a new part.

To remove the magneto, you need to remove the plastic casing from the trimmer for the grass. On different models of motorcycle, this process is different. It is usually necessary to unscrew the bolts, but on some benzotrimers it may be necessary to squeeze the latches. After that, access to the coil opens. To remove the part, you need to unscrew the holding fasteners and disconnect the wires.

When installing a new part, you need to correctly set the distance between the flywheel and magneto. To do this, you need to turn the flywheel with magnets up, install the coil and fix it, but the screws do not completely tighten, so that there is a short distance between the details. Further, between the coil and the flywheel, it is necessary to put a calendar, a business card or four.folded paper sheet of A4 format, you can also use a plastic strip cut out of the bottle. Such tricks will provide a suitable gap between the flywheel and magneto. A more competent solution will be the use of a special template, but it is impractical to purchase it for the sake of once. Next, you need to tighten the fasteners, remove the object between the details, and, holding the magneto with your hands so that it does not spin, tightly tighten the fixing screws. After that, you should crank the flywheel and make sure that it does not catch the coil anywhere. Now you need to connect the wires and insert the candle into the cap, and then check the operation of the device.

Prevention of the problem

Often, the breakdown of the ignition coils are associated with the closure or cliff of windings and mechanical damage to the magneto body. This is due to strong blows, fluid and oxidation, as well as overheating. If you avoid such incidents, you can not worry about the integrity of the ignition coil.

Important! To prevent regular failure, one of the most important components of the ignition system, you need to refuel high.quality fuel. Bad fuel spoils these details.

One of the nodes of Magneto, which regularly suffer when using, are high.voltage wires through which current from the ignition module enters the candles. They have a high service life, but the damage to them is caused by users by an inaccurate circulation when replacing candles, carefully pulling the wire itself, and not for the tip. Another problem that can happen to them is moisture and oxidation or damage to isolation. If you carefully pull out the candle and avoid the penetration of the liquid into the device, these problems can be avoided.

So, the repair of the ignition coil is not very complex and can be carried out by the user independently, but subject to the above procedure for disassembling and replacing the magneto or contacts of the interrupt.