How To Wind The Line Into The Trimmer Spool

We wind the fishing line

Slowly completed disassembly of the spool-spool without losing its spare parts allows you to proceed to the main task. winding the fishing line into the reel. Technological features of the spool design and the number of working antennae determine the sequence of actions.

Coil with two working antennae

In this type of spool, you should determine the number of grooves for winding the line, lying on the inside of the spool:

- One groove. both tendrils are wound together in one groove;

- Two grooves. each tendril is wound on an individual groove.

For both cases, a line with a length of 2-3 m is taken.In single-groove reels, the line is pulled into a through hole, its ends (antennae) are folded together and aligned, after which they are wound in the opposite direction of rotation of the bobbin on the rod side. inside the arrow usually indicates the correct direction of winding. If there are fixing grooves, the ends of the fishing line are threaded through them or held with the fingers of the free hand, threaded through the through hole of the outer half of the bobbin, the spool is closed and attached to the trimmer bar.

The difference in line winding in double-groove spools is that initially a 2-5 m long line piece is folded in half (to determine the middle fold), and the fold loop is inserted into a special groove between the grooves. Both antennae of the fishing line are wound each along its own groove, fixing the antennae and assembling the coil is similar to the above option with one groove.

The first execution of this procedure, perhaps, will seem long and rather laborious, but with time and experience this task will be solved much faster and easier.

The following will clearly show how to thread the line into the trimmer reel and wind it correctly. this operation is not difficult and with some patience it will certainly be crowned with success:

Coil with one working antenna

The most common option and easy sequence of actions:

- The dimensions of the reel and the length of the unique factory winding determine the recommended length of the line for winding. 2. 5 m.

- One end of the line is inserted into the fixing technological hole located inside the spool.

- The fishing line is wound on the drum in the reverse rotation of the spool on the trimmer product direction. usually, on the inside of the bobbin, an arrow indicates in which direction the winding is being carried out.

- A small section of the fishing line is left free to bring it out. it is fixed in a special groove on the inner side of the bobbin, created to hold the winding when assembling the bobbin into working condition.

- The left end of the line is passed through the hole on the outside of the reel.

- The bobbin halves are assembled and put on the trimmer bar.

Automatic line winding to a spool

There is a type of reel in which the automatic mechanism winds without the help of others. from the user it is enough to just fill the line correctly. How to insert line into the trimmer spool? Instruction. How to remove the spool from the trimmer? How to wind the line in order to tuck the line. The fishing line is passed through a hole on the inside of the body, its antennae without winding are passed through the hole on the outer body, the reel is assembled, and when the winding button is rotated, the fishing line is wound from the inside without the help of others. In such a spool, it is unrealistic to make the winding wrong: the mechanism itself will determine the correct direction, since it can only rotate in one direction.

The warranty production of the factory trimmer refueling will inevitably require line replacement. Having a very rough idea of how to thread the line into the trimmer reel on their own, beginners are reluctant to take up this business. However, with some skills, mastering this simple science does not present any difficulties, and the similar instruction presented below will make this process as easy as possible.

Coil with two working antennae

In this type of spools, you should find the number of grooves for winding the line, lying on the inside of the reel:

- One groove. both tendrils are wound together along one groove;

- Two grooves. each tendril is wound on a personal groove.

For both cases, a line with a length of 2-3 m is taken.In single-groove reels, the line is pulled into a through hole, its ends (antennae) are folded together and aligned, after which they are wound in the opposite direction of rotation of the bobbin on the rod side. inside the arrow usually indicates the correct direction of winding. If there are fixing grooves, the ends of the line are threaded into them or held with the fingers of the free hand, they are threaded into the through hole of the outer half of the bobbin, the spool is locked and attached to the trimmer bar.

The difference in line winding in double-groove spools is that initially a 2-5 m long line piece is folded in half (to determine the middle fold), and the fold loop is inserted into a special groove between the grooves. Both antennae of the fishing line are wound each along its own groove, fixing the antennae and assembling the coil is similar to the one-groove option discussed above.

The first execution of this procedure, perhaps, will seem long and rather laborious, but over time and experience, this task will be solved much faster and easier.

The following will clearly show how to thread the line into the trimmer reel and wind it correctly. this operation is not difficult and with some patience it will certainly be crowned with success:

Preliminary preparation

First of all, to wind the fishing line, you need to remove the spool (bobbin, spool) from the trimmer. specific actions will depend on the complexity of the configuration and the type of the product itself:

- Small electric trimmers with a working engine and bottom coil usually have side buttons on either side of the bobbin. When pressed at the same time, the upper part of the spool together with the inner content for winding the line is detached, while the lower part remains on the trimmer. It is advisable to disassemble the bobbin on a flat, smooth place so that the spring included in the structure does not jump out and get lost;

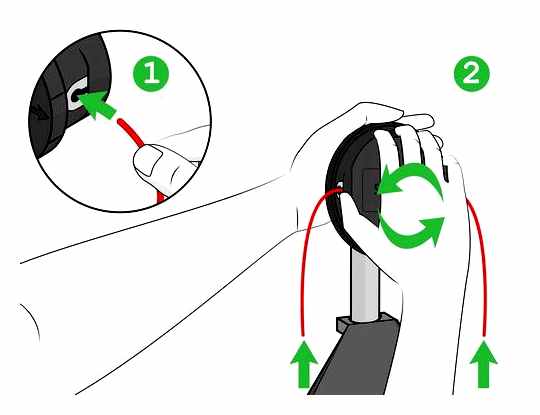

- Electric and gasoline trimmers with a curved bar without the possibility of installing a knife, as a rule, have spools with a special wing: in such designs, hold the spool in a stationary position with one hand, and rotate the locking reel on the rod with the wing nut counterclockwise with the other. After disconnecting the nut, the entire bobbin is removed.

- Electric and gasoline trimmers with the ability to install the knife on a straight bar (for example, Stihl trimmers) have a hole under the reel. To keep the rod stationary, a screwdriver or other suitable object is inserted into this hole and, with slow rotation, such a mutual arrangement is achieved when the screwdriver enters the hole and the bobbin is fixed. After that, the coil body is scrolled clockwise (with a left-hand thread) and removed from the trimmer.

For the second and third cases, the coils, depending on the design, are disassembled in different ways. In bobbins with a lamb, a lamb is unscrewed, in coils with latches, the latches are pressed and one part of the coil is released from the other. If the halves of the bobbin are connected by thread, then it is enough to turn them by hand in opposite directions until they are completely unscrewed.

How to thread the line into the Stihl trimmer spool

How do I load the line into the trimmer spool? Instructions

The guaranteed output of the factory trimmer refueling will inevitably require a line change. Having a very rough idea of how to thread the line into the trimmer reel without the help of others, the newcomers are reluctant to take up this business. How to wind the line on the trimmer reel, how to thread the line into the trimmer reel. Autocut for stihl fs 55 trimmer line threading into the trimmer reel 2 part line winding on. But with some abilities, mastering this simple science does not present any difficulties, and the similar annotation presented below will greatly facilitate this process.

Coil with one working antenna

The simplest option and uncomplicated sequence of actions:

- The dimensions of the reel and the length of the original factory winding determine the recommended length of the line for winding. 2. 5 m.

- One end of the line is inserted into the fixing technological hole located inside the spool.

- The fishing line is wound on the drum in the opposite direction of the spool rotation on the trimmer product. as a rule, on the inside of the reel, an arrow indicates in which direction the winding is carried out.

- A small section of the line is left free to lead it out. it is fixed in a specialized groove on the inside of the bobbin, designed to hold the winding when assembling the bobbin into working condition.

- The left end of the line is passed through the hole in the outer part of the reel.

- The bobbin halves are assembled and put on the trimmer bar.

How to wind line on a trimmer reel: key points

A gasoline or electric trimmer is an indispensable tool in the arsenal of a modern summer resident or owner of his own home.

Thanks to these gardening devices, even a large garden plot can be mowed with ease. After purchasing this tool and performing several mows, many people think about how to properly wind the line on the trimmer reel. For an inexperienced user, the first operation to replace it will seem problematic and time-consuming, since the developers often do not fully reflect the instructions for replacing the fishing line in the operating manual.

Single-barbed trimmer coil

Many owners and experts note the ease of use and ease of refueling the bobbin with one mustache. Depending on the manufacturer, the length of the threaded line can vary from 2 to 5 meters. The end of the line is inserted into the head into a special technological groove or hole, and the winding is carried out in the direction opposite to the working rotation of the bobbin. Most reels have arrow marks on the outside of the body that indicate the direction of travel of the trimmer reel.

After winding, you need to leave a free end of 15-30 cm to enhance the centrifugal force, which is decisive when removing the trimmer line in automatic and semi-automatic spools. We pass the left end through the working hole of the coil and assemble the head.

Trimmer head with two antennae

Double flute head

After removing the spool from the spool body, we determine the number of strands for winding the line (1 or 2). There is no fundamental difference between bobbins with one and two grooves, but if carelessly threading into the twin groove, there will be operational problems. Due to the likelihood of interweaving adjacent lines of the tool, a situation may arise when, after wear of the working antennae, it is impossible to remove new ones.

Regardless of the number of streams, a fishing line with a length of 1.5 to 3 meters is taken for refueling. Winding must be done in the opposite direction to the rotation of the head, since winding in the direction of travel will lead to the fact that the line will not be removed from the reel. After the fishing line is tucked into the trimmer coil, thread the free ends (15-30 cm) into special holes. Next, we assemble the head in the reverse order of disassembly and check the operability. Do not worry if the ends of the two antennae are very different in size, because when you start the trimmer, the knife installed on the protection will cut off the excess.

Preparation for winding the line

Before the winding process, it is necessary to remove the spool with line from the body. Depending on the manufacturer, power and type (electric or gasoline), there are three design types of trimmers:

-

Compact Electric Trimmers.

Straight bar trimmer

This model provides the ability to install a knife. Removing the coil in such models is done by means of two keys recessed into the coil body. To mount the trimmer knife, it is necessary to align the hole of the reel and the rod, and then insert the device in the form of a steel pin (screwdriver, iron bar). After fixing the coil, the body can be easily unscrewed by hand in a clockwise direction.

Winding the line to the trimmer

Measured and accurate dismantling of the spool from the spit coil makes it possible to go directly to winding the line. The design features of the head, the number and location of the fixing holes dictate the sequence of actions when performing this operation, and also determine the methods used. Today there are several types of reels, depending on the number of line antennae and the methods of threading it:

- Trimmer head with one working mustache;

- A bobbin with two line antennae;

- Auto winding reel.

Trimmer head with automatic line threading

Types of trimmer heads

Some models on the market have a reel with an automatic winding mechanism. It is enough for the owner to properly thread and fix the ends in the head, and the winding operation will be performed by the tool itself when it is turned on. It is almost impossible to wind the line incorrectly into a trimmer with such a head, since the coil independently determines the position of the antennae. The advantages of an automatic trimmer head include ease of threading the line, and the disadvantages are frequent breakdowns of the mechanism due to the complexity of the design and high cost.

Line winding algorithm

Depending on which trimmer model is used, the type, thickness and length of the line are selected. The diameter of the cord can be from 1.2 to 4 mm. It is not difficult to guess that the thicker you fill the cord, the harder and thicker grass it is able to cut.

There are 3 ways to find out which line diameter you can use on your mower.

- View information on the thickness of the cord in the instructions for the device.

- Look at the bobbin itself. It can contain information about the possible diameters of the line.

- Insert the line into the outlet. If it easily passes into it, then a cord of this diameter can be used.

The line is wound on a reel in the mowing head. Therefore, you first need to open it (this was discussed above). There are 2 ways to wind the cord.

High cord consumption

In general, the cord runs out quickly if the semi-automatic head is tapped frequently on the ground or if it is pressed down hard. The spool is unlocked, and the line, lengthening, is cut with a knife. Another reason that the cord runs out quickly is improper operation of the machine with an automatic head: the user often cuts the engine speed when mowing. But as we remember, the automatic head is designed in such a way that it is with each decrease in revolutions that a new portion of the line is supplied, so it is quickly consumed.

Second way

Some spools provide a second method of securing the cord: you can charge 2 pieces of thread instead of one folded in half. The line is replaced according to the following algorithm.

- Before you change or load a new thread into the spool, determine how many meters it will take using the method described above.

- Bend one end of the cord into a hook.

- Find the hole in the bottom of the bobbin for the line to be fixed, and insert the looped end of the thread into it.

- It is required to wind the cord according to the direction of the arrow to the required level not exceeding the spool diameter.

- Do the same for the second bobbin compartment.

- The assembly of the head is no different from the method that was shown when threading the bobbin with a double-folded piece of fishing line was considered.

For Shtil lawn mowers, there is a very simple and quick way to replace the line without disassembling the mowing head, which you can familiarize yourself with by looking at this.

The ends of the cord protruding from the holes in the casing can be cut to the desired length when the part is installed in the trimmer. This can be done in two ways:

- Turning on the trimmer (when rotating, the ends of the fishing line will be cut off against the knife fixed for this purpose on the protective cover);

- Cutting off the excess ends with scissors so that they do not touch the casing body.

The second method is used if a large diameter cord had to be supplied, and the edging knife cannot shorten it.

If the filament has been loaded into the mowing head, but the length of the protruding ends of the cord is not enough, then they must be lengthened before starting the machine. this applies to the head with manual adjustment. However, there are cases when using a semi-automatic mowing head, when due to the insufficient length of the protruding ends of the cord, they do not lengthen automatically. In this case, it is necessary to turn off the unit (on an electrical device, it is necessary to unplug the plug from the socket), manually press the button located at the bottom of the part and pull out a little line. After this procedure, the cord can again be extended due to centrifugal force, if you set the maximum spindle speed.

The thread does not hold

It happens that the thread unwinds if the spring in the semiautomatic head is loose. The line is constantly extended and cut with a knife installed on the cover, which increases its consumption. To check this, remove the cover and turn on the unit. If the line “climbed”, then you will need to replace the spring.

No cord feed, coil does not spin

An automatic or semi-automatic head should feed the line without stopping the unit. But if it does not come out, then the reasons may be as follows:

- The line in the reel is not wound correctly, because of which the latter does not spin;

- The cord is wound unevenly, and the thread can get stuck between the turns (the thread should be wound neatly, turn to turn, without distortions);

- Too short ends of the thread come out of the holes, as a result of which there is not enough centrifugal force to extract them, and the line is not fed (it is recommended to always adjust the cord length before starting the unit by pulling it slightly);

- The line is stuck together (will be discussed later).

Cord breaks

If the line breaks frequently, this may be due to the following reasons:

- Stones, small branches and other solid obstacles come across in the grass;

- The user mows the grass close to the fence, and if it is mesh, then it breaks off the “antennae” even faster;

- Poor cord quality (it is recommended to purchase a quality cord);

- The outlet holes in the mowing head are worn out, which causes the line to be erased on the sharp edges of the bushings and break off (a complete replacement of the part is required).

Types of trimmer heads

The grass mowing head is a cylindrical body in which a spool (bobbin) is inserted with a fishing line (cord) tucked in it. This design can be installed on both gasoline and electric trimmers. The heads differ in the way of threading and feeding the cord and are of 3 types.

- Automatic. Cord feed is performed after the user reduces engine speed. Although the automatic line feed is convenient if a large amount of work is being done, such bobbins have one drawback. a high thread consumption.

- Semi-automatic. The use of this type of heads does not require the user to perform complex manipulations. The principle of their operation is designed in such a way that the cord lengthens automatically while the apparatus is operating at full speed. It is enough to lightly hit the trimmer head on the ground (this removes the blocking of the cord), and the line is pulled out of the bobbin due to centrifugal force, and then it is cut to the required length with a knife located on the protective casing.

- Manual. To lengthen the cord, the device must be stopped, after which the line is pulled manually.

Based on the above, semi-automatic bobbins are the best option. It should also be borne in mind that the trimmer spools are single-string (used only for trimming the grass) and two-string, which are used for mowing tall grass and small, thin-stemmed bushes.

Option number 2

In this embodiment, the head is screwed onto the gearbox shaft. To remove it, you need to fix this shaft. To do this, in similar trimmers, for example, in the Huter and Champion, there is a hole through which you can insert either a thin screwdriver or a metal rod.

So, to remove the bobbin, follow 2 easy steps.

- Insert a screwdriver into the hole and lock the shaft.

- Grasp the head body and start turning it clockwise. Turn in this direction for the reason that the thread cut on the shaft is left.

The first way

To correctly determine how many meters of fishing line is required for a particular reel, it is necessary to wind it on the bobbin so that the skein does not exceed the diameter of the sides. If the line sticks out over the edges of the spool, you will not be able to insert it into the casing. After you have decided on the length of the material, it must be threaded into the bobbin, so do the following.

- It is necessary to fold the fishing line in half so that one end of it is 10-15 cm longer from the other.

- Please note that the bobbin is divided into 2 parts by a central border, from which charging begins. Find a groove on it and insert a cord bent in half into it, applying a little force.

- It is very important to determine in which direction the line is wound onto the reel. If you look closely, you can find an arrow on the bobbin or an inscription with an arrow indicating in which direction the winding should be carried out. There are times when there is no arrow on the coil. In such a situation, you can look at the arrow drawn on the mowing head and wind the cord in the opposite direction.

- Winding should be carried out neatly, turn to turn, with maximum thread tension.

- After the laying of the cord is completed, you will first need to fix the short end of the line by inserting it into a groove of a suitable diameter on the side of the reel.

- The second end, the one that is longer, is attached in a groove on the opposite side of the bobbin.

- After fixing the fishing line, cut off its ends, leaving about 10 cm allowances.

- Next, you need to install the loaded bobbin into the mowing head. To do this, alternately inserting and pulling the thread into the outlet holes of the head, place the bobbin in the casing, then, applying the required force, pull the fishing line out of the fixing grooves and tighten it.

- Now you can put on the cover and fix it with the latches.

than 200 types of trimmers in one place at the lowest prices. Click and watch

Now, having removed and disassembled the coil, we proceed, in fact, to winding.

How to properly wind the line on the trimmer spool

Many, having worked out the factory line on a recently purchased trimmer, try to wind a new one, but cannot, because they do not know how to properly wind the line on the trimmer spool (bobbin). It seems that there is an instruction, but it still does not work. Let’s try in this article to deal with this issue.

So, in order to wind the line, you first need to remove the coil from the trimmer. this will be more convenient. The removal method will depend on the type of trimmer.

Removing the coil from the trimmer

On small, bottom motor electric trimmers (when operating near the ground), the reel usually has two buttons on the sides. Click on them and disconnect one half of the coil body from the second, which remains on the trimmer. Together with the first half, the inner part is also taken out, on which the fishing line is directly wound. When disassembling, be careful: there is a spring inside that can fly out and get lost.

On electric and gasoline trimmers with a curved bar (there is still no way to put a knife on such trimmers), you need to wrap the coil body itself with one hand, and with the other hand you need to start rotating the lamb on it counterclockwise. It is he who attaches the coil to the trimmer bar. Having unscrewed the lamb, carefully remove the entire coil, trying not to lose the spring inside.

On electric and gasoline trimmers with a straight bar and a gearbox at its end (on such trimmers, in addition to fishing line, you can also install a knife), we look for a hole under the coil, insert, for example, a screwdriver into it, gently rotate the coil until the screwdriver crawls even deeper, and the coil will lock. Now turn the whole coil clockwise (since the thread is left-handed) and remove it from the trimmer. Then we disassemble the coil. It can be assembled with latches or twisted with a lamb. If the coil is on latches, then press on the sides on the base of the latches so that they bend and release one half of the coil body from the other. We just unscrew the lamb. There may also be a third type of connection between the two halves of such a coil: with it, you need to grab the lower part with one hand, and the upper part with the other, and start turning them in opposite directions. When disassembling such a coil, you also need to make sure that the spring inside is not lost.

Winding process

If your coil is designed to work with only one tendril, then it’s simple. You need to unwind 2-4 m of fishing line (depending on the size of the reel), find a fixing hole for the line on the inside of the reel, insert one end of the line there and start winding the line in the direction opposite to the direction of rotation of the reel on the trimmer. On the inside of the reel, they usually indicate with an arrow in which direction to wind the line. After winding the fishing line, we leave a small piece of it unwound to expose it. We fix this piece in a special groove located on the inner part of the reel and designed so that the line does not unwind at the time of collecting the reel. If there is no such groove, then you will have to hold the fishing line with your finger to prevent it from unwinding during the further collection of the coil. Next, we take the outer part of the coil and thread the outer piece of fishing line into the existing hole, assemble and put the coil back on the trimmer.

If the coil is designed to work with two antennae, then do the following. On the inside of the reel, we look at how many grooves there are for winding the fishing line. There may be one or two of them. If there is only one groove, then both tendrils are wound along this one groove. If there are two grooves, then each antenna is wound along its own groove. A reel with one groove must have a through hole through which the line is threaded. We unwind 2-4 m of fishing line, thread it through this hole so that it sticks out equally on each side of the fishing line. And we simultaneously wind both antennae of the fishing line in the same direction, opposite to the direction of rotation of the coil on the trimmer and coinciding with the direction indicated by the arrow on the inside of the coil. We leave a little of the fishing line unwound, fix the resulting ends in special grooves, and if they are not there, we hold them with our fingers. We pass both ends into the existing holes on the outer casing of the coil. We collect the coil and attach it to the trimmer.

If there are two grooves, fold a piece of fishing line 2-4 m long in half, insert the loop obtained at the place of the fold into the groove between the two grooves, and simultaneously wind both ends of the fishing line along its own groove. Further actions are similar to the previous option.

There are also reels in which the fishing line is threaded through a through hole on the inside. After that, the ends of the line, without winding, are threaded completely through the holes on the outer body of the reel, collect the reel and begin to rotate the button, which is usually pressed, in order to release the line during operation as it wears out. Rotate the button. the fishing line itself is wound inside. At the same time, it will not work to turn it in the “wrong” direction, since it can only rotate in one direction. If you get used to it, you can wind fishing line on such a reel without even disassembling it. you just need to combine the through hole of the inner drum with the holes on the outer body of the reel, and then thread the fishing line through them.

That’s all on this issue. Happy winding!

How to wind the line correctly on the trimmer spool?

Despite the fact that gardening equipment has been used for quite some time, it is still a novelty for some owners of private houses. That is why there are often questions about how to properly wind the line on an electric or gasoline trimmer.

This is essentially a simple operation, but all its stages must be performed correctly in order to achieve the desired result. over, in the operating instructions, only a few manufacturers provide an answer to this sore question. Explore the article and find out how the line winds around the trimmer reel.

The procedure for winding the line on the trimmer spool

First of all, you should know that trimmers have different working attachments. The reel can be designed for different lengths and thicknesses of the line. this point should be taken into account when purchasing consumables.

So how do you load the line into the trimmer reel? All work is divided into several stages:

- First you need to disassemble the trimmer head.

- Unscrew the nozzle by rotating the drum to the right.

- Press with your fingers on the two latches located on different sides of the entrance, and remove the top cover of the nozzle. You can pry off the cover with a screwdriver. This should be done carefully: reels with automatic line feed have a spring that can forcefully throw the cover along with all the contents of the reel.

- Remove scraps of old fishing line.

- Now you need to find the middle of the line. To do this, unwind it to the required length (for example, 10 m), cut it off and fold it in half.

- Hook the middle of the line into the existing recess or insert into the hole specially designed for this. And start winding. The direction is indicated by the arrow, which is usually marked on the trimmer reel body (usually against the rotation of the drum). Some models have a double-sided spool: in this case, the fishing line should be wound in different directions: one end in one direction, the other in the other, while the loop of the fishing line must be wound into the dividing slot in the middle.

- Leave loose ends of the line about 20cm each. Later they will need to be fixed in the recesses.

- And finally, the last step is to assemble the drum. Reinstall the washers and spring. On the top ring of the reel there are two notches where you need to tuck the antennae of the fishing line. Thread them through the holes and place the spool in the drum, trying to tighten the line without displacing the spring.

- Place the drum cover on top and close it with your fingers. The latches will snap into place with a characteristic click.

When you turn on the trimmer, the excess line will be cut off by the trimming blade.

As you can see, winding the line on the trimmer reel is easy: the main thing is to do everything right. And here are some more tips that will come in handy when choosing a fishing line, winding it and subsequent work:

- The line comes in different thicknesses and cross-sections. The best option for winding is the “native” line for this model;

- Never use fishing line or metal cables for the trimmer. This replacement may seem effective, but it is very dangerous. Jumping off a working trimmer, the cable can seriously injure not only the lawnmower himself, but also those around him;

- The line is cut when the trimmer is in contact with hard objects. Try not to allow this, otherwise you will have to stop each time, turn off the device and rewind the line on the reel;

- Use regular line for cutting lawn grass and pigtail line for coarse weeds. It is more durable and will not constantly cut.