Installation of Magneto on a trimmer for Champion grass. The procedure for checking and setting up proper engine operation

Ryobi trimmer 31cc will it run

trimmer for grass what gap on the coil

The most vulnerable element of the carburetor engine is the spark plug. This also allows us to judge the possible causes of the failure of individual nodes of the gasoline engine. The following procedure is recommended.

The gap should be adjusted when installing a new electric module on a magnetic engine. The optimal distance between the flywheel and the ignition coil for most chainsaws is 0.2-0.4 mm.

With such a small gap, an accessible measuring device cannot be used for direct measurement. In practice, Husqvarna saws are used, cut out of thin and flexible sheet material of the desired thickness. When it is installed, it is clamped in the space between the flywheel and the reel, and then removed.

To avoid ignition adjustment, use the tool carefully, avoiding blows. In particular, this applies to chainsaws with electronic chips in the ignition system, since they are very sensitive to mechanical damage

Settling of the ignition on the trimmer. How to set a ignition on a benzoca

On gasoline trimmers, both two.stroke internal combustion engines (ICE) and four.stroke. But the ignition system there is no different from each other, so the repair and configuration of this complex of accounting programs for ignition of fuel will be identical to different types of internal combustion engine.

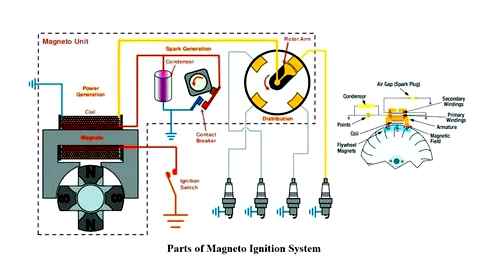

The ignition system of a two-stroke ICE consists of 2 parts: flywheel and coils (magneto). The figure below shows how they look.

There is a impeller on the flywheel, which works like a fan for cooling a motor. There are also permanent magnets on one side of the flywheel, the figure is shown by the arrow.

When the flywheel rotates in the coil, an electric current is produced, which serves for a spark on the spark plug. The spark appears at the moment when the magnets are directly under the magneto.

From time to time when the engine does not start, the ignition adjustment will be necessary. Naturally, first you need to check the serviceability of a candle and a high.voltage cable with a cap.

It is necessary to adjust the ignition on a two.stroke engine to ensure timely ignition of fuel in the combustion chamber of the motor. Below is a scheme, you can understand the principle of operation of the internal combustion engine.

The spark in the candle should appear at the time of compression of the fuel piston, when it does not reach the top of the upper dead point (VMT) more than the best. When the piston passes through the VMT, the fuel mixture is ignited, under the influence of which the piston goes down under the action of the energy of the explosion.

If for at least any reasons (to a greater extent this is due to the shift of the flywheel to the shaft relative to its starting position), the fire of fuel occurs earlier than the piston passes, then it will come back, and the crankshaft scrolls in the opposite direction. Such a movement can damage the starter knot, cut off the launch cord, etc.D. Then there is an early ignition of fuel.

Also, you will like a later ignition on the trimmer more for you: the piston after compressing the fuel, which did not ignite, goes down, and in this case there is a spark. Then the engine will either not be launched or significantly lose power and will be poorly gaining momentum.

But such tasks with early or late ignition on two.stroke ICE are quite found from time to time, because the flywheel with magnets is already established in the correct position, which is completely synchronized with the movement of the piston. In addition, the flywheel is fixed on the shaft using a key and nut. Therefore, the wrong installation of the part is excluded.

For the most part, the ignition adjustment is to set the correct gap between the magneto and the flywheel.

Magneto is the main detail in the ignition system of the motor and is a coil with primary and secondary windings located around the core. Often, due to the malfunction of the magneto, the spark on the spark plug disappears, and the fuel ignition does not occur. To check the coil, it will be necessary to use the tester, and fulfill the following acts.

- On the tester, going into the resistance measurement mode, you need to set 200 Ohms. In this way, the primary winding will be checked.

- Connect one tester electrode to the “mass” of the coil, and the 2nd-to the contact emerging from the magneto. Normally, the resistance will be from 0.4 to 2.7 Ohm.

- To check the secondary winding, it will be necessary to install the device switch by 20 kOhm. Further, one probe of the device is inserted into the cap of the candle, and the 2nd-is connected to the “mass”. Normally, the properties of resistance should be in the range from 4-6 kOhm and above (depending on the model).

When a circuit is broken, the device will show infinity, and when close. 0 (zero).

The first way

You can check the work capacity of the magneto using a tester. To do this, you need to perform such a sequence of actions.

- True tester: use the resistance measurement function and set 200 Ohms to remove measurements of the primary winding.

- The 1st electrode of the measuring device is put on the “mass” of the magneto, and the 2nd-to the output contact. If the primary winding is working, the characteristics should be from 0.4 to 2 Ohms.

- Install the tester switch by 20 kOhm to diagnose the secondary winding. Then bring the 1st probe into the cap of candles, and the 2nd-to the “mass”. If everything is in order, the characteristics will diversify from 4 to 6 kOhm, depending on the model of the trimmer for the grass, whether it is Patriot 547, Husquarna 128 R or a technique of another brand. If the chain is cut off, the infinity value appears on the tester display. And if there is a short circuit, zero will be displayed on the screen.

With which you can check the coil on the gas station

Many today use the tester to check the parameters of the mechanism. But not everyone is familiar with the multimeter, in fact, a similar device that includes an ammeter, ohmmeter and voltmeter, respectively, they can determine the voltage, current and resistance. This complex apparatus will answer the question: how to check the ignition coil on a benzokos

- Checking the primary winding. The device is adjusted to the resistance measurement mode and is attached to the positive and negative contacts of the winding.

- The average indicator should appear in the range from 0.4 to 2.0 Ohms-regardless of the manufacturer of the apparatus.

- If the resistance value is 0, then a short circuit is the main cause of the coil malfunction.

- If he demonstrates infinity, then you need to look for a scrap of a chain.

- The secondary winding is checked by connecting the multimeter to the output of the high voltage wire and positive contact.

- Here, normal value should be fitted into the framework of 6 to 8 kOhm. In other types of coils, the parameter can reach an indicator of 15 kOhm.

It is quite possible to do this with your own hands, and to understand for yourself whether the resulting parameter is located within the operated limits, only you need to navigate in the norms of specifically your unit, which can be read in the instructions, as well as in our useful articles. Less often, the efficiency of the ignition coil is checked by an oscilloscope, it also needs to be connected to the wires of the coil winding, as a result of which we will get numbers of its condition. It is important for users to understand the working condition of the coil, because it affects not only the start of today’s operation of the machine, but also the entire mechanism as a whole. Working ignition coil, like a fishing line for a trimmer for a trimmer for grass, is an important component of the entire complex of the device.

The main thing is the fuel mixture!

do not start after they are trying to “put them into operation” after a long storage. Troubles with starting in this case are often justified by the incorrect actions of the user.

If you are faced specifically with this phenomenon, then when you cool, you need to close the damper, then pump up a small amount of fuel consistency in the carburetor. After disassembling and assembling the Husqvarna 142 saw, a spark was missing on the spark plug. What to do. Then stretch the launch hand to a sense of resistance, then make a trimmer for the grass with sharp and energetic movements.

The ignition adjustment procedure

Setting the ignition system is performed simply and identical to different models of trimmers, whether it be Stihl FS55, Al-KO Sun 4125 or other lawn mower. First you need to remove the casing from the engine, having previously removed the fixing fixing. This stage of disassembly may have differences on different models of motorcycle (described below). Next, you need to partially unscrew the fasteners fixing the magneto, and turn the flywheel so that the magnets are at the top.

To make the optimal gap between the coil and the magneto, you must use a special template. It is impractical to buy it for a single use, therefore, as an alternative, you can apply a business card or a small calendar, as well as a paper sheet A4, folded four. A strip carved from a plastic bottle or other improvised materials that have the necessary thickness is also suitable. The optimal distance is usually indicated in the user guide. The selected item must be placed between the magnets and the coil.

Then the coil will be pulled to the flywheel with a magnetic field. Holding the magneto in this position, you need to tighten the fixing fastener, and then pull out the business card. After that, you need to scroll several times a flywheel to make sure that he does not touch the coil at all. The process is over. the ignition on the motorcycle is exhibited. Read more the process of adjusting the trimmer ignition system can be studied on the Internet, where many videos are available to this topic.

How to install a magneto on a sculler ant. How to configure the ignition of magneto on an ant

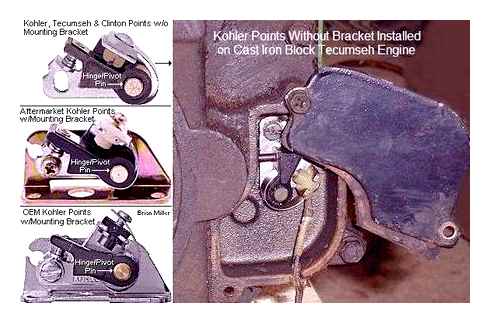

The history of models. Who is online. You are an anonymous user. You can register by clicking here. Soviet scooters: forum. Previous topic :: next topic. Matroskin interestedly registered: Dec 16, messages: Explain how to do this on the fingers, the instructions written about the meter which.then and so.

to come back to the beginning. First you need to write on which engine everything below applies to the Tula. If I am not mistaken, the opening of the contacts should begin 2. If the ignition is standard: we catch a 12V bulb with one end to the mass, the other to the coil terminal, to which the wire from the contacts comes, we take an iron bar of about 6 mm, about 10 cm long. Turn out the candle, stick the bar into the hole, resting slightly on the piston, turn the rotor counterclockwise to the VMT, installed the VMT, put the notching of risk on the bar with a file. We pull out the bar, and put the second risk at a distance of 2.

Now turn on the ignition, stick the bar back with the same side. And we turn the rotor counterclockwise when the second risk of the risk that you did the 2nd time appears. It is at this moment that the light should light up, which you connected to the coil, if it lights up earlier or later, then weaken the screws and turn the ignition, choosing the correct position. Well, it seems somehow on the fingers. Labuh wrote a:. Now turn on the ignition, stick the bar back with the same side. And we turn the rotor counterclockwise when the second risk appears, it is at this moment that the light should light up, which you connected to the coil, if it lights up earlier or later, then weaken the screws and cram the ignition, choosing the correct position.

In the pancake as intricate! Everything is so, only in practice it practically does not work! I inherent in this ignition, I usually correct in motion, achieving the best traction. But in general it has long been known about the electronic ignition. We have a lot of written about this, or you mean the interrupt? Matroskin wrote a:. Andrey wrote a:. Guys, I ruin it, I turn it for the impeller, and the lamp Syo is on fire.

The interrupter closed with a screwdriver. Syo is burnt. Taxi Aidate by order. How it should stand, the nest of the armor is closer to the frame or vice versa? Or from the coil immediately to the interrupter? Do not swear! The person puts the ignition for the first time, here and the experienced sometimes grabs the head. Matroskin If you take a photo of the ignition node of the eccentric installed on your scoller, the interrupter and its contacts, the wire going to the coil, the coil and its terminal. then it will be more convenient for us to show everything in the pictures.

And so again on points: 1. Fasten the eccentric of the interrupt on the dynostarter case. Install the fan grill and fix it with the 4th screws M6. The slot for the wire coming from the contacts of the interrupter should look up.

Establish the interrupter contacts in the deepening of the fan grill. Fasten them with screws. Contacts should look down and is like the left of the eccentric.

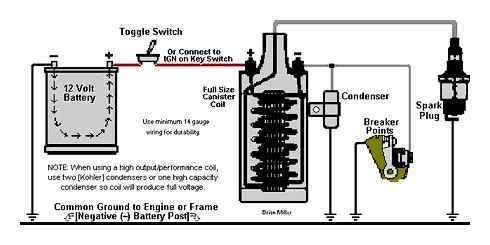

Attach the wire coming from the contacts to the terminal “minus” the ignition coil. Attach the condenser wiring to the same terminal, and fix the capacitor itself on the fan snail case. Connect the plus wire coming from the ignition lock to the reel on the “plus” terminal. If there is no marking on the conclusions of the coil, then she does not care where she has plus and minus. Connect the “Templar” light bulb with one wire to the terminal “minus” of the coil, to the other to the mass. Turn on the ignition.

Ignition adjustment algorithm

The ignition on the trimmer is adjusted quite simply.

Remove the casing from the engine by unscrewing all the bolts holding it. For example, on the Patriot gas.cave (Patriot) PT 2540, to remove the casing, you need to unscrew the air filter housing, and remove it with a flat screwdriver from the latches. After that, the plastic case will easily remove.

- Unscrew 2 bolts using a screwdriver (it is not required to be completely twisted), holding the magneto.

- Turn the flywheel so that the magnets are upstairs.

- Further, in order to properly set the best gap with a flywheel and coil, you can use a regular visit or a calendar. If you have neither one nor the other at hand, then to configure the ignition, you can use a sheet of A4 paper by curling it 2 times (as a result, you will get 4 sheets thickness). This thickness will be enough to get the optimal gap and adjust the ignition. Insert a business card or paper between a coil and magnets.

- The magnetic field will pull the coil to the flywheel. Holding the magneto with your fingers in this position, tighten the bolts holding it.

- Give a business card. After that, the ignition on the trimmer will be adjusted.

- source

Replace the fishing line for the trimmer disk or knife

When finishing the garden, park zones and other places where you need to mow various types of plants, you often have to change the cutting tool in the trimmer. This is due to the fact that the standard cord installed in the head of the lawn mower can only work with grass. But when a shrub or a young sprout of a tree appears in the way of the worker, a fishing line for a trimmer does not cope with this task and should be replaced by a more effective cutting tool.

Trimmer manufacturers have provided similar situations and complemented their products with a mass of nozzles in the form of knives with several “petals” or in the form of disks similar to disc saws.

If you replace the fishing line for a trimmer with a knife with several “petals”, then this tool can mow both high grass and plants with thick and dry stems. And having changed the fishing line for the trimmer on the disk, the user gets the ability to cut bushes or small trees.

Knives and wheels are installed according to the following algorithm.

- First, remove it by fixing the shaft, the mowing head (turn clockwise) or a nut with a shoe if the unit has not yet been used.

- Set a saw or cutting knife so that they are placed on a small ledge (sleeve).

Install the fastener on the knife and screw the nut to the shaft (counterclockwise). Tighten the nut (counterclockwise) using a pipe key.

You can watch this video to better understand the process of changing the tool.

Magneto. design and scheme of work

The purpose of the ignition coil is the conversion of rotation energy into a high.voltage discharge and the formation of a spark that ignites the fuel mixture. In the internal combustion engine, this part is called magneto, since in it alternating current is generated from rotation of a constant magnetic rotor or anchor.

Magneto constructively consists of two windings: high and low voltage. The condenser with interrupter contacts are parallel to the latter. Whereas the conclusions of the high.voltage winding are connected to the candle and body. They are both wound on a core between the poles of which a rotating magnet is installed, magnetized longitudinally.

How to change the cord?

It happens that in the impossibility of starting a starter is not to blame, but the cord itself. He can sit down or completely break. Dismantling the starter of the lawn mower or trimmer for the grass is universal in their steps.

- Remove the starter block from a trimmer for grass or lawn mower.

- Remove the main bolt holding the handbrake.

- Pull out the coil and melt the remnants of a worn cord from it.

- Unscrew the knot on the handle of the cord and pull its end from it.

- Untie the knot at the other end (at the beginning of the coil) and remove the old cord. The nodes that have become tight are unleashed with pliers or ticks.

- Tie a knot on one of the ends of the new cord, pull it through the hole at the beginning of the coil (closer to its axis).

- Shin a few turns of a new cord to the coil. If it is long, then the excess is doom.

- Season and soak the spring tensioner (if it starred) and the spring.loaded elements in the correct sequence.

- Put the coil in place and take the free end of the cord to the outlet of the starter and in the handle.

- Install the starter block in place.

Twist the starter by the cord, start the engine of the lawn mower or a trimmer for grass. The larger and more powerful the engine, the more cord jerks will be required when starting, the norm. no more than 7 times. Result. Fast and smooth starting of the engine, readiness of the unit for work.

When you need adjustment

It is necessary to adjust the ignition system so that the fuel is ignited at the right time in the combustion chamber.

Important! Когда поршень сжимает горючее и практически достигает мертвой точки сверху, в свече возникает искра. Further, when it passes the maximum upper point, the fuel is lit up, as a result of the explosion, energy forms and directs the piston down.

If the flywheel is shifted to the shaft relative to its original position, the fuel is ignited faster than the piston overcomes the upper dead point. As a result of this, the piston moves back, and the crankshaft rotates in the opposite direction. You can determine the early fire of the fuel by a broken launch cord, a broken starter node or other breakdowns.

Sometimes ignition is late. The piston compresses the irreparable fuel, and then goes down, and only then the spark forms. As a result, the engine either does not work or its power is reduced, and the speed is gaining much slower.

Typically, a flywheel with magnets is installed in an ideal position, as if coordinated with the operation of the piston, and in order to avoid displacement, it is carefully fixed. This allows us to say that an incorrect installation of a part is impossible. But if the shift of the flywheel is a confirmed fact, then it is a failure or accident. Thus, the installation of the moment of the ignition is not required, since problems with early or late ignition of fuel happen very rarely.

Important! It is very simple to regulate the ignition system. There is no need to calculate the ignition angle angle. The maximum that you need to do is to properly set the gap between the flywheel and the reel.

A Chinese lawn mower is not started.It is interesting.

Spare parts for Chinese motorcycle do not start Chinese

In the case when there is no spark on the trimmer, how to solve the problem you will be told by professionals for a hundred.

Sometimes, the problem can be with magneto. Magneto may become unusable due to the fact that you could pull the starter cord at the moment when the ignition was turned off, and the candle was not grounded for the mass.

Such actions can easily disable magneto. In such a situation, the only way out is to buy a new magneto.

How to correct the ignition coil on a trimmer for grass

Internal combustion engines are installed not only in cars or bicycles. They are widely used in various tools, for example, in chainsaws or a trimmer for grass. In the case of faulty, incorrect launch, it is often enough to set the correct gap between the flywheel and the ignition coil.

Attention was found a very popular way to reduce fuel consumption! Do not believe? A mechanic with 15 years of experience also did not believe until he tried. Now he saves 35,000 on gasoline during the year! Read more “

Not so complicated car by itself. But it is important to have at least some knowledge to find and eliminate any shortcomings.

Modern electronics developed so much that it made a revolution in the world of tools. The chainsaws of our time are light, but powerful, equipped with electric ignition systems.

In recent years, the ignition systems of chainsaws have been cam type. This had many shortcomings: he was heavy, complex, expensive and much, much more. The main drawback of archaic accounting ignition (software) is the complexity of the plant. Some models of accounting (soft) saws could not produce enough sparks for flash at a speed of crankshaft rotation.

Modern accounting software practically no problem. The models drank light and very durable, the coil is more skillful and takes a smaller part. But there are problems, but in most cases they can be eliminated with your own hands.

Consider the main types of malfunctions of chainsaws associated with the flywheel and ignition system.

One of the most common problems of modern chainsaws is the lack of spark ignition. This is directly related to the gap between the cylinder and the flywheel.

How to set up input blades, Partner, McCullock, Jonshed, Magneto gap

The most common installation malfunctions are always associated with the internal combustion engine. Problems arise in the ignition system, the fuel fuel module and the internal components of the engine itself.

As for the other components of the chainsaw, the malfunctions arise due to the failure of the brake mechanism, the lubrication system, etc.D.

If difficulties with the launch are associated with the engine, then in most cases the following symptoms are observed

- The engine does not develop sufficient power;

- does not start at all;

- begins, but quickly stops;

- unstable work.

As before, experts advise identifying the causes of defects by eliminating. In other words, it is necessary to go through the entire chain, diagnosing each node, each link.

NW non-working saw is a common reason, due to employment, the tool engine does not start. In most cases, it is recommended to start a search for a problem from this place.

Lawnmower Coil Pack Sparking System. Induction Coil, Transistor, Electrical System Works!

- First, check the spark plug, carefully disconnecting the spark plugs from the head and twisting the candle from the nest with a wrench;

- The second step is to check the spark of ignition by twitching the starter with the cap of the ignition wire, worn on the spark plug;

- Our article is devoted to checking this gap (more below).

A faulty spark plug indicates a faulty spark plug. Wet spark plugs for ignition of the fuel-air mixture indicate that there is actually too much fuel in the system, the carburetor is incorrectly adjusted or there are problems in SZ.

Check the spark plug only after drying it. T.e. Wipe it well with a napkin, dry the internal combustion engine, shut up the feeder, and then run the starter several times to release excess fuel consistency.

Then the spark plug is installed in place, and the client receives another check.

In general, the spark plug can tell a lot about the entire ignition system. If there is a dark carrier on the spark plug, this indicates a malfunction in the gas supply lines. Either the ratio of gasoline and oil is wrong, or the carburetor needs to be adjusted. Sometimes it is also caused by poor oil.

The polluted light of the ignition is cleaned of dark carbon deposits with a needle, as any other sharp object is called. Then the electrode is cleaned with sandpaper until the iron glow appears. The sparking returns to the place where it should be checked again.

Next step: checking spark. The sparkmer’s saucer is fed to the cylinder, the starter is launched. If a bluish spark is visible at a length of 2-3 mm, this is normal for our client. Skarer passing 0.5-1 mm is already considered a malfunction. Maybe there is no spark at all, this is also a big problem. Perhaps the case is a faulty wire.

This leads us to the topic of our article. The chainsaw may not be launched due to the gap between the ignition and the magneto Makhovik. This very gap at the moment is 0.2.7 mm. This is easy to check: there is a special seal between the flywheel and the flywheel. If he sits normally, slightly free and tight, then the gap is normal.

The flywheel is round, and it is impossible to check it using the gap meter. It would be better to check the backlash with a special device, but it is not often possible to buy it. And to take a template that is expensive, not everyone can do for a one.time implementation.

But instead of the overseas template, use a cut strip from a 1-2-liter plastic container for juice.

Checking the ignition coil without an engine (Lifan190FD)

A homemade template looks as follows:

Advice. It is recommended to cut a plastic strip in places where there are no embossed tubercles.

Magneto, Babbin, module. this is a coil of the ignition coil. This may not be related to the ablous of the tool, and the reason may consist exclusively in the gap or in some other way. Sometimes, however, the cause of the malfunction is the coil itself.

To check the coil itself, as in the case described above, use the method of excluding the elements from the chain. Or, speaking differently:

- Visually check the condition of the body for the presence of cracks and other visible defects;

- Check the cleanliness of the current compounds of individual components and parts;

- diagnose the isolation and serviceability of the armored pipelines, reliability of the mount, the absence of rust, etc.D;

- Visually assess the condition of the spark plug nest;

- Check the serviceability of the spark plug;

- diagnose a circuit breaker, which is especially important for Chinese.made chainsaws.

Malfunctions and elimination of problems

Electric and gasoline trimmers for grass have general malfunctions and defects. In the case of equipment with an internal combustion engine, this is:

- problems with the carburetor;

- Engine failure;

- Problems with the fuel system;

- failure of the gearbox, starter, muffler;

- sabo;

- air filter malfunction;

- Problems with ignition coil.

Electrical equipment has certain units:

In case of simple problems, you can repair a trimmer for grass with your own hands.

Why is your trimmer not starting for grass

The most common reason that the machine does not start is the use of low.quality fuel. The choice of gasoline of the brand below the AI-92 can lead to damage to the machine. If the used fuel of good quality, look for other reasons. For this, all nodes and systems are carefully checked. The following components must be checked:

The device may not turn on after a long period of inaction. Before starting a trimmer for the grass, carefully read the operating instructions. There are solutions to many problems.

If the trimmer for the grass stops when you press the gas pedal

There are several reasons why the trimmer for the grass stops on the throttle:

- The first reason is the malfunction of the carburetor.

- Flaw valve clogging.

- Clotting of the check valve.

- The weakened and unimportant hose of the carburetor or the weakened fuel intake hose.

To avoid the problems described above with the mower, carefully inspect the condition of the machine and its components. Timely cleaning and washing of the car and its parts will extend the life of the machine.

Starter malfunctions

The most unpleasant starter malfunction occurs when the cable breaks off and wound on the flywheel during engine operation. As a result, the spring may break, and the pulley is torn. In this case, only a complete replacement of the part will help. This type of refusal is rare. frequent cases are:

In this case, the starter is easy to repair on its own. The manufacturer has prepared a step.by.step instruction for this.

Repair of the gearbox

To maintain a gearbox of an electric braid for grass in good condition, it must be lubricated in a timely manner. Otherwise, the gears can be quickly worn out, and the transmission module can jam.

The main malfunctions in the transmission of a trimmer for grass

- Strong heating of the transmission node due to the use of a small amount of lubrication or its absence;

- The shaft was jammed due to rotating worn bearings;

- Staggering or slipping the shaft of the gearbox assembly due to damage to the housing;

- The inability of the output shaft rotate along with the disk due to wear of the teeth on the gears.

Most of the gearbox failures are caused by the destruction of bearings.

This is due to the use of poor-quality lubrication or its absence. Another reason for the breakdown of the gearbox is when a trimmer for grass is used at the limit of its capabilities and extraneous objects get inside. To replace a faulty bearing, it is necessary to disassemble the gearbox.

Features of electric models

Models of trimmers with an electric drive from the network have several main blocks

Each electric trimmer for grass has certain disadvantages. In the mechanical part, they depend on the fishing line used as a cutting element. Reasons for the termination of work:

The electric part of the braid braid can be found using the tool:

To solve this problem, use a cutter.

- damaged power cord;

- problems with an outlet and fork;

- damaged control handle;

- The starter solenoid burned, it is necessary to replace the engine;

- Damaged contacts can be repaired independently using a soldering iron.

These are the main reasons why there may be no spark on the trimmer.

How to adjust the ignition on the Patriot lawn mower

Self.healing chainsaws: analysis of the main malfunctions and ways to eliminate them

It would seem that a chainsaw for an elderly person who grows vegetables and fruits, or for the owner of a country house, who has a small garden and several flower beds? The question disappears when there is a desire to build a bath, repair a greenhouse, throw an old business or just make a bench. Unfortunately, each mechanism must be periodically prevented and replaced, and the structure of the device is well understood, and the repair of the chainsaw will save you time and money.

Structural elements of chainsaws

All chainsaws are similar in structure, regardless of whether they are European (Echo, Stihl, Husqvarna) or domestic (Cedar, Ural). The main elements are located inside the case. fuel tank and engine, and outside. starter, pen, saw (tire) with a chain. The engine starts with a sharp jerk of the cable, and this is a saw blade.

To begin with, with a video showing how a chainsaw is made and how it works:

From time to time there are malfunctions in the work of saws, the removal of which requires disassembly. What can happen to such a simple mechanism as a chainsaw? At least the following:

Most problems are associated with engine failures (fuel system, exhaust gas production system, ignition, part of the cylinder with a piston) or malfunctions of other systems and components (clutch, chain, tire, lubrication system). Consider the most common malfunctions and ways to eliminate them.

The chainsaw is launched by one jerk and does not miss the cutting

Checking the ignition system

The first thing to do when the chainsaw is destroyed. This is to check the spark plug by turning off the wire and carefully twisting it with a special key.

The components of the ignition system of the chainsaw: 1. flywheel with magnets, 2. ignition module, 3. Spend of the ignition, 4. High.voltage wire

Turn the spark plug to check its condition.

- Dry. Most likely, the fuel mixture does not fall into the cylinder. This is not about the ignition system, so the candle is twisted back.

- Very spray of fuel. The cause of the excess of the fuel mixture is either a violation of the launch rules or the incorrect adjustment of the carburetor. The spark plug is thoroughly lost, the fuel supply is turned off, and the starter is turned on. To remove excess fuel and ventilation of the combustion chamber. Then the candle is put in place and the mechanism starts again.

- It was covered with black soot. This may indicate the use of poor oil, incorrectly adjusted carburetor or incorrectly calculated gasoline ratio to oil. The candle should be washed, cleaned of carbon deposits with a sharp object (awl or needle), wiped with electrodes on the skin and replaced.

When checking the candle, you should pay attention to the gap between the electrodes: from 0.5 to 0.65 mm is considered normal. Damaged or worn gaskets must be replaced.

A large amount of black soot on the spark plug indicates an engine malfunction

You must also check the presence of a spark for complete confidence. To do this, place the ignition cable on the spark plug, connect the nut and cylinder of the spark plugs to the pliers, start the starter and follow the spark. If it is not, the candle should be replaced. If a new candle also does not produce a spark, the problem is in a high.voltage wire or the absence of connection to the candle.

- Fuel filter pollution. Remove the fuel hose and check for fuel leakage. If the stream is weak, you may need to clean the filter. It is removed through the hole in the fuel tank and is cleaned, and in the case of severe contamination, it is replaced by a new. As a prevention, it is recommended to replace the fuel filter every three months.

- Clogged breathing tube (holes in the lid of the fuel tank). In addition, check that the needle is removed by removing the hose in case of blockage.

- Deficiency or lack of fuel. There may be several causes of the malfunction. The first reason. Clotted air filter. The air stops entering the carburetor in the required quantity, and therefore, due to the too rich fuel mixture, the engine fails. The contaminated filter is carefully removed, cleaned and washed with water, then dried and replaced.

Another reason. Carbon displacement. Adjustment is carried out by three screws.

Timely replacement of the fuel filter provides a complete supply of fuel

The fuel hose and the fan drive should be tightly adjacent to the valve.

The throttle control cable should be in place

You must follow the instructions during work, otherwise you can only do it worse.

And the last reason is a violation of the integrity of the membrane or clogging of the ducts of the carburetor.

In order to repair the carburetor on your own, you need to familiarize yourself with all its details

All details should be clean, dry and intact.

Removal and cleaning of muffler

If the engine works smoothly at low speeds and begins to linger at high speeds, the reason may be that the muffler of the spark plug is clogged with combustion products.

- remove the muffler;

- disassemble (there are inseparable models);

- clean the precipitate with detergents;

- dry;

- Install in place.

Dry cleaning is unacceptable, because there are carcinogens in the sun that can inhale and are dangerous to health. After removing the muffler, the exhaust hole is closed with a clean cloth.

Malfunctions of chainsaws indicate a possible clogging of the muffler

To prevent clogging clogging, it is necessary to monitor the composition of the fuel mixture. The amount of oil should not exceed the level recommended by the manufacturer. Low quality of oil also negatively affects engine performance.

Assessment of the state of the cylinder-piston group

Often the engine does not start or does not work at full power due to low pressure in the cylinder. This can be caused by the wear of the piston or cylinder, the fall of the piston rings, the wear of the bearings. It is possible to partially consider the condition of the cylinder-piston group (CCG) by removing the muffler and looking into the hole.

A compressor located in the spark hole will help measure compression in the engine. Measurement results can also talk about the state of CPG. Accurate data is obtained only after a complete disassembly of the mechanism. If there are chips or scratches on the piston, it must be replaced. The piston ring should be clean, without carbon and exactly in place.

Wear of the piston and crooked-shaped mechanism is a serious problem.

Compression measurements can be used to assess the condition of parts.

Repair of the chain lubrication system

- Oil leak. Make sure that the pipes are tightly connected to the reinforcement of the pump and that there are no cracks on them. Problem tubes are sealed or replaced.

- Insufficient oil consumption. Most likely, lubrication channels are clogged.

- Cracks in the oil pump housing. The details of the part are required.

Material is also useful on how to sharpen a chain saw: https: // Diz-CAFE.COM/Tech/Kak-Zatochit-Cep-Benzopily.HTML

Here’s how to diagnose a lubricant system:

Brake circuit adjustment

Brakes often do not work due to clogged oil or sawdust of the brake tape and space under the hood. All parts should be cleaned of garbage. The tape may be simply worn out, and you must replace it.

Chain brake is restored by mechanical cleaning.

Some parts of the chainsaw wear out faster than others. These include the leading star, tire, chain, anti.vibration elements. For quick replacement, it is better to always have spare parts at hand. Do not neglect the sharpening of the chain.