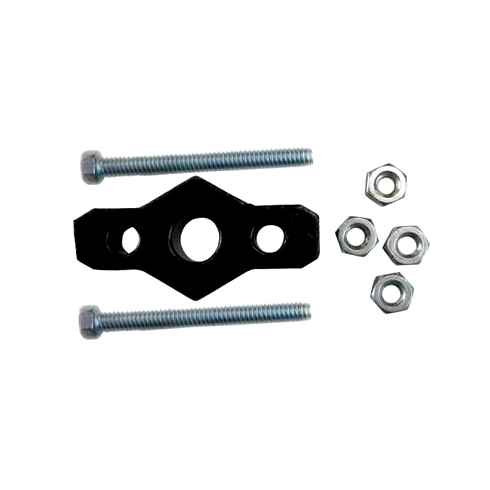

Push mower flywheel removal. Briggs And Stratton 19069 Puller-Flywheel (Briggs Oem Part)

Briggs And Stratton 19069. Puller-Flywheel (Briggs Oem Part)

Payment methods

SKU: 19069 UPC: 024847760866 MPN: Condition: New Availability: Ships (leaves our warehouse) within next business day if in stock Category: Miscellaneous/Puller

Cancer and Reproductive Harm. www.P65Warnings.ca.gov

069 BRIGGS STRATTON Briggs And Stratton Puller-Flywheel (Briggs Oem Part)

Briggs and Stratton 19069 Puller-Flywheel is a genuine OEM part designed to fit a variety of Briggs and Stratton engines. It is designed to help remove the flywheel from the crankshaft. This reliable and durable part is an essential component for any Briggs and Stratton engine. It is easy to install and requires minimal maintenance. With its superior quality and performance, this Briggs and Stratton part is the ideal choice for anyone looking to repair or replace their engine. Get your Briggs and Stratton 19069 Puller-Flywheel today and ensure your engine is running smoothly.

Briggs Stratton lawn mower engines are the perfect choice for your mowing needs. With a wide range of engine sizes, from small to large, you can find the perfect engine to fit your mower. Briggs Stratton engines are durable and reliable, and they offer a variety of features to make your mowing experience easier. Plus, they have pullers to help you change the blades and other components quickly and easily. With their reliable and efficient engines, Briggs Stratton lawn mowers will help you get the job done quickly and easily. So if you’re looking for a reliable and efficient lawn mower engine, look no further than Briggs Stratton.

When it comes to Briggs and Stratton 19069. Puller-Flywheel (Briggs Oem Part), it is important to buy original parts to ensure the highest quality and performance. Original parts are designed to meet the exact specifications of the manufacturer, providing the best fit and performance. Original parts are also designed to last much longer than aftermarket parts, saving you money in the long run. Additionally, original parts are tested for safety and reliability, so you can be sure that your equipment is running safely and efficiently. Buying original parts is the best way to ensure that your Briggs and Stratton 19069. Puller-Flywheel (Briggs Oem Part) is running at its peak performance.

At Briggs Stratton Store, we offer the highest quality original parts for your Briggs and Stratton engine. We have a wide selection of parts to choose from, including the Briggs and Stratton 19069. Puller-Flywheel (Briggs OEM Part). Our parts are guaranteed to be genuine and of the highest quality, so you can be sure you are getting the best value for your money. We also provide expert advice and technical support to help you get the most out of your purchase. With our commitment to customer service, you can rest assured that you will be taken care of when you shop with us.

Since 1971, we have been providing quality BRIGGS STRATTON replacement parts. Our extensive experience in the industry has enabled us to become a trusted source for all of your BRIGGS STRATTON replacement needs. We offer a wide selection of parts, from small engine components to complete engines, so you can find the exact part you need for the job. We are committed to providing the highest quality parts and the best customer service possible. Our knowledgeable staff is here to help you find the right part for your needs and answer any questions you may have. With our decades of experience, you can trust that you are getting the best BRIGGS STRATTON replacement parts available.

BRIGGS STRATTON Briggs And Stratton Puller-Flywheel (Briggs Oem Part) Specs

Part Manufacturer: BRIGGS STRATTON

Product Number: 19069

This Product Replaces:

The Briggs Stratton Briggs And Stratton Puller-Flywheel (Briggs Oem Part) is a tool designed to remove the flywheel from Briggs Stratton engines. It is designed to fit a variety of Briggs Stratton engines, including the Vanguard, Intek, and Professional Series engines. The Puller-Flywheel is made of durable steel and comes with a variety of accessories, including a wrench, a puller bolt, and a puller cap.

19069 Briggs And Stratton Puller-Flywheel (Briggs Oem Part) Manual and additional information

If you are unsure if a part is the correct one for your needs, you can always consult the parts manual section of the product or contact our knowledgeable customer support team. Our team is trained to help you find the right part for your needs and can answer any questions you may have. With our help, you can be sure you are purchasing the correct part for your needs.

If you’re looking for parts for your BRIGGS STRATTON equipment, you can find them in the fast moving parts section or by looking up specific equipment models in the parts lookup. You’ll be able to find the exact parts you need quickly and easily, so you can get your equipment back up and running in no time.

Briggs And Stratton Flywheel Nut Size

The flywheel on your small engine holds the momentum created by combustion in order to keep the crankshaft spinning between power strokes. By dispersing air around the engine block, the fins help cool. The fins also blast air across a pneumatic governor’s air vane, ensuring that the engine speed remains constant.

Finally, if a lawn mower or tiller blade collides with a rock or curb, the flywheel key may absorb the damage, considerably lowering replacement expenses. Always inspect the key and the keyway, which is the key’s slot on the crankshaft, for damage by removing the flywheel. The soft metal key removes any play between the flywheel and the crankshaft.

A flywheel key could be simple to remove, yet as with any engine, and not only Briggs Stratton lawnmowers, the flywheel can be hard to remove. To do so, the use of a flywheel puller is needed.

In our guide, you can learn the Briggs and Stratton flywheel puller bolt size. By the end, you’ll also find a guide how to remove the flywheel from your mower. (Read Briggs And Stratton Oil Capacity Chart)

What Size Bolt Is On A Briggs and Stratton Flywheel?

Briggs Stratton small engines, are found in lawnmowers, rototillers, and snow blowers. Each model can use a flywheel-based ignition method.

Magnets on the flywheel’s side spin past the ignition coil, telling the coil to ignite the engine by sending an electrical charge to the spark plug.

If the engine flywheel is broken and needs to be replaced, as well as if you need to access the ignition parts and components, it must be removed.

A simple socket wrench set will suffice for the most of the job, but a specialized flywheel pull tool will be required regardless of model. (Read Briggs And Stratton Engine Starts But Won’t Stay Running)

Flywheel Removal Tips

Do flywheel bolts have reverse thread?

The thread on the flywheel bolt/nut is standard (right tight, left loose). So, anything that prevents the flywheel from turning will suffice.

How should I remove the flywheel on a Briggs and Stratton engine?

Some Briggs engines include a flywheel clutch holding the flywheel in position. Others only have a cup and retaining nut to keep the flywheel in place. To keep the flywheel from sliding, unscrew the flywheel retaining nut with a socket wrench while gripping the flywheel with a strap wrench. (Read our Briggs And Stratton Snow Blower Reviews)

How can I remove the flywheel from the crankshaft?

Grab the flywheel strap wrench tightly and alternately but equally tighten the flywheel puller bolts with a socket wrench to remove the flywheel from the crankshaft.

After the bolts are evenly tightened, the flywheel will pop free from the crankshaft. With the flywheel strap wrench removed, lift the flywheel off the crankshaft.

Latest Posts

We are reader-supported and this article may contain affiliate links. As an Amazon Associate, we earn from qualifying purchases. This does not cost you anything

Engine Kicks Back When Starting – Check this first!

When you experience kickback, you won’t mistake it for anything else. Kickback is when you pull start your mower, and the pull cord is snapped from your hand. It can sometimes whip you as it does so, which is Oouch.

A lawnmower engine commonly kicks back when the shear key breaks. The shear key commonly breaks because the blade has kit a solid object and come to a sudden stop. Common symptoms of broken shear key include:

Before I describe the repair, it may be helpful to know a little about engine timing, don’t worry, I’ll keep it short.

Engine Timing

Timing maintains a mechanical set relationship between internal engine components and firing the spark plug at the optimum time. When the timing is out/off, you run the risk of severely damaging the engine.

Timing is vital for a few reasons. When the timing is out a lot, the mower won’t start. If the timing is out a little, your mower may run but run rough. A broken shear-key is, as you now know, the most likely cause of engine kickback. The repair procedure isn’t complex, but a few techniques need to be followed to nail this repair successfully.

If you need video help, check out “Shear-key replacing video”. It walks you through the whole process step by step, from checking the shear-key, tapping removing the flywheel, fitting the shear-key, torquing the flywheel, and setting the armature air gap.

Kickback – The recoiling of the pull cord stings a lot.

What Is A Four Stroke Engine?

Most lawn mowers are fitted with a four-stroke engine, and like all engines, they have a set sequence of operation. The main components involved with timing the engine are crankshaft, piston, flywheel, camshaft, valves, coil, spark plug.

Four-stroke engines are more reliable, live longer, quieter, and cleaner than two-stroke engines. So-called four-stroke, as it has four distinct stages in a complete cycle.

How does four stroke Work?

First Induction – piston travels down the cylinder and draws air/fuel mix in through the open inlet valve.

The second Compression – the piston starts to travel back up the cylinder and closing the inlet valve, creates a sealed, air/fuel compressed cylinder.

Third Power – the piston is now past Top Dead Center (TDC) and starting to turn back down the cylinder as soon as the piston is past TDC, the spark plug fires which sends the piston down the cylinder under power.

Forth Exhaust – the piston turns back up the cylinder, the exhaust valve opens, expelling the spent gases out the muffler, and the sequence starts over.

Valves – Rockers open and close valves as the engine moves through the cycle.

When Engine Timing is Out

So when the timing is out, lots of things don’t happen when they’re supposed to. Valves don’t open or aren’t closed. But most importantly, the plug doesn’t fire at the correct time. The engine is designed to run clockwise and fire the plug only when the piston is past TDC (third stroke power).

Firing the plug before TDC causes the piston to try and go back down the cylinder, working against clockwise crankshaft momentum. That’s when the pull cord is snapped from your hand. This has the potential to bend or break internal engine components not to mention your arm.

Firing too soon – When the timing is off, it means the plug is firing outside its narrow window of operation.

It’s firing too soon and that causes the piston to reverse, causing the crank to turn counterclockwise and snap the pull cord from your hand as it does so, Ouch!

What Is A Shear Key?

The Shear key is a small block of aluminum, so-called a key because it fits in a slot (keyway) cut from both the crankshaft and flywheel (see pic). The whole point of a shear key is to shear (break) when needed. Sounds odd I know.

Keyway – Crankshaft and flywheel keyway

When a mower blade, attached to the bottom of the crankshaft, hits something solid, the engine stops dead. The flywheel attached to the top of the crankshaft has mass and inertia will force it to turn, it’s at this point the shear key does its job and uncouples the flywheel from the crankshaft by shearing.

If the shear key wasn’t fitted, the crankshaft would most likely twist, this puts the timing out and the only fix is to replace the whole crankshaft. This isn’t a small job and really the engine is junk.

Shear key – New and damaged

How To Replace The Shear Key

Now the good news, the flywheel shear key is probably the cheapest part you can buy for your mower. The fact the key has sheared means your engine has been saved. Of course, the timing will need to be reset, and fitting a new shear key will sort this.

Fitting is mostly straightforward. However, you’ll need a socket set, torque wrench, and a flywheel puller. While it is possible to remove the flywheel without the pullers, it risks damaging the engine and isn’t always successful. In any event, a puller isn’t expensive, and you can find a link to a quality Briggs Stratton puller here on the “Small engine tool page” or check out the Amazon link below.

Wire Off – Remove the plug wire to disable the mower and turn off fuel. Remove plastic engine cover, couple of screws usually.

Remove – Remove engine cover and blower housing assembly.

Paint – Mark the nut in relation to the crankshaft. This lets you know how far to tighten if you’re not going to use a torque wrench. (A torque wrench is preferred)

Block – Use a block of wood to wedge against the blade to prevent the engine from turning as you loosen the flywheel nut.

Alternatively use an impact tool or use a piston stop tool, you’ll find all these tools on the “Small engine tools page”.

Loosen – Loosen the flywheel nut, and remove, using a socket set.

Check – At this point, you can confirm a shear key is your problem, the key ways don’t align. However, I’ve worked on mowers with kickback and found the shear key to be good. This, unfortunately, means that the crankshaft has twisted, it’s rare. Replacing a crankshaft may not be economically viable for some mowers.

Spray the keyway with WD40 and let it soak while you remove the coil.

Remove – Remove the coil by removing two bolts. Set the coil to one side no need to remove the wire connector. When reassembling, an air gap must be maintained. It’s all covered here, check out “Fitting a Coil”.

Pullers – Time to use the pullers. The pullers thread into the flywheel, however, some flywheels aren’t tapped, meaning an extra step is required to tap threads into the flywheel. A pain? Yes, but I have you covered with the “Shear key video”.

Tighten – Now go ahead and tighten the pullers, give the puller bolt a tap with a hammer if it’s not playing ball.

Remove – Remove the flywheel and remove the old shear key debris from the keyway. Check also the keyway on the engine.

Fit – Align flywheel and crank keyways, now push the new shear key into the keyway. Nice!

Tighten – Tighten nut to your mark. Or use torque wrench. You’ll need to swap the block of wood the other way to prevent the crank from spinning while tightening.

Torque to spec – Usually around 60 ft. lbs. / 80 Nm. Need help using a torque wrench, check out “Setting a torque wrench video”.

You’ll find a link to the Teng torque wrench I use here on the “Small engine tolls page”.

Fit coil – A special procedure is needed to fit the coil, it’s not difficult, it’s all covered here “Fitting a coil”. Alternatively, it’s all covered here in the “Shear key fitted video”.

Blade – Check your blade and blade boss (blade mount) for damage. Make sure it’s secure. A common symptom of a bent blade is excessive vibration. Check out the blade replacing video here.

Related Questions

Will a lawnmower start without a blade? Most mowers won’t start without the blade. The engine requires the force of the blade turning (inertia) in order to run as designed.

Lawnmower string won’t rewind? The pull cord recoil spring is worn or broken. A new spring can be fitted, often replacing a complete pull assembly is easier.

Hey, I’m John, and I’m a Red Seal Qualified Service Technician with over twenty-five years experience.

I’ve worked on all types of mechanical equipment, from cars to grass machinery, and this site is where I share fluff-free hacks, tips, and insider know-how.

And the best part. it’s free!