We Sharpen The Chainsaw Chain Ourselves With A File

How to sharpen a chainsaw chain with your own hands at home: an angle grinder, a file and on a machine How can you sharpen a chainsaw chain at home. Advantages of DIY methods.

Using a conventional angle grinder

Most owners avoid this method of direct sharpening of the chain, since they believe that such a tool can severely damage the cutting teeth. Over, this method is the most difficult of all existing today. Such fears are not taken, as they say, out of thin air, since in fact, a chainsaw can be hurt, especially if you are a beginner in this matter.

For this reason, if you are going to perform this kind of manipulation for the first time, then the best you can do is use the method presented above. But, nevertheless, we will still introduce you to the direct features of the chainsaw using this method.

And so, in the process of sharpening do not remove the chain from its place, since the manipulation is carried out on the chainsaw. It is also important that it is necessary to use a special disc that can work with metal material and the diameter of which must be at least 2.5 mm. But remember that in no case should the disc be new, but rather used and have rounded edges.

It is also important that you yourself can determine a right angle, by means of which sharpening will be performed. Remember that a wedge must be installed between the chain and the lower part of the bar, namely a wooden one. This process requires immediate skills. This is a very effective way and with such an ode of sharpening the chain will be able to serve you from 4 to 7 such manipulations.

How to sharpen a chain on a machine at home

Additional recommendations

First of all, you must remember that before making a direct sharpening, it is necessary to determine its level, starting from the most, let’s say, “dull” cutter, since it is a kind of reference point in this process.

It is also important to remember that you do not need to get too carried away with manipulation and deeply grind your chain. Since in this way you will simply violate its direct functionality, and its immediate strength and the strength of the link will decrease as well.

It is also important that most experts recommend, after direct sharpening, blowing the chain itself by using compressed air. And after such a process, put it in oil for several hours, but it must be clean.

In contrast, coal sawmills are industrial equipment used in woodworking.

Those who do not want to buy a circular sawmill can do it themselves. Read about this in our article.

File and chainsaw. A successful tandem!

Remember to pay attention to each link in the chain. The rule should also be taken into account that the efficiency of the saw is determined by the difference in heights: we are talking about the distance between the cutting teeth and the limiter itself. Differences in height parameters allow the teeth to cut into the tree (usually a stop tooth in its characteristics should be about 0.7 mm lower than the cutting tooth).

How to sharpen a chainsaw chain. Instructions for action

Do you want to use sawing equipment for a long time? Then take care of its timely prevention. It is necessary to sharpen the tool as needed.

How to sharpen a chainsaw correctly. We will show you the tool yourself!

A chainsaw without a normal chain belt is like a machine without a motor. This proven postulate will be confirmed by any tech-savvy person. The chain must always be well sharpened if you want to always use your chainsaw. Otherwise, she will not forgive you for miscalculations. This means that you will not see accuracy, efficiency and safety of work.

Any professional will confirm that the final result of such a laborious activity as working with a chainsaw will depend on sharpening the teeth of your tool, even more than on the motor itself. Experienced lumberjacks give the following good advice. Sharpening is necessary as the sharpening sharpness deteriorates. If you have to put in a lot more effort than before, the saw starts to cut as it pleases and changes the angle, slowing down your work, in which case you have no choice. Start sharpening.

Pay attention to the sharpness of the chain and escaping chips. If everything is in order with sharpness and sharpening, then your chips will be almost uniform, and the resulting sawdust will be square in shape. If the need for sharpening is ripe, then this will be seen by the dust in the shavings and sawdust in the form of needles.

How to sharpen a chainsaw correctly. We will show you the tool yourself!

A chainsaw without a normal chain belt is like a machine without a motor. This proven postulate will be confirmed by any tech-savvy person. The chain must always be well sharpened if you want to always use your chainsaw. Otherwise, she will not forgive you for miscalculations. This means that you will not see accuracy, efficiency and safety of work.

Any professional will confirm that the final result of such a laborious activity as working with a chainsaw will depend on sharpening the teeth of your tool, even more than on the motor itself. Experienced lumberjacks give the following good advice. Sharpening is necessary as the sharpening sharpness deteriorates. If you have to put in a lot more effort than before, the saw starts to cut as it pleases and changes the angle, slowing down your work, in which case you have no choice. Start sharpening.

Pay attention to the sharpness of the chain and escaping chips. If everything is in order with sharpness and sharpening, then your chips will be almost uniform, and the resulting sawdust will be square in shape. If the need for sharpening is ripe, then this will be seen by the dust in the shavings and sawdust in the form of needles.

How to sharpen a chainsaw chain. Instructions for action

Do you want to use sawing equipment for a long time? Then take care of its timely prevention. It is necessary to sharpen the tool as needed.

File and chainsaw. A successful tandem!

Remember to pay attention to each link in the chain. The rule should also be taken into account that the efficiency of the saw is determined by the difference in heights: we are talking about the distance between the cutting teeth and the limiter itself. Differences in height parameters allow the teeth to cut into the tree (usually a stop tooth in its characteristics should be about 0.7 mm lower than the cutting tooth).

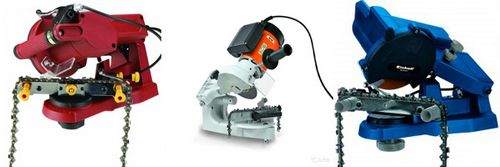

Electric sharpening machines

They are equipped with special adjustment functions to help you position the chain at a certain angle. At the same time, it is possible to accurately and accurately bring the disc to the chain teeth. There are machines equipped with automatic vices. They are switched on when the disc approaches the sharpened edge. Convenience and functionality are certainly high. You can find models at “lifting” prices.

Chainsaw teeth

Chainsaw teeth have a specific geometry. You need to understand and know what part of them should be sharpened. In general, the “logic” of cutting wood resembles a plane.

The cutting surface has two edges. One side, the other slightly beveled. The cutting depth limiter adjusts the thickness of the chips. Let’s take a closer look. The elements of the cutting-working link are arranged as follows:

- Base with axle holes;

- Tooth scapula;

- Cutting depth limiter;

- End face of the blade (placement. Vertical);

- Upper edge of the blade (placement. Horizontal);

Sharpened edge Dull After touching the ground

Do not over-grind or change the location of the links. The normal operation of the instrument depends on the identity of their location. Otherwise, increased stress on the chassis, tire and engine is likely. The cut can be crooked. There is also a small chance of breaking the circuit.

How to understand that the chain is dull

- Increased physical effort;

- Sagging (stretching) of the chain;

- Vibration and “braking” cutting passage;

- Inaccurate sawing and change in the type of sawdust (they become uneven with sharp “needle” edges, small and dusty). It already aboutAnswer the test.

“In the opinion of experts, and in my opinion too: well-sharpened teeth are more important than engine power.”

Why dull? The reasons are generally known, but I will name the main ones:

- Intense or voluminous work;

- Accidental contact with stone, earth, hard knots, etc.;

- Mishandling (broad term).