What Oil Should Be Poured Into The Chainsaw

All About Choosing Chainsaw Oil

Oil requirements for a 2-stroke chainsaw engine. Review of the best two-stroke oils from Stihl, Husqwarna. Fuel mixture, gasoline and oil ratio table. What oil to use to lubricate the saw chain.

All About Choosing Chainsaw Oil

The resource of any chainsaw, no doubt, depends on the quality of its maintenance and operation. The most important requirement for this unit is the timely lubrication of all its moving parts. Chainsaw oil is available in different types, namely: motor and chain oil. The motor is poured into the internal combustion engine, and the chain is intended for the saw chain. Let’s figure out how to choose the right oil for your chainsaw.

Stihl HP Ultra

The oil belongs to the highest category. It was created on fully synthetic base, has a green color and has high lubricating properties, and thanks to salt-free additives does not create carbon deposits.

The oil was specially developed for the lubrication of engines operating for a long time at high loads and low ambient temperatures, up to 25 ° C. In addition, this lubricant is not harmful to the environment. If spilled on the ground, it will decompose by 80% in 21 days. The grease is packaged in bottles of 100 ml and 1 liter.

Choosing engine oil

An oil intended for a 2-stroke engine must meet the following requirements.

- The lubricant must form during combustion minimum ash. Ideally, it should burn completely.

- The lubricant must have good solubility in gasoline and a high degree of purification from various impurities that can cause clogging of very narrow channels of the carburetor.

- The oil must have high anti-corrosion, anti-wear and lubricating properties.

There are certain standards for oils intended for 2-stroke engines: TC-W3 and 2T. Lubricant appropriate TC-W3 standard, used for water-cooled engines (outboard motors, jet skis). Oil 2T used as an additive in gasoline for 2-stroke air-cooled engines (lawn mowers, mopeds, chainsaws, etc.).

Motul Outboard Tech 2T Oil

When using poor-quality lubricant, the entire piston group of the engine can fail due to the formation of carbon deposits under the piston rings. As a result, they will not be able to compress, and scuffs will form on the cylinder walls. Also, improper lubrication of the bearings of the crank mechanism leads to overheating and, ultimately, to seizure. Important: it is forbidden to use diesel oil to prepare the fuel mixture, since it does not correspond to any of the above parameters.

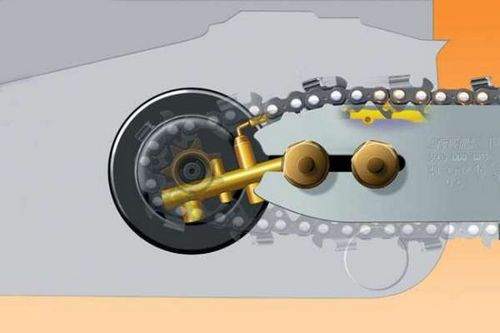

How is a chainsaw chain lubricated?

To understand further information, it is advisable to understand how the chain is generally lubricated if you do not already know this.

Every modern chainsaw has an oil pump. The oil poured into a special tank for lubricating the chain begins to swing by this pump immediately after starting and is poured through the oil channel to the oil intake hole on the tire. Through it, oil enters the groove of the tire and is carried by the chain along the entire working length of the tire, both along its top and bottom.

The main load when sawing falls on the bottom of the bar, since it is this that is applied to the material to be cut. However, the oil first hits the upper part of the tire, passes through its entire length, and then through the rounding at the end of the tire falls on the lower part. Naturally, when passing such a turn, part of the oil simply flies out of the tire and chain due to inertia. Therefore, it is important that it fly off as little as possible, so that the lower part of the bar is well lubricated and there is as little friction as possible between the chain and the bar.

Therefore, knowing this information, we can conclude that the oil for lubricating the chain must be thick enough and have good adhesion (in other words, stickiness) so that it fly out less at the rounding of the tire, and also it should not contain any particles so that it can freely pass through the oil channel without clogging it, and so that these particles do not create unnecessary friction.

All these properties are possessed by special oils for chain lubrication. They are quite thick, contain special adhesive additives, and naturally do not contain any particles. In addition, they form a kind of film between the chain and the bus, so that the chain and the bus do not actually touch each other.

The properties of these oils may vary slightly from one manufacturer to another. Those that are more expensive usually have more adhesion. But in any case, any specialized chain oil will be better than any other designed for other purposes.

Now with this information, you can answer questions about the use of other oils.

Use for lubricating the transmission oil chain

This option will certainly be better than using engine oil, since the transmission is simply thicker. However, it also does not possess the required adhesion. Therefore, although the lower part of the tire will lubricate somewhat better, it is still not good enough.

Chain lubrication workout

This option is the most disgusting. Exhaust is essentially the same engine oil, but it contains microscopic metal particles, which it has absorbed when working in the engine. These particles can clog the oil channel, and they also get clogged between the chain links and the actual tire and chain, and work there like an abrasive, because of which the tire and chain simply wear out, and the chains even break. Therefore, we also say no to working off.

Pro tips on the selection and use of chain oils

The operation of the lubrication system must be monitored periodically. Lack of oil supply can be easily identified by increased engine load and the smell of overheated wood. The crown and bearing of the driving and driven sprockets need additional lubrication.

Adjustment of oil density to external temperature factors

The use of chain oil at low temperatures up to 20 ° C negatively affects the performance of the oil pump and the durability of its drive.

In the absence of the required material, the problem is solved by diluting the oil thickened in the cold. Dehydrated kerosene is the best solvent.

Such an additive will provide full lubrication of the headset, but it is recommended to significantly limit heavy loads when the saw is operating on diluted oil.

Performance properties

Branded or standard chainsaw chain oil meets specific standards in terms of density, viscosity, debris removal and other performance characteristics.

- Organic and mineral compositions do not differ significantly in terms of working properties.

- Experienced users recommend working on organic consumables if the intervals between using the chainsaw do not exceed several days.

- The anti-corrosion and other protective properties of more expensive mineral oils are used if the tool is used for infrequent one-time work.

It is not difficult to check the oil for compliance with the external temperature, and at the same time the lubrication system for operability. To do this, hold the saw headset running at medium speed over a blank sheet of paper for a few seconds.

By the width and saturation of the oil strip, one can judge the suitability of the composition for long-term operation at a given air temperature and the performance of the built-in oil pump.

Fuel mixture: the proportion of oil and gasoline for the chainsaw

The chainsaw engine is the heart of the tool, so it is very important to use a properly prepared fuel mixture.

Chainsaw fuel mixture prepared from two components. Oil and gasoline. Chainsaws are equipped with two-stroke engines, so oil is not added to the lubrication system (like a four-stroke engine), but directly to gasoline. In this case, it is very important to observe the correct proportions of ingredients, of course, in no case try to work on pure gasoline, because in this way you will very quickly “kill” the chain saw.

If we talk about what kind of gasoline to pour into the chainsaw, then it will be optimal to use fuel with an octane number A-95, in this case, fuel savings can turn out to be deplorable. Often European manufacturers indicate that it is possible to use A-90 or A-92 gasoline, but in post-Soviet countries the quality of gasoline is inferior to that of Europe, so in our realities it is better to use higher quality gasoline.

As for the proportions of petrol-oil mixture, then everything is simple: you need to follow the instructions for the tool. All manufacturers of chainsaws indicate the required ratio in the instruction manual or in the passport of the tool, in addition, the proportions for refueling the chainsaw may differ depending on the model of the chain saw. As a rule, the proportion of oil and gasoline to a chainsaw of famous manufacturers is a ratio of 1:40 or 1:50, which means 1 part of oil for, for example, 40 parts of gasoline. Now arithmetic 1 liter of gasoline = 1000 ml of gasoline, divide by 40 and we get 25ml of oil. If you follow the same steps for the ratio 1:50, then we get 20 ml of oil per 1 liter of gasoline. As for budget chainsaws made in China, the situation is slightly different. The ratio of gasoline to chainsaw oil made in China 1:25, that is, divide 1000 ml of gasoline by 25, we get 40 ml of oil. The thing is that in branded chainsaws, a solid assembly and the distance between pistons and cylinders in the engine is much less than that of Chinese chainsaws, therefore, the required amount of oil differs almost twice.

Use a conventional medical syringe with sufficient volume to measure the correct amount of oil.

Another subtlety. First fill the dry gasoline can with gasoline and then oil. The procedure, on the contrary, is fraught with a low quality fuel mixture, because the oil is more dense, it will stick to the bottom of the canister. What a good mixing there is.

Be sure to prepare the fuel mixture in a canister and pour ready-made special fuel into the gas tank! Never cook or mix it directly in the fuel tank of your chainsaw!

If you figured out the question of how to breed gasoline for a chainsaw, then storage conditions and shelf life of the fuel mixture it is worth saying a few words. It is best and easiest to prepare a petrol-oil mixture for 1 liter of gasoline, it is recommended to do this immediately before working with the tool. Chainsaw fuel tanks have a volume of 0.3 to 1 liter. In the conditions of domestic use, the entire volume of the prepared combustible mixture is rarely used in one session, so the remainder can be saved until the next session. It is necessary to store the fuel mixture in a special canister for gasoline, in a dry, dark place. It is optimal to count that shelf life of the finished mixture will be 7-10 days. The fact is that the oil on the market now is not synthetic, but organic, that is, natural. After 10 days, all lubricating properties are lost, gasoline simply “eats” the oil. Naturally, it is no longer possible to use such fuel, this can cause breakdown and failure of the chainsaw.

At the end of the work, it is necessary to drain the fuel mixture, start the chainsaw, the tool will stall (so that the saw has a dry carburetor) and now you can leave it until the next operation.

Dispose of unsuitable fuel mixture.