Best Portable Jump Starters For Lawn Mowers. Starter for lawn mower

How Lawn Mower Starter Works? The Ultimate Guide

Whether it is a lawnmower or other automobile, no engine can start unless it has a significant amount of power.

So, how lawn mower starter works? The engagement of the flywheel is essential to start the mower. The battery plays a major role in sourcing the power and involves the flywheel. Then the crankshaft begins to spin, which is supported by the flywheel. Unless you press the solenoid button, you can’t switch on the starter motor.

In this article, we will share how lawn mower starter works in detail. Read until we finish to learn some precise information about it. Keep scrolling!

- How Lawn Mower Starter Works?

- How To Bypass the Starter Solenoid?

- Step 1 — Checking The Battery

- Step 2 — Switching On The Ignition Key

- Step 3 —Finding Out The Lawnmower Solenoid

- Step 4 — Identifying The Copper Posts

- Step 5 — Cleaning The Terminals

- Step 6 — Giving A Final Finish

- Defective Battery

- Clean Leads

- Spark Plugs Issues

- Functioning Starter Solenoid

- Defective Battery

- Defective Solenoid

- Defective Ignition Switch

- Defective Starter Motor

- Warning

- Step 1 – Disconnect Your Negative Cable

- Step 2 – Put a Bit of Loctite

- Step 3 – Install The Positive Battery

How Lawn Mower Starter Works?

After turning on the lawnmower mower ignition key, the engine starts to turn in motion and cranking. Do you think cranking is a simple process? No! It is a complicated process-not as easy as you think.

Unless there is the right level of air inside the engine, you will struggle to start it. No turn for the machine will occur if there is no airflow.

So, how does free airflow is achieved inside the engine? When the motor turns over and over, it creates suction. This helps to pass air inside the machine. If there is no air, the combustion of fuel won’t occur.

You can compare a lawnmower starter with a key of a locker. You are supposed to use the key to unlock the locker and then enter inside it.

After turning on the ignition key, the starter should work smoothly to turn over the engine. Only then can you start your lawnmower. When the starter works smoothly, you can do other things.

Lawnmower engines feature a flywheel that is mounted on the ring gear, and the crankshaft end is connected to it.

There is a pinion gear on the lawnmower starter, which is mainly located in the grooves of the ring gear.

The lawnmower starter receives energy after turning on the ignition key. The engagement of electromagnet also occurs.

A rod is pushed out from beneath the pinion gear that is connected to this. When the gear reaches the flywheel, the lawnmower starter will turn over.

As a result, the main engine will start spinning to collect air. Concurrently, spark plug wires convey electrical current to the plugs, and the combustion chamber receives fuel by the ignition process.

The starter disconnects once the engine is turned. Also, the electromagnet, which sends electricity through a coil of wire stops.

The rod pulls back into the lawnmower starter for another time to keep out of reach between the flywheel and the pinion gear.

If there is any connection between the pinion gear and the flywheel again, a Rapid engine spin for the starter will occur. It will ultimately cause damage to the starter.

So, this is the way how lawn mower starter works. Knowing the mechanism gives an entire idea of each part of starter functions and how they contact each other.

How To Bypass the Starter Solenoid?

Apart from knowing how lawn mower starter works, it is essential to understand how to bypass the starter solenoid.

Are you getting a clicking sound from your lawnmower but failing to start the lawnmower? The problem might be related to the starter solenoid or starter motor.

So, why does this happens? It mainly occurs when the starter solenoid is attempting to push for the engagement of the lawnmower machine. But, it may not happen if the starter solenoid doesn’t have enough power to move the gear for engagement. Also, the issue may seem if the starter solenoid becomes excessively cold.

One of the best methods to deal with this issue is by bypassing the starter solenoid. Wondering how to bypass the starter solenoid? Check out this step-by-step procedure to learn about how to bypass the starter solenoid.

Step 1 — Checking The Battery

First of all, you want to test the battery conditions whether it is working perfectly or not. You can use a multimeter or a battery tester to test it. The battery is supposed to read 12v if no issue with it. If it is okay, follow the next steps.

Step 2 — Switching On The Ignition Key

Try to turn on your lawnmower by pressing the “START” button. Despite receiving power, sputter would not begin

Now, you want to keep the ignition in the “RUN” option. By doing so, you allow the battery’s current to pass through the circuit.

Step 3 —Finding Out The Lawnmower Solenoid

Give your hands on the battery, which is mainly located below the mower seat. Now, find out the cable which is connected with the positive terminal. A cylindrical structure is attached to the positive terminal and has three or four wires connected.

Lawnmower solenoids either come with three-pole or four-pole. Common ground is connected to the three-pole solenoid, which is mounted on the mower. On the other hand, a special terminal is included for the ground on four-pole solenoids.

Step 4 — Identifying The Copper Posts

Two big terminals are equipped for a lawnmower solenoid, and each of them has large cables connected to them. One cable is connected to the battery’s positive terminal while the other one goes to the motor. In this case, these two huge

Step 5 — Cleaning The Terminals

Rust and dirt may store inside the terminals. You want to use a wire brush to get rid of them from inside and outside.

Step 6 — Giving A Final Finish

Now, you want to attach the positive terminal from the battery to the motor using a screwdriver. A complete circuit can be built this way, and the lawnmower will then start.

So, these are the complete steps of knowing how to bypass the starter solenoid.

What Are the Symptoms of a Bad Starter Motor on a Riding Mower Engine?

A riding mower engine is supposed to start smoothly if there is no issue with the starter motor. However, if there is an issue, you may struggle to start it or stop within seconds after running. What are the symptoms of a bad starter motor on a riding mower engine?

How to jump start using your NOCO Boost GB40

Here are the few common signs you will notice if you are wondering about,” What are the symptoms of a bad starter motor on a riding mower engine?”

Defective Battery

Is the lawnmower battery working perfectly? Does it produce a sufficient amount of voltage? To learn about it, you want to use a battery tester or a millimeter to find out the voltage it is generating.

Each lawnmower battery must have enough voltage to help the starter motor to start the engine. If it doesn’t have enough voltage, you want to recharge or replace the battery.

Clean Leads

Clean leads are necessary for the positive and negative wires, which are connected to the battery. With dirty leads, your lawnmower won’t be able to make nice electrical contact.

Make sure you regularly remove any corrosion or dirt from the cable clamps or battery posts using a wire brush.

Spark Plugs Issues

Have you checked the spark plugs of your lawnmower? They need regular cleaning for smooth operation. Check out any wear or fouling on spark plugs after removing the wires connected with them.

Carbonized or oily spark plugs can be the reason behind a bad starter motor. If your spark plugs are oily, it means piston rings already got damaged. Hence, changing spark plugs will not solve the problem unless you replace the piston rings.

However, replacing is a better option if you notice any wear or damage issues on the spark plugs. Start your lawnmower to see whether the lawnmower is working perfectly or not.

Functioning Starter Solenoid

A place between the starter and the battery is where the starter solenoid is located. It is a special switch. When you turn on the button, electric power is transferred to the starter motor to run the lawnmower engine.

So how do you test whether your starter solenoid is bad or good? After turning on the ignition key of your lawnmower, the starter solenoid jump. And, at the same time, closing the space between the two bolts on the solenoid will help you know the starter solenoid’s conditions.

While doing the test, if the engine runs, you might have a bad solenoid. Replacing it is necessary. However, the starter motor might be the main culprit if you fail to start the engine.

So, these are primary symptoms you will see to learn about “What are the symptoms of a bad starter motor on a riding mower engine?”

How To Start A Lawn Mower With A Bad Starter?

It is difficult to start your lawnmower with a bad starter. Various problems cause the starter to fail frequently. Here are the few common issues you may see if your lawnmower has a bad starter.

Defective Battery

Cutting grass with a defective battery is not an easy job. The first thing you want to do checking if any leakage issue on the battery.

So, why leakage occurs on the battery? Most of the time, it happens when water enters inside the battery.

You can first try out sealing leaks of the battery. If it doesn’t work, you have no option but to replace it. Keep your hands and eyes safe by putting on gloves and safety eyewear when working with batteries.

Further, you want to assure the battery has a considerable amount of charge. If not, you want to use a charger cable to recharge the battery.

Aside from that, testing the battery voltage is another essential job you need to do. When it reads 12 volts on the tester, you can take it as a good battery. The battery is likely to have a problem if it doesn’t work.

Defective Solenoid

If this is your first time locating a starter solenoid, you may find it challenging. You will either have to reach it by raising the front hood in the upper level or the rear wheel.

Follow the red wire on the battery if you are facing difficulty reading the directions. After finding the solenoid, inspect the conditions of the terminal attacher and screws that are connected with the solenoid. Tighten the screws if they are loose. But not overtighten them. Also, inspect the attacher.

Next, you want to turn on the lawnmower keys in the clockwise direction. Do you hear a clicking sound though the engine is not starting? If yes, replacing the solenoid is necessary.

Defective Ignition Switch

A defective ignition switch can sometimes cause a bad starter. By looking at the switch’s internal conditions, you can tell whether it is in good condition or not.

Inspect the switch from the backside and lower area. Make sure all wires attached with the switch are properly connected—no loose issues. Also, check out if there is any corrosion buildup inside it.

The ignition switch is often to blame for the problem with the starter if it is found to be defective. Replacing the ignition switch will help to deal with the issue.

Defective Starter Motor

You will struggle to run on your lawnmower if any issue occurs on the starter motor. Put your hands under the front hood, where you will notice the starter motor.

Typically, the starter motor and solenoid are connected together in the lawnmower. Take a jumper (a short length of the conductor) and connect the negative end with a screwdriver and the positive end with the jumper of the batter.

You are supposed to notice some sparks after attaching the screwdriver with it. You have no reason to fear a shock because 12 volts are not powerful enough to give you a shock.

If you notice the lawnmower is not starting even though you hear clicking sounds, replacing the starter motor is the best solution.

Warning

- It is the best rule of thumb to read all instruction manuals of each lawnmower part before starting the work. You will get a clear overview of them.

- Make sure you wear high-quality hand gloves and eye wears to protect your hands and eyes.

- Wearing a protective cloth is also appreciable if any unwanted accidents happen.

- Make sure you know how to use the screwdriver and multimeter.

- Kids should be away while doing the work.

Hopefully, you have learned about “How to Start a Lawn Mower with a Bad Starter?”

How To Replace A Lawn Starter? Step By Step

Apart from knowing how lawn mower starter works, it is also important to get an idea about how to replace a lawn starter.

Does your lawnmower have a problematic starter? When you try to start your lawn mower, all you hear is a grinding noise.

If your lawnmower starter has a problem, it will not appear to be engaging the flywheel. That’s the main issue with the starter.

Also, you may see the gear is stuck in the up position; there’s totally something wrong with that. Once the switch is off, that gear should be all the way back down. Additionally, the collar may not slide back down the shaft.

The most common reasons gardeners replace starters on the lawn are because they are burned out. People hold them way too long when the machine won’t start. This makes the starter overheat, and then eventually, it becomes completely damaged.

Step 1 – Disconnect Your Negative Cable

First of all, your negative cable needs to be disconnected from your battery. You are disconnecting the battery cable is for safety purposes as you don’t want a live positive wire.

Once you take it off at the starter dangling and touching the mower’s body, that would definitely cause sparks and a short. Next, you want to remove the positive battery cable here from the starter.

Step 2 – Put a Bit of Loctite

It is better to put a bit of Loctite on the bolts that hold the starter. You can use medium-strength Loctite, which makes the starter easy to install. You just line it up to the two holes underneath the starter and serve your bolts.

If your holes aren’t quite lined up properly, just move the starter a bit to get it in and install the bolts evenly. Make sure they are tightened fairly.

Step 3 – Install The Positive Battery

Then, install the positive battery cable on the starter and undo the nut. Before reconnecting the battery cable, it’s best to clean the posts and get rid of corroded bolts. With a wire brush and a drill, you can clean it.

Now you can add a bit of dielectric grease on the posts if you want. This will help prevent corrosion. So, removing and installing a new lawnmower starter is done. Now you can try to start the mower.

Wrapping Up

Are you still wondering how lawn mower starter works? We have already covered everything about this topic. Hopefully, you have learned many precise details on how lawn mower starter works. Thanks for reading!

Last update on 2023-01-28 / Affiliate links / Images from Amazon Product Advertising API

Lee Safin was born near Sacramento, California on a prune growing farm. His parents were immigrants from Russia who had fled the Bolshevik Revolution. They were determined to give their children a better life than they had known. Education was the key for Lee and his siblings, so they could make their own way in the world. Lee attended five universities, where he studied plant sciences and soil technologies. He also has many years of experience in the U.S. Department of Agriculture as a commercial fertilizer formulator.

Thoughts on “How Lawn Mower Starter Works? The Ultimate Guide”

Best Portable Jump Starters For Lawn Mowers

Don’t let a dead battery leave you dead in the water ever again!

With NOCO jump starters dead batteries become a non invent, assuming you have one!

iGoPro Lawn Supply is constantly doing the research for you to find the latest and greatest lawn and garden products on the market. We cater to lawn care business owners, and these portable jump starters are something any lawn care company that knows how much down time costs will want in each of their trucks!

Don’t let a dead lawn mower battery ruin the profitably of that day and push back your schedule for the rest of the week every again !

NOCO’s portable jump starters also jump start batteries on almost anything with a 6-volt or 12-volt battery including cars, trucks, boats, motorcycles, ATVs, RVs, and many more on or off-road vehicles with batteries.

Reliable Power To Jump Start Gas AND Diesel Engines

NOCO has been making jump starters since 1914. Yes, that’s over 100 years! The are the best in the business and you are about to find out why.

The only NOCO jump starter not rated for diesel engines in the GB20 model. All other models can safely jump start diesel engines making them very unique as many competitors only work with gas engines. We know you lawn care guys love diesels and we can’t blame you!

Picking the right jump starter can be the only jump starter you need for any battery powered piece of equipment you own.

Portable Jump Starters With Flashlights and USB Chargers

These portable jump starters are ‘not your grandfather’s’ jump starters!

NOCO jump starters are built for the modern world. Use them at work. Use them at home. Use them on your next camping or fishing trip.

You’ll quickly find having these portable jump starters/flashlights/charging stations are a real life saver.

Let’s look at the various models so you can decide which is the right one for you.

The NOCO GB40 Portable Jump Starter is Perfect For Residential Lawn Mowing Crews

Recommended for the primary use of lawn mower jump starting and will probably have plenty of power to jump start the truck pulling your trailer too if needed.

We recommend the GB40 for lawn mowing crews that primarily service residential customers. This portable lawn mower jump starter is priced under 100 at the time of this writing! That almost makes it a no brainer if you think of how much an hour of 2 of down time will cost your lawn care company if a battery dies on a mower and you have no way to get jumper cables on it from another mower or vehicle.

Fully charge the GB40 and you will be able to jump start 20 dead batteries before needing to recharge it. Pretty dang impressive if you ask us! The GB40 can even jump start diesel engines up to 3L.

Please consider the GB50 and GB70 models as they may be more ideal for your lawn care company. The GB70 can power tire inflators which would be crucial if you got a flat and just needed to get the mower back to the truck!

The NOCO GB20 Portable Jump Starter is a DIY Weekend Warriors Best Friend

If you will solely be using your portable jump starter on lawn mowers or other small engines such as ATVs/UTVs and motorcycles, you can save some money and get the GB30 model instead. It still has the power to jump start most cars!

Top 10 Best Portable Car Jump Starter In 2023

The GB20 still also allows for 20 jump starts before needing to be recharged. The GB20 is the only model not compatible with diesel engines and is rated for gas engines up to 4L.

Both the GB20 and GB40 have USB charging ports and flashlights as well.

The NOCO GB50 Portable Jump Starter is Ideal For Mowing Crews With 3 or Mowers Per Truck and Trailer

The next step up is the GB50 model which takes portable jump starting to another level!

Jump start 30 dead batteries before needing to recharge the jump starter itself. It also will hold its charge for up to 1 year! When you need a jump, you can count on the GB50 even if you forget to charge it for some time.

Rated for gas engines up to 7L and diesel engines up to 4.5L.

It’s the perfect portable jump starter for commercial lawn mowing crews!

The NOCO GB70 Portable Jump Starter Might Be Perfect

The next option from NOCO is the GB70 and it introduces a 12-volt power source to your portable jump starter! Power tire inflators, power invertors, and more right from your jump starter.

Rated for gas engines up to a whooping 8L and diesels all the way up to 6L. You get 40 jump starts before needing to recharge the GB70 too.

Shop our recommendation for the best value and most versatile portable jump starter on the market today.

The NOCO GB150 Portable Jump Starter Can Jump Start Just About Anything!

A jump starter for trucks, even big diesel engine trucks! And amazingly it can also safely charge much smaller batteries on lawn mowers, motorcycles, and everything in between.

Jump start an incredible 80 dead batteries before needing to recharge your GB150 NOCO portable jump starter. Remember NOCO has been making jump starters since 1914, that’s over 100 years! They are the leader in the jump start industry.

Rated for gas engines up to 9L and diesels up to 7L. The GB150 model also has the 12V power source along with a 500 lumen LED flashlight and USB charging port.

Ryan Sciamanna

Ryan is the owner and founder of Lawn Crack, LLC the parent company of iGoPro Lawn Supply. He has worked in almost every capacity within the lawn and landscape industry for small local companies, nationwide companies, and of course, owning his own lawn landscape business which he sold in 2018 before starting selling lawn and garden products online. Learn more about Ryan by subscribing to the LawnCrack YouTube Channel.

How to Start a Lawnmower with a Bad Starter?

All homeowners with lawns know pretty well that lawnmowers are unmatched machines for tending your yard. But it is only fun when the mower is working fine and smooth. When a mower is not running correctly or having problems, mowing becomes tedious and rather unenjoyable. Lawnmowers, like all machines, run into all sorts of issues. But could there be a more frustrating problem than the mower not starting at all? One of the reasons for this could be a bad starter. But don’t worry, even with a bad starter, there are ways to start your mower.

How to Start a Lawnmower with a Bad Starter:

- Clean the battery leads and seal any leakages, then try again. Replace the battery if it is faulty beyond repair.

- Bypass the solenoid and start the mower using the starter motor only.

- If the starter motor is faulty, you’ll have to get a new starter motor.

- Replacing the entire starter with a new one is better than replacing just the motor.

- In case of a faulty ignition switch, try to make its connections tight. If it is defective beyond repair, get a new ignition switch.

Reasons for a bad starter:

The starter is responsible for using the energy of the battery to start the engine. A bad starter won’t do this job, and the ignition system won’t get any energy, which means that there will be no spark and the engine will not start. A starter can go wrong because of these causes:

The final solution to a bad starter can be to replace one or more parts, but techniques like bypassing the solenoid can let you start the mower for now, and you can do the replacement later. To do that, you’ll need to get some basic information about a starter and its working. This article will surely help you in this regard.

What is a Starter?

The starter is an essential component in a lawnmower that transfers electricity from the battery to the ignition system, thus allowing the engine to start. A starter has two main components, a starter solenoid, and a starter motor.

Starter Solenoid:

Solenoid gets current from the battery and transfers it to the motor. When the ignition button is pushed, a current is sent from the battery to the solenoid through the wiring and then from the solenoid to the motor.

Starter Motor:

The starter motor is the starter component that is linked directly to the spark plugs. It sends current from the starter to the engine.

These two components are independent but work together to power the spark plug so that a spark can be generated in the combustion chamber, producing power from fuel. Though the starter solenoid and motor are independent, the chain is disrupted if one fails, and the engine won’t start when you push the ignition button. But because these two components are separated, the mower can still be turned on if one goes bad.

Before making any repairs or changes, you need to know what’s wrong. A lawnmower with a bad starter will show specific symptoms that can help you see the problem’s root cause.

Symptoms of a Bad Starter:

A satisfying rumble sound is always expected when starting the engine, but a mower with a bad starter will make abnormal sounds when it is being started. The sounds can be used to judge the nature of the underlying problems.

Abnormal Solenoid Clicking:

When the ignition button is pushed, the solenoid transmits an electric spark that starts the motor. The motor starts rotating a smaller gear that engages with a larger gear of the engine. This is how the engine is jump-started. When this process goes normally, a clicking sound is produced, followed by a whirring sound that indicates that the starter motor is engaging with the engine.

If you push the ignition button and only the clicking sound is produced, it is a sign that something is wrong and the motor is not engaging with the engine’s gear.

Whirring sound, but no Catch:

When the whirring sound is produced but is followed by a loud rumbling sound, it is a sign that the starter is not engaging with the engine in the normal manner. This is a sign of the starter’s smaller gear not correctly engaging with the engine’s gear. Another sign of this issue is when the engine starts but stops after just a moment. Broken teeth basically cause these problems on the starter motor’s gear or worn motor brush brushes. If this is the case, these faulty components will have to be replaced.

Not Starting Even with a Fully Charged Battery:

If your mower does not start even though there is no battery-related issue, it is the clearest and obvious indication that the starter isn’t working fine. When this happens, start looking for the cause of problems right away.

Solenoid Not Clicking:

If there is no solenoid clicking sound when you push the ignition button, it is an indicator of loose connections to the solenoid. This means that the current is not reaching the solenoid. If this is the case tightening solenoid connections will get your mower running.

Starting a Mower with a Bad Starter:

A bad starter is caused by electrical problems that can be fixed. Here’s a guide on how to do that.

Flat or Faulty Battery:

The first thing to get in order when your mower is not starting is the battery. If the battery fails to provide electricity, there is no way your mower will start.

Start by looking for leakages. Charge the battery with a charging cable, and if it becomes wet, then the battery is leaking. Small leakages can be sealed, but if the leak is too big, replace the battery. When dealing with leaks, wear safety gloves and glasses to avoid acid burns.

Check the battery voltage too. The battery voltage should be 12V. If the voltmeter reading is less than 12.4V, it is a sign of a faulty battery that needs to be replaced.

Ignition Switch:

Loose connections of the ignition switch wire or corrosion on the back part of the switch can also cause a bad starter. If the issue is not of a severe nature, you can fix it yourself. If the ignition switch has become so bad that it can’t be repaired, it should be replaced with a new one.

Solenoid:

The starter solenoid is a mounted switch that provides current to the engine’s starter motor. The solenoid has four threaded electrical lugs connected to the battery, ground, ignition switch, and starter motor.

Different lawnmower models have their solenoids at different locations. You can locate the solenoid in your mower by following the red battery wire. After locating the solenoid, check its connections and screws and tighten them using a wrench or a plier. Rotate the ignition key. If the solenoid clicks without starting the mower, the solenoid needs to be replaced.

Starter Motor:

The starter motor is attached to the crankcase of the engine. If you have already checked the components mentioned above and they are fine, but your mower is still not starting, the chances are that its starter motor is faulty.

To check the starter motor, connect it to the battery using a jumper cable while attaching a negative terminal screwdriver. You’ll see some sparks, but there is no danger of shock from a 12V battery. If the motor doesn’t start and gives clicking sounds, the motor is faulty.

Sometimes the winding, magnet, brushes, etc., inside the mower can get dirty or burn during use. Fixing them can solve the issue too.

A faulty motor can be rebuild. But this has to be done by a professional electrician.

Bypassing the Solenoid:

Like said before, the starter solenoid and motor are two independent components. If you have determined that only the solenoid is faulty, you can try to start the mower using the starter motor only.

A solenoid has wire connections from the battery/ignition switch. To bypass the solenoid, connect these wires to the motor using a metallic connection. Then try to start your mower. If it produces a whirring sound, it means that the mower can be started. You’ll need to try a couple more times to start the mower.

Use protective equipment while bypassing the solenoid.

Final Remarks:

The lawnmower not starting on a potentially enjoyable mowing day is very frustrating. Mowers fail to start when their starters go bad. But most of the time, starter problems are not too complicated and can be fixed by the user. Follow the guidelines mentioned in this article to get your mower running once again. Checking other electrical components such as spark plugs will help too.

Riding Mower Won’t Start Just Clicks – Mechanics advice with pics

This is a problem that usually arises in the spring, and for most, the fix is really simple. You’ve come to the right place, and you’ll be cutting grass shortly.

So what’s the problem with a riding mower that won’t start just clicks. The most common reason for a clicking sound on a riding mower when you turn the key is a flat battery. Other possible reasons include:

Yes, it’s a long list, but you won’t have to check all of them; I’ll bet your problem is one of the first three; I have listed the likely causes in order of commonality.

If your mower won’t crank and makes no click sound – Check out “Lawn Tractor Won’t Start.”

Bad Battery Connections

Bad battery connections are very common, and by bad, I mean the power is not passing from the battery to the cables because the battery connections are loose, dirty, or damaged.

Loose Connections

Battery cables become loose because lawn tractors vibrate a lot; this is why it’s a good idea to service your mower at the start of every season, no matter how well she runs.

Dirty Connections

Dirty connections are usually caused by the weeping of battery acid at the battery poles. The acid then crystallizes, causing high resistance; it looks like a white chalky build-up on the connectors.

Cleaning Connections

To clean the connections, add a couple of spoons of baking soda and a small amount of water, and pour this onto the acid build-up on the connections and battery poles.

The soda neutralizes and removes the acid; you’ll need gloves and protective eyewear. After removing the acid, go ahead and remove the connectors and give them a good cleaning with a wire brush or sandpaper.

If you have some petroleum jelly, a small coat will prevent a future build-up.

Connector – Mower blades and engines cause a lot of vibration; bolts come loose from time to time.

Check that both connections, positive (RED ) and negative (BLACK – ), are clean and tight.

Cables – Check the cables for damage, and corrosion; mice find them irresistible.

Flat / Faulty Battery

A flat battery is a real pain in the ass. I know what it’s like; you just want to cut the grass, right? The fastest way to solve this problem is to jump-start the mower.

Leaking Battery – Check your battery for leaks before attempting to jump-start. If it leaks and it’s a sealed battery, replace it.

However, it’s usually only wet batteries that leak, so best to check your electrolyte level and top up if necessary. As you know, the acid will burn the skin and eyes, so, you know, gloves, etc.

If the acid build-up is excessive, your battery may be on its last legs, so don’t be surprised if it fails or does so soon.

But if the leaking is excessive, don’t jump-start; replace it. Batteries are easy to fit; just be sure the battery is the correct size, and the poles are in the proper places.

Jump Starting

You’ll need jump leads and any 12-volt vehicle. Most cars, trucks, and even Hybrids have a regular 12-volt battery fitted somewhere. Sometimes finding it is the hardest part. If you’re unsure of the voltage, when you find the battery, a sticker on the casing will indicate 12v.

Of course, your battery might be faulty, jump-starting will probably get you rolling, but the problem will still be there. You can test using a voltmeter test tool, which I’ve listed here on the “Small engine repair tools” page.

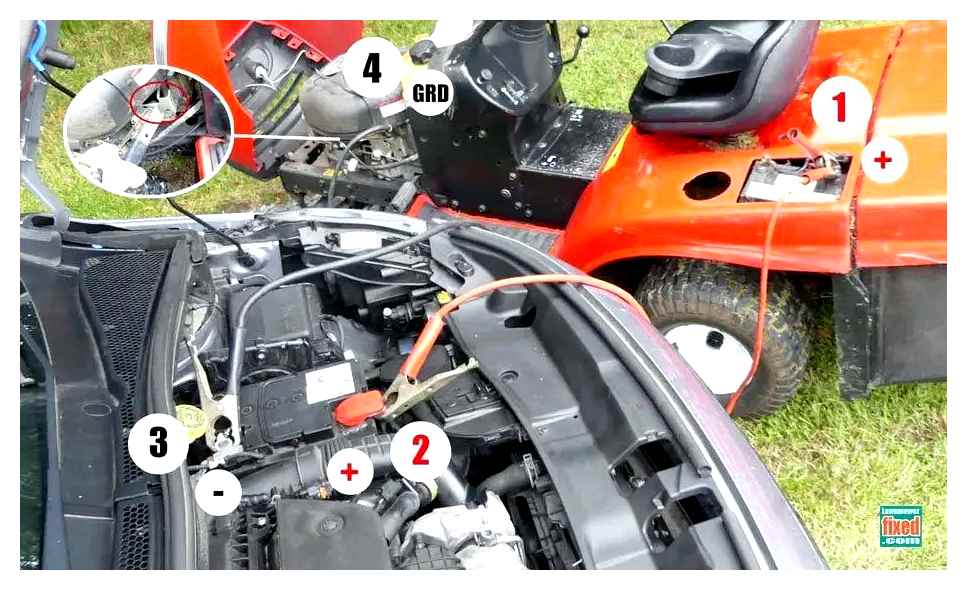

To jump-start – begin by connecting the positive red of the mower to the red of the car.Now connect the negative black (-) on the car to a ground (GRD) source on the mower. (Any bare metal will work)

Connect – If you are not familiar with jump-starting, you’ll find a complete guide here, “Jump starting riding mower.” Add the cables in sequence 1, 2, 3, and 4, start the mower, and while idling, remove jumper cables in reverse order 4, 3, 2, and 1.

Battery Testing

You can check the battery and alternator using a voltmeter. Batteries don’t like sitting idle; they were designed to be charged and discharged continuously. A battery that gets fully discharged will sometimes not come back to life.

Use a voltmeter to check the battery voltage, and connect red to positive and black to negative. I have listed a voltmeter on the “Small engine repair tools page.”

Test – Check battery voltage using a voltmeter – attach a voltmeter to the battery and set it to 20 volts.

If you have a reading above 12.5 volts – go ahead and attempt to start the mower; watch the voltage; a reading below 8 volts is a bad battery and needs to be replaced.

Buying a Battery

When buying batteries – wet batteries will not ship with acid. The acid must be purchased, and the battery must be filled and charged; it’s a lot of work.

I would buy a gel or maintenance-free sealed battery; these can be shipped, fully charged, and ready to roll. Check out quality common ride-on mower batteries on the Amazon link below.

Battery Charging

You’ll need a battery charger to keep your battery in top condition over winter. I recommend a trickle/Smart charger; they’re simple to use; pop on the color-coded crocodile clips, plug it in, and that’s it. Forget it till next spring, then turn the key and mow.

I’ve listed a good-quality Smart charger on the “Small engine repair tools” page that won’t break the bank.

Batteries work best and last longer when their state of charge is maintained; off-season charging is always advised. Check out “Mower winter storage video.”

Charge – Always disconnect the battery before charging. Simply connect red to red, black to black, and plug in the charger. The length of time on charge will depend on how low the battery is and the amp rating of the charger. Usually, 2-3 hours cooking time.

Faulty Solenoid

The solenoid is a large relay of sorts. When you turn the key to start your mower, a 12-volt supply from the ignition switch to the solenoid activates it. The solenoid’s job is to connect the battery to the starter motor and crank over the engine for as long as you hold the key.

The click sound is the solenoid trying to work by pulling in the armature; they fail regularly, and I replace lots of them.

However, the click sound can also be made for a few other less common reasons, and without fully diagnosing, you may find replacing the solenoid doesn’t solve the problem.

Hey, if you feel lucky and don’t want to do the diagnosing part, I understand. So, if your battery is full and the cables are tight, go ahead and replace the starter solenoid. They’re cheap and easy to fit.

Check out, “Mower solenoid repair tools” it lists useful tools and parts that will help you nail the repair.

Solenoid – Solenoids are a universal fit; they give lots of trouble.

On the upside, they’re easy to fit and cheap to buy.

Where’s the Solenoid?

Often just finding the starter solenoid can be challenging; I sometimes think that they hide them for fun. If you don’t find it under the hood, try under the rear wheel, behind the gas tank, or under the seat.

The easiest way – follow the red battery cable from the battery. On some engines, the starter and solenoid will be one unit (Kawasaki and Honda engines).

Where? – Husqvarna, craftsman-like to, hide theirs under the rear wheel fender or the dash beside the steering column.

However, most solenoids will be easy to locate. Fitting is easy, but do disconnect the mower battery first.

Solenoid Test

Remove – The first step in testing the solenoid – remove the spark plug.

If, when removing the spark plug, gas pours from the spark plug hole – move on and check “Carburetor troubleshooting.”

Test – Turn the key; if the clicking sound persists – Go ahead and replace the solenoid.

If, on the other hand, the engine cranks over, move on and check for excessive valve lash.

Tight – Check the solenoid terminals; all wiring should be secure and free from corrosion.

Binding Starter Motor

The gear head of the starter motor can bind against the flywheel; this locks the engine and starter motor together. So when you hit the key, all you hear is the click sound.

Testing

Testing for this condition involves turning the engine by hand anti-clockwise. Some engines will have a cover over the flywheel; if so, try turning the crankshaft with a ratchet and socket, from the underside of the engine.

If turning the motor anti-clockwise frees it up – you have found your problem, the starter motor is binding. Usually, a spray of wd40 on the starter gear head will fix it. If you are lucky, you can get the straw of the WD40 directed at the gear head without removing any covers.

Starters can bind for other reasons – worn bearings, worn gear head, misaligned or loose starter motor.

Binding – Starters can bind against the flywheel. To fix it – spray the starter gear with wd40 and retest. If it continues to bind, replace the gear head or complete the starter motor.

Turning the engine anti-clockwise by hand will unlock it.

Excessive Valve Lash

Engines have valves that open and close in sequence. The inlet valve allows the fuel/air mixture in. It then closes and seals the combustion chamber. After the power stroke, the exhaust valve opens and allows spent gases out.

What’s Excessive Lash?

The valve lash describes a precise gap between the valve tip and the rocker arm. As the engine wears, this gap gets bigger and must be adjusted. The inlet and exhaust valve lash will usually be different specs.

Correct Lash

When the valve lash is set correctly – you crank over the engine, the valves open, and release cylinder pressure. This allows the engine to crank over at sufficient speed to create a spark strong enough to start up the engine.

When the valve lash is out of spec, the valve is late opening which means pressure in the cylinder is too great for the starter to overcome; that’s when you hear the click sound.

Incorrect Lash

Check out “Valve lash adjusting” it’s for a walk-behind mower, but the process is identical. Adjusting lash isn’t difficult but will require an inexpensive tool called a feeler gauge. You’ll find a link to a good feeler gauge set on the “Small engine repair tools” page.

Test – If you can, place your hands on the flywheel screen – try turning the engine clockwise.

If you’re unable, you likely have excessive valve lash. Lash should be checked every season.

Lash – Adjusting valve lash requires an inexpensive tool called a feeler gauge.

Hydro-locking

A carburetor fuel supply usually consists of a fuel bowl, float, and needle. The float is, as its name suggests, a float. Attached to it, is a needle with a rubber tip.

The function of the float is to lift the needle as the fuel level rises in the fuel bowl. When the fuel bowl is full, the needle will be pushed against the fuel feed port, sealing it.

Hydro-locking – Worn carburetor float needle seals have a habit of leaking gas into the cylinder, and when the cylinder is full of gas, the piston can’t move; this is known as hydro-locking. Because the piston can’t move, the engine will often make a clicking sound as you try to start the engine.

Removing the spark plug and turning over the engine will release the gas, but the carburetor float valve and the engine oil will need to be replaced.

Other signs that your carburetor needle seal leaks are: overfull oil level; white smoke from the muffler; oil leaking from the muffler; gas dripping from the carburetor; a strong smell of gas in the garage.

Fuel Valve Solenoid

Newer model carburetors have a fuel solenoid fitted to the bottom of the fuel bowl; its function is to stop the fuel supply when you shut the engine off. So if you have this newer type of carburetor fitted, you will not likely have a hydro-locking condition.

Leaking Carburetor Valve Seal

Failure commonly occurs in the older type carburetor when the rubber needle seal wears. This results in fuel filling the carburetor and eventually entering the cylinder and crankcase.

Gas in the Oil

If you have gas in the oil, don’t run the engine; the diluted oil offers little protection to internal components. First, fix the issue by replacing the carburetor and then changing the oil.

Check out “Carburetor types” page; it lists popular mower carburetors. Check out “Carburetor troubleshooting” also for more details on the issue.

Check Oil – Too much oil is a sign that your carburetor needle seal is leaking unless, of course, you overfilled the oil yourself.

Needle – The needle wears over time; they turn pink when worn. The fix – replace the seal or the complete carburetor. Using your manual fuel valve will prevent future problems.

Faulty Ignition Switch

A faulty ignition switch can cause all kinds of problems; the click sound can be caused by a bad connection in or at the back of the switch.

Try the Wiggle Test

When turning the key, wiggle the wiring at the back of the ignition switch and see if it makes a difference. It will very often show you where the fault is. Wiring pinouts are specific to each manufacturer.

Wiggle – Try wiggling the wires at the back of the ignition switch while attempting to start the engine; you may need a helper.

Often wires come loose but do check them for corrosion.

Faulty Control Module

Control Modules are not fitted to all mowers. The function of the control module is to receive a start request from the ignition switch, and to output a 12-volt supply to the starter solenoid, but only if all safety sensors are in the correct position.

Control Module Test

Control modules do fail and also suffer from loose connectors. Try the wiggle test on the connectors and check for obvious signs of water/corrosion damage. The control module will often live behind the dashboard in a plastic box about the size of a mobile phone.

Wiggle – Like the ignition switch, wires come loose, have a helper attempt to start the engine while you wiggle the wiring connectors.

Check also for damage, water, or scorch marks on the panel itself.

Faulty Starter Motor

A faulty starter can fail electrically, mechanically, or both. Electrically – the copper winding can break; brushes can break or wear out. Mechanically – the top and bottom bearings and the gear head can wear. These issues can cause the starter to bind, so all you hear is the click sound.

Testing the Starter

Checking the starter motor is easy; connect a 12-volt supply direct from the mower battery to the supply wire at the starter. An even easier way is to cross the starter solenoid as per the guide below.

If you find your starter has failed, removing and fitting a new one is simple. The starter motor for Briggs and Stratton offers a good quality starter. Be mindful that BS has two types of starter – plastic gear head or metal; check before ordering.

Starter – Some starters will have a solenoid and starter motor combined in one unit.

To test, use a jumper lead to bring power from the positive of the battery to the positive post of the starter. If the engine doesn’t crank – Replace the starter.

Common – Most mowers will have the starter and solenoid separate.

Solenoids are fitted to the body, usually under the hood.

Test – Cross a metal screwdriver from one connection to the other, as per the picture.

There will be arcing (sparking) as the screwdriver contacts the poles.

RISK OF FIRE – Keep clear of gasCAUTION THE ENGINE MAY TURN OVER – Place the mower in the park with the parking brake applied and the blade off.

If the engine doesn’t crank over – your starter is faulty; replace it.

Internal Engine Damage

If you’re still reading, I fear the worst has happened. It’s unusual for mower engines to fail completely. They’re generally well-built robust units. I have seen failures like the con rod breaking out through the engine casing; the main bearing seizing; the con rod bending; cylinder head failures.

Some of these faults can be repaired, but most are uneconomic to repair.

New Engine

On the upside, if you have a total failure, a complete engine fully built with a guarantee is available, and fitting involves four bolts, two electrical connectors, a fuel line, a throttle cable, and a crank pulley.

BS and Kohler’s engines are of great quality and ready to go. The completed job will take less than two hours. Be mindful that all engines are shipped without oil.

Failure – Total failure doesn’t happen often.A hard life, and low/poor quality oil, without doubt, increase the chances.

Related Questions

Can you jump-start a mower? A flat or bad battery is a more common fault than a starter. Try jump-starting; if your mower starts, the battery needs attention. If jump starting doesn’t work, investigate a faulty solenoid or starter.

Can a bad alternator ruin a battery? A bad alternator can ruin a battery. Alternators have two main components. A voltage regulator that monitors and controls battery charging and the alternator whose job it is to create voltage. Common problems include a faulty regulator, which damages the battery, and alternator diode failure, which drains the battery.

Hey, I’m John, and I’m a Red Seal Qualified Service Technician with over twenty-five years experience.

I’ve worked on all types of mechanical equipment, from cars to grass machinery, and this site is where I share fluff-free hacks, tips, and insider know-how.

The Starter Relay and Why a Mower Won’t Start

A lawnmower requires several amperes of electrical current to start the engine. For safety reasons, a lawnmower (and other electric-start internal combustion powered vehicles) contains two parts to the starting circuit: a start switch circuit and a relay circuit. Since an electromechanical relay can only be used for a specified number of cycles before failure, a faulty starter relay can prevent a lawnmower from starting.

Why a Lawnmower Contains a Starter Relay

A relay allows a low-power, light-duty switch to actuate or disengage the starter circuit without being directly wired to the starter circuit itself. If the lawnmower starter circuit did not contain a relay, heavy-duty wiring would have to be wired to the lawnmower starter switch. This would pose a potentially fatal shock hazard if the starter switch or starter circuit wiring became damaged. The starter switch would also be prone to electrical arcing and excessive heat, which would eventually destroy the switch and potentially damage the lawnmower.

- A lawnmower requires several amperes of electrical current to start the engine.

- For safety reasons, a lawnmower (and other electric-start internal combustion powered vehicles) contains two parts to the starting circuit: a start switch circuit and a relay circuit.

Why a Bad Relay Prevents a Lawnmower from Starting

When the starter switch is turned on, the switch circuit provides power to an electromagnet inside the relay. This electromagnet pulls the relay switching mechanism closed and engages the relay circuit. The relay circuit provides power from the battery to the starter.

If either the electromagnet or the switching mechanism in the relay is faulty, the relay circuit will not engage. This prevents electrical current from flowing to the starter from the battery.

Why a Bad Switch Prevents a Lawnmower from Starting

Since the switch circuit provides power to the electromagnet in the relay, the switch circuit is just as important as the relay circuit. If the switch is broken, the switch circuit will not provide electrical current to the electromagnet. Without electrical current flowing through it, the electromagnet will not work and the relay cannot be actuated.

Other Considerations

Both the switch circuit and the relay circuit require a power source and transmission lines (wires) to operate properly. If there is a break in the wire on either side of the circuit, or if the power source connection is loose or faulty, this will prevent the lawnmower from starting as well.