Brush screwdriver or brushless motor which is better

Principle of operation

Increased reliability, reduced cost and easier manufacturing are ensured by the absence of mechanical switching elements, rotor windings and permanent magnets. At the same time, an increase in efficiency is possible due to a decrease in friction losses in the collector system. The brushless motor can operate on AC or continuous current. The latter option is distinguished by a noticeable similarity with brushed motors. Its characteristic feature is the formation of a rotating magnetic field and the use of a pulsed current. It is based on an electronic switch, which increases the complexity of the design.

Magnetic elements

The arrangement of the magnets can be different according to the dimensions of the motor, for example, at the poles or across the entire rotor. The creation of high-quality magnets with greater power is possible thanks to the use of neodymium in combination with boron and iron. Despite the high operating rates, the brushless motor for the permanent magnet screwdriver has some disadvantages, including the loss of magnetic characteristics at high temperatures. But they are more efficient and less lossy than machines with windings.

The pulses of the inverter determine the rotation speed of the machine. With a constant supply frequency, the motor runs at a constant speed in an open-loop system. Accordingly, the rotation speed varies depending on the level of the supply frequency.

Calculation of position

Pulses are generated in the control system after a signal that reflects the position of the rotor. The degree of voltage and supply directly depends on the speed of rotation of the motor. A sensor in the starter detects the position of the rotor and provides an electrical signal. Together with the magnetic poles passing next to the sensor, the signal amplitude changes. There are also sensorless positioning techniques such as current flow points and transducers. PWM input terminals provide variable voltage retention and power control.

For a rotor with fixed magnets, no current is required, so there is no loss in the rotor winding. The brushless screwdriver motor features low inertia with no windings and no mechanized manifold. Thus, it became possible to use at high speeds without arcing and electromagnetic noise. High currents and easier heat dissipation are achieved by placing heating circuits on the stator. It is also worth noting the presence of an electronic built-in unit on some models.

Characteristics

The valve motor operates in the set modes and has the functionality of a brush analogue, the speed of which depends on the applied voltage. The mechanism has many advantages:

- no changes in magnetization and current leakage;

- correspondence of the rotation speed and the torque itself;

- the speed is not limited by the centrifugal force affecting the collector and the rotor electric winding;

- no need for a commutator and excitation winding;

- the magnets used are lightweight and compact;

- high torque;

- energy saturation and efficiency.

How a brushless motor works

The operation of a brushless electric motor is based on electric drives that create a rotating magnetic field. Currently, there are several types of devices with different characteristics. With the development of technologies and the use of new materials characterized by a high coercive force and a sufficient level of magnetic saturation, it became possible to obtain a strong magnetic field and, as a result, valve structures of a new type, in which there is no winding on the rotor elements or a starter. The widespread adoption of semiconductor-type switches with high power and reasonable cost has accelerated the creation of such designs, facilitated implementation and eliminated many of the complexities of switching.

Using

Brushless permanent magnet DC motor is found mainly in devices with power within 5 kW. In more powerful equipment, their use is irrational. It is also worth noting that magnets in motors of this type are particularly sensitive to high temperatures and strong fields. Induction and brush options are free from such disadvantages. Engines are widely used in electric motorcycles, car drives due to the absence of friction in the manifold. Among the features, it is necessary to highlight the uniformity of torque and current, which provides a decrease in acoustic noise.

Best cordless screwdrivers

Top 14 screwdrivers

In general, a screwdriver is a device almost as versatile as a screwdriver or a hammer. Not a single repair or construction can do without it. A good device effortlessly copes with tasks such as installing audio or television equipment, installing baseboards or drywall, assembling furniture, attaching shelves and paintings, installing door handles and much more. The presence of a screwdriver, at the same time, makes the process not only faster, but also of higher quality. A correctly selected model will help to cope with the task in a few minutes. How do you choose the optimal solution? View my list of the best home screwdrivers.

Best cordless impact drivers

Bort BAB-14N-1

An inexpensive offer with all the functions you need in everyday life. Its advantages:

- compact size and ergonomic shape of the handle;

- the presence of a reverse;

- smooth control of rotation speed;

- torque 15 Nm;

- battery with a capacity of 1, 2 A.

The model is easy to operate and great for home use. A decent quality device for a reasonable price. Among the disadvantages is low efficiency when working with metals.

The best professional screwdrivers

Makita FS4300

The power tool of this manufacturer is compact, reliable and high-quality assembly, and the FS4300 screwdriver model is no exception. Convenience and ease of use of the device are due to:

- the presence of an ergonomic rubberized handle;

- rotation speed up to 4000 rpm;

- chuck for working with 1/4 bits;

- the presence of a reverse.

This corded drill / driver is perfect for any job, no matter the size. The disadvantage is the cost, which is not much inferior to professional models.

BRUSHLESS vs BRUSHED tools – Which one is the best option?

Elitech Ш 550РЭ

- rotation speed up to 4500 rpm;

- the ability to adjust the frequency of rotation;

- the presence of a special hook for carrying on the belt;

- long three-meter frost-resistant cable;

- lock button to prevent accidental activation.

The advantages also include a convenient clamping diameter for bits of 6.3 mm. The main disadvantage is only one torque step.

Best screwdrivers 2019. 2020

A screwdriver is a more modern analogue of a screwdriver, when working with which less effort is spent, and the work is done faster and better. When choosing a tool, it is important to take into account that the cordless screwdriver is mobile, but it can be discharged at an inopportune moment. And the electric should always work close to the outlet or, in extreme cases, to the extension cord. The torque power, the presence of backlight, reverse and nozzles also matter.

Our top 10 best screwdrivers will help you make your choice. According to buyers, it is these screwdrivers that lead the rating of the best in terms of price-quality ratio. So, the technique in 2019. 2020 pleased the following models.

Minuses:

- This is a household model, therefore, with frequent and active use, the engine may burn out.

- Illumination sight can be shifted.

- Lies loosely in the case. it makes noise during transportation.

Pros:

- Keyless chuck type.

- Has a reverse.

- Fits comfortably in the hand.

- Affordable price.

Pros:

- Equipped with a flashlight.

- Sold with bits and bit holders.

- Charges fast.

🛠️ Are brushless tools worth the extra money?

10 Interskol DSh-10 / 320E2

The product of the Russian manufacturer definitely deserves attention, at least due to the fact that it opens our rating of the best screwdrivers 2019. 2020. This 320kW drill / driver has a sleek design and sleek design. The only model in our rating that works from the network, which means that it will not fail at the most difficult moment (cable length. 2 m). Another advantage of the screwdriver is the maximum torque is 35 Nm.

8 Hitachi DS14DVF3

Another member of our top with ergonomic design, battery operation and stable power. The battery is of the Ni-Cd type, which means that it must be completely discharged. But the Hitachi DS14DVF3 comes with a second, spare battery, so you won’t have to take a break.

Minuses:

- The gears in the gearbox are plastic, which makes the screwdriver lighter, but if used carelessly, it may require replacement.

- The chuck shades slightly on the drilling site.

How a brushless motor works

There are many types of screwdrivers. To understand the advantages of each, you need to study their data, the principle of operation. This will allow you to understand which screwdriver is better than brush or brushless, in which cases you need to use them. After all, all electrical tools are different in technical parameters.

At the end of the last century, there were changes in the field of semiconductor electronics. This allowed not to use the usual brushes. The mechanical way of connecting the contacts in the brushless was replaced by an amplifier.

Studying how the brushless screwdriver motor works, it can be noted that it is much more convenient when working, and provides a higher torque. This type of engine wears out less, it is quieter, protected from dirt getting inside.

In this case, the speed of rotation is enhanced by the tension created internally, and not by centrifugal force. In this case, the engine works in the desired mode, without giving any failures.

Even if current seeps in or magnetizes the motor, the speed will remain the same.

No commutator and winding are required for normal operation. And the built-in magnet is not needed as large as in brush equipment.

A brushless motor has a rotor and stator as elements of any motor. But there is no collector here. Therefore, its brushless version will be more reliable.

Interesting! Such devices are installed in low power screwdrivers (up to 5 kW). In models with large parameters, they are less effective.

The advantages of brushless tools in practice

The theoretical advantages are fully realized in practice. This must be taken into account when choosing a brush or brushless screwdriver, which motor can be better known after working with it.

Experts note that such a tool:

- Much lighter and smaller. Compactness makes it possible to work in difficult places and carry even in a regular bag.

- powerful and more efficient in terms of electricity consumption. Modern electronic motor technology enhances user performance.

- Brushless battery models work on a single charge for a long time. Compared to classic motors, this is 30% more.

- Low heat generation does not require additional cooling and interruptions during operation.

- When working, it does not make too strong sounds, does not give sharp jerks.

- No sparks. This allows you to work in difficult conditions next to fuel tanks, gas appliances.

- Easy to maintain. No need to buy and pick up brushes.

- It breaks less often, since the absence of a brush allows you to work even at high loads without fear of clogging the engine.

Why is the brushless tool so expensive

The main disadvantage of such a tool is its high price. It is due to the presence of an expensive power board and electronic controls. This makes the electric motor more reliable.

But the high cost of such a tool sometimes becomes a decisive factor when buying a tool. Which screwdriver is better brush or brushless, each user decides for himself. And many are inclined in favor of a cheaper product.

Important! Replacing parts with brushless tools is always expensive.

Should you buy a brushless motor tool?

If the tool is needed several times or just for home use, then it is better to choose the cheaper option. But professionals need a reliable and powerful screwdriver that pays off very quickly. This can be understood by seeing how the brushless screwdriver works, and how many processes can be done with it without interruption.

We can wait for the technology to become more affordable. After all, it was introduced not so long ago and the new engines with which they are equipped are too expensive, unlike conventional ones. When analyzing the price, the difference will be 30-50%. Such overpayments are too significant to buy a tool just to have a home.

Brushless screwdriver operation

Comparison of brush and brushless screwdriver. advantages and disadvantages

When you need to tighten screws, and a large number of them, a special tool will help save time. A screwdriver is a power tool that helps you assemble furniture, install a shelf, and much more. There are different types of it, the properties of which must be taken into account when choosing.

Design and principle of operation

The collectorless tool has taken its place in the set of necessary tools. When buying equipment for a house, the owner must familiarize himself with the principles of its operation.

You can consider the features of how a brushless motor works in a screwdriver:

- The current is switched here in the stator windings. There is no coil on the anchor, and the magnetic field is created using magnets installed inside the case.

- The time when you need to connect electricity is regulated using built-in sensors. Hall effect is used. Short electrical impulses and speed signals that regulate operation are transferred to the integrated processor. This action is called a PWM signal.

- The alternately generated pulses are directed to amplifiers, which amplify the current. Inverters (amplifiers) are connected to the stator winding. These elements accumulate the current generated by the coils and, using pulses, transmit it from the internal processor.

As a result, a magnetic field arises, which causes the armature to rotate and the tool begins to work.

The advantages of brushless motors in theory

We have already figured out the device of the brushless motor and now it is worth considering the positive and negative sides of such tools.

There are several advantages to such engines:

- They don’t have the problems that brush models have. They are more resistant to wear and tear as the brushes do not generate internal friction. The fire rate is also lower. No arcing allows you to work in the most difficult conditions.

- Simpler torque control system. The number of levels (15) allows you to immediately select the desired mode and just press the button. They have a higher level of efficiency.

- Economical in terms of the use of electricity. This is especially true. If the engine is battery-powered. The tool can work on any material.

Important! In addition, brushless motors can deliver maximum rotations almost immediately.

Brushless motor

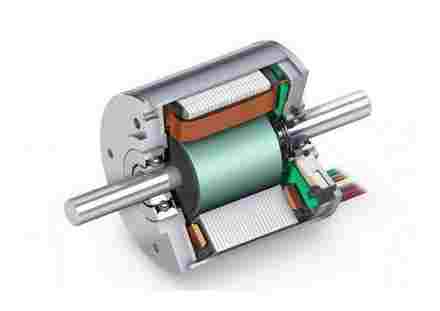

If in a collector motor everything is driven by mechanics, then in a brushless motor it is pure electronics. Also, the positions of some elements in the structure are reversed. In a collector motor, the windings were on the rotor, and the permanent magnets were on the stator. For a brushless, permanent magnets are transferred to the rotor, and the coils with windings are located on the stator. Also, the rotor and stator can change their positions: there are models of motors with an external rotor. There are no brushes and a collector, instead of them a microprocessor (controller) and a cooler are added to cool the system. Microprocessor controls rotor position, rotation speed, uniform voltage distribution across the winding coils.

The main types of brushless motor are:

- An induction motor is a motor that converts AC power into mechanical power. The name comes from the different speed of rotation of the magnetic field and rotor. The rotor speed is less than that of the magnetic field generated by the stator windings (e.g. DigiPro motor used in Greenworks products).

- Synchronous is an AC motor, in which the rotor speed is equal to the frequency of rotation of the magnetic field.

- Less friction due to the lack of brushes.

- Less subject to wear and tear.

- No sparks or possible fire.

- Simplified torque adjustment over a wide range.

- Saving energy consumption.

- Reversible tools have the same power in both directions of rotation.

- Fast start-up at high speeds.

- Can be accelerated to the limit.

- Some models are equipped with a motor protection system under heavy load.

- Significantly more expensive than brushed motors.

- specialized maintenance.

Conclusion: Undoubtedly, brushless motors are focused on professional work with a decent load. Despite the high performance of the improved engine type, its only drawback hits the wallet. And before purchasing a tool on a particular engine, first of all, you need to ask yourself the question: for what purposes it is needed. Already based on the answer to make your choice.

How many people. so many opinions. Greenworks strives to make quality products on different types of engines, so that everyone can choose a tool according to their preferences, functionality and the required power for specific tasks that each client has their own. Which is better? The choice is yours!

Brushless motor vs brushed motor

For several years now, we have seen the brushless motor dominate the advanced electric motor industry. Does it really matter to use a brushless motor? Yes of course. There is a significant difference between them.

Let’s take a look at the basics of a DC motor. DC motor. all about magnets and electromagnetism.

Oppositely charged magnets attract each other. The basic idea behind a DC motor is to hold the opposite charge of a rotating component attracted to the stationary magnets (stator) in front of it so that it generates a constant attraction. This forward thrust movement is caused by the physical behavior of electromagnetism.

Collector motor device

Anchor. The core of the entire structure is an anchor, it is also a metal shaft. The shaft is the moving element on which the torque depends. It also houses the rotor.

Rotor. Connected to the drive shaft. Its external structure resembles a drum that rotates inside the stator. The task of the rotor is to receive or deliver voltage to the working fluid.

Bearings. They are located at opposite ends of the armature for balanced rotation.

Brushes. They are usually made of graphite. Their task is to transfer voltage through the collector to the windings.

Collector (switch). It is made in the form of interconnected copper contacts. During the rotation process, it absorbs energy from the brushes and directs it to the windings.

Windings. They are located on the rotor and stator of different polarities. Their function is to generate their own magnetic field under the influence of different polarities, due to which the armature comes into action.

Stator core. Made of metal plates. May have an excitation coil with a polar voltage of the rotor winding. Or. permanent magnets. This design depends on the voltage source. Is a static element of the entire mechanism.

- Less cost than brushless motors (BR).

- The design is relatively simpler than the DB design.

- In view of this, maintenance is easier.

At high speeds, the friction of the brushes increases. Hence follows:

- Rapid brush wear.

- Reduced tool power.

- The appearance of sparks.

- Tool smoke.

- Failure of a tool before its “life cycle”.

Conclusion: If we consider the domestic sphere of application, then the collector motor is a traditional and budgetary option for operation (and the most frequently used one). The tools on this type of engine will faithfully and faithfully cope with any daily task within their capabilities. Because such tools are much cheaper than tools on a brushless motor at a cost, they are considered by a category of consumers who adhere to the opinion: “nothing lasts forever”. Why overpay if any unit can fail? We believe that under proper operating conditions, any tool can serve faithfully for quite a long time. But the choice is yours.

In many ways, brushless is better

Power usage. The brushless motor does not have a brushed collector, therefore there are no losses for friction, heating and sparking. Due to this, on average, the brushless motor is more economical by about 30%. For example, with a brush screwdriver you tighten 200 self-tapping screws, and with a brushless screwdriver 270 self-tapping screws.

Engine resource. In a brushless motor, there is simply nothing to break apart from the bearings. In a brush motor, the brushes and the commutator wear out over time.

The motor without brushes has lower discharge currents. This saves the battery a little.

I took a pine board of 20050 mm and tried to screw wood grouse screws into it, 8180 mm in size.

The brushless one unambiguously spins these capercaillies faster. It feels right.

If you are from the future, take a look at the main page of my channel. There should be a video where I show how capercaillies twist into a board.

In general, the brushless have some advantages. There is only one minus. Price. Brushless tools often cost twice as much.

Using these screwdrivers as an example: I paid 4,500 rubles for a brushless one, and 6,800 rubles for a brushless one.

In the brush screwdriver, I liked the gear shifting. On the back cover. You can easily switch speeds with your finger while holding the screwdriver in your hand.

On a brushless, gear shifting is located where the battery is attached, and it is unrealistic to switch gears with one hand.

For myself, I made the following conclusion: if you work with a tool constantly, then you need to take a brushless one. If from time to time then take a brush.

I have a Makita screwdriver, with which I screwed a couple of hundred thousand self-tapping screws, but the brushes on it have not yet worn off.

Therefore, for the pace at which I work, there is no point in buying a brushless instrument.

Brush motor or brushless whichever is better

Brush or brushless tool? My point of view

In a few comments under my articles, people asked which tool to buy: brush or brushless?

I recently got two screwdrivers, a brush and a brushless one. Both are RYOBI ONE. One battery in this range fits all tools in this range.

It is not clear to me why they are called differently. The brushless is called an impulse screwdriver. Brush. impulse wrench. Chuck size 1/4 ” for both.

The brushless is smaller, but heavier and more powerful. 270 Nm vs 220 Nm.

Battle of technology. Brushless versus conventional screwdriver. Makita VS DeWALT

Have you ever wondered if it is worth buying a brushless screwdriver today, or is it worth waiting for this technology to become even more affordable? Indeed, even now, when enough time has passed since the introduction of brushless motors, screwdrivers equipped with them are much more expensive than similar ones with conventional motors. Sometimes this difference reaches 30%.50%, and you won’t immediately understand whether brushless screwdrivers are really so much better than conventional ones that they are worth this overpayment.

Let’s figure it out.

Structurally, in our case, a standard, brushed motor has a rotor with windings and a stator with permanent magnets.

And a brushless, aka brushless motor, on the contrary, consists of a rotor with permanent magnets and a stator with windings.

Brush and brushless motors

Also, for the operation of the brushless motor, a rather complex motor control board is required. Which, in the end, will give us some improvement in the consumer properties of our screwdriver (improved protection, for example, energy efficiency as well as the most important factor)

In the design of the brushless motor, there is no complex, heavy and sparking assembly that requires maintenance. the collector. The engine is lighter and at least shorter. Switching losses are noticeably reduced, since the collector contacts and graphite brushes can be said to be replaced by the motor control board. As a result, we have an electric motor with the best efficiency and power per kilogram of weight. with a wider rpm range. Likewise, the brushless motor also heats up less. than collector Carries more torque load.

In theory, we get that brushless motors in the tool are really useful and justified. But what will we see in practice?

At the expense of better motor protection, there is a video that shows what happens to a conventional screwdriver when overloaded (the main cause of screwdriver breakdown):

and what’s with the brushless:

Well, in the new video, we will consider in practice how much a brushless screwdriver is better than a conventional screwdriver, and whether it is better at all. We will compare how many screws a Makita DF332 can screw on one battery (as an example of a brushless) and how many DeWALT DCD710 is a good, proven screwdriver with a classic brushed motor: