Carburetor Adjustment Stihl Fs 130 Lawn Mowers

Filter diagnostics for lawn mowers

Another reason why the gasoline scythe stalls is the air filter. To eliminate it, try removing the filter and starting the trimmer without it. If possible, then you will have to change the air filter to a new one, or at least blow through and thoroughly clean the old one.

The petrol trimmer may not start due to a dirty fuel filter. This is the next step in our algorithm. Here we check the condition of the filter element and, if necessary, replace it with a new one. When replacing, try not to leave the suction inlet without a filter at all, this is prohibited by any operating instructions. Haste can turn into repair of the engine piston group.

Eliminating the reasons for not getting a petrol pump

The fuel mixture must be prepared with the exact proportions of gasoline and oil. In this case, you cannot use another brand of fuel. Gasoline should be left in a glass or metal container for 2 days to prevent dirt from entering. Do not use plastic containers for storing fuel. The oil is accurately measured with a medical syringe without a needle. Use only freshly prepared mixture, do not leave spent fuel in the tank. If the engine is disobedient, gasoline stops when you hit the gas, this is probably the fuel to blame.

We carry out diagnostics of a candle and a candle channel

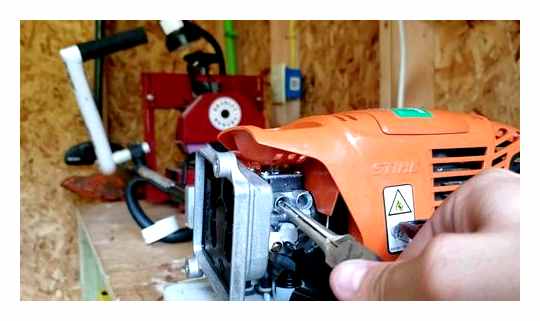

If the quality of the fuel mixture is not in doubt, and the lawn mower stalls when started, then a flooded spark plug may be the cause. Here, for repairs, an ordinary candle wrench is suitable (every motorist probably has) and a spare candle.

- We unscrew the candle and wipe it;

- Dry it thoroughly (do not ignite);

- We drain the excess fuel in the chamber through the spark plug hole and dry it;

- We clean the old candle from carbon deposits using a file or a lady’s file;

- We set a gap with a distance of 1 mm (you can check with any coin);

- We put everything back in place and try to start the trimmer.

If the candle is working, the socket where it is located is completely dry, and the lawn mower does not want to start, lubricate the threaded connection with gasoline. It should be slightly damp. No matter how wonderful a spark the candle gives out, there is simply nothing to light up in a dry chamber.

If the trimmer motor still does not start, a reason such as the absence of a spark due to poor contact between the spark plugs and the high-voltage wire should be ruled out. If the connection is of good quality, but there is still no spark, most likely, your ignition unit has “flown”. Here it will not be possible to do without a master, since the part is not repaired, but is sold as a single unit.

Checking the fuel mixture

Before starting the engine of the gasoline streamer, check the presence and quality of the fuel mixture. Do not save, do not be greedy and “do not be clever” in this matter. Repair or replacement of the piston group will cost you too much (sometimes up to 70% of the cost of a new tool). Prepare the oil-fuel mixture strictly according to the instructions. Calculate its amount based on real needs. Excess gasoline left over after work loses its quality over time.

Lawn Mower Stihl Fs 55 Will Not Start Reasons

How not to get confused if you don’t get a gas pump

The tool, despite its small size, is a complex technical device. If you study the operating manual, it turns out that the reasons why the petrol pump has not started are known and eliminated. You need to consistently rule out factors that make it difficult to launch the tool. They usually start with more accessible nodes with a simple maintenance check.

How to start diagnosing lawn mowers

If the lawn mower does not start or immediately stalls after starting, it is necessary to sequentially check all the main components and assemblies. The verification algorithm is as follows:

- Fuel tank (fuel quality);

- Candle and candle channel;

- Air filter;

- Fuel filter;

- Breather;

- Exhaust channel.

These nodes are most often the source of major problems that can be eliminated after a thorough inspection.

Rules for the operation and storage of lawn mowers

In order for the lawn mower to start well in the future, you need to provide it with good storage and operation conditions:

- During operation, carefully monitor the cooling system, carefully and in time clean the channels in the housing, as well as the ribs of the starter;

- If necessary, use solvents, kerosene and other detergents for cleaning;

- Do not clean the tool “hot”. let it cool;

- Strictly follow the instructions for the operating mode, otherwise you may overheat the engine;

- If you do not plan to use the lawn mower in the next month, the fuel mixture must be drained from it, because Over time it breaks down into heavy fractions, which will definitely clog the carburetor channels;

- After draining the fuel, let the trimmer run at idle speed until it stalls, this will help completely remove the remaining working mixture.

Before winter storage, follow these steps:

- Disassemble the braid completely, rinse and clean all the parts you can;

- Inspect the parts for damage, if necessary, eliminate distortions, tears, bends and any other malfunctions;

- Fill the gearbox with sufficient oil and clean the air filter;

- You can partially disassemble the motor, rinse, blow out and grease all moving parts;

- In order to lubricate the piston, you need to unscrew the spark plug, lift the piston to the dead center with the starter, pour a little oil into the spark plug hole and turn the crankshaft a couple of times;

- If you are storing the lawn mower outside the house, wrap the engine with oiled rags.

This is the design of a four-stroke engine. The camshaft (aka the cam that opens the valves) rotates 2 times slower than the crankshaft.

By clearances: reducing the clearance from the recommended one is much more dangerous than increasing it, because both the valve and the saddle can burn.

Thanks for the tip. Only now it is almost impossible to expose this “recommended” one: it is tight, then it is generally free. Very small spacing. Better means freer, clear.

I changed the candle, it works more or less normally, although there is vibration. It seems, after all, there is too much oil in the mixture, although it was poured as usual with a 20 ml syringe.

It’s just that the butter is probably not very good. The valve was last regulated “by eye”. I dripped oil into the gap and watched “wiggle”. Worked out since that time

10 liters of mixture. All OK. Even the cable has not yet broken at all, and it works on 3 hairs. And from large gaps in the timing, the plastic camshaft will most likely be destroyed. And more. remove the muffler and check for carbon deposits on the exhaust valve stem.

HP Super, green. Not Ultra, it’s true, but the hand doesn’t rise to it (1350 rubles per liter with us).

I read about this yesterday in the manual for the basic motor. I’ll check it out for the weekend.

Hello everyone! I am the owner of 130 for the 4th season, judging by the oil, I burned 115-120 liters of gasoline. I tried feeding the 92nd. I didn’t feel much difference. All these years in winter it was stored with a dry tank wrapped in paper. This year I noticed one feature when you roam the primer through one of the valves inside the primer contains air bubbles and the primer is filled to 5-6 mm. You will work for 10-15 minutes, you will turn off immediately, you will start up with half a turn, but if you lie down for 5 minutes, it will start only from the START position and then from the 5-7th time. I start it cold the first time. This year I changed the air fuel filter and the spark plug. I adjusted the valve though everything was almost normal. Can someone tell me where the air came from? R.S. Not in the subject but cool guys adjust the valve

”

Gee-gee. They twist everything that turns to him. Stretch screws on carburetor (not adjusting).

This is the beginning of the end of the diaphragm. It all started the same for me. How to fix. is in this thread.

Father-in-law to replace the diaphragm?

You can try to reduce the clearance between the valve lever and the diaphragm. Bend to the plane of the connector by

0.5 mm. Collect and check. The new diaphragm will die anyway.

Der-traktor Thank you very much! I’ll try to bend the lever then unsubscribe.

Good evening everyone. There was a problem with 130 of which 5-6 years. After winter it started up from the first poke and worked properly for a month, after the next refueling it stopped starting. The reason was a wet air filter. I took it to the service, said the problem in the carburetor, cleaned the carburetor, convinced After the service, the scythe used up two tanks, it seemed like everything was fine except for idle speed (swam a little) and after the break I had to mow. I refueled I come to the place, but the scythe does not start, I remove the filter, it is wet. Again, service, sentenced to replace the carburetor, just one more problem was added, the engine does not develop rpm.Help with advice if it is possible to reanimate the scythe without replacing the carburetor.

Friends, the question is. would you change stihl 130 for stihl 250 for free? Why?

P.S: Thank you in advance for your answers, I am facing a choice of 130 or 250, this is the reason for the question.

Arist.

I’ve been thinking about it for a while now. When I bought my 130th, I also looked at the 250th. The difference was only 1 sput. The toad and faith in new technologies won (4-mix). Economical. yes, but the presence of valves, timing and everything connected with this has recently begun to annoy me a little. Maybe this is just my special case. But the thought that today I would take the 250th without hesitation. visited.

I have been using stihl 250 for 10 years, I have only changed the candle, there are no complaints about the work of the braid.

Vitil, and what exactly is the irritation caused by? So that these nodes fail? difficult to maintain? Or something else?

Increased requirements for oil quality. mineral water is no longer desirable, increased requirements for the concentration of oil in gasoline. even a small overflow has a bad effect on the operation of the engine and the condition of the exhaust valve. The requirement for precise valve adjustment. you can’t squeeze, you can’t squeeze. too, you need to catch the golden empirical mean. you can’t understand without checking. Timing material. plastic. How long it goes, we’ll see. As the theory of reliability says. an increase in the number of elements leads to a decrease in the reliability of the system.

In general, this is not an antithesis. The scythe is working, but last night he burned another litrushka. The cause of vibration (see above) has not yet been determined.

We will see).

By the way, who is interested. yesterday I tried out the reinforced Oregon line 2.4 Duoline. The general impression is that nifiga is not stronger than the usual yellow round of the same Oregon. On obstacles and dry branches it breaks in the same way. Better she did only one thing. sintered in the spool. Yesterday I caught two sticks. up to a cliff when trying to pull through. I was puzzled. why is she better?

complex reasons for lawn mowers failure

If the step-by-step troubleshooting algorithm does not work, and your scythe still does not start or stalls, it is worth inspecting the carburetor and the engine itself. A clogged carburetor can be one of the reasons for erratic tool performance. There are three main problems here:

- Clogged ducts or nozzles. All this is cleaned by special washes or blown by a powerful jet of compressed air from the compressor. Do not use needles and wires, as the bore may be damaged;

- Worn carburetor gasket. Exit. replacement of a failed gasket;

- Violation of tightness. To check this indicator, you can use an ordinary household tonometer, replacing it with a suitable pressure gauge. Watch the readings: if they do not change, everything is fine, but if the pressure starts to fall, then some part of the carburetor is faulty. We’ll have to find it and replace it with a new one.

If everything is in order with the carburetor, then the petrol trimmer may not start due to wear of the piston group. If chips, scratches or scuffs are found, the piston or cylinder should be replaced. Piston rings are subject to mandatory checks. A small backlash of the piston when rocking the connecting rod indicates that it is time to change the rings. This procedure is best entrusted to the specialists of the service center.