Chainsaw chain oil flow adjustment

Specifics of Chinese chainsaw repair

A large proportion of the imported chainsaw range is made by Chinese-made chainsaws. Many models are copied from the best European designs with more or less success.

The main advantage of Chinese budget segment products is the high level of interchangeability of spare parts, components and systems. To repair Chinese chainsaws in some cases you can use parts from models of other manufacturers that are identical in power and purpose.

Adjusting the carburetor of a chainsaw with their own hands

For an independent option of the carburetor it is necessary to get acquainted with its structure and understand the order of works that are carried out to adjust the parts responsible for the proper functioning of the components of the device and the parts close to it.

It is necessary to be careful with the items to option the system, also to determine the compliance of the exhibited characteristics to very acceptable values.

Problems with chain lubrication

The main problems with chain lubrication, which the owner of a chainsaw may encounter during the operation of the tool:

The reason: not enough oil for lubrication, the filter is clogged, the thread on the pump pinion is torn.

Such a malfunction is eliminated by replacing the filter and adding oil to the crankcase, replacing the threads.

We recommend watching thematic videos about this problem, which are placed further in the article.

The reason: This fault can be recognised by oil stains on the underside of the chainsaw. To correct the problem, a sealant is applied to the hose seat after it is secured to prevent oil leaking during future use.

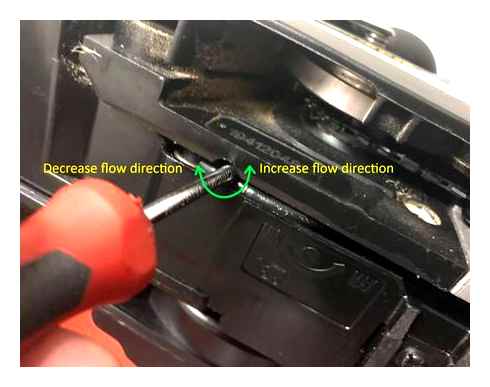

How to reduce the oil flow to the chainsaw chain

adjusting the chain oil in the chain saw

In order for the existing design of the lubrication system on the chainsaw to give it away, the oil must have a suitable viscosity. Mechanically speaking, the oil pump does not care whether you use automotive, transmission or specialty oil. The main thing is that the viscosity should be within the specified permissible range. However, this does not mean that you can pour any oil. The purpose of chain oil is not to save you money on buying it, but to lubricate the tire and chain parts. Different oils do this differently. But more about this in another article, “Chain Oil. What to pour?”.

Practical hints

Diagram of lubrication holes.

Before you start operating a chainsaw you need to check the chain lubrication system of the chainsaw. To this end, you need to hold the end of the tire, putting a paper sheet under it. When the revolutions increase, an oily streak should form on the leaf.

Proper chain lubrication increases the life of your chainsaw chain by a wide margin. If there is not enough oil, the unit will run dry. Cutting headsets will break quickly. Friction on chain should be minimal, so all guides, hinges and joints should be coated with oil.

When the chain moves on the guide bar, the lubrication system must provide a constant flow of oil. This is the function of the oil pump. It is used to apply the correct amount of oil to the guide bar and its groove.

The leading chain links spread the oil over the total length of the groove. A guarantee of proper chain lubrication is considered:

Before starting work, the lubrication system must be checked continuously. The proper supply of lubricant is determined by the sides of the chain, they must be lubricated at all times.

Lubricant requirements always vary. It depends on what needs to be sawed. When the length of the cut reaches large values, the wood has a high hardness and thick bark, it is necessary to have a large reserve of oil.

If there is smoke in the cutterbar or the chain stops, there is too much heat. The main reason is a lack of lubricant. Other causes may be:

Checking Acceleration Performance

A small amount of research must be carried out. The unit starts to accelerate. Check that the engine is running properly when it reaches maximum speed. When the engine is functioning properly, it means that when you press the gas pedal speed rapidly increases to 15,000 rpm.

If this does not happen or the increase in speed is too slow, the screw marked L must be used. It turns counterclockwise. It is necessary to observe moderate movements, because the turn cannot be more than 1/8 of a full circle.

The design of the lubrication system

Depending on the brand of chainsaw, the details of the lubrication system may vary slightly structurally, but their overall number and connection scheme remains the same.

The main components of the lubrication system, are:

-

oil tank, usually located in the engine crankcase.

Benefits of high-end oil pumps

Repairability of dismountable pumps is sufficient to restore the unit to operation at home.

Drive gears of budget chainsaws pumps are mostly polymer. Technically advanced, brand-name models with adjustable capacity are equipped with drive trains made of non-ferrous metals. The cost of such systems is compensated by economical, up to 50%, flow of lubricating fluid.

3 Easy Ways To Check If Your Chainsaw Is Oiling The Bar & Chain. Video

Repairing the STIHL MS 180 carburetor

Repairing the STIHL MS 180 carburetor is a tough business. Note that in the process of repair there is practically no risk of sharp changes of the cylinder-piston group.

If the chainsaw does not start, then apply the following steps:

1) Open and close the gas tank lid;

2) it is advisable to remove the spark plug and then drain it;

If after that there are no positive results, it is better to check the condition of the air filter, the process of gasoline supply and the functioning of the spark plug.

This problem is related to the valve (blindfold), which clogs, and as a result, a vacuum is formed. All about repairing chainsaws with your own hands I’m not leaking oil from why in a chainsaw. To eliminate this inconvenience, it is necessary to clean the valve (blind plug) with a needle.

Systematically check the filter, if the muffler is clogged, then the unit will not be able to give the power that it is built in.

If the chainsaw was purchased with a warranty (there is usually no other option) immediately take it to the service.

In summary, the STIHL MS 180 chain saw is very easy to use, has good ergonomics and a number of tangible advantages.

Sprocket Replacement

The most common cause of faults in this element is chain jamming due to chain skewing or significant wear on the chainsaw sprocket itself. If you see any signs of these deviations, carefully inspect the plane and teeth of the drive transmission element, paying attention to the depth of drift (it should not exceed 0.5 mm).

If severe wear or deformation is detected on the sprocket body, it can sometimes be repaired, but serious wear and tear requires complete replacement. Regardless of the nature of the damage found, before repairing you will first need to remove the sprocket from the chainsaw, that is, completely free it from all retaining fasteners.

Note! To access the sprocket, you must disassemble the entire implement drive assembly, including the air filter, clutch basket, and more.

Most chainsaws have the same clutch. For disassembly, you should use a spark plug wrench, which is usually included with the chainsaw, a coupling puller and a piston stopper.

First unscrew and remove the tire, remove the chain. Remove the top cover to access the spark plug, unscrew it and install the piston lock. Often a rope or string is used for stopping, but experts advise against it. It is better to use special stopper when you remove the clutch. To remove the side cover, unscrew the clutch (clockwise rotation)!) and get to the sprocket.

Or unscrew the starter and remove the cover to hold the assembly that is being unscrewed from the back. The order of complete disassembly of the main parts of the chainsaw is well presented in the video

All removed parts must be stored in one place so they do not get lost. You can take pictures of chainsaw assemblies to quickly reassemble the tool in reverse order after the repair later.