Chainsaw Kickback And How To Prevent It Explained. Chainsaw kickback guard

Chainsaw Safety: A Guide to Training, Hazards, and Inspections

Chainsaws are one of the most frequently used power tools on the market. They’re also one of the most dangerous because chainsaw safety is incredibly complicated.

Each year, 36,000 people in the U.S. seek emergency help for chainsaw-related injuries. And a far greater number of people have close calls. Because even chainsaw experts, like professional arborists or lumberjack champions, can and do experience chainsaw hazards that threaten their lives.

This chainsaw safety guide is a helpful tool for utility workers, agricultural workers, arborists, or even those using chainsaws for one-off tasks at home. In this guide, we’ll walk you through:

- OSHA Chainsaw Training Requirements

- Dangerous Chainsaw Hazards

- Required Chainsaw PPE

- Chainsaw Do’s and Dont’s

- Chainsaw Inspections

How Dangerous Are Chainsaws, Really?

Chainsaws are an incredibly common power tool used across several hazardous industries. And you likely have one at home for occasional use. However, they’re also a tool that is too often underestimated. The hazards associated with a chainsaw are both numerous, and each hazard has the potential to be fatal, even if you manage every other risk well.

To illustrate, let’s take a look at an OSHA recordable fatality from the Christmas holiday period in 2000. The OSHA Accident Report Detail says:

BEWARE THE CHAINSAW KICKBACK!

- Three employees were trimming trees on a December day.

- One of the employees was inside a utility truck bucket cutting a 20-ft long limb from a 75-ft high tree. He was not wearing fall protection.

- Two other employees stood on the ground holding a rope tied to the limb.

- The employee in the bucket saw the limb lean towards him and asked the ground workers to hold the rope tighter.

- The limb leaned away from the tree and hit one of the workers on the ground. The limb also hit the boom of the truck, and the employee fell out of the bucket. He died at the scene of the accident.

In this case, everything that could go wrong did. And a man died three days before Christmas.

These cases show why it’s so important to not only provide dedicated chainsaw operator training but to regularly train teams on potential hazards that come with chainsaw operations.

In other words, it’s not just about the power tool itself. Your ability to stay safe while operating a chainsaw requires excellent planning and a full risk assessment of the potential knock-on effects that can come from chainsaw work, especially the impact of something going wrong.

What are the OSHA Requirements for Chainsaw Training Safety?

Tree care (excluding logging) falls under the General Industry Standards (29 CFR 1910). According to OSHA, the most relevant standards within 1910 for the industry include:

To be compliant with OSHA chainsaw training, all chainsaw operators should know how to:

- Inspect, maintain, and carry a saw

- Operate the saw correctly and safely (with special training for operating a saw within a tree)

- Identify and work safely around hazards

- Wear and inspect the PPE needed to operate the chainsaw

- Initiate emergency procedures

While it’s tempting to run training on a case-by-case basis, particularly if chainsaw use isn’t included in the daily job risks, it’s always better to go through comprehensive training prior to beginning the job. In addition, you should run regular toolbox talks to reinforce best practices, address near misses, and provide training or compliance updates as needed.

If you’re looking for OSHA chainsaw training options, consider resources such as:

There are also some great videos from the U.S. Agricultural Safety and Health Centers for people who might use chainsaws occasionally but not as part of their day-to-day job duties:

What Are the Most Dangerous Chainsaw Hazards?

There are many hazards that can threaten even the most experienced chainsaw operators. Every chainsaw operator must identify these hazards before starting work. The most dangerous chainsaw hazards are:

- Tree or branches hitting the operator or a passer by (springback)

- Explosive tension in logs or branches (binding)

- Slip, trip, and fall hazards

- Fuel tank issues (using incorrect fuel-oil mixtures, fueling on the ground, using an unapproved container, fueling near sources of heat)

- Work at height hazards

Chainsaw Kickback

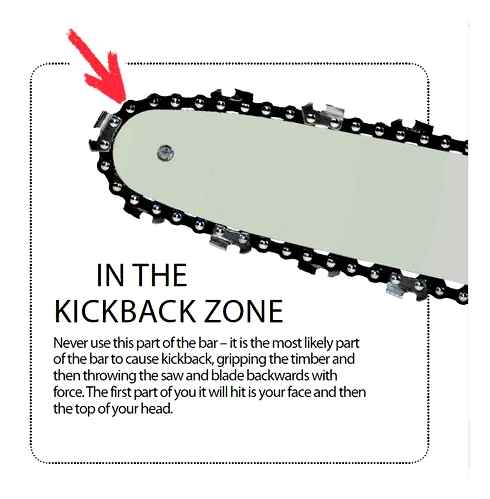

Chainsaw kickback occurs when the chainsaw jolts or jerks suddenly in an upward direction. What causes kickback on a chainsaw? According to the Canadian Centre for Occupational Health and Safety, “Kickback occurs when the end portion of the nose of the bar (the kickback zone) strikes an object and momentarily snags or is pinched.”

It can be difficult to appreciate how dangerous kickback is until it happens to you. Here’s an example of how powerful kickback can be and an explanation of just how dangerous it is:

In the video, he explains that if it wasn’t for the tree, the power of the kickback would have sent the saw 180 degrees and hit him while the saw was running. In other words, the tree prevented him for experiencing a serious, or even fatal, injury.

- Low engine speeds

- Overreaching and cutting above chest height

- Failure to maintain the chainsaw according to manufacturer’s instructions

- Incorrect replacement of chains and guidebars

Why is kickback so dangerous? When kickback occurs, the blade tip can move upward and go as far back towards the chainsaw operator. If you’re holding the chainsaw and the blade tip hits you, then you could become seriously injured. Most chainsaw fatalities happen as a result of kickback.

You can prevent chainsaw kickback with thorough chainsaw training and refresher training for operators as well as the use of safety tips to cover the nose of the bar (the kickback zone).

Vibration Disease

Vibration disease (or white finger syndrome or hand-arm vibration syndrome) is an ergonomic hazard that every operator and employer should take seriously. The disease occurs as a result of the vibration of hand-held power tools, especially chainsaws. Some experts believe that it’s not only the most common neuromuscular disorder in environments like construction and forestry but also the most underappreciated. Once vibration disease fully develops, it’s irreversible.

Hearing Loss

The noise made by chainsaw operation is a huge hazard for operators. Although it may seem minor for occasional users, CDC data shows that noise-exposed workers in Forestry and Logging had a higher percentage of hearing loss than every other industry with noise exposure combined.

Wearing hearing protection is important as is installing mufflers and silencers on equipment. Ensuring all tools are well-maintained and reducing exposure time are also vital for protecting hearing.

Remember that hearing loss isn’t only caused by noise. Vibration disease can also impact hearing, possibly through changes to the blood flow as it travels through your inner ear. So, wearing the correct PPE is imperative because there is an overlap between these two high-risk hazards.

CO Poisoning

Carbon monoxide (CO) poisoning is another underappreciated hazard among arborists, forestry workers, and farmworkers. Small gasoline-powered engines emit a dangerous amount of carbon monoxide and are particularly dangerous for loggers. Data from a NIOSH study shows loggers experience twice the CO exposure compared to workers who also perform limbing and other operations.

Unfortunately, CO is odorless, colorless, and tasteless. It’s also deadly, even in small amounts. The CDC provides an example of a farmer who died of CO poisoning after working only 30 minutes indoors with a gasoline-powered pressure washer.

Working outside will not necessarily protect operators from CO poisoning. In situations where the dispersal of exhaust fumes is hindered by another factor, fumes can still build up and threaten the operator and those in the immediate vicinity.

Electrical Hazards

Electrical hazards can come in several forms. While electric chainsaws aren’t often used outside of domestic use, like pruning and cutting trees, they still pose a danger; any electric chainsaw comes with the risk of electric shock and electrical fires. You should always inspect the cord, plug, and socket for burn marks or arcing and you should only use an appropriate extension cord and a socket with an RCD (residual current device).

The other electrical hazards for gas-powered chainsaws relate to falling branches or trees and the risk of contact with power lines. Before operating near a power line, you must verify that the line has been de-energized.

What PPE Do You Need to Operate a Chainsaw?

Chainsaw PPE includes six components. For safety and OSHA compliance, you must wear:

- Protective gloves

- Hard hat (head protection)

- Safety glasses (eye protection)

- Steel-toed boots

- Hearing Protective Equipment

- Leg protection (kevlar leg chaps, either internal or external)

The operator’s clothes should fit neatly. You don’t want any sleeves or trousers flapping in the wind as these can become a hazard in an accident.

If you’re working in a tree or off the ground, you will also wear fall protection as required. Working at height requires its own risk assessment and should be considered for when you’re planning the job.

Do you always need to wear the full set of chainsaw PPE, even for a quick job?

Wearing the right PPE can seem cumbersome for people who operate chainsaws regularly or even just for a short job. However, chainsaws are so powerful that there’s no level of experience that can protect you from these hazards. Just look at this Champion lumberjack who nearly experienced a serious leg injury during a competition — if it weren’t for his chaps.

How to Use a Chainsaw Safely: A Guide to Chainsaw Techniques and Ergonomics

Learning how to use a chainsaw safely will help avoid operator error and potentially fatal incidents. OSHA also requires that anyone who uses a chainsaw must learn how to use it correctly and understand the hazards before they are allowed to take on into the field.

The first rule of chainsaw operation is to always follow the manufacturers’ instructions. After that, competent operators can follow these steps for a safe work environment.

Complete a Work Plan or Risk Assessment

Before even picking up the chainsaw, every operator should run a risk assessment and complete a work plan for the job to be done. The process should identify and document any key risks, including the risks associated with the chainsaw and its use.

For example, if the job involves trimming branches and working at height, be sure to account for the potential of a branch to hit the worker on the ground as well as any possibility that the worker may fall.

Chainsaw Risk Assessment Example

| Risk | Potential Harm | Risk Severity | Action |

| Chainsaw wounds | OperatorsParticipantsSpectators | Medium | Provide training for competency; Wear full PPE as provided by safety management plan; Replace chain cover and apply the brake when saw is not in use |

| Burns | OperatorsParticipantsSpectators | Medium | Wear gloves and chaps; allow the machine to cool before inspecting, refueling, or re-starting |

| Eye injuries | OperatorsParticipantsSpectators | Medium | Wear eye protection |

| Noise | OperatorsParticipantsSpectators | High | Wear hearing protection |

| Falling limbs branches | OperatorsParticipantsSpectators | Medium | Complete work plan to assess the potential of falling branches; wear PPE in the vicinity |

An example of a chainsaw risk assessment to perform prior to starting a job

Part of the work plan should always include spotting hazards around the work area and eliminating them where possible. You need to clear everything away that you don’t intend to cut and remove any potential trip and fall hazards. It’s also vital to ensure you have a retreat pathway available to you.

Start the Chainsaw Safely

Your chosen OSHA chainsaw training will cover how to start the chainsaw safely. This is an often-overlooked part of chainsaw operations. There are several methods for starting the chainsaw, but the golden rule is: never drop-start the chainsaw.

You can get step-by-step instructions for starting a chainsaw from:

- Keep the saw away from your body and anything you don’t intend to cut.

- Avoid contact with any object as the chainsaw starts.

- Cover the guide bar when the motor stops.

- Always turn off the engine before putting the chainsaw back down.

Hold the Chainsaw Correctly

The way you hold a chainsaw will determine how you manage the remaining hazards that you haven’t eliminated through the hierarchy of controls.

You should hold the chainsaw with your right hand on the rear handle and your left hand on the front handle. Operators should use a firm grip to hold the saw securely. However, you should take extra care not to hold on for dear life: if your grip is too tight, you amplify your risk of vibration disease, which is painful and irreversible, even if you wear the correct gloves.

There are four golden rules for chainsaw operation:

- Hold the chainsaw with two hands. No exceptions.

- Stand to the side of the chainsaw. Never rest it on your leg.

- Keep the saw parallel to the ground when cutting.

- Carry the chainsaw with the guide bar pointed to the rear, so the blade drops off behind you.

When you put the chainsaw down, always keep it on a level surface.

Cut Safely

You’re ready to work. Your plan of action will dictate how and where you cut. However, there are general rules to follow:

- Don’t cut anything above mid-chest height.

- Make sure you don’t cut a tree where the diameter is greater than the length of the blade.

- Always work with a companion.

- If you get tired, stop work. When you’re tired, you can lose your concentration and grip, resulting in a severe incident.

Remember that the size of the tree isn’t fully indicative of how dangerous it is. Brush and small branches can cause accidents by grabbing the chain and throwing the operator off balance.

What Should You NOT Do With a Chainsaw?

There are a few things that no operator should ever do when their job involves a chainsaw. Forgetting these rules not only increases the chance of an injury but even grows the chance of a potential fatality.

Never Work Alone

Chainsaws come with many risks. Even when you complete a thorough risk assessment, you can’t control everything. Because of the increased severity of chainsaw accidents compared to other power tools or tasks, operators should never work alone.

Never Carry a Chainsaw While It’s Running

A chainsaw can cause injury anytime the blade isn’t covered. Carrying a chainsaw when it’s running puts you at risk of cutting yourself, those around you, objects, or animals in the vicinity and increases the chance of a burn.

Never Use a Chainsaw When You’re Tired

Mitigating hazards like falling branches requires your complete attention. Don’t operate a chainsaw when you’re tired, as you could lose FOCUS or find it difficult to maintain the correct grip.

Take frequent breaks when using the chainsaw and let a supervisor know if you’re struggling to concentrate.

Never Saw Above Shoulder Height

There are three very good reasons to never use a chainsaw above mid-chest or shoulder height:

- Holding a chainsaw overhead throws off your center of gravity, making it easier to lose your balance.

- Raising a chainsaw too high impedes your view. It’s much harder to see where and what you’re cutting.

- Lifting a chainsaw makes it more prone to kickback. When combined with impaired balance and vision, kickback becomes exceptionally dangerous.

Never Use Faulty Equipment

If a chainsaw inspection results in any question or doubt about the chainsaw’s maintenance, you must report it to the relevant person immediately. You should never use a chainsaw that doesn’t pass an inspection with flying colors.

How and When to Inspect a Chainsaw

Every operator should know how to inspect a chainsaw before they start the equipment. The chainsaw inspection should include the:

- Chain

- Bolts

- Brake

- Handles

- Ignition

- Clutch cover

- Fuel and oil

- Cord and plug (if electric)

If any part of the chainsaw is up for review, turn it over to the equipment manager and get a new one. Never use a chainsaw that you have any doubt about, even if it’s the only tool available. A loose chain, missing bolt, or sticky brake can land you in the hospital.

You can find free pre-operational chainsaw inspections from Northern Hire Group Chainsaw Pre-Operational Checks. Safesite users can also ask for a chainsaw inspection to be uploaded into their organization’s template library, so you can assign it to operators for completion and better manage equipment and hazards.

Chainsaw Safety is a Job that’s Never Done

The issue with chainsaw safety is that you can be the most skilled chainsaw operator in the world and still be at risk from half a dozen or more different hazards. And all of those hazards could present a severe risk to your body. As a result, it’s vital to avoid any complacency in chainsaw operations. Whether it’s suiting up with the correct chainsaw PPE or performing a chainsaw inspection or risk assessment, every step you take could be the step that prevents an injury if something goes wrong.

Are you looking for more information on OSHA training obligations? Check out How to Comply with OSHA Safety Training Standards.

Chainsaw Kickback And How To Prevent It [Explained]

Every year 36,000 people are injured by chainsaws and another 250 die. Chainsaw kickback is responsible for a significant percentage of these numbers.

Chainsaw kickback is when you get a sudden and Rapid motion from a chainsaw that you weren’t expecting.

To safely use a chainsaw, understanding kickback, its causes, and how to avoid it is important.

Chainsaw safety: Kickback, pushback, and pull-in

Before you pick up your chainsaw again, make sure you understand what chainsaw kickback is and how you can prevent becoming part of a statistic.

Types Of Chainsaw Kickback

There are two types of chainsaw kickback, each caused by a pinched chain or contact with the tip of the chainsaw bar. Learning how to avoid making either mistake is important for basic chainsaw safety.

Rotational Kickback

Rotational kickback is the most common type of chainsaw kickback. This type of kickback happens when the top tip of the guide bar/chain comes into contact with an object like a log or a branch, sometimes out of sight beyond what you are trying to cut.

The chain will get snagged and violently rotate up and towards the operator.

Rotational kickback is one of the easiest ways to severely injure yourself with a chainsaw as it causes the saw to launch up and toward the body or face of the operator.

Linear Kickback

Linear kickback is a sudden motion that occurs when either part of the chain at the end of the bar is pinched by the log, thrusting the saw back toward you.

The log can pinch the blade when it sags inwards as you cut, sending the chainsaw directly back towards you throwing you off balance and putting you in danger.

What Causes Chainsaws To Kick?

There are a variety of reasons why your chainsaw can be kicking back. Before using your chainsaw, you should ensure it is in proper working order to minimize the chance of kickback.

Dull Chains

A dull chain can easily cause your chainsaw to kick back. The teeth of the chain won’t be sharp enough to cut through the wood and will eventually get pinched or snagged.

Poorly Tensioned Chain

Tight chainsaw chains can cause different problems, but a loose chain can easily cause the chainsaw to kick back. Ensure your chain is properly tensioned before each use.

Pinched Chain

Chainsaws generate a lot of force, a force that is usually used to move a chain at fifty miles an hour. When the chain gets pinched, that force has to go somewhere.

Pinched chains transfer the energy of the chainsaw into the body of the saw, causing the blade to immediately and violently launch upwards toward the operator.

Re-Entering A Cut

Extreme caution should be used when re-entering a cut. You can easily pinch the blade or accidentally enter the cut when the saw isn’t at max power.

Chainsaw Kickback Zone

While operating a chainsaw, it’s important to stay out of the chainsaw kickback zone. The chainsaw kickback zone is a 90-degree angle from the tip of the saw, back toward the operator.

This area is where the chainsaw will violently fly if the blade is suddenly pinched or the tip of the chainsaw touches a branch.

How To Avoid Chainsaw Kickback

Avoiding chainsaw kickback isn’t hard. The majority of the time you experience kickback, it’s because of user error or improper handling of the saw.

Avoid making the following mistakes and you can prevent most kickback scenarios.

Check That The Chain Brake Is Working Correctly

Chainsaws come with a number of safety features, but the chain brake is perhaps the most important one. Chain brakes are installed in most modern chainsaws as mechanical braking systems.

On the inside of the chainsaw is the mechanical brake, while externally there is a chain brake handle you can rest your wrist or forearm against to quickly enable the mechanical braking system.

If the saw were to kick back, your wrist would push the handle forward as the saw rotates backward. It will then activate and stop all movement of the chain, preventing you from becoming seriously injured.

You can easily test that the chain brake stops the chain before use by engaging it while the saw is running and verifying it works.

Most saws also have an inertia braking system to stop chain saw kickback even if your wrist is not near the brake handle. The way to test this is to drop the power head from about a foot above a table. The saw should not be running for this test to work.

Make Sure The Saw Chain Is Sharp

A dull chain isn’t going to help you cut a log, but it can still definitely cut you.

Ensuring your chain is sharp can help prevent the chain from getting pinched or stuck, causing a kickback.

Make Sure The Chain Is Tensioned Correctly

Loose chains can easily cause the rotating chain to get snagged and increase the risk of kickback.

Most saws feature an easy and adjustable chain tension system. Ensure yours is tightened to specifications before use.

Run The Chainsaw At Full Throttle

Running the chainsaw at full throttle ensures the chain can do its work and efficiently cut the log or tree.

A sharp, fast-moving chain will have a less likely chance of getting pinched and kicking back.

Avoid Making Contact With The Chainsaw Bar Nose

The easiest way to lose control of your chainsaw is by touching a branch, log, or another object with the top tip of the chainsaw bar.

It’s simple physics. As the chain runs forward, the chainsaw will be pulled back with equal force.

Keep A Solid Grip

You should always have complete control of the chainsaw when operating it.

Always have a solid grip, with one hand on the rear handle and the other on the front handle.

Always take breaks if you feel your arms or hands getting tired.

Stand To The Left Of The Chain

Standing to the left of the saw can help keep you out of the kickback zone.

When chainsaws kick back, it’s often a direct and vertical motion from the tip of the saw. Standing to the left should hopefully move you out of the potential kickback zone.

Be Prepared For The Kick

Kickback happens. If you use a chainsaw regularly, you will experience kickbacks at one point or another.

The best thing you can do is prepare for it and ensure that if it does happen, you are in the best possible position to deal with it.

The best position is one that is out of the kickback danger zone.

Clear Your Surroundings

Being able to have a firm footing is really important to handle the risk of kickback.

If you have debris all around you then you might take an awkward step when you experience kickback, leading to a more serious injury that could have been avoided.

Never Saw Above Shoulder Height

Using a chainsaw properly is all about control. Using a chainsaw at or above shoulder height is an easy way to lose control.

Holding a heavy chainsaw that produces a ton of power over your head can throw off your center of gravity and cause you to lose your balance.

Protective Gear To Keep You Safe

Using the proper protective gear when operating a chainsaw is essential if you’d like to remain safe.

Luckily, there are a variety of different products on the market to make your life safer and avoid getting tore up from kickback.

Chainsaw Chaps

Chainsaw chaps should be worn by anyone operating a chainsaw. Chaps are made of cut-resistant fibers like kevlar that jam the chainsaw.

They provide the best protection for your legs and can quickly stop a chainsaw that comes in contact with them.

Protective Gloves

Gloves are a must when using a chainsaw. Not only can they protect your hands from the rough, rugged logs, but they also can jam a chainsaw if it were to come in contact with your hands.

Not all gloves are made from materials that will stop the chainsaw, so be sure to check that your gloves are cut-resistant.

Logging Or Steel Toed Boots

A good pair of boots can save your feet in a number of different ways. Boots should be comfortable to stand in all day, yet durable enough to take years of beatings.

A good logging boot will also protect your foot from some falling logs, and can even help prevent serious injury from a chainsaw.

Helmet With Metal Face Guard

Your head and neck are the most dangerous places to strike with a chainsaw in the kickback zone. It makes sense to invest in gear that will protect them.

Chainsaws are great for cutting through wood, but they can’t do much against a metal face guard.

Most loggers wear helmets anyways to protect their heads from falling branches. It’s easy enough to purchase one with a metal guard.

Low Kickback Chains

A low kickback chain, or a reduced kickback chain, is great for any new chainsaw user or someone that is worried about kickback.

A low kickback chain doesn’t mean the chainsaw blade will never kickback, it just reduces the chance of it.

Check your local chainsaw dealer or online for a low kickback chain.

Install A Safety Tip

A safety tip, or a guide bar tip guard, is installed on the guide bar’s nose and prevents you from accidentally making contact with it.

Most kickbacks happen when the tip touches an object. Kick guards ensure that your chainsaw tip will never come in contact with anything accidentally.

Final Thoughts

Chainsaw kickback is no joke. It has killed or caused serious injuries for thousands of people over the years and if you want to prevent yourself from being part of that statistic, there are a few things to keep in mind the next time you pick up a saw.

Always make sure you stay out of the kickback danger zone, avoid touching logs with the top tip of the guide bar, and wear proper protective gear.

Chainsaws kick back, it will happen eventually if you use a chainsaw often enough. The best thing you can do is minimize the risk of kickback and stay prepared.

How fast is Chainsaw Kickback?

Chain saw kickback is fast. extremely fast. The chain saw kickbacks so fast that you might not be able to react to it in time and move out of the way.

What is the most common Chainsaw injury?

The most common chainsaw injuries are to hands or legs. Only about 10% of injuries involve the head or neck.

How does Kickback happen?

Kickback occurs when the top tip of the chain saw touches a log or other object. This causes the chainsaw chain saw to rotate towards the operator very quickly, almost in the blink of an eye.

Kickback can also occur when the chain gets pinched or snagged. Avoid using dull chains or touching the tip of the saw against anything.

AMAZON AFFILIATE DISCLOSURE

Chainsawadam.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com.

Chainsaw Kickback Safety Guards Is The Best For Safety

Chainsaw kickback safety guards is an important facts that has a wide range of uses with chainsaw. However, you need to be cautious when using a chainsaw because it can cause serious injuries if it is not handled properly. Safety measures in some products are usually just a precaution, but there are other products whose safety measures are a legal requirement. Manufacturers and professionals recommend that you inspect your chainsaw to ensure it is safe before using it. The safety measures in a chainsaw are mainly focused on preventing chainsaw kickback injuries. For us to be able to address this problem we need to understand what chainsaw kickback occurs

Chainsaw Kickback

Kickback occurs when the upper tip or the nose of the chainsaw touches an object such as a piece of wood, and it is pushed upwards, or there is swift reverse action towards the operator. Kickback is common when the chainsaw touches an object while the chain is rotating. If you are a beginner or you, do not have enough experience in using a chainsaw you may not know how to react when this sudden upward push occurs. Kick back can also occur when the piece of wood you are cutting closer in approximation pinching the chain of the saw. Here are various ways avoiding chainsaw kickback injuries.

Kickback Safety Measures

- Avoid touching the ground with the guide bar nose when cutting pieces of wood laying on the ground

- Ensure that the chainsaw has the correct tension

- Always maintain full power when cutting

- Use the default gauge settings or the manufactures settings

Cut a single piece at a time Always ensure that the chain is properly sharpened according to the requirements Maintain the correct angle and depth of the chain teeth Operate the chainsaw when standing on the side of cutting path Always hold the chainsaw in the correct position with both hands for safety purposes When operating the chainsaw always maintain a safe distance from the cutting attachment Always wear protective pieces of equipment such as helmets and gloves when operating the chainsaw Lubricate the chainsaw before using it Check whether the brake is functioning before you start cutting Stand firmly and well balanced when using the chainsaw Make sure there no obstructions near the chainsaw before starting it Other than the above kickback safety measures, there are other important safety tips that will help you operate your chainsaw smoothly without risking your life. Operate a chainsaw only after a proper and safe training Read and understand instructions before attempting operating any chainsaw Wear a proper Chainsaw kickback safety guards before using chainsaw Observe how other experienced operators handle the chainsaw and they react to sudden saw movements Operate the chainsaws that have been manufactured and maintained in accordance with the required standards. Never start the chainsaw when it is resting on any part of your body

Always engage brakes when starting the chainsaw Never carry the chainsaw while it is still running Ensure that the chain of the saw is not moving when the chainsaw is idling Use the appropriate saw for each job regarding blade size and chain power. Keep your chainsaw free of dirt such as oil, sawdust and dust Always pay attention when operating the chainsaw so that you can be able to react accordingly if the saw misbehaves. Be aware of your working environment – power lines, animals, kids, building, and topography among other things

A chainsaw can be very useful in handling various tasks such as chopping firewood, cutting huge branches and logs among other uses. However, you need to notice the above safety measures to avoid events such as kickback injuries. Safety is crucial whenever you are operating a chainsaw. Chainsaws are very helpful when it comes to cutting but can turn out to be a nuisance when used improperly. Wearing Chainsaw safety guards is one of the best ways to protect yourself from injuries caused by chainsaws. Incidences of kickbacks can easily be prevented from causing injuries. Personal Protective Equipment (PPE) are the standard equipment that should be when operating a chainsaw by the occupational health and safety agency.

What Is A Chainsaw Kickback? Tips Tricks To Avoid Kickbacks

A chainsaw becomes extremely dangerous in the hands of an inexperienced operator, especially when the untrained cutters put themselves at risk of kickbacks. Therefore, before operating the chainsaw, every sawyer must learn what is a chainsaw kickback, how it is caused, and how to avoid it!

Kickback is an unexpected reaction of the chainsaw that happens so quickly. It is the most common cause of chainsaw-related accidents. In kickback, the chainsaw guide bar moves upward suddenly, and it happens when the nose of the guide bar hits an object. Remember that even a still chainsaw chain can cut the flesh. Therefore, you can think of how dangerous could a running chainsaw be.

Fortunately, many modern chainsaws are equipped with chain brakes and kickback protection. The chainsaw safety features prevent the chainsaw operator from life-threatening injuries caused by the kickbacks. But, if your chainsaw is not equipped with these safety features no need to worry about that till you follow all the preventive measures.

Provided below is the explanation of what is a chainsaw kickback, its causes, and useful tips from the experts. So, let’s head into the details!

What Is A Chainsaw Kickback: A Complete Understanding

So, you have been searching to know what is a chainsaw kickback. It is the sudden upward movement of the chainsaw. Kickbacks are dangerous and the most common cause of chainsaw accidents happening around the globe.

Remember that once the chainsaw decides to bite back, lefts nothing you can do. That is because; you should always keep yourself prepared and take preventive measures to avoid this jolt while working with a chainsaw.

When you are working with the chainsaw, and if its chainsaw gets snagged, the kickback would be the result you will face. The chainsaw engine is still running, and the tool is getting energy continuously; therefore, it has to go somewhere. As there is a reaction for every action, the chainsaw causes the kickback. So, you can also conclude that the more a chainsaw gets stuck, the more violent the kickbacks will be.

The kickbacks most commonly happen on the kickback zone, which is the 90 ° angle at the tip of the chainsaw bar. So, if you use this point for cutting the chainsaw, the tool can easily get pinched in the wood, resulting in kickback.

In addition, other factors can also cause the kickbacks as basic maintenance or setup. For instance, if the chainsaw chain is dull and you have been using it as it is, there is a high risk of kickback.

Furthermore, if the chainsaw chain is not tight enough, it will significantly increase the risk of chainsaw kickback. You can prepare for the kickbacks by wearing the right safety equipment and maintaining the chainsaw!

What Are The Different Types Of Chainsaw Kickbacks?

Chainsaw kickbacks are classified into three different types. Let’s have a look over them all and find out who they occur:

i. The Linear Kickbacks

The linear kickback bars occur when the chainsaw bar at the other end is pinched shut because of any object you are cutting. So, remember that any time you cut the wood, if the chainsaw chain gets pinched from any side of the object, the chainsaw will be pushed back at full throttle. It happens due to the excessive power of your tool.

So, to ensure the safe use of a chainsaw, never allow the chainsaw chain to get pinched in, and always work carefully.

ii. The Rotational Kickbacks

Rotational kickbacks are the most common type of kickbacks, but they are also pretty dangerous. The kickback is not controllable and occurs as the tip of the chainsaw guide bar nose touches any object. Resultantly, the chainsaw gets wild and is pushed back to the chainsaw user at full speed. The nose tip causing the rotational kickbacks is also known as the kickback zone.

The chainsaw would run on the wood instead of cutting the wood when the cutting angles of the teeth angle back. The force used to grain into the wood moves the chainsaw guide bar’s tip upward toward you.

It happens all of a sudden that you will not get enough time to control anything. So, it is how a chainsaw user gets surprised by the kickback in a split second!

iii. The Pull-In Kickbacks

The pull-in occurs when the chainsaw gets hit by the wood or nail at the other end. As a consequence of this encounter, the chainsaw will be jerked forward away from the operator’s grip. It could be equally hazardous as it can hit anybody working or standing in your territory.

What Are The Potential Causes Of The Chainsaw Kickbacks?

The chainsaw kickbacks usually occur when the chainsaw gets pinched in any object as wood or nails. When the chainsaw teeth hit the wood, the tool could not cut the wood any further. So, in the end, the power of the chainsaw engine results in a kickbacks bar of the chainsaw. Therefore, the more a chainsaw chain gets stuck into the wood; the more brutal the consequences will be.

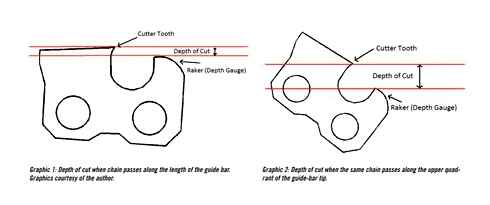

Normally, the chainsaw chain teeth take a little piece of the wood while cutting. The process is pretty quick, so you get clean cuts. The depth gauges decide the depth of each cut, which lets the chainsaw t cut only a small piece of wood, but, in the kickback zone, the chain is aligned in such a way that it cuts more wood than the advised, which is not safer in any way.

So, if you want to cut safely and want to keep yourself prevented from kickback, find out the causes of kickback just below and avoid them while operating the chainsaw:

The Kickback Danger Zone

The top of the chainsaw guide bar tip is known as the kickback danger zone. It is the part of the chainsaw guide bar which is at the highest risk of kickbacks. You should never use this part of the chainsaw guide bar while cutting the wood. Using this part while cutting increases the risk of kickback multiple times.

When the chainsaw kickback danger zone touches anything like a log or branch, a sudden kickback occurs. The larger the chainsaw guide bar nose is, the higher the potential for the chainsaw kickback.

When The Wood Pinches The Chainsaw Chain

When you cut with the chainsaw, and the wood gets closed around the chainsaw chain tightly, it results in kickbacks. That is why chainsaw experts always recommend making a plan before every cut while operating the chainsaw.

Many chainsaw operators try to cut through the truck in one cut, but it could be dangerous. It is because the chainsaw chain can get pinched while cutting the wood. Therefore, you must perform two instead of one cut to stay safe when using the chainsaw. The following are the two approaches you can opt for cutting while using the chainsaw:

i. Cutting A Log Which Is Supported At Both Ends

When the log is supported at both ends, the middle part of the wood is always clear for you to make cuts. So, the following would be the steps you follow for cutting the wood:

Cut Down The Wood Through the Top

First, you will cut the wood halfway through the top and stop afterward. If you continue to cut the wood this way, the wood will pinch the chainsaw chain, and kickback will result.

Cut Up The Wood Through The Bottom

Now, cut the wood from the bottom and meet the first cut. In this way, the wood will fall away from the chainsaw blade.

ii. Cutting The Log Supported At One End Only

If the wood is supported at one end only, then you will follow the below-mentioned steps:

Cut Up The Log Through The Bottom

You will cut through the bottom of the wood halfway up and then stop cutting. If you continue to cut, the wood will pinch the chainsaw and result in kickback.

Cut Down The Log Through The Top

It’s time to make the other cut. So, start cutting the wood from the top to meet your first cut. The two pieces of wood will fall.

Different Other Factors Contributing To The Chainsaw Kickbacks

Alongside all the factors mentioned above, the following are the other factors that boost the chances for kickbacks:

- When you cut with a dull chainsaw chain, kickbacks result.

- By not maintaining the chainsaw, you increase the risks of chainsaw kickbacks. So, take special care of your chainsaw in use.

- If the chainsaw chain is too loose, kickback will occur

- The chain breaks with use, so if you are using a cracked or damaged chain, it could be a reason for kickbacks

- Incorrectly installed chainsaw chain parts

- If you have sharpened the chainsaw at incorrect angles

- Loose rivets can be a cause for kickbacks

- Incorrect chainsaw chain depth gauges

Remember that the chainsaw occurs because of two or three factors collectively. Therefore, to keep yourself safe, you must maintain your tool and pay extra attention while using the longer chainsaw, as it increases the chances of chainsaw kickbacks.

How Can You Reduce The Chainsaw Kickbacks: Different Ways

Now that you have learned why the chainsaws can kick back, below is how you can significantly reduce the chances of the kickbacks.

Read The Chainsaw Manual

Reading the chainsaw manual to understand the manufacturer’s instructions would be the first thing you must do while starting the chainsaw. The manual provides you with the information needed for chainsaw usage. So this way, you can learn how to use a chainsaw, especially if you are a beginner.

Don’t Forget To Check The Chainsaw Chain Brakes

The chainsaw chain brake is a crucial safety feature of the chainsaw. The brake has been specially designed to stop the chainsaw chain saw by applying the brake. So, you would find it pretty useful if the kickbacks occur, as the brake will keep you safe from serious chainsaw kickback injury by stopping the chain. Getting hit by the stopped chainsaw is better than being hit by a spinning chain.

The chain brake also stops the chainsaw chain from accidentally getting a higher speed while you are switching the cutting positions; the chainsaw has two different types of braking systems, including the mechanical braking system and the inertia braking system. At the same time, many chainsaws, like Husqvarna chainsaws, can have a TrioBrake. You can also look for a chainsaw that has an anti-kickback chainsaw brake.

Always Keep The Chainsaw Chain Sharp

The dull chainsaw chain increases the risk of kickbacks. It is because the teeth cannot cut through the wood. As a result, the chainsaw gets stuck, and kickback occurs. So, always keep the chainsaw chain sharp.

Prepare The Chainsaw

Checking the chainsaw before using it is always a good idea. Keep in mind the chainsaw with sharp teeth always cuts efficiently and quickly. Besides that, you must check the chainsaw air filter, muffler, spark plug, and other chainsaw parts and ensure that they work perfectly.

It is a way to ensure that the chainsaw engine will run better and reduce the risk of kickbacks later on. You can also keep the instructions manual while operating the chainsaw, so you can get to know anything you feel you need.

The right chainsaw chain tension ensures the long life of the chainsaw chain so you can cut more precisely. The loose chain can be a reason for chainsaw injuries. Likewise, a too-tight chainsaw chain can easily become old and blunt.

Lastly, the lubrication of the chainsaw chain is necessary to keep your tool in good working condition for a long time. So, you must frequently check the chainsaw bar oil and refill it per your needs.

Maintain The Solid Grip

When using the chainsaw, you must have a solid grip. Holding chainsaws with both hands when you are using a chainsaw is pretty crucial. Also, ensure that the chainsaw does not slip because of sweating. Also, you can use a good pair of gloves for this purpose.

Watch For The Kickbacks Zone

Never cut with the chainsaw guide bar’s tip. It is an area notorious for kickbacks. So, you remain alert and must use the right part of the chainsaw for cutting.

Learn How To Operate The Chainsaw Safely

Per the instruction of the American National Standards Institute (ANSI), while operating the chainsaw, you will put your right hand and thumb around the forward handle to grip it firmly. At the same time, hold the rear handle with your right hand. over, remain in a steady and firm body position when you are going to start the chainsaw.

I explained all the techniques for using chainsaws safely in my other post. If you are worried about chainsaw safety precautions, please look at them and keep yourself safe from any bad incident. “How To Use A Chainsaw Safely: Tips Tricks“

Inspect The Working Area And Stay Alert

The working area must be free of any obstacles. If you find anything else, like the electrical wire, remove them from the working zone first. The wood pieces can get into you anytime, so stay active and alert while operating the chainsaw.

Wearing The Right Safety Equipment

For safe working, you must wear the right chain saw safety equipment to keep yourself protected. You must wear eyewear, chainsaw pants or chaps, heavy work boots, gloves, and a safety helmet. Besides that, earmuffs are also a must, especially if you use a gas-powered chainsaw.

Helmet:

A durable and right-size chainsaw safety helmet is necessary to use as it saves you from injuries in the head at the time of any incident while using the chainsaw.

Please look at a few options of chainsaw safety helmets available in the market and click on the link for detailed information about chainsaw safety helmets.

Pants:

Wearing the safety dress while using the chainsaw keeps you safe from unexpected injuries and helps you complete your job. Because chainsaw safety pants offer hooks and other places for holding and gripping chainsaws and related tools for cutting wood/branches.

Still, if you dont have chainsaw safety pants, go for the best ones from the below option.

Gloves:

Chainsaw safety gloves are important because they protect you from injuries while working and help gripe chainsaws and other tools.

Various brands are available in the market that offers chainsaw safety gloves; please have a look at the below options.

ear muffs

If you dont want to become deaf while working with a chainsaw, you must use Ear Muffs. Chainsaw engines produce high DB noise while running, hurting your listening power. Therefore, buy earmuffs if you dont have them yet.

What Do You Know About The Anti-Kickback Chain?

Chainsaw kickbacks occur frequently and commonly cause chainsaw injuries. Therefore, manufacturers now provide newly designed chainsaw chains to minimize reactive forces. These chains are known as anti-kickback or low-kickback chains.

The anti-kickback chainsaw put a limit on the amount of wood fiber that is hooked as a working corner in the kickback zone. To accomplish this limitation, an extra metal is added to the tie straps between the cutting teeth. As a result, the straps function at higher depth gauges as they move around the top of the chainsaw bar.

In addition, the newly designed chainsaw chains reduce the chances of kickbacks due to the drive links, which have built-in bumpers and ramped depth gauges. So, the chainsaw deflects the wood fiber to a specific limit when the chain moves through the kickback danger zone.

The only drawback of these chainsaw chains is that you can’t use the chainsaw for felling trees. The tool is only suitable for bucking, limbing, firewood cutting, and pruning. But the following are the other features you can opt for to minimize the chances of kickbacks:

- The chain brake stops the chainsaw chain from spinning at the kickback time.

- A tip guard installed on the front of the chainsaw bar prevents you from using that part of the bar while cutting.

- The front hand guard protects the top hand from accidental injuries.

Avoiding The Chainsaw Kickbacks: Tips And Tricks

The following are the tips I used to follow while operating the chainsaws, and I found them very effective as these preventive measures reduce the kickback chances significantly. So, let’s have a look over these and understand how you need to operate the chainsaw:

- When operating the chainsaw, always hold the tool firmly with both hands. With your right hand, you can firmly grip the rear handle and hold the front handle with the help of your left hand.

- While cutting, you must keep an eye on the chainsaw nose bar and ensure that it does not come in contact with any object, like branches, logs, or other objects.

- When you start your work, ensure that the area in which you work is free of all obstacles.

- It may surprise you, but through my experience of several years, I have realized that the cutting efficiency of chainsaw chains increases at a higher speed and also reduces the risk of kickbacks.

- Always use specially designed low-kickback chainsaw chains to avoid kickbacks. These chains can significantly reduce the chances or risk of chainsaw injuries.

- Hold the chainsaw close to yourself, and never cut above the shoulders.

- The small wooden pieces of the wood pieces can be thrown upwards at you. So, take care of them while operating, as you may lose control because of them.

- It is better to work on the left side of the tree and remain as close as possible to the chainsaw. This way, you can get maximum control over your tool while working.

- Whenever you feel unwell or distracted, it is better not to operate the chainsaw.

- It is not safe to cut the stacked logs or branches. Therefore, you must separate them all and then cut one piece at a time.

- Before operating the chainsaw, it should be your duty to ensure that the chainsaw chain brake system is working perfectly.

- If everything fails, the personal safety equipment will always be there for your safety and protection. Therefore, wearing the complete safety kit while using the chainsaw is necessary.

Chainsaw Kickbacks: What Do You Not To Do?

The following are the things that a chainsaw operator is not supposed to do at any cost:

- Never stand behind the chainsaw directly.

- No need to cut with the tip of the chainsaw guide bar or avoid cutting with the kickback zone

- Don’t cut anything else which is above your shoulder height

What Is A Chainsaw Kickback: Frequently Asked Questions

How often does the chainsaw kickback happen?

The chainsaw kickback occurs in a few seconds as soon as any of the chain links come in contact with the wood. The kickbacks are so quick that the chainsaw operator doesn’t get enough time to react.

What is the most common chainsaw injury?

The most common chainsaw injuries involve the hands and foot, and only a few injuries (less than 10%) involve the head or face. The death rate from such accidents is pretty low.

Can A Woman Handle The Chainsaw?

The women can easily handle the chainsaw and can use them successfully felling the trees. So, the chainsaws for women are the same for men.

Which Is The Safest Chainsaw?

Electric chainsaws are the safest whether they are corded or battery-operated. Electric chainsaws run at a slower speed and are less powerful than gas-powered chainsaws, and most importantly, the chainsaw for kickbacks will be pretty low if you use an electric chainsaw.

Final Words: What Is A Chainsaw Kickback

Those woodworkers who operate the chainsaw regularly know how dangerous a log or limb could become when the chainsaw guide bar hits it. It is how kickbacks are caused. If you don’t know what is a chainsaw kickback, it is a quick and unexpected response as it encounters any object.

Consequently, the chainsaw falls on the operator and may cause severe chainsaw injuries. The best way to prevent these kickbacks is to avoid those circumstances with a risk of this accident. So, you should always hold the chainsaw with both hands and observe the safety operation principles while using the chainsaw!

What is Chainsaw Kickback? What Causes Kickback? (And Tips on How to Avoid It)

Would you also like to know how to avoid a kickback injury?

I put this article together to give you all of the information you need to use your chainsaw as safely as possible.

So, keep reading to discover what chainsaw kickback is and how to protect yourself from it.

What is Chainsaw Kickback?

The term “kickback” is used to describe the sudden, upward motion of a chainsaw’s guide bar.

Believe it or not, but it’s one of the most common causes of accidents that happen with a chainsaw, and it’s usually caused by not using proper chainsaw cutting techniques.

Kickback can happen in the blink of an eye too.

It’s incredibly dangerous and could result in a serious injury that could send you to the hospital

In fact, about 30,000 chainsaw-related injuries happen each year, with chainsaw kickback accidents being the most common hazard.

What Causes Chainsaw Kickback?

In general, there are three situations that cause chainsaw kickback.

- The chain hits a hard object in the kickback zone.

- The wood pinches the chain in the middle of a cut.

- Other factors that contribute to chainsaw kickback.

The Kickback Zone

There’s one part of your chainsaw that’s referred to as the “kickback zone”.

The kickback danger zone is the very tip of the chainsaw bar.

The reason it has this name is that the chainsaw tip is the most common part of the chainsaw that can cause a kickback.

Since that area of the chainsaw has the highest kickback risk, it’s advised that you never use this part of the chainsaw bar to cut.

If you do, you’ll significantly increase the chances of experiencing dangerous kickback occurrence.

Should the tip of the chainsaw bar touch an object, including a branch or log, it’s highly likely that the kickback reaction will occur.

This is true even if you have one of the best rated chainsaw models with the most safety features.

The Wood Pinches the Chain

If you’re cutting with a chainsaw and the wood closes around the chain tightly, it can cause a chainsaw kickback to occur.

Therefore, it’s always best to make a plan before you cut a log or tree trunk so that the chain doesn’t become pinched.

As a new chainsaw user, your instincts might tell you to cut all the way through a tree branch or trunk in one cut. But, that can be dangerous due to the chance of the chain getting pinched during the cut.

So, you’ll want to perform two cuts, NOT one, to stay safe while using your chainsaw.

Here’s how to approach the most common cutting situations in the safest manner possible:

How to Cut a Log Supported on Both Ends

- Cut down through the top of the wood about halfway through. Then stop. (If you were to cut all the way through, the wood would pinch the chain since the downward pressure of the load would force the two halves of the wood together before you could finish the cut.)

- Cut up through the bottom of the wood to meet the first cut. (The wood will bow down and inward, falling away from the chainsaw blade.)

How to Cut a Log Supported on One End

If a log or branch is supported on one end, as you’ll often see with a downed tree, then you’ll want to make your cuts in this order:

- Cut up through the bottom of the wood about halfway through. Then stop. (If you were to cut all the way through, the wood would pinch the chain since the downward pressure of the load would force the two halves of the wood together before you could finish the cut.)

- Cut down through the top of the wood to meet the first cut. (The wood will fall down and away from the chainsaw blade.)

Note: The reason you wouldn’t want to make just one cut down through the top of the wood is because of the downward pressure of the load. If you didn’t provide a relief cut from under the bottom of the wood first, the branch or log might snap off before you finish the top cut. Therefore, using two cuts is a much safer process.

Other Factors That Contribute to Chainsaw Kickback

While the first two things we covered will contribute the most to chainsaw kickbacks, there are a few other factors that can increase the chance of a kickback happening.

- Chainsaws that have not been maintained properly.

- Cutting with a dull chain.

- The tension on the chain being too loose.

- Chain parts that have been incorrectly installed.

- Chain parts that are cracked, bent, or broken.

- Chain cutting angles that have been sharpened incorrectly. (Always use a high-quality chainsaw sharpener for this reason.)

- Chain depth gauge settings that are excessive.

- Chain depth gauge shapes that are incorrect.

- Rivets that are loose.

When it comes to chainsaw kickback, one or several of these factors might also play a role.

So, keep your chainsaw properly maintained and inspect it thoroughly before each use for any potential problems or defects.

Additionally, as the size of the guide bar’s nose gets larger, the potential for kickback increases.

Therefore, you should be extra cautious when operating a longer chainsaw blade like an 18 inch chainsaw model.

How to Reduce Chainsaw Kickback?

Now that you know what is chainsaw kickback and the top factors that cause it, we can now talk about some steps you can take to reduce your chances of experiencing a kickback.

- Before using a new chainsaw, make sure to read the operating instructions in their entirety. Don’t assume that every chainsaw works exactly the same. Educate yourself on the proper way to handle the equipment you have.

- Always be awake and alert when using the chainsaw. Never use a chainsaw if you’re feeling fatigued.

- Double-check that the chain brake on your saw works before you start cutting.

- Never cut with the tip of the chain. This is considered the “kickback zone”.

- Be overly cautious when removing tree branches. If the nose bar strikes anything, including stumps, hidden branches, or logs, this could cause the chainsaw to kickback.

- Never use the chainsaw above shoulder height. You have less control over the tool and might not be able to stop a sudden backward thrust of the blade.

- When felling a tree (cutting it down), always use the bottom side of the bar to make your cuts. Never cut with the top of the bar.

- When felling a tree or crosscutting wood, consider boring the base of the chainsaw into the trunk or log. Many chainsaws include bucking spikes to help stabilize the tool and prevent sudden kickbacks.

- Always know where the nose of your chainsaw is and how it’s positioned.

- Consider using a low-kickback chain on your chainsaw.

- Use chainsaws that have narrow nose bars. Remember, the larger the nose bar is, the greater the chance of experiencing kickback.

- Always wear the right chainsaw protective gear and equipment to protect yourself while using a chainsaw. The items you should be wearing include:

- Protective eyewear

- Chainsaw chaps or pants

- Chainsaw gloves

- A hard hat (if you get a helmet with a face shield, this will keep your eyes protected and you won’t need separate safety glasses)

- Earmuffs or earplugs

- Heavy work boots (you might consider wearing logging boots that are made specifically for chainsaw work)

- Always keep your fingers wrapped tightly around your chainsaw handles. Using a half-grip doesn’t give you as much control over the tool.

- Make sure you follow the maintenance instructions that are provided with your chainsaw and chain to keep both in proper working condition.

What is an Anti-Kickback Chain (Low-Kickback Chain)?

Since chainsaw kickback is such a common occurrence—and a dangerous one—some chains have been designed to minimize this reactive force.

These types of chains are called “anti-kickback” or “low-kickback” chains.

These low-kickback chains work by putting a limit on the amount of wood fiber that can be hooked as the working corner rounds the upper half of the bar (i.e. the kickback zone).

This limitation is accomplished by adding extra metal to the tie straps between the cutting teeth.

This results in the tie strap functioning at a higher depth gauge as it goes around the top of the bar.

Some of the other ways that low-kickback chains reduce the chances of kickback occurring include having drive links with built-in bumpers and ramped depth gauges, which deflect the fiber to a certain extent as the chain travels through the kickback zone.

Your chainsaw can also be equipped with other features to reduce the chances of kickback occurring.

- Chain brake that stops the chain from spinning when a kickback happens.

- Front hand guard to protect your top hand from accidental cuts. This often doubles as the chain brake if you chainsaw has that safety feature.

- Tip guard that’s installed on the front of the chainsaw bar to prevent you from using that area to cut wood.

Summary of Chainsaw Kickback

As you learned, kickback can happen at any time, and withing a split second. Also, chainsaw kickback is the most common type of chainsaw injury that people encouter.

So, it pays to stay safe while operating your tool.

I hope this article answered all of your questions about what is chainsaw kickback, what causes chainsaw kickback, and methods to avoid it.

Happy sawing!