Circular saw invented. Circular saw invented

US800426A. Circular saw Google Patents

Publication number US800426A US800426A US1904219158A US800426A US 800426 A US800426 A US 800426A US 1904219158 A US1904219158 A US 1904219158A US 800426 A US800426 A US 800426A Authority US United States Prior art keywords saws saw bars devices circular Prior art date 1904-08-02 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Expired. Lifetime Application number Inventor Almon B Calkins Current Assignee (The listed assignees may be inaccurate. Google has not performed a legal analysis and makes no representation or warranty as to the accuracy of the list.) AMERICAN MATCH Manufacturing Co Original Assignee AMERICAN MATCH Manufacturing Co Priority date (The priority date is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the date listed.) 1904-08-02 Filing date 1904-08-02 Publication date 1905-09-26 1904-08-02 Application filed by AMERICAN MATCH Manufacturing Co filed Critical AMERICAN MATCH Manufacturing Co 1904-08-02 Priority to US1904219158 priority Critical patent/US800426A/en 1905-09-26 Application granted granted Critical 1905-09-26 Publication of US800426A publication Critical patent/US800426A/en 1922-09-26 Anticipated expiration legal-status Critical Status Expired. Lifetime legal-status Critical Current

Links

- 239000000463 material Substances 0.000 description 8

- 238000010438 heat treatment Methods 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 4

- 230000002093 peripheral Effects 0.000 description 4

- 239000002023 wood Substances 0.000 description 4

- 240000001987 Pyrus communis Species 0.000 description 2

- 235000014443 Pyrus communis Nutrition 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 239000002699 waste material Substances 0.000 description 2

Images

Classifications

- B — PERFORMING OPERATIONS; TRANSPORTING

- B26 — HAND CUTTING TOOLS; CUTTING; SEVERING

- B26D — CUTTING; DETAILS COMMON TO MACHINES FOR PERFORATING, PUNCHING, CUTTING-OUT, STAMPING-OUT OR SEVERING

- B26D3/00 — Cutting work characterised by the nature of the cut made; Apparatus therefor

- B26D3/18 — Cutting work characterised by the nature of the cut made; Apparatus therefor to obtain cubes or the like

- B26D3/185 — Grid like cutters

- Y — GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10 — TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T — TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T83/00 — Cutting

- Y10T83/647 — With means to convey work relative to tool station

- Y10T83/6584 — Cut made parallel to direction of and during work movement

- Y10T83/6587 — Including plural, laterally spaced tools

- Y10T83/6588 — Tools mounted on common tool support

- Y — GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10 — TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T — TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T83/00 — Cutting

- Y10T83/647 — With means to convey work relative to tool station

- Y10T83/6584 — Cut made parallel to direction of and during work movement

- Y10T83/6635 — By feed roller

- Y10T83/6636 — Pinch rollers

Description

-ALMON B. oALKINs. 0E “BE LL EVILLE, NEW JEEsEY, ASSIGNOR To i PAMERIoAN MATCH MANUFACTURING o MPANY, OF

which the following is a specification, reference being had to the accompanying drawings,’forming a part thereof.

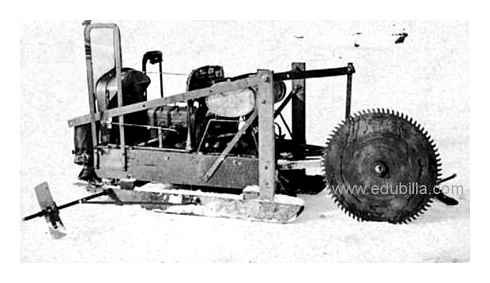

My invention relates to improvements in circular saws, and particularly to circular saws and gang sawing machinery for sawing blocks of wood into veneer. Saws adapted for this purpose need to be very thin, in order that there shall be as little waste of material operated upon as possible, and should revolve at an extremely high rate of speed. With ordinary circular saws of the common disk form there is a limit to the running speed, because of the tendency to buckle, due to unequal heating, and it is desirable in this class of machinery to run the saws at a rate of speed much beyond this limit. To this end I have devised a circular saw comprising a peripherally-toothed ring or annulus, and in carrying out my invention I employ a plurali-ty of these saws arranged around a’drum carrying them. An annulus of this description will heatmore evenly throughout than will a disk, and the tendency of the same to buckle will be largelyreduced. Hence I am enabled to run the saw at a higher rate of speed than would be otherwise possible. Further, it will be seen that in heating up an annulus may expand radiallywithout seriously buckling the same, while a disk being held by the central portion from expanding radially will necessarily buckle. I also employ holding or steadying devices, which engage opposite sides of the saws above and below the material fed thereto, and. by this means should any buckling occur throughout the annulus or ring comprising a saw-the operating portion thereof will be held steady and will remain properly spaced from contiguous saws, so that veneers of uniform thickness Will result. 4 i

My invention is particularly designed for the purpose of severing blocks of wood into veneer cards about one-tenth of an inch in thickness, to be finally subdivided into splints for employment in the manufacture of v. Specification of Letters Patent Application filed August 2, 1904. Serial No. 219,158.

matches, and as a result thereof I am enabled to obtain an exceedingly uniform veneerwith a minimum loss in the saw-kerf. My invention further consists in “certain noveLdetailsof construction and combination of parts, as will hereinafter more fully’ap pear.

I will. now proceed to describe a machine embodying my invention and will then point out the novel features in claims.

elevation of a machine embodying my inven tion. Fig. 2 1s a View 1n central transverse section therethrough. Flg. 3 1s a view in plane of the line 3 30f Fig. 1.

detail view, in transverse section, of certain feeding devices employed, the’plane of section being upon the line 4 4 of Fig; 2. Fig. 5 is a detail view of one of the saw-rings removed. Figs. 6, 7 8, and 9 are fragmentary detail views showing more particularly the means for supporting the upper and lower bars which carry the steadying-plugs.

The frame 1 of the machine supports suit-‘ able bearings-2 for the-saw- shaft 3. shaft 3 carriesa drum 4 of a diameter preferably not less than one-half the diameter of the saws. It is here shown of a diameter somewhat greater than one-half thediameter of the-saws, and so far I consider. that the larger the diameter of the drum with respect to the saw the better the results 1′ am likely to obtain. The saws comprise each a peripherally-toothed ring or annulus 5, one of which ameter of the rings 5 is substantially equal to the exterior diameter of the drum k’by which they are carried. Intermediate each of the saws is a spacing-ring or washer 6’, andside plates 7 are provided at each end of the-drum,

about equal to the outside diameter of the said the saw-rings, the side plates, and the spacingpieces and secure the parts firmly together.

erwise secured to the saw-shaft Y The saw-bed 9 is supported upon the frame 1 of the machine and i tself’acts as a supporting-plate for brackets 10, carryingholding or steadying devices for the saws. These hold-.In the drawings, Figure 1 is a view in end longitudinal section substantially upon the Fig. i is a The sawsaid side pieces preferably having a diameter The side plates 7 are preferably’keyed o’r oth-‘ is shown in detail in Fig. 5. The interior di rings or spacing- pieces 6. Bolts 8 pass through m or steauying devices comprise a plurality of bars 11, arranged above the level of the bed, and another plurality of bars 12, arranged flush with or below the level of the bed. The bars 11 are strung upon bolts 13, secured to the brackets 10, and thimbles or spacing- pieces 14 maintain the bars the proper distance apart. The bars 12 are strung along similar bolts 15, supported by end plates ’26, secured to the frame 1 of the machine, and thimbles 16 in like manner act as spacing-pieces to space them the proper distance apart. The width of the bars 11 and 12 is somewhat less than the distance between the saws, so that they will be out of contact therewith at alltimes; but the said bars are provided with looselyinserted plugs 17 of antifriction metal, which extend beyond the sides thereof and engage the faces of the saw-rings, so as to guide and steady them. Set-screws 18opposite the plugs 17 may be employed to take up any slight vanation which may exist; but it will-be understood that the plugs areintended to be of just exactly the length to properly engage the sawfaces so as to steady them without applying undue friction thereto, the function of the setscrews 18 being to take up but very slight variations. As explained, the bars 11 will be some distance above the level of the bed or table 19, preferably such a distance as just to permit the work to be acted upon to pass beneath them, while the upper edges of the bars 12 will preferably be about flush ‘with the surface of the table 9, so that the work will substantially fit between the lower faces of the bars 11 and the upper faces of the bars 12. The antifriction- plugs 17 will preferably be.as near the lower edge of the plates 11 and the upper edge of the plates 12 as is possible, so that the saws will be steadied as close to the work as practicable; By this arrangement it will be seen, first, that the saw-rings will have but a verysmall tendency to buckle, even though they may be mad-eof very thin material, because, being of ring-like instead of disk-like form, they will heat more uniformly throughout; second, in heating the rings may expand radially with but slight tendency to buckle; third, the ring-like form permits a greater percentage of the saw-body to be employed in the work than would be possible in a disk form, whereby the surface friction throughout the saw is more uniform, and, fourth, should the saw-rings buckle the alinement at the operating-point will be maintained because of the antifriction spacing devices employed.

I have shown feeding means for the material to be operated upon comprising two paddle- wheels 19, geared to rotate together and provided with peripheral feed- blades 20, the said wheels driven by a belt connection 21 from the saw- shaft 3 through suitable gearing, such ‘as will give the proper direction and speed thereto. operated by a rocking lever 23. conti olled by a detent 24, which engages successive paddleblades 20 of the lowermost feed-wheel. The feed-wheels rotate continuously, but give an intermittent impulse to the detent 21-, rocker 23, and pusher 22, a spring 25 operating to return the parts to a normal position between each movement forward, at which time a new block may be dropped in front of the pusher to be fed to the feed-wheels at the next impulse given thereto.

WVhat I claim is 1. In sawing machinery, the combination with a plurality of circular saws, of two sets of bars arranged between contiguous saws, but out of contact therewith, metallic plugs carried by said bars of each set projecting beyond the sides thereof, arranged to engage the side faces of adjacent saws, but to clear the teeth thereof, and means for feeding. work to be operated upon between the two sets of bars.

In sawing machinery, the combination with a plurality of circular saws, or means for feeding work thereto, and steadying devices for the saws, arranged to engage the side faces thereof at points above and below the point at which they engage the work and within the teeth-line thereof, said devices including supporting means arranged between, but clear of, the teeth of adjacent saws.

In sawing machinery, the combination with a circular saw, of-ineans for feeding work thereto, and stead ying devices for the saw, arranged to engage the side faces thereof at points above and below the point at which it engages the work but clear of, and out of contact with, the peripheral teeth thereof.

In sawing machinery, the combii-iation with a plurality of circular saws, and steadying devices located freely between them, near the peripheries thereof, and arranged longitudinally in a line, of take-up means for the steadying devices arranged at the end thereof, substantially as specified.

In sawing machinery. the combination with a plurality of saws, steadying devices located between them, near the peripheries thereof, and in a line with each other, bars freely supporting the said steadying devices, and take-up devices opposite the ends of the line of steadying devices.

In sawing machinery, the combination with a plurality of circular saws, of a set of bars arranged between them, plugs freely mounted in said bars and projecting laterally therefrom upon opposite sides of the said bars to engage the side faces of adjacent saws, and an end adjusting-screw for simultaneously adjusting all the said plugs.

In sawing machinery, the combination with a plurality of circular saws, each comprising a peripherally-toothed annulus or A pusher 22 is provided,- 5

of said saws, said steadying devices engaging the side faces of the saws above and below the point at which the said saws engage the work’to be operated upon.

Circular saw invented

A good circular saw is a “must have” tool, it will be used for home improvement or renovations and it is the easiest way to cut a sheet of plywood down to sizes manageable on a table saw or bandsaw for your projects. There are many different styles and models on the market,select a style that feels comfortable, I find some very heavy, others have an awkward positioned handle. Purchasing a higher quality model is a good investment, this is a tool that you will use for a lifetime so you might as well get a good one. Don’t go cheap on the blade it is not worth having tearout on an eighty dollar sheet of plywood an inch wide on each side of the cut just to save a few dollars.

The first practical portable electric circular saw was invented by Edmond Michel and patented in 1924.

He founded the Michel Electric Handsaw Company to manufacture the saw in partnership with Joseph Sullivan.

The company name was later changed to Skilsaw Inc.

Portable circular saws in general are often referred to as Skilsaws or Skil saws.

This style offers better control and accuracy, used mostly by professionals,

ThIs is the most common style, available in right and left hand models. Used by both contractors and the home handyman.

With the better life of L-ion batteries this type of saw is becoming a popular choice. Extremely handy in locations where power is not available.

With a table saw’s accuracy, a panel saw’s capacity, and a circular saw’s portability, the track saw makes precise, splinter-free cuts in almost any situation with minimal setup.

Simply lay the zero-clearance 59-inch track on your work-piece and plunge in with the 1,300 watt saw. The track’s undermounted friction strips “grab” your stock. no clamping necessary. while the saw slides smoothly on four low-friction glide strips.

Available in both corded and cordless models.

40 Tooth

The more teeth on the blade the smoother the cut.

16 Tooth

This blade is used for fast cutting of construction grade material.

Vinyl Panelling

Cutting thin material requires a fine tooth blade

Always treat these saws with respect, make sure that you have a firm hold on the saw and the material being cut. Position the saw on the edge of the material aligned with the cut mark, start the saw and push it straight into the material. Be aware of where the cord is, it is easy to saw through it. Make sure that you will not be sawing into your sawhorse or bench. Use a sawhorse with a wide top to hold material being cut.

This triangle shaped guide allows it to be held to the board with your left hand with room for the saw motor to pass. Make the sides of the triangle about 9″ long out of 1/4″ thick plywood, the front guide ois a 1″ X 3/4″ strip about 14″ long. Fasten the triangle to the strip with wood screws with the perpendicular edge of the triangle at right angles to the top of the strip. Your first cut should cut through the strip and the end of it is now used as a guide to position the jig.

Use a Sheet Rack to support the sheet, cut along a straight edge, either make one or purchase a factory made one. Cut on the back side of the sheet with a quality blade for a smoother edge.

Have firm control of the saw and material being cut.

Make sure the blade is sharp and suitable for the job at hand.

Make sure blade guard is working, never tie it up out of the way.

Check used material for nails or other foreign objects before cutting.

Unplug saw before making adjustments or changing blade.

Do not over-reach, always have firm footing.

Allow saw to reach full RPM before starting cut.

US2121069A. Circular saw. Google Patents

Publication number US2121069A US2121069A US14806237A US2121069A US 2121069 A US2121069 A US 2121069A US 14806237 A US14806237 A US 14806237A US 2121069 A US2121069 A US 2121069A Authority US United States Prior art keywords saw cradle frame arbor arm Prior art date 1937-06-14 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Expired. Lifetime Application number Inventor James G Collins Current Assignee (The listed assignees may be inaccurate. Google has not performed a legal analysis and makes no representation or warranty as to the accuracy of the list.) ATLAS PRESS CO Original Assignee ATLAS PRESS CO Priority date (The priority date is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the date listed.) 1937-06-14 Filing date 1937-06-14 Publication date 1938-06-21 1937-06-14 Application filed by ATLAS PRESS CO filed Critical ATLAS PRESS CO 1937-06-14 Priority to US14806237 priority Critical patent/US2121069A/en 1938-06-21 Application granted granted Critical 1938-06-21 Publication of US2121069A publication Critical patent/US2121069A/en 1955-06-21 Anticipated expiration legal-status Critical Status Expired. Lifetime legal-status Critical Current

Links

- 241000763859 Dyckia brevifolia Species 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 230000003028 elevating Effects 0.000 description 2

Images

Classifications

- B — PERFORMING OPERATIONS; TRANSPORTING

- B27 — WORKING OR PRESERVING WOOD OR SIMILAR MATERIAL; NAILING OR STAPLING MACHINES IN GENERAL

- B27B — SAWS FOR WOOD OR SIMILAR MATERIAL; COMPONENTS OR ACCESSORIES THEREFOR

- B27B5/00 — Sawing machines working with circular or cylindrical saw blades; Components or equipment therefor

- B27B5/16 — Saw benches

- B27B5/22 — Saw benches with non-feedable circular saw blade

- B27B5/24 — Saw benches with non-feedable circular saw blade the saw blade being adjustable according to depth or angle of cut

- B27B5/243 — Saw benches with non-feedable circular saw blade the saw blade being adjustable according to depth or angle of cut the saw blade being arranged underneath the work-table

- Y — GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10 — TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T — TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T83/00 — Cutting

- Y10T83/768 — Rotatable disc tool pair or tool and carrier

- Y10T83/7684 — With means to support work relative to tool[s]

- Y10T83/7701 — Supporting surface and tool axis angularly related

- Y10T83/7705 — Adjustable angular relationship

Description

J. G. COLLINS CIRCULAR SAW I Filed June 14, 1957 3 Sheets- Sheet 1 a a R.fl m m N/ R E0 0 Waw? 1 A l 0 WM m M June 21, 1938. J. G. coLLlNs CIRCULAR SAW Filed June 14, 1957 a sheets-118652 INVENTQR.

Jamm 6. fa/fl/w ATTORNEYS June 21, 1938. J. G. C )LL|N’S CIRCULAR SAW 3 shqets- shee t 3 Filed June 14, 1937 Z7 INVENTOR. BY Q/0/7766′. ‘o/fl’ms ATTORNEYS.

Patented June 21, 1938 s PATENT OFFICE CIRCULAR SAW James G. Collins, Kalamazoof Mich assignor to Atlas Press Company,

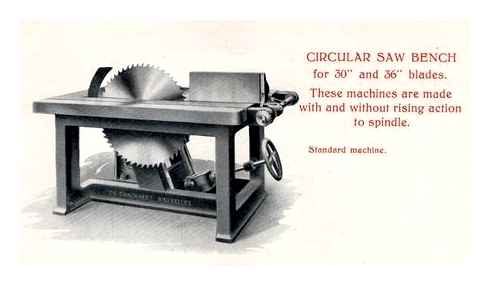

This invention relates to circular saws and in particular to that type of circular saw in which the saw extends through a slot in the tableand may be raised or lowered and tilted with reference to the table for sawing to different depths J or at different angles.

Further objects and advantages pertaining to details and economies of construction and operation will appear from the description to follow.

A structure embodying the. features of my invention is illustrated in the accompanying drawings, wherein:

Fig. 3 is a detailed sectional view taken on the line 33 of Figs. 1, 5, and 6, showing the saw in ‘one position in full lines and in dotted lines in another position. I

Fig. 4 is a broken sectional view on the lines l4 of Figs. 2 and 3, showing the details of the cradle mounting for the saw support.

Fig. 5 is a detailed sectional view taken on the line 55 of Fig. 6, showing the means of mounting the saw arbor and the means for clamping it in adjusted position.

Circular saw MOTORIZED home made

Fig. 6 is a detailed sectional view taken on the line 6-6 of Figs. 1, 2, and 5, showing the tilting mechanism for adjusting the saw supporting cradle.

I is the frame of the saw supporting a saw table 2 which has a slot 3 therein through which the circular saw 4 may be adjusted vertically. 5 is a saw guard pivotally supported at 6 on a splitter 1 which is in line with the saw blade above the table 2.

The saw is mounted on an arbor 8 on the end of a pivoted arm 9 which is pivoted to the pivot 10 and has at its other end a motor H. A pulley I2 is provided for the saw arbor and a pulley I3 is provided for the motor. These are preferably connected by a v-belt l4, and since the arbor and motor are maintained in fixed relationship’ at all times, the vertical.adjustment of the saw in and out of the slot 3 does not necessitate continual adjustment of the belt I6.

The motor is mounted on a platform l5 which is hinged at 16 to the arm 9 and is provided with a set screw H for adjusting the distance between the motor and the pulley. The arrangement with the saw arbor at one end of the arm 9 andthe motor II at the other end’ thereof assists in adjustment because the motor and the saw counterbalance one another.

Dan’s Circular Saw Hack #shorts #carpentry #diyhacks #diy

The pivot ill, on which the arm ‘9 is pivoted, is mounted on a cradle l8 which is mounted on trunnions l9 and 20 on the frame I. The tr unnions are so disposed that the cradle I8 may be rotated about an axis which coincides with the line of intersection between the saw and the table top so that the saw, regardless of its tilted position, is always disposed at the same place on the table top. In order to rotate the cradle I8 on its trunnions l9 and 20 and to adjust the position thereof, I provide a screw 2| which is screw threaded in a pivoted at 23 on the cradle la. The other of the screw is-provided with a thrust bearing 24 which holds the screw in fixed position for rotation. The thrust bearing is pivoted to the frame at 25 and a wheel 26 with a crank handle 21 thereon is mounted on the screw for rotating the same. It will be apparent that by turning the screw it is possible’to move the cradle from the full lined position in Fig. 3 to various positions such as the one indicated by dotted lines The splitter 1 is mounted on the ,in that figure.

In order to raise and lower the saw, I provide a curved rack 28 at. the end of the arm 9 adjacent the saw arbor. A pinion 29 is fixed on shaft 30 rotatably mounted on the cradle l8 in mesh with said rack, and on the same shaft 30 to which the pinion is fixed, I fix a worm gear 31 which is in mesh with a worm 32 on a shaft 33 mounted on the cradle and extending through a segmental opening 34 in the front of the frame I. A wheel 35 with a crank handle 36 is provided for turning the shaft 33.

To look or clamp the saw in adjusted position, I provide on the end of the arm 9 a curved brake shoe 31. A brake beam 38 has one end pivoted at 39 to the cradle l8 and is disposed to engage the curved surface of the brake shoe 31. A brake rod 40 is mounted on the cradle l8 and has one end fitting in a socket 4| on the end of the brake beam 38 to push the brake beam into engagement with the curved brake shoe 31. The other end of the brake rod 40 engages the end 42 of a cross member 43 which nut 22 which is end is mounted on the cradle I8 and is provided with a clamping member 44 for clamping the cross member 43 against the cradle IS. The other end 45 of the cross member 43 is disposed to clamp against the frame I when the clamping member 44 is tightened, so that a tightening of the clamping member serves to hold the saw firmly in its elevated position through the pressure on the brake beam 38 and to hold the saw and cradle against tilting movement by clamp ing the cradle firmly against the frame i.

In order to permit the operator of the saw to read the angle of the saw with reference to the table top, I provide a gauge or scale 46 on the frame and a cooperating pointer 41 on the cradle and extending through the opening 34 in the frame.

To determine the elevation of the saw above the table top, I provide a simple gauging mechanism consisting of a sprocket 48 mounted on the shaft 30 which carries the pinion 29 and the worm gear 3i, having a chain 49 extending thereover and in engagement with a sprocket 50 mounted on a shaft 5| on which is mounted a scale 52, said shaft and scale being carried upon the cradle is to permit a reading of the height of the saw. An idler eccentric 54 is provided for keeping the chain 49 at the desired tension.

I have shown a preferred embodiment of my invention and wish to claim the same specifically and also broadly as pointed out in the appended claims.

In a saw, the combination of a frame, a saw table supported thereon having a slot through which the saw projects for use, a saw, a saw carrying cradle on trunnions in said frame to rotate about, an axis which lies at the intersection of the saw and the table top, means for adjusting the position of the cradle on its trunnions, an arm pivotally mounted on said cradle between its ends carrying a saw arbor at one end on which said saw is mounted for movement through the slot in the table top, a motor at the other end of said pivoted arm, a belt drive between said motor and said saw arbor, means for adjusting the elevation of said saw arbor by turning said arm on its pivot, an opening in said frame’adjacent one trunnion of said cradle, means for holding said cradle and saw in adjusted position, comprising a curved brake shoe on said pivoted arm, a brake beam pivoted on said cradle and in operative relation to said shoe, clamping means on said cradle extending through a slot in said frame, a cross piece on said clamping means having one end engageable with said frame and the other end engageable with a brake rod, and a brake rod connecting the other end of said cross piece with said brake beam whereby tightening of the clamping means forces one end of said cross piece against the frame and the other end of said cross piece against said brake rod to clamp said brake beam against said brake shoe whereby the saw is held firmly in adjusted position.

In a saw, the combination of a frame, a saw table supported thereon having a slot through which the saw projects for use, a saw, a saw carrying cradle on trunnions in said frame to rotate about an axis which lies at the intersection of the saw and the table top, means for adjusting the position of the cradle on its trunnions, an arm pivotally mounted on said cradle between its ends carrying a saw arbor at one end on which said saw is mounted for movement through the slot in the table top, means for adjusting the elevation of said saw arbor by turning said arm on its pivot, an opening in said frame adjacent one trunnion of said cradle, means for holding said cradle and saw in adjusted position, comprising a curved brake shoe on said pivoted arm, a brake beam pivoted on said cradle and in operative relation to said shoe, clamping means on said cradle extending through a slot in said frame, a cross piece on said clamping means having one end engageable with said frame and the other end engageable with a brake rod, and a brake rod connecting the other end of said cross piece with said brake beam whereby tightening of the clamping means forces one end of said cross piece against the frame and the other end of said cross piece against said brake rod to clamp said brake beam against said brake shoe whereby the saw is held firmly in adjusted position.

In a saw, a saw table having a slot through which the same projects for use, a pivoted arm having a saw arbor at one end on which a saw is mounted and having a motor mounted at the other end, a belt drive between the motor and the saw arbor, means for adjusting the elevation of the saw arbor by turning said arm on its pivot, comprising a curved rack at one end of the pivoted arm adjacent the saw arbor, a pinion in mesh with said rack, a worm gear operatively connected to rotate said pinion, a shaft having a worm thereon in mesh with said worm gear, and means for rotating said shaft, curved brake shoe on said pivoted arm, a brake beam pivoted in operative relation to said shoe. and means for clamping said brake beam against said shoe to hold said saw firmly in adjusted position.

In a saw, a saw table having a slot through which the same projects for use, a pivoted arm having a saw arbor at one end on which a saw is mounted, means for adjusting the elevation of the saw arbor by turning said arm on its pivot, comprising a curved rack at one end of the pivoted arm adjacent the saw arbor. a pinion in mesh with said rack, a worm gear operatively connected to rotate said pinion, a shaft having a worm thereon in mesh with said worm gear. and means for rotating said shaft, a curved brake shoe on said pivoted arm, a brake beam pivoted in operative relation to said shoe. and means for clamping said brake beam against said shoe to hold said saw firmly in adjusted position.

In a saw. a saw table having a slot through which the same projects for use, a pivoted arm having a saw arbor at one end on which a saw is mounted, means for adjusting the elevation of the saw arbor by turning said arm on its pivot, a curved brake shoe on said pivoted arm, a brake beam pivoted in operative relation to said shoe, and means for clamping said brake beam against said shoe to hold said saw firmly in adjusted position.

Who Invented the Circular Saw? A Look at the Pioneering Mind Behind the Tool

The circular saw is a widely used tool in modern construction, but it wasn’t always so. The invention of the circular saw revolutionized the industry, allowing for more precise and efficient cutting of materials than ever before. But who was responsible for this revolutionary tool? This article will explore the history of the circular saw and the pioneering mind behind its invention.

An In-Depth Look at the History of the Circular Saw

Before the invention of the circular saw, there were several different types of saws that were used to cut materials. These included the handsaw, which was used for simple straight cuts, and the pit saw, which was a large two-man saw used to cut through logs. However, these saws were not suitable for curved or complex cuts, and their use was limited.

In 1780, the first machine-powered saw was invented by Samuel Miller. This saw was powered by a water wheel and had a rotating blade that could make curved or complex cuts. While it was an improvement on previous saws, it was still too slow and inefficient for commercial use. It wasn’t until 1846 that the first true circular saw was invented by Alexander Mitchell of England.

How Innovation Led to the Invention of the Circular Saw

The invention of the circular saw was made possible by the contributions of many inventors and engineers throughout the years. For example, in 1777, John Smeaton developed the crank-shaft, which allowed for the transfer of power from a stationary source to a moving object. This made it possible for saws to be powered by steam engines, which increased their efficiency.

In addition, advances in technology played a major role in the development of the circular saw. In the early 19th century, steel manufacturing became more widespread, which allowed for the production of stronger and sharper blades. This made it possible for saws to be more powerful and efficient than ever before.

The Pioneering Mind Behind the Circular Saw

The man responsible for the invention of the circular saw was Alexander Mitchell, an English engineer and inventor. Mitchell was born in 1817 in Liverpool and received his education at the University of Glasgow. After graduating, he began working as a civil engineer and eventually established his own engineering firm.

Mitchell’s invention of the circular saw revolutionized the industry and made him a wealthy man. He went on to patent several other inventions, including a lighthouse lens and a marine propeller. He died in 1887 at the age of 70.

The Early Years: A Timeline of the Circular Saw

The first circular saw was invented by Mitchell in 1846 and was known as the “Mitchell Saw”. It was powered by a steam engine and was capable of making curved or complex cuts. In 1876, the first electric circular saw was invented by William Newberry, which made it even easier to use the saw. In 1895, the first portable circular saw was invented by George Platt, which allowed for greater mobility and convenience.

In the early 20th century, the circular saw continued to evolve and improve. In 1915, the first radial arm saw was invented by Raymond DeWALT, which allowed for greater accuracy and precision when making cuts. In 1946, the first circular saw with a laser guide was invented by Robert Bosch, which further improved the accuracy of the tool.

A Closer Look at the Circular Saw’s Inventor

Alexander Mitchell was a pioneering engineer and inventor who changed the course of history with his invention of the circular saw. He was born into a wealthy family and received a good education, which enabled him to pursue a career in engineering. His invention of the circular saw made him a wealthy man and helped to revolutionize the industry.

In addition to his work as an engineer and inventor, Mitchell was also an active philanthropist. He founded several charities and was involved in many social causes. He was a strong believer in education and was a patron of the arts. After his death, a monument was erected in his honor in Liverpool.

The Impact of the Circular Saw on Modern Construction

The invention of the circular saw had a profound effect on the construction industry. It allowed for more precise and efficient cutting of materials, enabling faster and more accurate construction. The circular saw is now one of the most popular tools in the industry, and its use has become commonplace in both residential and commercial construction.

The circular saw has also been instrumental in the development of new technologies, such as CNC routers and laser cutters. These advanced machines have revolutionized the way materials are cut and shaped, allowing for greater accuracy and precision than ever before.

Conclusion

The invention of the circular saw by Alexander Mitchell changed the course of history and revolutionized the construction industry. It allowed for more precise and efficient cutting of materials, enabling faster and more accurate construction. The circular saw is now one of the most popular tools in the industry and its use has become commonplace in both residential and commercial construction.

The legacy of Alexander Mitchell lives on today, and his invention of the circular saw will continue to shape the future of construction for years to come. His pioneering spirit and innovation have inspired generations of inventors and engineers, and his legacy will no doubt continue to influence the industry for many years to come.

(Note: Is this article not meeting your expectations? Do you have knowledge or insights to share? Unlock new opportunities and expand your reach by joining our authors team. Click Registration to join us and share your expertise with our readers.)

By Happy Sharer

Hi, I’m Happy Sharer and I love sharing interesting and useful knowledge with others. I have a passion for learning and enjoy explaining complex concepts in a simple way.