Clutch for lawn mower. A Look into How Lawn Mower Clutches Work

A Look into How Lawn Mower Clutches Work

The average homeowner may not know what a lawn mower clutch is, let alone how it works. But, the truth of the matter is that these clutches are very important and can be one of the most expensive parts of your lawn mower.

An electric lawn mower clutch also referred to as a power take-off (PTO) clutch, sends power to the blades of the mower. The electromagnetic apparatus acts as a brake to slow down the blades when the clutch is disengaged.

The clutch is a vital part of the functionality of the lawn mower. This article will explain what the clutch is, how it works, and how you can make sure yours is running at the best quality.

A multimeter is valuable in helping you diagnose your clutch problems.

What is a Lawn Mower Clutch?

It is essential that you understand your lawn mower clutch before starting to operate it. In a nutshell, it’s where the blade connects with the engine and transmits power to cut grass.

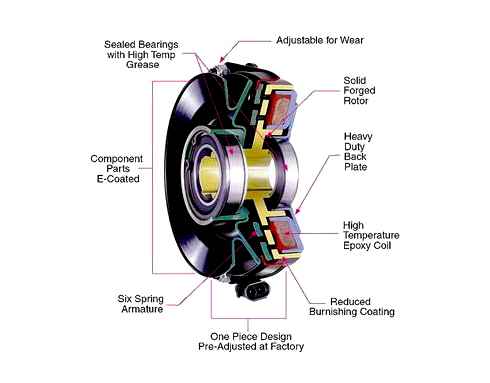

It is made out of multiple, complex components, including a powerful magnet that works to engage the blade. It also includes a brake pad, which is the piece that slows down the blade when you turn off your lawn mower.

While the mechanism is complex, it is important to have an understanding of how it works so you do not waste your money on replacements or repairs that are not needed.

There are multiple types of lawn mower clutches that have slight differences in parts. Ultimately, all of the clutches serve the same purpose.

How Does a Lawn Mower Clutch Work?

The clutch in your lawn mower works by connecting the power of your engine to the blades of your mower.

On top of the clutch is a flat pulley connected to the clutch through a shaft that goes through the middle.

When the engine engages the pully, it spins a rotor inside of the clutch. When the clutch is disengaged, the rotor spins freely inside of it.

Once you engage the clutch, the powerful magnet inside is activated and pulls against a plate within the rotor. When this process occurs, it begins to spin the pulley that is connected to the blades.

The clutch also acts as a brake when the blades are turned off. When you disengage the clutch, the magnetic force is released, and the brake pad on the clutch makes contact with the pulley to slow down the deck.

You activate your clutch by flipping the switch on your lawn mower dashboard. You should hear the clutch turn on under the deck; otherwise, there might be a problem with your mower.

How Will You Know Your Clutch Needs Replacement?

There are many reasons that your clutch might need to be replaced. With so many variables, it can be hard to determine when your clutch might need replacement. One of the most common reasons is when you notice that your lawn mower blades are not spinning or that they are not engaging when your turn on the clutch.

Some examples of when you might want to replace your clutch include:

- The lawn mower won’t start when you engage the blades.

- The deck doesn’t spin fast enough when engaged.

- When the blade starts to spin, it vibrates too much and slows down.

Before replacing your clutch, you want to be sure that the problem is actually with your clutch and not another part of your machine.

How do You Check an Electric Lawn Mower Clutch?

If the lawn mower is making any unusual sounds, not running properly, or beginning to vibrate, this could indicate that there may be a problem with the clutch.

If you need to check your electric lawn mower clutch, there are a few things you can do.

Check the Power Line Going into Your Clutch

The first step should be to make sure that your clutch is receiving enough power. If you do not hear the clutch is engaged when you flip the switch, you should use a multimeter to gauge the amount of electricity being sent to the clutch.

We really like this multimeter, also known as the volt/ohms meter from Amazon.

In general, the clutch should be receiving about 12 volts of electricity. If your clutch is not getting enough electricity, you know that there is something wrong with your lawn mower and not the clutch.

In contrast, if your clutch is getting enough electricity, you know something wrong with your clutch.

Check the Magnet in Your Clutch

If your clutch is receiving power, then there may be a problem with the electromagnet inside of the clutch.

A potential problem could be with the resistance against the magnet. In order to check for resistance, you will need to use your multimeter again.

Resistance is measured in Ohms, so you will need to set your multimeter to Ohms and attach it to your electromagnet. In general, your Ohm reading should be between one and three.

A high Ohm reading means that there is a higher resistance rating. This would require more energy to complete the circuit. On the other hand, a lower Ohm reading might mean there is a problem with the wiring, and the electromagnet is too powerful.

Check the Brake Pad on Your Lawn Mower Clutch

When checking a lawn mower clutch, it is important to inspect the brake pad. This should be easy by removing and inspecting the hub for buildup, corrosion, or other obstructions that could prevent good contact.

The pulley that is connected to the blade of the lawn mower needs to make good contact with the brake pad in order for it to work correctly.

The brake pad should be replaced when it is worn out. The fine grit on the brake pad will wear down and need to be replaced.

Check the Plates, Bolts, Springs, and Pulleys

There are many intricate parts to your lawn mower clutch. You will want to check all of them to make sure there is no wear-and-tear or severe damage to them.

Making sure everything is securely tightened can help extend the life of your clutch. This includes making sure that your clutch has the right amount of torque.

Generally, your clutch should have 50-60 ft-lbs of torque to make sure everything is tight enough to be secure but not too tight. Each machine will have different specifications, so be sure to find that out prior to disassembling your machine.

Some clutches are able to be disassembled for you to examine all of the pieces. If possible, you should try to inspect these pieces when you can to help extend the life of your clutch, and ultimately, your lawn mower.

If any of the components listed above are broken or damaged, you should consider replacing those parts or getting a new clutch, depending on the situation. In most cases, the dealer for your lawn mower will have the replacement part that you need.

Final Thoughts

Lawn mowers are a valuable commodity for many homeowners. Keeping them running smoothly and making sure they last as long as possible is important to you, your lawn, and your wallet.

Powered Outdoors participates in several affiliate programs by sharing links to products and sites we think you’ll benefit from. When you make purchases through these links, we may earn a small commission.

How Do You Know If A Lawn Mower Clutch Is Bad?

I’m sure you’ll agree with me that owning a lawnmower comes with tons of amazing benefits. In case you don’t know, one of the many benefits attached to that is that it allows you to mow your lawn regularly, and doing that can make you achieve a stronger lawn. However, owning a mower isn’t without its issues.

A lawnmower can always develop issues unexpectedly; an example of that is when its clutch becomes defective. Sadly, this can become very annoying if you’re not aware of the issue.

There are several different warning signs that you’ll get to understand that your lawn mower’s clutch is defective. For instance, one of the symptoms is when you keep experiencing a hard or sticky clutch. When engaging your lawnmower clutch, if you encounter high engine rev, this could also be a warning sign.

Do lawn mowers have clutches? How exactly do lawn mower clutches work? What are the warning signs that you’ll get to understand that a lawn mower clutch is bad? These and more are the frequently asked questions that you’ll get answers to as you read through the rest of this article.

Do lawn mowers have clutches?

Yes, lawnmowers, be it electric or gas, are usually equipped with clutches. Usually called “power take-off (PTO) clutch,” an electric lawn mower clutch is the component responsible for engaging the blades.

When a PTO clutch engages the lawnmower blades, what happens is that it’ll stop the blades from spinning when the engine is still running. Since that’s the case, it means that the lawnmower clutch is the safety component of the farm equipment.

Furthermore, the function of an electric mower clutch also extends to transferring the engine energy to the drive train.

How exactly do lawn mower clutches work?

As earlier mentioned, the PTO clutch is the safety component of your lawnmower. The primary function of the component is to engage the blade, stopping it from spinning when the engine is running. The clutch does that by transferring the energy from the lawnmower engine to the drive train.

Here’s how a PTO clutch works; it’s connected to two drive shafts inside the electric mower. The clutch works together with these shafts to secure your lawnmower when the engine is running.

In case you don’t know, the PTO clutch comes with a couple of basic components. For instance, it has a pulley, which you can always find on the housing brace of the machine. over, the pulley is designed in a way that allows it to spin easily around the housing brace of the lawnmower.

Here’s the thing; when the power to the PTO clutch switches off, the magnetic energy releases control of the rotating coil of the electric mower. When this happens, the springs controlling the rotation of the coil force the coil back against the brake.

It’s the brake that stops the PTO pulley, which in turn stops the blades from spinning. The working principle of a power take-off (PTO) clutch is no doubt complicated. For a clearer understanding of how the component works, you can watch this video.

What are the warning signs to know that a lawn mower clutch is bad?

The lawnmower clutch is, no doubt, one of the essential safety components of the farm equipment. Since that’s the case, it’s very important to understand the signs that come with having a bad clutch.

As previously mentioned, there exist several warning signs to know that the lawnmower clutch is faulty or bad. Let’s have a quick look at a couple of them below:

Do you keep experiencing a hard clutch every time you try to operate your lawnmower? If yes, you need to understand that this could be a warning sign that your PTO clutch is defective.

A power take-off clutch is designed to engage the lawnmower blades. However, if the component is hard, it’ll become pretty difficult for you to operate for both engagement and disengagement.

If you also experience high engine rev every time you try to engage the clutch, this could be a sign that your lawn mower clutch is defective. Yes, it could be that the machine has a worn friction plate.

How to replace a bad electric clutch on your zero-turn riding lawn mower

If you end up having a defective PTO clutch, the best thing you can do is to replace the component with another one. To do that, you can follow the simple and direct steps below:

- Locate the spark plug of your electric mower. After finding it, the first thing you need to do is disconnect the spark plug’s wires.

- Next, you need to release the belt around the blades. To do that, start by lowering the electric mower deck to the least cutting position. Then, remove the left pulley cover. This way, you should find it easy to release the blade belt.

- After successfully releasing the blade belt, the next thing you need to do is to remove the clutch. This doesn’t come easy though. To do that, start by unplugging the electric clutch wiring located around the motor. Next, locate the flywheel cover and remove the mounting screws. Now, carefully pull off the PTO clutch from the engine crankshaft.

- Install the new clutch where you removed the defective one.

The Best Self-Propelled Lawn Mowers in 2023 for Making Your Yard Work Easier

These lawn mowers drive themselves, taking the load off you in the process.

By Roy Berendsohn Published: Mar 21, 2023

One of the perks of the warm-weather season is getting to spend time outside. If you own your own home and have a yard, it’s very likely that in order to enjoy your outdoor space, you need to mow the lawn. The larger the yard, the more work it will be to maintain. If you have a lot of grass to cut, you’d be wise to consider a self-propelled lawn mower especially now that there are a ton of sales just in time for Memorial Day.

The primary difference between a standard push mower and a self-propelled mower is that the former moves when you push it, and the latter essentially moves itself with only your guidance. Once the engine is running, all you have to do is squeeze a handle or push a lever and the mower will start moving forward with you as you walk.

Turning the mower around is your job, but once you have your heading, just keep the drive handle squeezed and escort the mower down the path, no pushing necessary.

Self-propelled law mowers take power off the engine and route it via a belt to a pulley on the transmission and axle. When you move the drive control lever on the mower handle, you tension the belt, causing the pulley to turn, and this drives the transmission, moving the mower forward.

Move the drive control lever back and the tension is released, the pulley stops turning, and the mower stops moving forward. The belt-driven transmission is a time-tested design to power the mower and take the load off you in the process.

What to Consider

A mower is like many consumer products in that the more features a manufacturer adds, the more expensive it becomes. But a longer or more eye-catching list of features isn’t necessarily better. Sometimes less is more. Here are the most important to keep in mind.

Front-wheel drive mowers tend to be less expensive than rear-wheel drive units. They can be easier to turn because you don’t have to disengage the drive wheels to do so. Simply push down on the handlebar to raise the front wheels off the ground. However, their traction isn’t as strong on hills or when the bag is full, as there isn’t as much weight over the drive wheels.

Rear-wheel drive mowers do cost more and aren’t as easy to turn, as you do need to disengage the drive—but this isn’t too much of a hassle. Rear-wheel drive mowers shine on hills and inclines, and when the grass bag is full. In either scenario, weight is shifted rearward and over the drive wheels, which enables superior traction, thus making the self-propel more effective.

An engine as small as 125 cc can power a mower, but most are somewhere in the 140 cc to 190 cc range. A large engine helps when powering through tall, lush grass or in extreme conditions, such as with a side discharge chute in place and mowing tall weeds in a border area. Also, the extra torque provided by a larger engine can improve bagging when the going gets tough (tall, leaf-covered grass in the fall). But if you mow sensibly and pay attention to deck height—and especially if you don’t let your lawn get out of control—an engine between 140 and 160 cc has more than enough power to get the job done.

A mower can have all four wheels the same diameter (7 to 8 inches), or it may have rear wheels that range from 9.5 inches to 12 inches in diameter. Larger rear wheels help the mower roll more easily over bumpy ground.

With some mowers you can start the engine with the twist of a key or the press of a button. It’s a great option, but a luxury. Keep the mower engine tuned and use fresh fuel with stabilizer added to it, and you’ll never have trouble starting.

Any number of mechanisms can control a mower’s ground speed—a squeeze handle, a drive bar that you press forward, even a dial. There’s no single right answer here. Look at the design and think about how you like to work. For example, if more than one person will be using the mower (and not all of them are right-handed), a drive control like that on a Toro Personal Pace mower might be the answer. Just push down on the bar to make it go faster. Let up on the bar to slow down.

A mower that can bag, mulch, and side discharge is known as a three-function mower, the most versatile kind. Two-function mowers bag and mulch or mulch and side discharge.

Mowers will typically have one, two, or four levers to control the deck height. Single-lever adjustment is the easiest to use, but it requires more linkage, which adds weight and complexity. If, for some reason, you find yourself varying deck height frequently, it’s a good option. Otherwise, two or four levers work just fine.

Only Honda makes a gas-engine mower with a high-impact plastic deck (there are battery mowers that have plastic decks). Otherwise, mowers generally have a steel deck, and a few manufacturers—Toro, for one—offer a corrosion-resistant aluminum deck. An aluminum deck won’t rot the way a steel deck will, but you still need to keep it clean.

This is a hose fitting mounted on top of the mower’s deck. When you’re done mowing, hook up a hose and run the mower to power wash the underside of the deck. We’ve had mixed results with these, but they’re better than just letting a mass of dried grass clippings accumulate.

expensive mowers come with a more durable bag with more dust-blocking capability. If you bag a lot, especially leaves or other lawn debris in the fall, then you need a mower with a higher quality dust-blocking bag. Having said that, if you rarely bag, the standard one that comes with a mower will last you the life of the mower.

Also called wide-area mowers, machines in this subgroup help homeowners better reconcile their need for more power and speed with the fact that they may not have enough storage for a tractor or zero-turn mower. A typical residential walk mower has a single-blade deck that cuts a swath from 20 to 22 inches wide. Wide-cut mowers (built for homeowner use) have either a single blade or, more typically, a pair of blades, cutting from 26 to 30 inches with each pass. Some of these are rated for light commercial use and have larger decks, in the 32-inch range, and engines that start at 223 cc and go up to about 337 cc.

Wide-cut mowers typically employ gear or hydrostatic drive transmissions, and they have top speeds of about 4 to 6 miles per hour. At their fastest, they move so quickly you have to trot to keep up with them. Needless to say, they’re overkill for small yards; only opt for one of these if you’ve got a significant plot of land that you need to keep tidy, but not one so large that you’d be better off going with a full-on riding mower.

How We Tested and Selected

We compiled this list based on Popular Mechanics mower testing and our knowledge of the lawn mower market at large. For our testing, we put mowers through the paces using our standard Popular Mechanics methodology: We cut turf grasses such as fescues and blue grass and rougher non-turf grasses like Timothy, clover, orchard grass, and wild oats, all in both normal and shin-deep heights. We mow uphill, downhill, and across the faces of hills. The maximum slope we cut is about 30 degrees.

That may not sound like much, but it’s about all you can do to stand on it, let alone push a mower up it or across it. We mow damp and wet grass to test general cutting performance and whether clippings accumulate on the tires. And we cut dry and dusty surfaces to see how well the bag filters under less-than-optimal conditions.

Honda HRN 216VKA

Key Specs

Honda mowers enjoy a sterling reputation. Having tested their walk and self-propelled mowers for the last 30 years, we feel confident that Honda’s entry level mower is a great choice for homeowners looking for power and durability. The HRN features a GCV 170 gas engine that’s built to withstand long hours of operation.

If you do your own maintenance (and most owners who buy this class of product do), you’ll appreciate the easily accessible spark plug and the fuel shutoff valve that enables better winter storage. Close the fuel shutoff and run the mower until it sputters to a halt. This will clear the carburetor of any gasoline, which will prevent the ethanol in it from disintegrating and causing running issues later on. Open the shutoff valve in the spring, add some fresh gasoline, and the mower should start easily.

All this maintenance stuff is great, but we can also tell you that our past test findings on other Hondas prove that their cut quality is outstanding for cleanliness. Sharp blades deliver a velvet-like finish. And their bagging ability is also quite good, in the same league with other well-bagging mowers from Toro.

In all, if you take mowing seriously, you should enjoy this Honda. If you have a little wiggle room in your budget, consider the Honda HRX, which features a mower powerful engine and a composite deck that won’t rust and is renowned for its durability.

One note is that Honda has announced that it will cease selling lawn mowers in the United States after this year—so if you’re considering buying one, best do it sooner rather than later.

Toro Recycler 60-Volt Max Lithium-Ion

Key Specs

Toro mowers have garnered more recommendations from us than any other brand for two reasons: build quality and cut quality. These were amply demonstrated in our testing as the Recycler turned in the best ratio of cut area per amp-hour of battery in the self-propelled category, while at the same time not skimping on cutting, mulching, or bagging quality.

We attribute this outstanding mower performance to three features, all upgrades to the previous version of this machine. First, the air vent at the front of the mower deck seems to improve mulching and bagging performance. Toro calls it Vortex technology, a design that increases air flow under the deck. This helps to stand the grass for a cleaner cut, which improves mulching performance, and also allows better airflow into the bag when collecting the clippings.

Next, the company’s redesigned “Atomic” blade configuration appears to assist the air flow and clipping movement. Finally, the three-phase, 60-volt motor is exceptionally efficient, resulting in a large cut area for a single battery.

Toro has maintained features that make this mower work: rear wheel drive, a one-piece deck that’s all steel (no plastic nose), 11-inch wheels to help it roll over roots and crevices, and the same fold-forward handle that was an industry breakthrough when it was introduced some years ago.

Ryobi 40-Volt Brushless Self-Propelled Mower

Key Specs

This is one of Ryobi’s top-of-the-line mowers, and it’s American-made construction is something we wish we saw more of. It delivers a tremendous cut area with its two 6-Ah batteries providing a total of 12-Ah of capacity, and its X-shaped blade leaves a pristine surface in its wake.

Ryobi estimates the design should provide 70 minutes of run time; we didn’t time our cut, but it strikes as plausible. Its rear-wheel drive and reasonably aggressive tire tread pattern provide good hill climbing and sidehill cutting performance, and its bagging on all surfaces (level, sidehill, and uphill) is also commendable.

Other ease-of-use features include an easily installed or removed bag that mounts and dismounts straight up and down through the handle; deck adjustment is quick and easy thanks to a single-level deck height adjustment. The straight edge deck is polypropylene; it will never rust and needs very little care other than basic cleaning.

Toro TimeMaster 30 in. Briggs Stratton Personal Pace

The Toro Timemaster 30-in. mower has been around for several years and has earned a reputation as a sturdy workhorse for homeowners who want to cut down on their mowing time. It’s also used by some professionals as well. A few years ago the Timemaster got a slightly more powerful Briggs and Stratton gas engine, so it should have no issues powering through most demanding mowing jobs.

The Timemaster is rear-wheel drive and features Toro’s Personal Pace drive system that’s used on many of its self-propelled mowers. This allows the mower to move at your speed by simply pushing down or releasing the handle, which is spring-tensioned.

With a 30-in. deck, Toro claims the Timemaster will help you reduce your mowing time by about 40% compared to using a standard-sized mower. You can mulch, back, or side discharge with the Timemaster, and the handlebar can be locked in a fully vertical position to reduce space consumption in storage.

If you have half an acre to a full acre of lawn to mow and prefer the experience of a walk-behind mower versus a tractor or zero-turn, the Timemaster is worth a look.

Craftsman M220

Key Specs

Craftsman mowers have been doing very well in our tests, so we can recommend this one because it’s so much like the many other of the brand’s models that we’ve tested. If you’re looking for a good blend of maneuverability and power, you’ll get it with this mower. Its front drive helps move it along and makes it easy to turn.

It’s important to note that front-drive mowers do lose some traction when running uphill, particularly with a full grass bag. But if your slope is less than 20 degrees, and you’re not bagging uphill, you’ll be fine. The side discharge will also help you handle tall grass. Adjust the two deck levers to bring the mower up to full height and have at the rough stuff.

The fact that this mower bags, mulches, and side discharges is a plus, enabling you to handle a wide range of mowing conditions, from early spring and late into the fall. Three-function mowers like this are our preference for that versatility.

Toro Super Recycler Self-Propelled Lawn Mower

Key Specs

This is a beauty of a mower, with a cast-aluminum deck and a smooth-running Briggs Stratton 163-cc engine. We tested the Honda engine-equipped version, and it was effective at both bagging and mulching, even in moist grass.

Equipped with rear-wheel drive and the Personal Pace system (the farther you push the drive bar, the faster the mower goes), it’s an effective hill climber and moderately effective on sidehill cutting. It has relatively small 7.5-inch tires on all four corners, which causes this Toro to bump up and down a bit on washboard surfaces. But the good news is that it’s equipped with a far higher quality tire than we’re used to seeing these days. We didn’t notice them pick up any grass on moist surfaces.

Other features we like include its forward-fold handle that has a built-in shock absorber that Toro calls a Flex Handle Suspension, and a high-quality grass bag that loads through the handle, from the top.

QA

Are there special maintenance considerations with self-propelled mowers?

Yes. Both front- and rear-wheel drive mowers typically feature a drive belt, which can crack or wear out over time. Fortunately these belts are not difficult or particularly expensive to replace.

Secondly, you may have to replace the drive wheels occasionally. These wheels are driven with gears. there are typically teeth on the inside diameter of the drive wheel that line up with a gear on the axle. These teeth can wear out, especially if they are made of plastic. Higher-end mowers may feature drive wheels with a metal gear that meets the metal axle gear, which improves longevity of these components.

My lawnmower says I don’t ever have to change the oil, but just add oil when needed. Is this OK?

It’s not a good idea to never change the oil in your lawn mower. In a lawn mower, same as a car, oil degrades over time and is less effective at reducing heat and friction in metal components. Changing the oil in your lawn mower is easy to do and will significantly increase its service life. For most homeowners, changing the oil at the beginning or end of each mowing season should be sufficient, though there is certainly no harm in doing it more often.

Roy Berendsohn has worked for more than 25 years at Popular Mechanics, where he has written on carpentry, masonry, painting, plumbing, electrical, woodworking, blacksmithing, welding, lawn care, chainsaw use, and outdoor power equipment. When he’s not working on his own house, he volunteers with Sovereign Grace Church doing home repair for families in rural, suburban and urban locations throughout central and southern New Jersey.

What Are The Symptoms of bad PTO Clutch?

PTO clutches are generally used with outdoor power equipment that used for start the rotation of and implement a cutting blade. Also, It helps to slow down the implementation when the clutch is turned off.

You’re here because you wanted to know what are the symptoms of bad PTO clutch. Don’t worry, the dedicated article is on this topic. You will learn some common signs of bad PTO clutch in the following post. Plus, The solution to those problems.

What Are The symptoms of bad PTO clutch?

Hard To Start

Usually, the common symptom of a bad PTO clutch is taking time to engage. In the beginning stage, It takes several seconds for the blades to engage. It will be getting hot after running for a while.

Noise:

The PTO clutch will make some awkward noise when engaging or disengaging. If you hear such type of noise when your release or depress the PTO clutch, or both at the same time when the engine is off, It’s probably a problem with the PTO clutch and Its release mechanism.

Also, When the transmission is neutral, the car makes a chirping, whirring, or grinding sound, but the sounds go away by depressing the clutch pedal that indicates the PTO clutch problem. The possible reason behind it is the noise is coming from a worn-out input shaft bearing.

You can use noise to understand that is the clutch has any defect or not. For this, first, disengage it and turn it on and off few times. If you notice that the power takes off slowing down or stopping and won’t make a disengagement noise, It indicates the PTO clutch galled together fo heat or slip ring has jammed.

Engine won’t turn over

The blades will not engage if the PTO clutch solenoid is defective for this clutch won’t get any power. Also, The engine won’t get any power if the switch has any defect.

How to solve bad PTO clutch symptoms?

There aren’t a single solution to solve the PTO clutch problems. For example, If your PTO clutch solenoid is defective, then you need to replace the clutch. But, If the problem occurs on a switch, the problem will solve by replacing the switch.

Also, Adjusting the PTO clutch, especially electric clutches, are mandatory for getting the highest performance. Otherwise,You will notice the gap between contact plates that reduces magnet power and complexity to hold them together. For this, with a heavy load, the contact plates may slip, which will cause heat from the friction of lowering.

Sometimes, Adjusting the PTO clutch from time to time can solve some common issues and provide optimal performance.

Here are some common issues and solutions you may apply to solve the PTO clutch problem:

How do I Test A PTO clutch?

Follow this quick guide to test a PTO clutch:

- First, Use a floor jack to lift the vehicle up and use two jack stands under the rear frame and two in the front frame to provide clearance to look at clutch drive assembly.

- Read the volts using a good engine source. If you find output below 12.4 volts or equal, then charge the battery because it won’t engage without enough voltage.

- Then, Check the in-line fuse. If it turns black or blown, replace it with the same amper fuse rating as the original.

- Active the engine and carefully check the blade operation. If it makes noises, first replace the ignition key and unplug the battery cable.

- Remove any type of broken branches that jammed into the drive belt and the pulley.

- Again plug in the ignition key and negative cable with a socket. Turn on the clutch engagement lever and disengage it after starting the engine. Then, turn it on and off several times. If the pulley is slowing down and stopping frequently, It’s the sign that plates and clutch have galled together. For this, you need to remove the clutch and inspect the internal issue.

How Do You Remove A PTO clutch?

Fortunately, We don’t need any type of special tools and equipment to remove a PTO clutch. Just a screwdriver, a socket wrench set, and a pair of good-quality gloves are enough. After you collect those tools, let’s jump into the removing part:

- To reduce the risk, first, disconnect the spark plugs.

- Then, You will have to take off the plastic covering from the pulley, which protects the belt from any sort of damage.

- Then loosen the blade belt to access the clutch.

- After removing the belt, you’ll find two sets of wires which directly connect with the PTO clutch. Disconnect those wires before releasing the clutch.

- In this step, A assistant must be needed. There is a bolt connected with the top of the mower or vehicles. At the same time, unscrew the bolt, the assistant help you to keep the nut in place, and he used a screwdriver to take off the flywheel cover.

- Finally, You can remove the PTO clutch after the bolt is out.

Final Words

The power takeoff clutch is a piece of important equipment used on small tractors that activate mower tillers or blades. It’s used electricity to produce a magnetic armature to rotate the blade. But, to get the optimum performance, you need to keep it in regular maintenance.

So, Knowing some common Syndrom of bad PTO clutch helps you do the maintenance process easily and find out any problem quickly. In the above guide, You find some common syndrome and how to solve those, which might help you identify the problem and solve it.

s: