DIY tumor. one -axle tractor with differential…

DIY tumor for a walk.behind tractor and care

Motoblocks have been considered high.class and reliable assistants for the farmer for several years. A hinged equipment also adds considerable functionality, which allows you to turn a classic uno.ears of a tractor into something more versatile and useful.

In today’s article, we will talk about a very curious adaptation of a driver, which will contribute to a decrease in the speed of the course. A similar feature will be relevant if the operating speed of the unit is slightly less than the transport speed indicator. Thanks to the installation of the driver on a single tractor, you can significantly increase the torque and improve the indicators of the traction force.

The device of the driver

The design of the mechanism is quite simple from a technical point of view and includes:

You can choose a driver for a walk.behind tractor at any specialized point of sales of agricultural machinery. In the case of independent manufacture, you can save and leave a considerable amount of money for anything else necessary in the garden. Before making the structure, it is better to prepare drawings of all nodes with sizes.

In this video, consider the installation of the driver:

Why this element

The wheel of the walk.behind tractor, which passes along the outer arc when turning, should go a larger way. And here there is a need for a differential or other mechanism for distribution of power, which will avoid slipping. If this element does not have a given element, this will cause hidden movement. over, the larger the distance between the wheels, the more difficult it will be rotated.

The main part of the works that are carried out on Earth, for example, cultivation or fertilizer is carried out, is carried out in a straight line. But this one does not mean that the device will never turn. Of course, the standard version of the walk.behind engineer with a hard drive for 2 wheels allows you to use it quite conveniently to use it in most agricultural work. But if necessary, frequent turning the problem with slipping and management will have to be additionally solved. If you do not use special mechanisms, then the vehicle will slow down with soil. Such work will be difficult even for a person with great physical strength.

Most often, experts choose the use of overall couplings as a solution to such a question.

These are simple and universal installations that allow you to properly distribute the load between the wheels if necessary. The versatility of this method is that overall couplings can be used not only on a stiff axis, but also on the connected. In this case, when turning, the wheel will strive to make rotations faster than the front shaft. This makes it possible to conveniently control the machine and work even in small areas, since the device becomes more maneuverable.

Options for power distribution mechanisms

Structurally, the simplest way to solve the wheels of the problem arising due to the strict connection is the use of overall couplings,

which allow the wheel to rotate faster than the axis is driven in motion.

This mechanism is well.known in all its variations: both with a ratchet mechanism (a bicycle wheel sleeve), and with the crumbling of the rollers (Bendix of the electric steamer).

Overall couplings are used in power drive

a number of cars with connected axes. However, such a solution has a characteristic feature: when turning the turn, the overtaking coupling is disconnected on a wheel walking along the external radius, since it seeks to rotate faster than the drive shaft.

To facilitate entering the turn, on the contrary, most of the torque should be informed precisely.

This problem is solved in the classic gear differential

, Distributing power inversely in proportion to the resistance of rotation of the wheels.

But it is noticeably more complicated in production, and also requires a compulsory complete or partial blocking on the off.road, since otherwise it redistributes all power to the masking wheel.

What is a tugs and why it is intended?

Garden equipment can be made even more efficient and functional if you use additional equipment with it. Such devices include the driver to the motor.cultivator. It is enough to make this kind of product yourself, as a result of which you will get an effective tool that helps to reduce the speed of movement of the cultivator.

Most often, the driver is used paired with pneumatic fires. A little less often equipment is used along with wheels equipped with soil. This helps to significantly improve the clutch of the cultivator with soil, which is often required in conditions of very loose and soft soil.

It is often required to slightly reduce the speed of the cultivator in the case when the operator needs to direct the power of the cultivator not to its speed indicators, but to an increase in torque or increasing the traction force.

Elements of the mechanism

Regardless of whether the purchased or home.made reducing gearbox will be used in the walk.behind tractor, it is necessary to understand how the elements of the mechanism are located, how to serve and repair them. Reducing gearboxes of motoblocks can be several types, each of which has its own advantages and disadvantages.

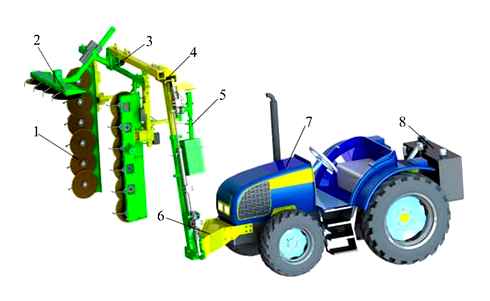

The attachment diagram of the driver to the gearbox

Gear gearbox

As a rule, it consists of one or two steps; The main elements are gears. This type is one of the most reliable mechanisms used in howling. Used in the most powerful motoblocks. To their advantages can include:

Machining Axles. Tracked Amphibious Vehicle Build Ep. 6

Such driver are not devoid of disadvantages, the main of which are repairs and price. In the case of a breakdown, as a rule, they are replaced entirely, which requires significant cash costs. In addition, you need to control the presence of lubrication, the absence of which can lead to rapid wear.

Worm gear

The main element is the worm transmission. It allows you to reduce the dimensions of the walk.behind tractor and improve the weight due to the perpendicular location of the drive shafts and wheels. Most often they are placed on light and low.power motoblocks.

The main disadvantage of the worm gearbox is the lack of reverse. In addition, in the case of a breakdown, the reducer is replaced completely.

Chain gearbox

One of the most popular types of gearboxes among users. Most often made collapsible, which simplifies maintenance and diagnostics. The most common breakdown is the rupture or stretching of the chain, cutting the teeth of stars or a drive of the drive shaft. All these breakdowns, as a rule, are quite easy to eliminate independently, replacing the failed part.

The advantages of a move of this type include:

A separate article about a home.made chain gearbox for a walk.behind tractor.

Combined gearbox

Gearboxes of this type are characterized by the presence of various types of transmissions in one mechanism: gear-building or worm-building. The need for such movers is dictated by the fact that in the gear and worm reducers, the interdosseous distance between the host and the driven shaft is regulated by the size of the transmission and directly depends on the gear module and the number of teeth. In the chain gear, the distance between the shafts can be adjusted by removing or adding links.

When laying the design of the walk.behind tractor, it is far from always possible to arrange all the units in an ideal position, and there is a need for an intermediate gear link. This function is successfully performed by a chain gear, which compensates for the distance from a six or worm reducer to the wheel or drive shaft.

What does the move reducer consist of

Depending on the type of lowering gearbox, a homemade driver consists of the following main details: incoming (high.speed) shaft, output (low.speed) shaft, worm and worm wheel, leading and driven gears or stars.

At the same time, leading stars and gears always have a larger number of teeth than the driven. Auxiliary elements can be various couplings, bearings, and whales. There is a case in six and worm gearboxes, which cannot be said about chain. They may either be completely absent in the case, or cover only part of the mechanism.

Maybe you will be interested in making a mower for a walk.behind tractor or adapter for a walk.behind tractor.

How to make a walk.in for a walk.behind tractor with your own hands

Self.assembly of a move reducer can be an excellent alternative to buying such equipment in a store. If you stock up on the right tool and read the processes of work, then it will not become something critically impossible. To do this, just understand the device of the block and the design features of its action.

Of course, it’s good if there is a professionally executed drawing at hand, so as not to make the calculations “by eye” itself. After that, you need to choose a piece of durable metal from which the case for the future apparatus will be arched. Some craftsmen use parts that are suitable in terms of dimensions removed from non.working freight motorcycles of Soviet production. Or use the finished case from under any small generator.

As a toolkit, as well as materials, you will have to stock up on the following:

As soon as the necessary materials and tools are ready, we begin to act according to the following algorithm:

- Having measured the diameter of the future lowering gearbox, we cut out the membrane of the bearings from the metal. These will be bearings located on the drive of a gear shaft.

- Steel flanges should be placed on the opposite side of the gearbox. This should be borne in mind when selecting bearings. A bearing and a steel washer placing inside each flange.

- Using fasteners, we fix them to our body.

- Next, we will need a lead gear, the shaft of the driven and steel key.

- All these nodes are connected to the transmission mechanism and the shaft of the rotary generator.

- Spring washers and nuts will need us to fix the pulley with a driven shaft.

A few more recommendations to a novice master. Bearings will play functions of shaft supports. Given the loads attributing to them, the reliable and durable device of the entire unit as a whole will depend on their competent choice. To minimize their service, masters use radial closed bearings. But the chain with the stars will have to be taken ready, but there are many mechanisms from which they can be borrowed.

OpenRC Tractor build with me part 3 differential

If everything is collected correctly, then with the help of this device we will be able to reduce the course of the walk.behind tractor. You can safely install it and use it on a power plant operating from any fuel. Cooling of such an aggregate will be airy type. Periodically, it will be necessary to clean it of accumulated dirt, diagnose the serviceability of the decrease function and be sure to lubricate at least once every 3 months. With proper care and operation, the device can serve the farmer for more than one year. If you read questions and clarifications, do not hesitate to write about them in the Комментарии и мнения владельцев to the material.

We do it with our own hands

How to make a driver on a single tractor with your own hands? The design mechanism is very similar to the gearbox. Its inclusion in the work of the walk.behind tractor redistributes part of the traction force for additional attachments. Work on the manufacture of the device can be conditionally divided into several stages:

- Preparatory events. At this stage, a case is selected for the future mechanism, metal pipes, bearings, gears, steel sheets and screws are harvested.

- Make shafts. The main material is the round rental of hardened steel. Using machines, the workpieces are pulled, achieving the exact size, and also make grooves. The shafts transmit the torque, and the radial bearings hold them.

- Set the chains and stars. This material is best purchased in the store.

- After assembling the body of the driver, it is tested. In the event of any extraneous sounds and creaks, the work is suspended and corrected violations.

Advice. You should take up the manufacture of home.made devices only if you have experience and when assembling clearly adhere to the algorithm of the necessary operations.

Necessary materials and tools

A driver is an ordinary reducing gearbox that increases torque due to a reduction in engine speed. Such gearboxes exist of different types, for the walk.behind engineer the most applicable gear.

To assemble a lowering gear reducer, you will need:

- measuring-drawing devices for creating a drawing;

- saw for metal;

- drill with drills;

- bearings;

- pulley;

- a steel sheet 3-4 mm thick (Steel ST3 is suitable);

- finished case (from the generator);

- conical leading and ordinary led gears;

- Vedic and rotary shafts.

You will need various bolts, nuts and washers for fasteners. In some cases, it is advisable to use a welding machine.

Madoor

Clutching the wheels of the earth.processing machine with the soil can be strengthened if you use soil.bearing or a motorized carrier for a walk.behind tractor. The driver is one of the attachments. It makes it possible to reduce the speed of the agricultural unit and increase the traction force along with the torque. The analogue of the gearbox works with a chain and stars on the shafts. If desired, this device can be made with your own hands. Details are used from other equipment.

Each considered converter is endowed with its shortcomings. To minimize their number, you should try to make the device yourself. A homemade thing can become a better and more convenient in operation than a purchased copy.

First of all, the stars of the primary shaft are mounted. If the design is massive, flange or key mounts is fixed by means of point welding. At the next stage, they choose the method of attaching the driven shaft and a pair of half.skinned axes.

When installing, it should be taken into account the possibility of shifting a star in one of two directions. The case is made independently or with the help of specialists. If the first option is selected, take into account the features of the seals, the corresponding seals and bearings.

All about tugs for a walk.behind tractor

Motorics, in particular, motoblocks, for several years have been for the owners of agricultural plots faithful assistants who are able to carry out a great range of work with the lowest costs of effort and time. However, sometimes the operational parameters of these units are no longer enough to carry out certain tasks, or the equipment is functioning badly. In this case, a device such as a move (reducing gearbox) for a walk.behind tractor will help manage individual problems in this case.

How much oil is pour into a motorblock gearbox

When working for a walk.behind tractor, it is necessary to maintain a constant level of oil in the gearbox. If this simple rule is not observed, the remaining lubricants can boil and jam the parts. Only high.quality oil is poured. Even with constant maintenance of the level, breakdown occurs. During chain gear, the chain is torn or extended. If traces of oil appear outside, this is a sign of leakage of the oil seals. Worn details require replacement by similar. It is better to purchase them from the manufacturer who has proven themselves on the good side.

The gearbox provides uninterrupted operation of the walk.behind tractor, extends its service life and increases the efficiency of using the unit. In this matter, a good assistant is the lubrication of his details. For lubrication, transmission oil is poured. Its possible brand is ZIC 10W40, SUPER T-3. The oil level is determined in this way:

- You need to take a wire about 70 cm long instead of a probe and bend it in an arc;

- insert into the hole for filling to the stop;

- pull out a home.made probe back;

- The wire should be lubricated with oil for a length of about 30 cm.

This level is considered the norm. If the oil is not enough, you need to add it to normal. In the purchased gearbox, the level should be indicated in the instructions. Chinese one.axic tractor can be sold without oil.

The purpose of the lowering gearbox

There is no simpler and more reliable solution to reduce speed than a reducer. This is a type of attachment equipment in which the main working element is a reducing gearbox. It is he who implies when they talk about the reducer of the course of agricultural machinery. Using an additional chain, it transforms the driving force of the walk.behind tractor for the operation of auxiliary equipment.

The main purpose of the driver is to reduce the engine speed, increase the rotational moment. Its operation is in demand and useful when using any attachment equipment with a motor.cultivator. However, it is necessary to carefully approach its purchase or create with your own hands, focusing on what work will be required of it.

Of course, the easiest way to achieve reduced speed is to reset the power of the power plant. However, the power in this case will be lost, and, together with it, and the performance of agricultural equipment. Devices can come to the rescue that can lower the gearbox so that the engine speed does not fall.

Often, together with garden and garden cultivators, auxiliary equipment is used to expand its functionality or achieve greater performance. This is precisely this refers to the driver, which will allow the walk.behind tractor to move at a lower speed for various operations.

The main conclusion: a decrease in the speed of the course is necessary when the vehicle of the machine is required to direct the excess power not to improve speed indicators, but to increase the traction force or torque.

Before proceeding with an independent assembly of the driver, you need to know what specific components it consists of. This will subsequently allow it to serve it more professionally. The main components are more than 10:

- casing;

- gearbox;

- power shaft;

- adhesion unit with a gearbox;

- soils;

- side covers;

- axis and stars;

- cargo;

- gears;

- bearings;

- dowels;

- couplings;

- Bolts and nuts of various diameters.

Varieties of howl for motor vehicles

Motics reducers can have a different structure and principle of operation. Therefore, any of these mechanisms has various parameters, advantages and imperfections.

According to such indicators, the reducing gearboxes for motor vehicles are divided into several types.

- Sixth lowering gearboxes. this equipment has a particularly strong design. The steel from which the gears are produced is covered with specialized protective equipment, which significantly increases stability and lengthens the period of use of gearboxes. Of the shortcomings of this type of device, it is necessary to make Accent at a high price.

- Worm reducing gearboxes. motor vehicles with engines equipped with vertical ramparts are equipped with similar devices. The worm driver for the unit is intended mainly for plowing before the cultivated soil. The use of a worm reducing gearbox on uncontrolled lands leads to its inevitable failure.

- Chain drivers. equipment of this type has a long working resource and affordable price. The shell of the device can be of collapsible and non.vegetable. The first sample is much more practical, since when you fail the unit with a collapsible membrane, it can be repaired in any case on its own.

- Combined (gear-cod) drivers-devices of this type are the most suitable solution for tractors equipment. They are characterized by a low price, have a long functional resource and perfectly withstand high loads.

Any reducing gearbox behaves in different conditions of use. This must not be forgotten, choosing a certain device for motor vehicles.

Worm

The worm gearbox is widely used in the set of mini-tractors and motoblocks. This model has gained popularity due to the long period of trouble.free work and high reliability. A worm type device has a reverse that allows the aggregate to move reverse.

The screw can have a four.set thread or two.stroke. It coincides with the thread on the gear. Teeth on high.quality details are made of antifriction steel. The effectiveness of the device is high. Its advantages:

- The gearbox allows you to extend the life of the engine;

- creates little noise during work;

- The device of only 2 parts consists;

- has a large transfer number;

- has a smooth move;

- High effect of self.molestation.

All positive qualities appear with accurate assembly and adjustment of the mechanism.

Gear

A gear transducer with a differential is used in heavy.class motor blocks. It is well suited to engines in which the crankshaft is located vertically. The gearbox publishes little noise during operation, has high performance. It is able to function in straight and angular schemes.

On heavy units, a gear converter is often equipped with a gearbox. This transmission allows you to move in reverse. Reverse occurs during the reverse rotation of the gears in the case. This is achieved by a change in the position of the lever outside the body.

Gear gearbox is the best choice for heavy agricultural machinery. The engine equipped with this mechanism operates longer than with a worm version.