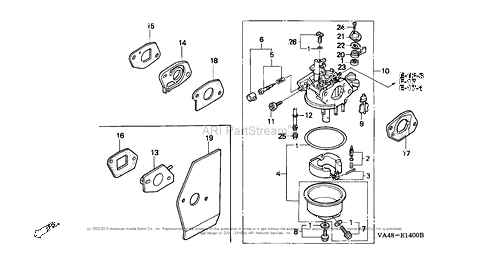

Honda mower carburetor assembly. Honda Lawn Mower Carburetor Adjustment: How to Do It

Honda Lawn Mower Carburetor Adjustment: How to Do It

This post may contain affiliate links. As an affiliate of retailers(like Amazon), we earn from qualifying purchases.

When your Honda lawn mower’s engine doesn’t idle, lacks power at high speed, or won’t start, it could be time to adjust the carburetor. If you have never done this before, you are probably wondering how difficult it will be, what tools you will need, and if you should just call an expert.

Adjustments to a Honda lawn mower’s carburetor should be made after it has been cleaned. If the carb is dirty, adjustments will be temporary. You will need some screwdrivers, a wrench, a carb cleaner, and an hour or two. Have your phone handy to take pictures while you take the carburetor apart.

Keep reading to find out how a carburetor works, what could be causing different problems, as well as preventative measures.

How Does a Carburetor Work?

Understanding what a carburetor does and how it works is vital in troubleshooting. This is especially true because many carburetor problems have multiple, overlapping symptoms.

The carburetor’s role is to provide the space where gas and air mix. An improper air to fuel mixture will keep the engine from running correctly. An incorrect gas and air mix cause most carburetor problems. Your job is to figure out what is causing the mix to be off.

- Float Chamber: The float chamber holds fuel, and as the amount of fluid increases, the float rises until it is pushed into its seat. When fuel leaves the chamber, the float falls. As more fuel enters, it rises again.

- Intake: Air rushes through the throat of a carburetor, and then a narrower passageway called a venturi. This causes the air to speed up, creating a vacuum that pulls fuel into the fuel nozzle.

- Fuel Jet: Once the proper gas/air mixture has been created, the fuel is pulled through the fuel jet. This creates the explosion that powers the engine.

- Throttle Valve: This valve controls the amount of gas that goes into the carburetor. An open valve increases the engine’s power, and a closed valve stops the engine.

Carburetor problems can occur at each of those points, and the way to fix most carburetor problems is to get inside and see which of these is causing the problem.

Why You Should Clean the Mower’s Carburetor

Although you might be tempted to play around with the throttle or make other adjustments, clean the carburetor. Otherwise, any corrections you make will be temporary, and you could wind up causing even more damage to the carb.

Also, get a parts cleaner, such as WD-40 Specialist Carb/Throttle Cleaner. It contains the solvents you need to clean out the gunk, and the spray will blast away dirt and deposits. For tools, you will need screwdrivers and a socket wrench.

Mower Engine Starting Problems

If your engine is not starting, you have difficulty starting it, or it stops after you get it started, then the following could be causing starting problems:

- The main jet, main nozzle, or main nozzle air path could be clogged.

- The float isn’t moving correctly.

- The throttle stop position is wrong.

Mower Speed Problems

If the engine speed does not increase, the speed is unstable, or the engine performs poorly at high speed, then an additional clog to check for is the pilot jet—either its air path or the jet itself are clogged.

Should speed problems happen at low speeds or the idle speed is unstable, then in all likelihood, the pilot jet or its air path is clogged. You will need to check for dirt and clean.

Mower Gasoline Problems

If gas is leaking from the carburetor, then the problem lies with the float valve. Either the float valve is worn out or coated with dirt, or the valve seal is worn or dirty.

Getting to the Mower’s Carburetor

Before you get started, we recommend you disconnect the spark plug cap. This is to prevent the mower from accidentally starting. Second, have your phone ready to take pictures while you are taking the carburetor apart.

Fix Without Taking the Carburetor Apart

You might get lucky and avoid having to take the carburetor apart. To do so, FOCUS on cleaning out the carburetor idle jet. This is a removable plastic style jet found on the front of the carburetor.

- First, spray the carb cleaner and remove the dirt and gunk.

- Look for a plastic screw with a Phillips head bolt. That’s the idle adjustment screw. Loosen and remove it.

- Now you will have access to a rubber plug with a hole. This is the idle/pilot jet.

- To remove the pilot jet, you need to pull it out gently. Use flathead screwdrivers to wedge it up.

- After you get it out, you should clean it with the carb cleaner. The small hole on the end often gets plugged. Honda makes Jet Cleaner sets, but a tiny pin will be a good substitute.

- After you have cleaned the pilot jet, push it back in carefully, and then replace the idle screw. Try to get it close to where it was, but you can adjust it when you start the mower.

Clean Out the Float Bowl

The float bowl is at the bottom of the carburetor. It is easy to take off, but before you do, turn off the fuel line. Then loosen the bolt on the bottom and take out the bowl.

There are two gaskets—one where the bowl connects to the housing, and another one on the bolt. Inspect both for cracks. Then clean out the bowl and replace the housing.

Copyright article owner is ReadyToDIY.com for this article. This post was first published on 2020-08-27.

Taking the Mower’s Carburetor Apart

If the mower is still not running correctly, then the carburetor must be taken apart so that you can clean it. This is a much more complicated procedure and could take an hour or more.

- First, remove the air filter. If it is dirty, replace it. A dirty air filter can affect how well your mower runs better. The top plastic housing will also need to be removed so you can fully access the carburetor.

- Next, you will take the air filter box off so that you can get to the carburetor. In most models, it is held on by two bolts. As you loosen the bolts, hold onto the carburetor. The bolts run through the carburetor and mount it to the motor housing.

- Now that you have access to the carb, get ready to start taking pictures. Anything you unhook needs to be hooked back correctly. Keep an eye out for the tiny spring attached to the top.

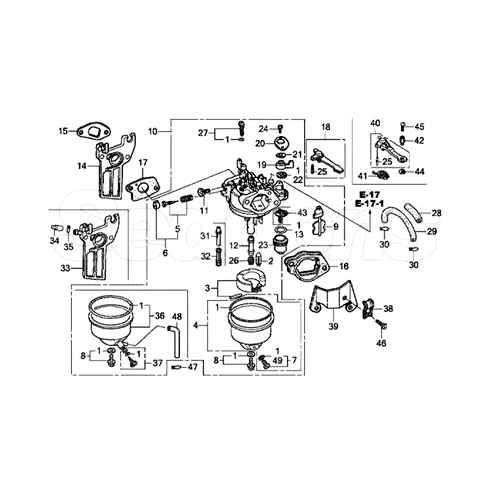

- Once you have taken the carburetor off, it is time to disassemble. As you do so, check the gaskets—worn ones need to be replaced. Continue taking the carb apart and cleaning. Every hole needs to be clear of dirt.

Finally, the carburetor will have to be reassembled. Hopefully, you took lots of pictures so that you have them as guides.

Rather than taking a carb apart, some folks simply buy a new carburetor. Be sure to check compatibility with your Honda Mower.

Check out this 12-minute video that will take you through the steps of fixing a lawn mower carburetor:

To prevent future problems, make sure you are following Honda’s recommendations. Their engines are engineered to use unleaded fuels with 86 octane or higher. Ethanol fuels can be used as long as the fuel has no more than 10% ethanol (E10). A fuel with methanol should contain no more than 5% methanol.

Fuel with higher ethanol or methanol content can cause problems with the mower’s performance. The engine’s warranty does not cover damage to the engine caused by fuel with more than 10% ethanol.

If possible, regular unleaded gasoline is ideal. Avoid E85 at all costs because Honda considers it an alternative fuel since it is 85% ethanol and only 15% gasoline.

Storage Suggestions to Prevent Carburetor Problems

These are some suggestions to prevent future carburetor problems. Gasoline can begin to deteriorate within three to four weeks, so use these if you only mow every couple of weeks:

- Fill up the tank. As fuel is exposed to heat or air, it oxidizes and can gum up the carburetor’s jets. Keep the tank full to minimize how much gas can enter the tank through the vent.

- Run the engine out of gas. No fuel = no oxidation. If the mower only has a little gas in the tank, run it dry and close the fuel valve.

- Storage container. Make sure you close the container tightly and store it in a cool place. Honda discourages metal fuel containers since they might rust, and tiny rust particles can clog the carburetor.

- Fuel Stabilizer. Fuel stabilizers should be added if gas is stored either in the container or the mower for three months or longer. If you plan to use the mower within a year, there is no need to drain the gas from the fuel tank or carburetor—as long as you add the stabilizer.

Final Thoughts

Carburetors are an essential and often overlooked part of a lawn mower. If your mower is not running well and you have checked the air filter and spark plug, you might have to work on the carburetor. Taking the carburetor apart and cleaning it is time-consuming but not difficult. You may decide that rather than repairing the carb that you purchase a new one.

Related Articles

ReadyToDIY is the owner of this article. This post was published on 2020-08-27.

Honda Lawn Mower Won’t Start – Beginners guide with pics

Honda makes reliable, well-designed, and constructed mowers. You bought one, so you already know this.

A gummed carburetor is the most common reason a Honda lawn mower won’t start. Other possible causes include:

I work on lots of Honda’s and major failures are very rare. Let’s begin by doing some basic checks. Sometimes this will solve the problem or at least point you in the right direction.

This guide will assume that components such as pull cord, throttle levers, etc. are working OK. If you think that this is not the case, I wrote a guide that covers all pull cord common problems – check out “Pull cord troubleshooting”.

Diagnosing a no-start Honda is pretty straightforward, carry out a few basic tests to eliminate ignition, fueling, and mechanical faults. Tests are not difficult, but you’ll need to execute them correctly to avoid burning time or replacing parts needlessly.

This post covers the subject pretty well, however, if you need video help, check out “Mower won’t start video”.

It covers the full diagnosing process and repairs of the most common causes of a no-start mower.

Check the Basics

If you need video help checking the basics, check out “Pre repair no start checks video”.

In the workshop, I find the majority of Honda mower engine problems are related to bad gas. Common symptoms of bad gas include, Honda won’t start, the engine starts then dies and engine surging.

Oil Level

Some Honda mowers won’t start if the oil level is low, this isn’t a flaw, it’s designed that way to protect the engine. It’s good practice to check the oil level every time you fill the gas tank. Check on level ground and with all wheels set to the same height.

The Honda will take.58 of a quart (.55lt) from empty. If you are in any doubt about how to check the oil, you’ll find this guide helpful – “How to check lawn mower oil”.

Check Oil – A Honda won’t like to be overfilled with oil either, this can damage the engine, cause it to smoke, leak oil and sometimes not start.

Gas Level

Is there gas in the mower? Sometimes the obvious is the solution, and as Sherlock Holmes says “we should check a fact is indeed a fact”. The customer may have filled the gas tank with what they thought was good gas.

At my shop, I have found many strange concoctions – diesel, water, white spirits, vinegar, and of course last year’s gas makes a regular appearance in the tank. The fix for bad gas – drain the tank and clean the carburetor. You might find this guide helpful, it walks you through the whole process – “Carburetor clean out”.

Gas Tap On

The fuel tap is used to cut the fuel supply to the carburetor. I tell my customers to turn off the fuel when the mower isn’t in use. It’s easy to forget to turn it on. Honda fit their fuel tap on the right-hand side of the engine when viewed from the front of the mower.

This short guide with pictures shows you where your gas tap is, what it’s for and when to use it. Check out “Where is my lawn mower gas tap”.

Air Filter

A blocked air filter will prevent the mower from starting. The Honda air filter needs to be kept clean, check it every 25 hours of use, and replace it every 100 hours. Honda fit tool-less air filter covers, which makes cleaning super easy.

The air filter cover is on the right-hand side of the engine, opposite the muffler. Cleaning the filter with compressed air would be nice, but banging on the ground will do just fine. This guide will help you service your mower in under an hour – “Mower tune-up”.

Plug Wire On

It’s easy for the plug wire to come loose, happens all the time. The plug wire lives right at the front of the engine, so it’s banging into shrubs and hedges and the like. It’s the black wire with the rubber boot on the end. Make sure it’s making good clean contact with the plug. Bad or no contact will give you a no start.

Choke On

I meet lots of customers who don’t know how to use the choke correctly, and I don’t blame them, it is likely they weren’t shown by the retailer. The choke is used to start a cold engine. A cold engine needs more fuel than a hot engine, so the choke creates a richer air-fuel ratio.

Some Honda’s will have the traditional choke lever and more modern mowers will have the auto choke set up.

Not sure if your choke is working? This guide will walk you through the testing procedure, see choke testing below.

If your mower doesn’t start on the 3rd attempt, it’s very likely the plug is saturated in fuel – a condition known as flooded. The fix is to remove and dry the plug or leave the mower for 30 minutes to dry out, then try again, this time without choke. Check out the Unflood mower video.

If you are in any doubt about how to start a mower, this guide covers it all, you’ll be a pro 2 minutes from now – “How to start a lawn mower”.

Choke On – Some Honda mowers are fitted with an auto choke and so the choke won’t be controlled by the lever.

Bail Lever On

The Bail lever or dead man’s lever is a safety feature. Its function is to stop the spinning blade within 3 seconds of release. It does this by shutting the engine off and applying a flywheel brake. If the bail lever isn’t held the mower won’t start.

This guide will walk you through testing for spark and how to change a coil, it’s simple. Only some Honda mowers will have the stop/start controlled by the bail lever. Other Honda’s have the stop/start control built into the throttle lever.

Check For Bad Gas

Bad gas is the number one cause of no starts. Your gas could be clean but stale, and mowers don’t like stale gas. Gas starts to go off after one month, it losses its ability to com-bust which causes poor performance and misfiring. When it goes completely stale, usually around 3 months old, it starts to solidify.

This has become such a big problem, last season I got a ton of questions about fuel carburetor cleaning.

Gas Stabilizer – It’s simple to use, just dump one ounce of gas stabilizer into 2.5 gallons of gas, fill your gas tank and run the engine to mix it throughout the fuel system, that’s it.

This stuff will protect and clean your fuel system and can be used in all gas-powered kit including 2 stroke engines. See video here.

Check out the “Carburetor cleaning tools” page, it lists all the tools I use including the gas stabilizer.

Gumming – It’s a carburetor killer, using a gas stabilizer will prevent a lot of problems.

That’s all the easy stuff checked, now we’ll dig a bit deeper. Bad gas has become a real problem, especially in Honda’s, the carburetors are so sensitive to contaminated gas and for that reason, we’ll perform the gas shot test next.

Try The Gas Shot

Your engine needs fuel, spark, and compression to start. Fuel, Spark, and Compression are broader areas than their title suggests. Testing will take into account the complete system, for example, fueling is more than just the gas, it includes carburetor, tank, air and fuel filters, gas line, intake manifold, etc.

The most likely cause of a no-start Honda is fueling, and so we will start there. The next most likely is spark and the least likely of all is a compression issue.

To quickly test for a gas issue – bypass the fuel system. We do this by pouring some fresh gas directly into the carburetor.

If you need video help, check out “Mower won’t start video” which shows you how to nail this test like a pro.

The symptoms of bad gas vary: mower won’t start; mower runs rough; runs but only with choke; splutters when cutting on a slope; dies when cutting grass; lawnmower starts and then dies.

Remove – Remove the air filter, by pressing the two plastic tabs.

Tilt your mower over and pour a cap full of gas into the carburetor.

Pull – Attempt to start the mower in the normal way.

There are two possible outcomes –

(1) Mower attempted to start or started – tells us we have a fueling fault. Check out the Choke system test below(2) Mower made no attempt to start – then we’ve likely eliminated a fueling fault, and the fault will probably be a lack of spark. Check out the Ignition system test below.

Does Your Honda Need A Tune-up?

Your Honda engine should be serviced at least once per season, ideally in the spring. Tune-up kit includes: oil; plug; air filter; fuel filter (if fitted); new blade (optional).Your Honda engine will likely be a GCV 160 or GCV 190cc.

The service kits will be identical, however, Items such as carburetors and blades will be different. Check out “Mower tune-up guide”.

Buying the tune-up kit online is easy. You can find your model code right at the base of the handlebars, on the body of the mower. Honda mower engines are very common and so you won’t have a problem getting a tune-up kit to match.

Test The Choke System

Your mower won’t start if the choke is faulty. In this next step, we need to be sure the choke system is working correctly. The correct starting procedure for a cold engine will require giving it extra gas to enrich the fuel/air mixture which a cold engine needs for a smooth start. Honda uses a choke plate type system to achieve a fuel-enriched condition. Your mower won’t start if the choke is faulty.

The manual version will have a throttle lever to control the choke. The auto choke version won’t have a choke lever. Instead, a wax thermostat mounted in the cylinder head heats and pushes on a lever that opens the choke plate.

To test we’ll need to remove the air filter, this allows us to view the choke plate. If you have a manual choke control, move the throttle lever to the full choke position to start a cold engine.

Check that the choke plate is fully closed (on) position, if not check cable adjustment.

Full Detailed Honda GCV160 GCV190 Carb Clean [4k]

Your Honda may have an auto choke. If so, when cold, the choke plate should be closed, as per the picture. If not, move the plate by hand to see if it’s stuck. If sticking, try WD40.

When the mower has started, the throttle should be moved to the run position. Check that the choke plate is in the fully open (off) position as per the picture. If not, adjust the cable.

A sticking choke will run poorly and puff black smoke from the muffler. Your Honda may have an auto choke. If so when hot, the choke plate should be open, as per the picture above. If not, replace the choke thermostat at the muffler.

If you found no issues with your choke system, move on to clean the gas bowl.

The Problem With Ethanol Gas

Honda recommends not using fuels with more than 10% ethanol. Ethanol is an alcohol fuel made from sugar, corn, and other plant materials. This alcohol is then blended with gas to make ethanol.

It’s claimed that the alcohol content of the ethanol will damage the carburetor’s rubber seals and hoses.

E15 contains 15% ethanol and is not OK to use in Honda mower engines. E15 burns hotter than other fuels, your mower is not designed to run at these temperatures. Ethanol absorbs moisture from the atmosphere.

If the fuel is left in the mower over the winter, the moisture collects in the carburetor. The water will often corrode and leave a varnish type deposit that blocks up the ports. This is what causes the poor running/no start.

If you need help prepping your Honda for hibernation, check out “How to winterize your mower video”.

Gas Stabilizer

Regular gas older than three months is stale unless you use a fuel stabilizer. Ethanol fuels are stale after one month. Gas is the number one reason for a no start or poor running.

Using a stabilizer will prevent lots of these problems. As you know, you don’t have to use the stabilizer all season, but do use it towards the end and when winterizing the mower.

Treating your gas will save you downtime, hauling your mower to the shop, and in repair costs. If you need video help on the subject, check out “Adding gas stabilizer video”.

Stabilizer – Just dump a few drops into the gas tank, and run the engine. Simple!

Try Cleaning The Gas Bowl

Often just cleaning the gas bowl does the job. Removing the carburetor is a bit of a mission, so if cleaning the bowl gets us out of trouble, it’s worth trying. If you suspect stale gas, then you’ll need to drain the gas tank also.

You can drain the tank by removing the fuel line, but I use a Briggs and Stratton oil extractor instead, which makes the job a ton easier, you’ll find a link to amazon here on the “Small engine tools page”.

If the bowl cleaning doesn’t work we’ll need to remove the carburetor, clean it thoroughly and drain the gas tank.

Honda mowers are fitted with different sizes and types of engines. These engines will be fitted with different types of carburetors. Your carburetor may look different, but the process is the same.

If you need help, the “Honda mower surging video” covers the bowl draining and cleaning process.

In this part of the guide, I will remove just the fuel bowl, spray in some carburetor cleaner. You can find your fuel bowl behind the air filter. You don’t need to remove the air filter housing to access the bowl.

Remember, if your gas is older than three months, it’s stale. So cleaning the bowl won’t always make it go. You may need to drain the tank, carburetor bowl and fill it with fresh gas. If this works out for you, great!

If not, check out this guide it covers the whole process and includes pictures – “Carburetor cleaning”.

Pull Wire – When working on your mower remove the plug wire and turn off the gas. This prevents a spill.

Removing the 10mm drain bolt will drain the bowl, but won’t clear the grit from the bowl. I like to remove and clean the fuel bowl. Drain the fuel tank now, if you need to.

Turn on the gas to check fuel flow, if no fuel flows from the carburetor, move on to – Fuel flow test below.

Spray some carburetor cleaner up at the main fuel jet before refitting the bowl.

That’s it, test mower and if it’s still not right, check out “Carburetor cleaning”.

Try Cleaning The Carburetor

Okay, I will assume you have tried cleaning the fuel bowl as per the above guide without success. Now you need to remove the carburetor and clean it.

Have some carburetor cleaner or similar, a container for nuts and bolts, and take lots of pictures to help you remember where levers and gaskets are positioned.

There are a couple of different styles of the carburetor, yours may look a little different, but the process is the same. Some will have a manual choke, others will have an auto choke. Some will be more challenging to remove than others.

If you need video help check out “Honda mower surging video”. It covers both types of carburetors and guides you through the process of removing the carburetor, stripping, cleaning, rebuilding, refit and adjusting.

Here are some of the tools I use to clean carburetors, they’ll make the job a lot easier. “Carburetor cleaning tools”.

If you find carburetor corrosion or it’s badly gummed up, go ahead and replace it, because nobody likes doing a job twice. Replacement carburetors are not expensive.

Note that GCV 160cc and GCV 190cc carburetors look the same, but are different. So when ordering has your model number handy.

Check out “Lawn mower carburetor types”, it’s a list of common type carburetors

Carburetor Removal

Removing a Honda carburetor can be a little challenging. It’s not complex but there are lots of gaskets that must be replaced in the same order. In addition, the air filter housing bolts are also the carburetor bolts, so the challenge is to align gaskets, carburetor, and air filter housing before threading the bolts.

Take lots of pictures of gaskets and carburetor link positions. Layout your gaskets in an order that makes sense to you. All you really need here is patients. Buckle up!

Remove – Remove plug wire and turn off fuel as before. Loosen the bolt on the fuel bowl.

Loosen the air filter box/carburetor bolts (3) – two carburetor bolts and one air box bolt.

Use a suitable container for small parts.

Fitted to the back of the housing is a pipe which just pulls off, it’s the crankcase breather.

Take pictures of gaskets and locations.Remove 3 bolts and take more pictures of throttle link locations.

Set any loose gaskets aside, and in order.

Some gaskets will stick to the carburetor or other components and that’s fine don’t remove them.Gaskets must be fitted in the same location and orientation.

Drain Gas – If you haven’t already, drain out the old gas. Use a long flat screwdriver, pry off the gas line, removing the gas cap speeds up the draining process. Best to do this outside, gas stinks.

With the fuel line removed, you can turn the carburetor on its side to unhook the choke, throttle links, and spring. Don’t be tempted to bend the links.

With the carburetor free, move to a bench.

Strip Down – Remove bowl, float, and needle, this is done by pulling the pin. If your bowl is very corroded, go ahead and order a new carburetor as repairing rusty carbs isn’t worth the effort.

Check the needle tip, a worn tip turns pink. When these seal tips wear, they can cause either too much fuel flow or no flow. Replace needle or replace whole Honda carburetor.

Remove the main jet retaining screw. These guys are made from brass which is a soft metal. So a properly fitting screwdriver is essential, otherwise, the screw will be damaged.

The brass emulsion tube needs to be pushed free. Take a suitable screwdriver and push on it. It may need further encouragement, tap on the housing as per the picture until the tube is free.

Clean the portholes of the tube and thoroughly. I use a strand of wire plucked from a wire brush. The holes may look clean but are dirty. After you have cleaned them, they will be noticeably bigger. This allows more fuel to flow to the engine.

Spray all carburetor ports liberally with carburetor cleaner, fuel inlet, float needle seat, jet, throttle plate, choke plate, and any other ports you can see

Reassemble, fit the jet, screw, float, and needle. Careful when fitting the gas bowl, the large o ring can become pinched, apply some oil to help it seat. Don’t over-tighten the bowl, it causes it to leak.

Refit carburetor to the mower. Take special care when fitting the gaskets. Check your reference pictures. This bit gets overlooked, but it’s important. Clean out the fuel can and your gas tank.

Check the tank for grit and if you’re not sure the gas is good, replace it. Fill with gas and turn on the fuel. Fit spark plug wire, and you’re good to go.

Check The Gas Flow

This section deals with a lack of gas flow from the carburetor. The areas for consideration are gas cap; carburetor float needle seal; fuel filter; fuel tank; fuel lines.

If you have too much gas flow, the float needle is at fault, and yes you could replace the needle but often this doesn’t fix the problem. I like to replace the whole carburetor. This page list popular carburetors “Carburetor types”.

Small engine mowers use gravity flow to get fuel to the carburetor. Meaning the fuel tank should be higher than the carburetor. To test for flow make sure you are on level ground and have a minimum 1/4 full fuel tank.

Common reasons for no fuel flow are bad gas caps and dirty float needle seals.

The best way to troubleshoot no fuel flow is with the fuel bowl removed. A fuel tank needs to breathe. When fuel leaves the tank it needs to be replaced with air.

A sealed tank will prevent fuel from flowing. Remove the gas cap and check flow, if it now flows, replace the gas cap, it’s faulty.

Honda employs a mesh screen in the bottom of the fuel tank to filter the gas. Look into the gas tank, which is easier when it’s empty, and check the filter for grit. I use a suction pipe to clean the bottom of the tank, however, sometimes you need to remove it to clean it thoroughly.

Check if the gas tap is the problem, remove the gas line to the tap and check flow.

Remove the float and check the needle seal. Use fine wire to clean out the needle seat in the carburetor. I use a strand from a wire brush.

Blow some into the needle seat on the carburetor. Fuel should start to flow.

Test The Ignition System

Spark is just as important as fresh gas. When it comes to spark, your plug is the first component to check. So be sure to have a good plug on hand. In this section, we will check the: plug; plug wire; coil; coil control wire; bail lever.

The test will require removing some covers. You don’t need any special tools to complete this test, but I prefer to use a spark testing tool and a plug gap tool. you can find both here on the “Small engine tools page”.

You can check out Ignition system testing and repairs here “Mower won’t start video”.

A video on testing and repairing the ignition system is included in the mower repair video library.

For this test you will need a spare plug, any plug will do for the test. But only fit Spark Plug (BPR6ES) to a Honda GCV 160 and 190.

You’ll also need a plug spanner, insulated pliers, and a very brave helper, who can withstand extremely high voltage……. I’m Joking, it’s only moderately high.

Spark Test

Note: The best way to test spark is with the In-Line Spark Tester tool or similar, as it will load up and stress test the coil. You’ll find a spark test tool listed on the “Small engine repair tools page”.

Remove the plug from the mower and put the plug wire back on the plug. Now hold the plug against the metal of the engine using the insulated pliers, take care to ground it well.

The helper now attempts to start the mower while you observe the plug spark. You should see a bright blue spark. If no spark, try the new plug.

Spark Test – There are 2 possible outcomes:

(1) No spark with either plug. If so keep reading.(2) Spark is good, if that is the case, check out “Carburetor cleaning” and if that fails run a compression test.

If you have no spark or your spark is poor you could have a faulty coil; spark plug wire; coil cap; a short circuit of coil control wire or poor bail lever cable adjustment. Look for obvious signs of damage.

Throttle Stop / Start

Most Honda mowers are fitted with stop/start control at the throttle lever and some have the bail lever stop/start, which is covered next.

The stop/start coil control switch seen here is mounted beside the carburetor. Check that the switch is being operated by the linkage when you set the throttle to the start position. If not, adjust the cable at the throttle lever.

Testing Throttle Switch – I don’t usually test these switches, because they don’t give trouble. So at this point, I would go ahead and fit a new coil.

However, you can test them by unplugging and repeating the spark test performed at the start of this guide.

- If after running the test, the plug now sparks, replace the switch.

- Still no spark, replace the coil.

Bail Stop/Start

This is the other type stop/start system, the bail lever, and is connected to the engine brake which incorporates a simple stop/start switch. When the lever is released a brake block pushes against the flywheel slowing the engine down. At the same time, the simple stop/start coil control switch is operated.Check that the switch is being operated when you pull the bail lever. If not adjust the cable.

LAWNMOWER GOVERNOR ADJUSTMENT: Honda Lawn mower REVS UP TOO MUCH or NOT ENOUGH?

Testing Bail Switch – At this point, I would go ahead and fit a new coil, because I have never fitted one of these switches. But you can test the switch by unplugging and checking for spark as before.

- If after running the test, the plug now sparks, replace the switch.

- Still no spark? replace the coil.

Replacing Coil

Coil Replacing – Your engine may look different but this process will be the same. Remove plastic pull assembly cover. Remove pull assembly held on by 3 nuts.

Fuel tank is now free, take this opportunity to clean it if needed, otherwise no need to remove the fuel line, just set it to the rear of the engine.

Remove – Remove two bolts that hold the coil in place. Remove the coil control push on wire connector, under the coil.

Fit Coil – Fit push on wire connector and bolt the coil in place, but don’t tighten yet.

An air gap must be maintained between the coil and the flywheel. A business card is just the right size. Push the coil snug against the business card and tighten the two bolts. Remove the business card. Rebuild in reverse order.

Don’t forget to refit the push-on wire connector and turn on the gas.Nice work!

Related Questions

Brand new Honda mower won’t start? The most common reason a new Honda mower won’t start is because the fuel tap is turned off. The tap is positioned just below the gas cap.

Other possible causes include:

Honda lawn mower troubleshooting self-propel? The Honda mower self-propel handlebar control operates by cable and the power from the engine is transferred to the transmission with a belt.

Common problems include:

- Drive belt breaks (Replace cable)

- Drive belt jumps off (Refit cable)

- Weak or no drive – Adjust cable on l/h handle bar

- Mower hard to pull back-ways – Cable over adjusted (Adjuster on l/h handlebar)

John Cunningham is an Automotive Technician and writer at Lawnmowerfixed.com.

He’s been a mechanic for over twenty-five years and shares his know-how and hands-on experience in our DIY repair guides.

Johns’s fluff-free How-to guides help homeowners fix lawnmowers, tractor mowers, chainsaws, leaf blowers, power washers, generators, snow blowers, and more.

Don’t Google small engine repair near me the next time your lawnmower sputters. Learn how to do it yourself. Small engine repair is all about a clean carburetor.

Family Handyman

Introduction

Solve most lawnmower or other small engine starting problems with a simple diagnosis and a carburetor cleaning or rebuilding. It will only take a few hours, and you’ll avoid the minimum 80-plus-parts repair bill.

Materials Required

If you can’t get a small engine started, it takes too many pulls to get it going, or it runs poorly, ask yourself this: Did it sit for a long time with gas in it? Like over the winter? If so, your problem is most likely a corroded or gummed-up carburetor. Small engine repair shops earn about 50 percent of their revenue by cleaning or replacing carburetors sidelined by old gas. Look at your lawnmower carburetor next time you sharpen the blades or complete a lawn mower tune-up.

Before you start taking things apart, take a minute to confirm the carburetor is the problem. We’ll show you how to do that, as well as how to clean, rebuild or replace a lawnmower carburetor. Either way, you’ll save about an hour of shop labor (about 80). You can complete the carburetor rebuild project in a single morning, including the time scouting for parts.

How to Find Lawn Mower Carburetor Parts and Prices

Whether you buy parts from a local small engine repair shop or online, you may need all this information:

- Machine brand (Toro, Snapper, Honda, etc.), model and serial number.

- Engine brand and serial number (Tecumseh, Briggs Stratton, Honda, etc.). The engine model and serial number are usually located on a plate above the spark plug.

- You may also need numbers from the old carburetor itself, usually stamped onto the carb body or its mounting flange.

- You can buy locally, or try smallenginepartswarehouse.com or psep.biz.

Where is the Carburetor on a Lawn Mower?

The carburetor is usually located towards the top of the engine, and is connected to the gas tank.