How Can You Cut Tiles At Home

Process description

You can correctly cut the paving stones at home by following all the recommendations. Step-by-step instructions will help you to cut the slabs to a given size with your own hands.

- Preparing the desktop. You need to clear the place, prepare supplies and tools.

- The marking of the elements intended for trimming. Test laying can be performed beforehand. When creating a pattern, the edges are often trimmed in the process, during the fitting of elements.

- Attaching a diamond disc of the correct diameter to an angle grinder.

- Fixing the tiles with clamps. This is necessary so that the element does not move during cutting.

- Cutting. It is necessary, directing the cutting element away from you, bring the rotating disc to the drawn mowing line, and start moving. To speed up the too tight stroke of the diamond wheel, the supply of sand to the cutting site will help. You need to drive the tool away from you at a speed of up to 3500 rpm.

Guillotine work

You can cut off the extra edge of concrete or stone tiles, paving stones, either with a hand tool or with a machine. The only difference is in the way the material is presented. If a guillotine is used, work is carried out in a specific order.

- The tiles are laid in the gap between the table and the cutting element. It is necessary to position it so that the knife falls exactly on the selected plane.

- Setting the knife in motion. The handle starts the mechanism, the cutting element, under the influence of its own gravity, lowers with considerable force, breaking off part of the tile. It is important to act on the entire handle when pressing, and not transfer force only to the edge of the lever, otherwise the effect may be unpredictable.

- Removing finished tiles. The guillotine allows you to put the cutting on the stream.

- Control over the condition of the knife. He needs replacement or sharpening if obvious defects, extraneous spots, areas with a burnt surface remain on the surface of the material, and the cut acquires a rough, not very aesthetic structure.

All About Cutting Paving Slabs

Cutting paving slabs with machines, an angle grinder and other devices at home requires the correct selection of tools and safety. Most of the street paving pavements are made of concrete, have high strength, so the question of how you can cut them without damaging the decorative layer is always especially acute. To figure out how to properly cut the paving stones with your own hands to the desired size, an overview of the available methods and technologies will help.

What can be cut?

There are different opinions on the matter, the better and more efficiently you can cut the paving slabs. When it comes to porcelain stoneware and its outdoor varieties, you can use a simple tool. Even a mechanical tile cutter of the appropriate size, working on the guillotine principle, will do. Paving slabs with a thickness of 20-80 mm cannot be easily cut. In this case, you should use more powerful tools. Let’s list them.

- Angle Grinder. This tool uses a diamond cutting blade that rotates at a specific speed. up to an average of 3500 rpm. The high hardness of the disc allows you to cut out materials with a dense structure, cut stone. Its diameter can reach 23 cm, the power of the tool can exceed 2 kW. When cutting with an angle grinder, the tiles must be securely fixed with a clamp on a flat, flat surface.

- Guillotine knife. This is the name of a special machine, which includes a table for laying paving slabs, guides, handles and a knife that descends on the surface of the product to be cut. Unlike working with an angle grinder, cutting with a guillotine is almost dust-free, quickly and efficiently for any amount of work.

- Concrete saws. They can be gasoline or electric, but certainly with the ability to cut concrete. In this case, the material is also placed on a special working platform of the machine, positioned and then cut with diamond blades. The only problem is finding suitable consumables. The size range of the clamp is also limited. from 7 to 23 cm, which greatly narrows the scope of the machine. There are also pluses: these saws easily cut material at an angle to within a degree.

Using any of these tools, you can get a clean and even cut on the tile exactly according to the specified mowing line. Depending on the volume and complexity of the work, the type of processing is selected. For example, an angle grinder is good at cutting small batches of material. The guillotine will help you cope with inline cutting. The saw works well where you need to cut at an angle, ensures the accuracy and clarity of the resulting edge.

Features:

Paving slabs are positioned as a completely ready-to-install material. But in practice, it often turns out that its dimensions do not correspond to the parameters of the paving site. In this case, the simplest solution is to cut the paving slabs to the specified parameters right during installation. True, this process has its own characteristics.

The process of cutting paving slabs is to remove excess length or width of the product. At the same time, the decorative paving stones themselves:

- Has dimensions from 20 to 80 mm in thickness;

- Consists of solid and dense artificial stone;

- May have a curly shape, relief;

- Difficult to work with conventional methods.

When using tiles with complex geometry, cuts are made not only in a straight line, but also along a diagonal or a more complex path. This requires precision and accuracy, any careless movement will lead to the formation of an uneven cut. The presence of crushed granite in the tile does not make the task at all easier.

Recommendations

It is necessary to carry out work on cutting and grinding the edges of the tiles only in overalls, using a full set of personal protective equipment: from a respirator to glasses. In addition, you should take care of the absence of strangers or pets nearby. Reasonable precautions should also be taken when using the tool.

- Protect your hearing with ear plugs or noise-canceling construction headphones.

- Control the rotation of parts and mechanisms. Replaceable components must be replaced based on recommended wear.

- Keep fingers away from power tools, machine tools in the area of their cutting element.

- Use shoes with rubber soles to avoid accidental electric shock.

- Hold the angle grinder strictly with both hands using the side handle. Install a protective shield, if available.

It is important to organize the cutting correctly. It is necessary to allocate a special place for this, away from the rest of the stocks of material. When cutting, concrete dust is generated, which can damage the already laid floor or stored elements. It’s good if you manage to equip a separate workbench with a vice and everything you need.

Upon completion of the work on cutting the paving slabs, the master receives a blank with an edge that needs additional processing. It doesn’t matter if you sawed or chipped off the edges, fine-tuning is still required. Noticeable defects are eliminated by chipping off problem areas with a chisel, filing them with a hacksaw with a blade for metal.

For information on how to cut paving slabs, see the following.

Cutting tiles with a glass cutter

The second way to cut the tiles into pieces is with a roller glass cutter.

The very name of the tool contains the material with which this unit is adapted to work. When working with glass, it is convenient, although there are more modern substitutes for it. In fact, it is not intended for cutting, but only for applying a scratch to the surface in order to further gently break the material, like a bar of chocolate. This is why only a small amount of ceramic tiles can be cut with this tool. In this case, the material should have a small thickness and not have a relief on the plane.

When working with this tool, the most difficult thing is strictly once to draw it along the markings, drawing with the same pressure a groove of the required depth so that the tile does not break in the wrong place.

If you want to break the ceramics in a straight line, this is relatively easy to do, but if you want to break along a curved mowing line, then difficulties arise.

A wooden block is placed under the groove and pressed on the material from both sides, trying not to cut yourself on the uneven edge. This is how the tile breaks along the mowing line drawn with a glass cutter.

How to cut a tile with a glass cutter

The most affordable, albeit difficult, method for small volumes of work on cutting tiles, especially since almost every owner has this device and there is no need to run to buy it.

If it is still not at hand, and the choice fell on this cutting method, then buy an oil one. The fact is that in these models, kerosene or machine oil is fed from the handle to the cutting roller, and this will simplify cutting.

How to properly cut ceramic tiles with your own hands with a glass cutter? The process is quite simple, but it still requires certain skills:

- We lay the material on a smooth surface

- We make markings with a marker or felt-tip pen

- We attach a ruler to the markup (preferably metal)

- With effort we draw a glass cutter along the mark from edge to edge several times in a row

- We put a match under the plate from below, you can use a carnation or align the cutting line with the edge of the table

- Pressing “breaks” the tile

- If you did everything right, it will easily break along the cut

The cut edge will turn out to be rough, so polish it gently with a special file or emery stone.

Please note that this cutting method can only be used if the tile thickness is not more than 5 mm. It is usually wall-mounted glass or ceramic. You cannot cut the floor in this way, it is thicker and stronger, so the tool will need more powerful.

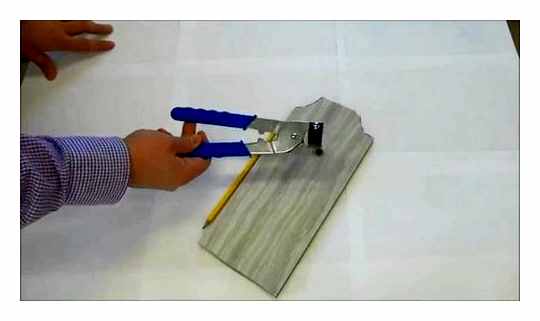

Tile cutter tongs

This is a small budget option for cutting tiles. There is a cutting wheel on one side and a transverse plate on the other. With its help, it is quite easy to cut ceramics. This will require a straight edge ruler on one side.

Tile cutter is used for light cutting

- The desired distance is marked on one side of the tile on the front side.

- Along the mowing line marking from the far edge of the tile towards you, an incision is made once with medium pressure. The result is a visible streak.

- The transverse plate of the forceps must be placed on top of the front side so that the line of the fracture runs strictly in the center of the plate.

- At the last stage, with a smooth compression of the tongs, the tile breaks along an even mowing line.

- In the case of cutting thick tiles, it is also recommended to make a small groove on the inside with a depth of 2-3 mm.

In the process of laying tiles, they are faced with the need to cut through the tiles, make curly cutouts in order to bypass the bulges and pipes. Curly cutting is also possible with a glass cutter, however, in this case, you will additionally need special nippers and sandpaper.

How to cut tile. expert advice

Ceramic tiles are a material for cladding kitchens, toilets and bathrooms. It is durable, easy to care for and aesthetically pleasing. To fit the material to the existing wall dimensions, cutting the tiles with a jigsaw, tile cutter, angle grinder or other tools is required, and this is one of the disadvantages of the material. The advantages of cladding overlap this moment, and builders still use ceramics in most cases.

Glass cutter and stationery knife

The main thing when cutting with these tools is accuracy and precision of movements. You need to act calmly and consistently:

This option is more suitable for cutting thick tiles.

- Use a flat surface of the floor, table or stool;

- Put the tiles on it with the front side up, make the necessary marks and draw the line with a ruler and pencil;

- Attach a ruler to the mowing line until it is completely aligned;

- Make a clear cut along the ruler, pressing firmly on the glass cutter;

- Tap along the notch;

- You can put a drill under the line of the notch and, gently pressing on the edges, break the tile. If you place the tiles along the cut groove on the edge of the countertop and gently press down, you will also get a good result;

- If the tile is cut well, it will break exactly along the mowing line.

You need to cut with a clerical knife using a similar technology. The only difference is that the cuts must be made several times on the same mowing line in order to deepen the furrow.

It should be noted that these methods are not suitable for cutting thick tiles. In such cases, it is necessary to duplicate the facial incision using a groove on the inside.

Working with a glass cutter

This simple tool is in almost every home, and many also have experience with it. over, the algorithm of actions when cutting ceramics is no different from cutting glass.

On the material previously soaked in water, mark the place of the future cut with a pencil or marker. On an absolutely flat surface, lay the tiles with the glossy side up, along the ruler set according to the marks, pressing hard enough on the glass cutter, make a deep cut.

Cutting tiles with a glass cutter requires the least material costs and skills

Note that the furrow should be done in one run. The next step is to tap on both sides of the tile with the handle of the glass cutter along the cut, and then, putting the tile on the edge of the table, press with your hand, while the tile is divided into parts along the made groove. If the required part does not break off quite evenly, the protruding edges can be trimmed with pliers or wire cutters, and then the cut line can be finished with sandpaper.

Tile cutter tongs

This is a small budget option for cutting tiles. There is a cutting wheel on one side and a transverse plate on the other. With its help, it is quite easy to cut ceramics. This will require a straight edge ruler on one side.

Tile cutter is used for light cutting

- The desired distance is marked on one side of the tile on the front side.

- Along the mowing line marking from the far edge of the tile towards you, an incision is made once with medium pressure. The result is a visible streak.

- The transverse plate of the forceps must be placed on top of the front side so that the line of the fracture runs strictly in the center of the plate.

- At the last stage, with a smooth compression of the tongs, the tile breaks along an even mowing line.

- In the case of cutting thick tiles, it is also recommended to make a small groove on the inside with a depth of 2-3 mm.

In the process of laying tiles, they are faced with the need to cut through the tiles, make curly cutouts in order to bypass the bulges and pipes. Curly cutting is also possible with a glass cutter, however, in this case, you will additionally need special nippers and sandpaper.

- You can solve this problem at home with a drill using special nozzles. The attachments can be as follows:

- “Ballerina”, working like a compass;

- Tubular drill;

- “crown”;

- Conventional drill.

Tiles are easy to cut with wet cutting attachments

It is better to drill the floor tiles with a universal drill with a victorious finish. In this case, before drilling, it is necessary to prepare the point of application of force, destroying the enamel. The drill must be periodically moistened with water.

The best way to cut floor tiles is using the electric version of the diamond wire jigsaw. To do this, after laying, fix the tile on a flat surface of a chair or table. In this case, the area with the drawn line on the front side should be suspended. By running the tool along the mowing line, you can get an even cut line without chips.

Large quantities of ceramic tiles can be cut with an “angle grinder” using a diamond disc. When carrying out these works at home, special attention should be paid to safety issues. The person working with this tool must have the necessary skills and follow clear rules. For example, tiles are cut strictly towards you. In this case, the tile must be rigidly fixed. The airway must be protected from dust with a mask.

Before learning how to properly cut an angle grinder, prepare the tool appropriately.

In general, the use of an “angle grinder” at home has several disadvantages. First of all. the abundance of dust and noise. In addition, working with this tool is potentially hazardous and requires sufficient skill.

Depending on the availability of certain tools, you can choose the best repair option at home and, after training on illiquid material, get to work.

What tools are required

Cutting tiles at home during renovation requires little work.

Therefore, you do not need to purchase a professional tool.

You can use a cheaper cutting method, for example, using:

- Angle Grinder

- Nipper

- Glass cutter

- Mechanical tile cutter

For cladding a bathroom or kitchen with ceramics, one of the listed tools will be enough. In addition to them, you need to prepare for the convenience of the process:

- For markings: marker, pencil or felt-tip pen

- Measuring tape

- Elbow, preferably metal

- Goggles and respirator for cutting angle grinder. headphones

Working on the floor with tiles (squatting) is very inconvenient. Therefore, prepare a table with a straight and smooth plane. How to properly cut ceramic tiles with your own hands at home? Let’s consider several ways in more detail.

How to cut tiles with wire cutters

Working with nippers

Nippers are indispensable if you don’t know how to cut floor tiles around pipes or other small irregular objects. This process is slow, because if you hurry, you can make a mistake, and the chip will turn out not in the place of the marking.

In order to start nibbling the tile, mark the smooth side with a marker or pencil. Use the tool to break off small pieces when placing the cutter on the line. At the same time, a lot of dirt does not form, there is no dust at all, but this is not the main way to separate particles from tiles.

In order for the break to be as accurate as possible and correspond perfectly to the marking, cutters with carbide clamps should be chosen.

Work should start from the edge, gradually moving towards the middle of the object.

The advantage of cutting pliers lies in their low cost, ease of use and the ability to cut not only at right angles. In parallel, of course, there are many worries with the processing of an uneven edge: sandpaper or special grinding tools will come to the rescue.