How to cut a doorway in a gas concrete wall.

Strengthening the doorway from foam block. All about jumper for walls from foam blocks

The installation of door and window jumpers of foam concrete is in the construction process, as it may seem at first glance, secondary importance. Perhaps this is due to their invisibility in the overall construction of the building. over, many of those who have never worked at a construction site do not even think about their presence in the wall.

Nevertheless, this element of the building frame is just as important as all other structural parts of the house. Indeed, without the presence of special foam blocks installed over the openings of doors and windows and holding the pressure of the wall, deformation and even serious destruction are possible in such places.

Therefore, to ensure the safety of the building and guarantees of its long.term operation, it is necessary to know the types of indicated jumpers, the main parameters of their structure and installation.

We make the right doorway in the wall of foam block correctly

Foam block material is one of the most popular in the construction of low.rise structures. The block successfully combined the acceptable cost, excellent heat.insulating qualities, a high strength indicator. For this reason, it is used not only for the construction of partitions, but also of the bearing walls. For obvious reasons, sooner or later the question arises. how to make a doorway in a wall of penlogs.

What is the material

The main difference is that in the process of construction work there is no need to spend additionally on thermal insulation, the costs associated with the heating premises are reduced by three times.

The material does not create a large load on the foundation base, it is easy to work with it. A comfortable microclimate is supported inside the room.

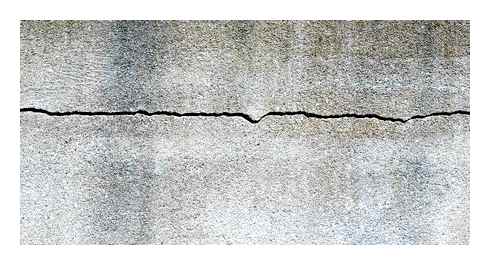

There is only one drawback. fragility. Houses from foamed material are necessarily reinforced with several levels.

How to make a partition from foam blocks. step.by.step instructions and accurate marking zones (90 photos)

For the construction of the partition, you can consider several options. A good choice will be either a plasterboard structure or a design of foam blocks. The recommended option is precisely foam blocks. It’s easier to work with them, they will cost inexpensively. And most importantly. during operation there are no problems such as during the operation of a drywall septum, when it becomes extremely problematic to hang on the wall even a relatively light shelf. Prepare the sled in the summer, and the cart in the winter. says the old saying. But sometimes construction work has to be carried out not only in the summer, in the fall, and even in winter. To do this, you need to take care of high.quality, winter overalls.

How to lay foam block

According to a pre.created scheme, the frame of the partition on the floor is outlined, and then with the help of a plumb line the boundaries are transferred to the ceiling. Using a coloring thread or level, a fishing line for a trimmer of borders is beaten off on the floor and ceiling. On the adjacent walls in the same way, a frame of the future design is applied. These frames are needed to build even interior partitions from foam blocks. You can still fix metal profiles on the walls for the installation of drywall partitions.

And in order to control the evenness of foam concrete walls along their entire plane, they pull the fishing line for the trimmer between the installed pendulums. This will subsequently save time and effort during plastering and spacing work.

Before the first masonry, the floor is sweeping and cleaned of dirt, dust and applied a primer of deep penetration. If the base is wooden, pins are driven into it to give the fortress the future wall, only then to the solution. If the floor is concrete, then you can put foam blocks immediately on the solution.

The following rows can also be laid on the solution, or you can use adhesive mixtures and gypsum plaster. For these purposes, glue for tiles may also be suitable. However, its consumption at 2 mm layer thickness will be approximately 15 kg/m³.

The joints in the ranks need to be done in a checkerboard pattern to make a partition from foam blocks stronger and stronger. For this, 1 row begins with a whole block, and the next from half. Since this material is easy to process, this will not be difficult.

Manually creating the 1st door opening in the concrete wall 💪💪💪

For greater strength, a reinforcing grid is laid through each 3-4 row. Also, iron pins are inserted into the supporting walls so that they later enter the masonry.

When the installation of the partition from the foam blocks is completed, all the holes, cracks, cracks are put off puttying. After that, the surface is primed. They begin to plaster only after the mixture and putty drying out.

How to cut it in aerated concrete?

The technology of the device of door and window openings is different and has several nuances.

For the door

To make a passage in the existing masonry use 2 methods:

- Shock. The use of a jack of a hammer will be required. This method is preferable when it is known where all communications and networks pass. If this factor is unknown, then it is better to refuse this method. In addition, before working with a junk hammer, it is necessary to correctly calculate the increase in the load on the opening, which will be instead of a solid wall. To do this, you need to invite a specialist.

- Unstressed. Implies the use of corner grinding disk. First, make notches in the wall, make markings. After that, neatly with a corner grinding with a diamond disk, strips of low depth from both sides are carried out.Then, using a hacksaw, finish the hole of the desired length. Stones are knocked out or carefully selected. First install an anchor with an increase so that the masonry does not collapse.

As soon as the opening is completely made, it is strengthened with a jumper. An unstressed way involves the use of corner grinding disk. First, make notches in the wall, make markings.

After that, neatly with a corner grinding with a diamond disk, strips of low depth from both sides are carried out. Then, using a hacksaw, finish the hole of the desired length. Stones are knocked out or carefully selected. First install an anchor with an increase so that the masonry does not collapse. As soon as the opening is completely made, it is strengthened with a jumper.

If the opening is done at the stage of the construction of the walls, then the matter will go easier. It is enough to correctly calculate the dimensions of the aisle and put the gas block according to the plan. In this case, it is much easier to equip a jumper, since it is not required to break through a hole in the wall in advance.

For the window

Window holes in the wall are easier, but here it will also require the manufacture of a jumper. It acts not only in the role of an amplifier, but also as a support for laying a gas block above the opening.

First, side areas are erected, then the formwork is made using U-shaped blocks. Pour concrete and continue masonry. It is very important to adhere to the permissible window width sizes.

Read more about the device of the window opening in the article on the link.

How to lay a doorway: ideas and methods

During the repair process, it may be necessary to redevelop the dwelling and in this case it is necessary to determine what is better to close the doorway instead of the door. For this purpose, materials of various types and properties can be used. In this case, you can completely eliminate the opening and equalize it with the wall or make a decorative design.

The need for work

First you need to determine for what purpose it is necessary to close the doorway, this largely depends on the list of works and the choice of materials that will be used instead of the door. There are several options:

- redevelopment. involves the complete elimination of the opening, the entrance will be equipped in another place, and this section will become a simple wall;

- The niche device is an alternative to the previous option, in this case you can equip a convenient place for storing things;

- Decorative replacement of the door. the opening is essentially untouched, but instead of the door, other devices will be closed, leaving the passage free.

If you want to avoid wall deformation, use materials similar to those of which the primary design is erected.

Brick

The most radical measure is a complete deliverance from the opening, in this case you need to decide what is best to lay the doorway. For such a goal, in most cases, brickwork will be the best option. You can also use foam blocks if the walls are quite thick. This masonry option is best suited for supporting structures.

To close the opening with brick, it is recommended to use a cement solution prepared from cement, sand and water, if necessary, you can strengthen the composition with modifying additives. For foam blocks it is better to use special glue.

For bearing walls, the best solution will be brickwork

How to lay a doorway with ordinary brick:

- Prepare the base. To do this, remove the flooring to the level of concrete.

- Start laying brick on a sand-cement mortar. Make the rows with a shift in half a brick.

- To fix the new and old masonry, use large nails. On one side, the nail is clogged into the end of the opening, the other part of it is hidden in the seams.

- Advance from the bottom up, applying the solution by a not too thick layer. Tam the rows with the back of the outfit. Be sure to check the level and smear the sidewalls.

Drywall

There is nothing easier than closing the doorway with drywall sheets. This method is great for embarrassing walls in a straight line and for the construction of niches. Working with him is much more convenient, in addition, this will require much less funds.

Installation of a partition with drywall is carried out by fixing it on the frame. As materials for it, you can use special metal profiles or durable wooden beams. It is much more convenient to work with the first view, since you can build a design of any shape.

Drywall is attached with self.tapping screws on a frame made of metal profile

How to close the doorway using drywall:

- Using self.tapping screws and drills, fix the metal frame along the perimeter of the opening.

- Cut the profile into transverse strips. They are installed in steps from 20 to 40 cm to strengthen the wall structure with drywall in the opening.

- Measure the size for drywall sheet and cut out suitable fragments.

- Fix them using self.tapping screws to profiles.

- If you decide to make a niche in the opening, the frame is first built in its shape, and then closed with drywall sheets.

- All joints between drywall are glued using a Serpyanka grid.

- After that, you need to put the joints and completely leve the surface.

Decorative solutions

The capital elimination of the doorway is not always required, it can be closed with something else. The most popular solutions are:

Decorative options for closing the doorway

Decorative curtains are interconnected small fragments: bamboo, vine, beads, threads that form a partition to close the doorway. A variety of available options allows you to choose exactly what will perfectly fit into your interior.

The second way to close the opening is the use of fabric. This is a kind of imitation of window curtains. As a material, you can use both translucent tulle, spider webs, and dense curtains. To hang them in the opening use the cornice. You can simply hang a piece of fabric or create a complex composition of several elements different in color and texture.

For a classic interior, an excellent solution is to add lambrequins, however, they can be used in modern rooms if you create an unusual hard lambrequin.

Less popular, but one of the most convenient is the option using blinds. They allow you to completely block the passage into the room if necessary. There are two types of blinds:

Preparatory work

Before laying the doorway, it should be prepared properly:

- Remove the old door and dismantle its details: a door box, threshold and sealing material;

- If the door stood in the opening of a brick or concrete wall on wooden embedded details, then they should be knocked out;

- remove the layer of the old solution from the ends of the partition, where the masonry will subsequently adjoin;

- remove the flooring and part of the screed to the floor slab;

- remove garbage and dust.

The doorway laying should be made on a strong base. the foundation or floor slab. If the screed under the door is made recently and efficiently, then it is allowed to put the partition directly on it, in other cases this layer of solution must be dismantled. Before carrying out masonry work, a new waterproofing layer from roofing material from roofing grounds should be laid from the tape foundation.

When preparing window openings for sealing, the same operations are performed, only instead of the threshold you need to remove the windowsill. During dismantling, pieces of exfoliating plaster are also better to remove. Remove all wooden details from the wall and remove garbage.

For masonry, it is recommended to use the same brick from which the construction structure is folded. The former is also suitable for the material, provided that it does not consist of continuous halves and does not crumble in the hands. If the structures of the house are concrete or slag block, then both white silicate and red ceramic brick will fit. For holes in the walls of foam blocks and aerated concrete, brickwork is not suitable, they are closed with appropriate material.

Entrance door

The old English proverb says: “My house is my fortress”. So that “the fortress does not fall on the mercy of the winner” in the absence of the owner, you need the correct installation of the door in the gas concrete wall.

Aerated concrete popular due to effectiveness has a significant drawback. small strength. You can install the door in the opening of the blocks, but the fragility of the material will lead to a gradual loosening of a heavy metal door. Cases are not rare when poorly fixed doors fall out of the opening with the door box. There are several ways to reliable door fixing:

- Building strengthening of a embedded part (performed simultaneously with wall laying).

- Enhancement of wood.

- Strengthening the metal structure.

The width and height of the doorways are determined at the stage of wall construction. You can’t do without cutting aerated concrete blocks in size using a special power tool or a regular use of aerated concrete.

Strengthening the opening opening

The first method of fastening is reliable. It is provided for by the design documentation at home.

Simultaneously with the laying of the walls of the doorway in a gas concrete wall, a embedded part of a metal corner with a cross section of at least 100x75x8 mm with a 600-900 mm musted with corrugated reinforcement with a diameter of 8-10 mm is strengthened. The mustache is laid in the seam masonry.

On each side of the opening are installed, their number depends on the height of the door. At a height of 2.1 m horsemen three.

In the upper section, the mustache is laid in the seams between the elements of the jumper.

Squeezed of work:

- Make the required number of embedded with a weld mustache;

- Perform anti.corrosion protection of mortgages;

- Install mortgages in the process of maintenance of walls;

- Set the box in the level of vertical and horizontal;

- Fix the box to the embedded anchors;

- Fill the seams with mounting foam;

- On the facade side, protect the mounting foam from ultraviolet radiation with plastering solution.

Strengthening the opening of wood

Unfortunately, not all creators of projects, especially typical ones, are concerned about the protection of housing from unauthorized penetration. In the event that the walls are erected, and the framing of the opening of the front door is not with metal, the intensification of the opening in the second way. the overhead design made of wood.

In this case, a P-shaped strapping from the boards to the wall thickness is attached around the perimeter of the opening. The outer and internal strapping is made of a beam with a cross section of at least 40×60 mm or boards 40×100 mm. Binds between themselves are connected with a thickness of 20-40 mm with self-tapping screws. Wooden frame is attached into slopes with anchors. So that the framing does not protrude from the plane of the wall, along the perimeter of the opening from the side of the facade, you can cut the stroke in size of the beam. The door box in the opening is attached with anchors.

Squeezed of work:

- Prepare the wall with a strengthening primer or net;

- According to the size of the opening, prepare two sets of timber. two in height, one in width;

- To fasten the P-shaped structures with anchors and install in the opening from the external and inside;

- Frame the slope, fastening the structure with self.tapping screws or anchors (dowel. screws);

- Fix the frame in the slopes of the dowel. screws;

- Insert the box into the opening and attach with anchors;

- Carry out joints in the first way.

Strengthening the opening of a metal frame

The third method constructively repeats the previous one, but is made of metal.

In terms of the size of the doorway, the corners are cut by a profile of at least 100x75x8: two in height of the opening, one in width. two sets: facade and internal.

The corners are connected by welding into the frame, the outer and inner facets of the wall are framed by the frames.

Then the frames are connected to each other with overlays made of metal plates with a width of 50, 3-4 mm thick. The length of the plate depends on the thickness of the wall, after 500-600 mm. There should be at least three in the height of the plates doors. Instead of plates, corners can be attached with reinforcement with a diameter of 6 mm.

The slopes after the binding are placed. Then the door is installed. The box is attached to the metal corners of the framing.

Squeezed of work:

- Prepare the wall for work (strengthening masonry with a primer or net);

- Cook metal for framing: two sets of corners. two in height of the opening, one in width, connecting plates (the number depends on the size of the opening, but not less than three on the sides, two at the top);

- Boil the corners in the P-shaped frames, clean the seams;

- All metal elements are primed and painted;

- Install frames in the opening, fasten with plates on welding;

- Fasten the frames in the slopes of anchors (dowel. screws) by overlays;

- Plaster slopes;

- Fix the box with anchors to the plates;

- Perform joints.

- Blocks of cellular concrete. fragile material, for attaching structures you can not use a percussion tool. All anchors are screwed (dowel. screws);

- Before the work, it is recommended to primer slopes and the edges of the doorway with a soil to strengthen or stick a construction grid to give additional strength;

- If an aerated concrete is installed in a second or third way in a wall with insulation, an additional thickness of the insulation should be taken into account;

- To exclude the formation of “cold bridges” (freezing of metal, ice and condensate) take measures for thermal protection of the box. If the box of the selected door does not have insulation, fill it with mounting foam or liners from any insulation. foam pool, mineral or basalt cotton wool.

- Metal elements (corners, plates or reinforcement) in contact with masonry to protect from corrosion with special soil or metal paint.

After the box is mounted, smear all the seams. It is best to use a sealant. The cracks also need to be removed, the mounting foam is perfect for this. When it froze, remove the excess, carefully cutting off the remaining foam with a knife, and apply mastic to the site of the slices.

Installation rules

Foam block material is soft and porosity, and the metal door is installed in it in several ways:

- use fastening with anchors, which is great for narrow openings;

- use chemical anchors according to aerated concrete;

- cook the frame base made of metal;

- arrange a strainer of wood;

- Additionally laid out a wall of brick material.

Many are interested in how to fix the door frame in the opening of foam blocks to a wooden stranger?

When inserting the door into the wall of aerated concrete, it must be taken into account that it stands on a foundation basis, as a more reliable element.

The massive door creates significant loads, from which fasteners are shaken over time. To prevent such deformation manifestations, experts recommend installing the box so that the load efforts are distributed for the larger area. To do this, use a wooden frame with a embedded beam. Wood is first treated with an antiseptic composition.

It is recommended to use larch as more resistant to moisture.

If a small door is planned for the installation, then the embedded beams are buried in aerated concrete, or in the openings are placed on the overhead panels corresponding to the thickness of the wall. Such panels can be solid or installed by individual elements. Upon completion of the installation, the free space between the wall and the door frame must be disconnected. This will make it possible to fix the frame harder.

A frame of wood material is made under a large door, the installation of the strapping is more firmly performed. An anchor is installed after sixty centimeters, to a depth. at least fifteen.

To strengthen the openings, the frames are cooked from a metal corner or profile thick.walled pipes. They are allowed from floor to ceiling, the ceilings are fixed with anchors. The pipes are allowed to drown in foam blocks, but for this you will have to cook the strobes. After that, holes are drilled in the frame to fix it to aerated concrete.

Maximum reliability of fixation is given by metal embedded, installed during the construction of the wall. Represent such elements of the plate with welded reinforcing bars that are frozen in the walls during the masonry work. The frame is fixed using a welding machine or bolt compounds.

How to move an opening in a wall of aerated concrete blocks?

I want to move the doorway into the bathroom half a meter in a wall of aerated concrete blocks 100 mm thick. There is already a screed on the floor (from the developer). How best to do it? For example, is it possible to simply lay the current opening and cut a new opening nearby? If so, is it possible to put the blocks on the screed and whether it is necessary to tie them to the pie between the openings? Is the approval in the relevant authorities required for such a shift?

Coordination is desirable, but if the apartment is not for sale, then you can ignore. You can move the opening. There is a jumper over the doorway now?

You can put the wall on the screed calmly. Fix it to the existing one. be sure to. After the construction of the wall, make a horizontal groove for the entire length of the opening of 150. 200 mm for the factory of the ends of the jumper. After that, start a jumper, and only then choose the opening itself.

There are several more subtleties, I will write later.

At some point she will interfere. So that during the operation the upper blocks do not move away from the ceiling, come up with some temporary supports with a support on the floor. But so that they themselves do not prevent them from starting a jumper to a new place.

Pool. It is more convenient for corners. We neatly insert one corner-65 into a prepared place, on the one hand 300 mm entering the wall, on the other hand, weld to the existing jumper. Put a support under the corner from the floor. Then we cut off the extra blocks. On the other side of the wall, put the second corner-65, and weld both corners with transverse stripes. In principle, this is a classic for strengthening the openings.

I deliberately did not write about this so that the customer would not be much tied to the written. Because there are other options.

Pool wrote: the upper blocks did not move away from the ceiling

And how can they move ? the mechanism of “sliding” of light blocks fixed with the masonry solution how this can happen ? There were precedents ?

FHNTV. It happens that in stupidity the upper seam is completely filled with a hard mixture. There is a plot of a slab-block. If you do not insure yourself with a support/corner, a crack may go.

To move away is to go down, breaking away from the ceiling.

the mechanism of “sliding” of light blocks fixed with the masonry solution

There is no sliding. There is just lowering under your own weight. The pantry does not save.

How it can happen ? There were precedents ?

The not.ended fragment strives under its own weight down, looking up from the ceiling. There were not only precedents. they are all right.

I agree, the program is maximum with the careless stroke of fragments. a crack

Pool wrote: to go down, looking up from the ceiling.

Try to simulate this situation on the domino on the table. In order for the block to go down 0 He needs to either slip along the neighboring ones that is completely unrealistic, or so that his neighboring blocks describing the semicircle go sideways. down which is excluded by masonry conditions

Pool wrote: just lowering under its own weight

This phenomenon in the fastened masonry is not observed. only in a liquid fresh

Pool wrote: The fragment strives under its own weight down, looking up from the ceiling

He is not so attached to the ceiling, so let him “come off” again to go down the stone. he needs to either slip or break down by choosing a gap (where we have a gap in the masonry?) neighboring stones and both. science fiction

- You can put the blocks on the screed.

- you need to tie the pieces between the openings.

- First gently cut part of the wall, to the rudder. If the jumper does not give signs of life, then the jumper can be left, she will be like a console beam pinched on one side. Then lay the opening from the other side. Everything.

How to UN-Professionally Cut a Doorway in a Block Wall

I looked at the clips masonry rollers and, if I understood correctly, you need to tie the first and third row, for example, using soft suspensions. But whether it is necessary to glue the blocks to the pie between the openings? Another question, the screed must be primed for the first row?

Zakharka wrote: I looked at the clips masonry rollers and, if I understood correctly, you need to tie the first and third row, for example, using soft suspensions. But whether it is necessary to glue the blocks to the pie between the openings? Another question, the screed must be primed for the first row?

Zakharka, it is necessary to glue the blocks to the pie. If you glue it well, then the mechanical fastening is not needed by corners. Mechanical fastening is just additional insurance. A statement about every third row is a fake. You can even in every row. Or once in the middle of the wall. There are no clear instructions about this. As Larry Hong says, “specify the number of clogged nails in your regional rules.” It is not necessary to primer the screed, but it is better than not, than not.

How to make an expansion of a door and window opening in a concrete wall with your own hands, the price of specialist services

Installation of doors and windows is far from always passing smoothly.

Sometimes, even with properly made measurements, the structure does not fall into place. To solve this problem, it is necessary to increase the area of the opening.

Why you need to expand?

The functionality of the room depends on the size of the door and window openings. Therefore, the main reason for increasing their size is the convenience of using living space. Other grounds to change the area of the opening include:

- Redevelopment. Sometimes an increase or decrease in the width and height of the opening is the only way to realize the plans, for example, combine rooms, or distinguish between them.

- Improving the general perception of the interior. Wide windows and doors look solid, attract attention, allow me to mount non.standard structures.

- Lack of the ability to install the purchased door or window. Most often this is due to errors in the performance of measurements.

Changing the sizes of door and window openings in the concrete wall by more than 10 cm is considered by law as redevelopment and requires coordination with the corresponding authorities.

When this cannot be done?

We can meet the opinion that it is impossible to expand the openings in the bearing walls. In fact, it’s not the case.

Legislation does not prohibit increasing their size, but not always and not in every place. It depends on the features of a particular house.

Thoughtless demolition and expansion of structures can lead to the redistribution of the load and collapse of the construction.

So, the opening in the bearing concrete wall can be increased by no more than 10 cm (5 cm on each side). In the partitions, this indicator can be larger, but the upcoming changes must be agreed upon. Professional organizations with permission and license should be performed.

In the process of work, engineering networks and communications should not be affected. In a private house, the regulatory authorities cannot prohibit the doorway. However, this does not mean that work can be carried out without taking into account the features of the structure. Like any other house, a private building is also subject to destruction.

Experts do not recommend expanding the doorway more than 100 cm 2. If you exceed these dimensions, you will have to install additional supports.

Methods and tools for work

To expand the door or window opening in the wall, the following tools will be required:

- A hammer and a chisel.

- Hand saw.

- Plane.

- Peorator, electric screwdriver, corner grinder and drill.

- Screwdrivers of different shapes and diameter, pliers.

It is possible that some tools in work will not be useful. It all depends on the volume of upcoming work and the features of their implementation.

You can solve the task in three ways:

- Rough method. Its implementation will require a sledgehammer, a peorator, a jack of a hammer, etc. Before starting work, markings are necessarily performed, to go beyond which it is impossible. The main disadvantage of this method is the risk of microcracks on the background of the application of rude force. In addition, to achieve the goal, considerable physical efforts will have to be made.

- Dry cutting method. For its implementation, a corner grinder is used. With the help of this tool, it will be possible to give the opening the desired circuit, cut off the reinforcement, which is often found in the walls and significantly complicates the work. The disadvantages of this method include excess dust formation and rapid grinding of a diamond disk.

- Wet cutting method. It is realized in two ways. The first. using a special construction cutter. The tool is equipped with a large diamond disk and water capacity. It has professional builders in stock. The second is using corner grinding and spray gun, which irrigates the processed surface. This method is good in that it allows you to perform work with the minimum dust formation.

Regardless of the chosen method of expanding the opening, you need to take care of personal protection tools. You can start work only in construction glasses and a mask.

How to expand with your own hands?

Depending on the type of wall, methods of expanding door and window openings will differ. Special attention is required by monolith. Interference in the supporting structure without using a special tool can be dangerous.

Monolithic wall

The expansion of the opening in a monolithic wall should be carried out after approval with supervisory authorities (city housing inspectorate). Work can only be carried out using a cutting tool. It is forbidden to use chips and peorators. Also you can’t knock out the circuit of the opening with a sledgehammer or drill it out.

Cutting is performed by diamond disks. This allows you to completely exclude the shock effect on the wall. The edges themselves will turn out even, will not lose the desired strength. A prerequisite is to strengthen the opening with metal frames or a jumper from the channel.

- Make markings that will navigate in size.

- Moisten the wall to reduce dust formation.

- With the help of a diamond cutting, remove the walls of the wall. Cut off in small areas. Elements cut out. square or rectangle.

- After completion of work, the expanded opening is strengthened in the chosen way. Therefore, you need not to forget to cut part of the wall designed for supporting corners. Metal frame-cancellation is diluted with plates, anchor and plastered. This approach will increase the opening to the required width and prevent the collapse of the wall.

If the expansion of the doorway is significant, it is necessary to establish a temporary amplification. To do this, use wooden racks or racks of formwork.

Concrete panels

To expand the doorway in a panel house, you can use the peorator. First, indicate the area of the wall that needs to be removed, after which the concrete is systematically knocked down.

Creating the opening

During the construction of structures from a gas block, it becomes necessary to create window and doorways.

Not a single house is complete without these elements, but working with a gas block requires attentiveness and accounting for the characteristics of the material in the construction of passages.

Do not forget about the strengthening of such elements and their correct location in relation to the floor slabs.

What it is?

An opening in a wall of aerated concrete blocks. this is a hole in the masonry made of stone for access to another room. Openings are window and door. Window openings are organized in the middle of the wall, with approximately the same distance from the ceiling and floor.

Window elements are necessarily reinforced with jumpers, since the floor slab will affect the design. The openings for the window can be laid out at the initial stage during the laying of the gas block on the walls, as well as cut down in the finished wall, if the redevelopment suddenly thinks.

Most often, the holes for the windows are made on the supporting walls, to ensure additional natural light in the house.

Doors open openings can be performed both on supporting, on the internal walls and partitions. A passage on a bearing wall is often the main entrance to the house or exit to the backyard. Passes of the partitions are made for further installation of interior doors.

Such holes also require increased passage to avoid excessive load. The door passage is made from the floor to the ceiling, sometimes from the floor and not reaching the ceiling of several tens of centimeters.

Requirements

Openings can be built in the load.bearing walls and partitions. For the construction of such holes in the wall, you must familiarize yourself with the requirements of documents on the design of a residential building.

To the window

According to SNiP, it is necessary to organize a jumper over the window opening.

To do this, use either ready-made reinforced concrete jumpers or a U-shaped gas concrete blocks. A reinforcing frame must be thought out to strengthen the hole.

Window openings are laid out of a gas block of a certain thickness, most often 400 mm.

The width of the wall varies depending on the number of storeys of the building and the width of the window opening.

For example, for a piece of 60 cm wide, the width of the window opening should be no more than 90 cm. With a piece of 90 cm, the window will be no more than 1.8 meters, and if the layers are 1.2-1.5 meters, then the window width will be from 0.9 to 2.1 meters, provided that the house is built in the 2nd floor.

If a block with a thickness of 500 mm is used for the construction of the openings, then the width of the openings and beds can be increased due to the strength of the stone.

In the walls-overgrown, you can not use amplifier jumpers if the distance between the upper mark of the opening and the top of the partition is larger or equal to 2/3 of the width of the opening.

To the door

The same requirements are made for doorways, the difference is that often the doors are installed with a width of 60 to 100 cm. If this is a partition, then you can do without a jumper, and if a carrier wall, then you need to strengthen it with a beam or formwork, in which concrete with reinforcement is flooded.

All these issues are resolved at the project planning stage. If the house is built, but the owners need to make a redevelopment, then they need to contact BTI. Then the owner calls a specialist who evaluates the risks for the overall design and determines whether it is possible to make an opening.

It is necessary to sign all the documentation before performing work and cut a hole in the wall. If this is done without paperwork, then in the future, when selling a house, problems of inconsistency with the technical plan may arise.

Asseting device in a gas concrete wall

There are 2 options for the device of jumpers in aerated concrete walls:

- Ready.made reinforced jumpers from a gas block. This option is more convenient to use, since it is not destroyed during operation, does not crack and belongs to high.strength structures of small weight.

- Prefabricated structures from U-shaped aerated concrete. This option is no less popular: the jumper is made at the construction site. To do this, take an aerated concrete of the U-shaped type, the reinforcement is placed inside it and poured with a solution, the formwork from the plywood sheet is pre-made.

Full information can be found here about jumpers for openings.

How to cut it in aerated concrete?

The technology of the device of door and window openings is different and has several nuances.

For the door

To make a passage in the existing masonry use 2 methods:

-

Shock. The use of a jack of a hammer will be required. This method is preferable when it is known where all communications and networks pass. If this factor is unknown, then it is better to refuse this method.

After that, neatly with a corner grinding with a diamond disk, strips of low depth from both sides are carried out.Then, using a hacksaw, finish the hole of the desired length. Stones are knocked out or carefully selected. First install an anchor with an increase so that the masonry does not collapse.

As soon as the opening is completely made, it is strengthened with a jumper. An unstressed way involves the use of corner grinding disk. First, make notches in the wall, make markings.

If the opening is done at the stage of the construction of the walls, then the matter will go easier. It is enough to correctly calculate the dimensions of the aisle and put the gas block according to the plan. In this case, it is much easier to equip a jumper, since it is not required to break through a hole in the wall in advance.

For the window

Window holes in the wall are easier, but here it will also require the manufacture of a jumper. It acts not only in the role of an amplifier, but also as a support for laying a gas block above the opening.

First, side areas are erected, then the formwork is made using U-shaped blocks. Pour concrete and continue masonry. It is very important to adhere to the permissible window width sizes.

How to make a doorway in a brick wall?

The actions performed when punching an opening in a brick wall differ from cutting a concrete panel. The masonry consists of rows with the dressing of the seams. The top of the door passage should coincide with the joint. You can not cut bricks along. Such actions will weaken the tub and cracks will go along the partition.

After applying the markup, they begin to increase the opening in the brick wall with the top of the upper jumper. A row of brick is chosen above the marked line. A jumper is gripped into the void with a length of the width of the aisle.

Further actions are aimed at cutting the opening in the brick wall with the selected tool. If the masonry is disassembled, it is wiser to pick out bricks with a mount. The seams are drilled with an electric drill. The uneven ledges of the ends of the door passage are equal to the corner grind.

How to make a doorway in a wooden wall?

To cut the doorway in a wooden house, you will need a chainsaw or an electric saw.

Additionally stored with bars with a cross section of 1010 cm. The length of the blanks is equal to the height of the room. Bars are needed to strengthen the wall. When cutting the door passage, a wooden partition can bend. In order to avoid deformation of the structure, the bars vertically put the walls on both sides near the slots of the future passage. The through holes are drilled in the racks and partition and pull the structure with long bolts.

To correctly make an opening for a home from logs, they are convinced of the presence of a whole element on top of the passage of. It will be a supporting jumper. Marking is applied so that 1/5 of the thickness of the whole log is additionally left from below and on top of the passage during the notch.

Sprinking glued beams with a chainsaw can result in stratification of the boards. In order to prevent the destruction of the material, they beat the bars with long nails next to the drinking place. At the end of the sawing, the passage is strengthened with a plunger, and temporary bars are removed.

To arrange a doorway in a frame house, the skin is first dismantled with an internal insulation. After cutting, a frame from the beam is installed around the perimeter of the passage. Thermal insulation along with the sheathing is returned to its place.

Strengthening the opening

After cutting the opening or expanding it, it is necessary to strengthen the walls with additional metal structure. There are such types of strengthening the openings:

- One.row. strengthening is performed using a channel. A P-shaped frame around the opening is performed. In such designs, different types of channels and methods of attachment to the wall can be used. Places where the channel does not adjoin the wall is filled with a solution.

- Corner. finishing the corners on both sides of the wall is carried out, the corners are fastened together with hairpins, metal plates. Such designs are most often used.

- Combined. a channel and corners are used to strengthen.

Coordination of openings in the bearing walls

The device or expansion of the opening should take place in accordance with all norms, with the permission of the relevant authorities. When a redevelopment decision is made, different shows are taken into account

- the floor on which the redevelopment is carried out (the higher the floor, the less the load on the wall);

- year of building a house;

- the width of the opening and its placement (joints of the plates, distance to the outer walls);

- The condition of the walls in the room.

The redevelopment can be carried out by organizations with permission to perform such work. Recently, people are increasingly making buildings redevelopment, expanding old openings in the walls, and equip new. Diamond cutting. leader of the dismantling robot. With the help of cutting elements, concrete more than 60 cm thick is cut. Hydrobrase cutting method is the most environmentally friendly and safe.Oxygen-cocked drilling is effective, but requires certain preparation and skills, there is a risk of burn.

Depending on the thickness of the walls, the desired result, everyone can choose the right cutting method. But it is important to remember that the changes in the supporting walls must be calculated and agreed in the appropriate authorities, the openings are strengthened.