How to cut a metal pipe correctly with a saber saw. Electrodynamic brake

Electric hacksaw purpose and use of the tool

The question for what is a saber’s saw for and whether it is needed at all in the household, is still discussed on the wide fields of the Internet. We will try to answer it by considering, first of all, that the saber’s saw can, or, as it is called differently, the electric heater.

It is more convenient for her than a hand hacksaw, trim the trees in the garden. it turns out faster. With a chainsaw, climbing trees is not very handy, a saber garden battery saw, for example, Bosch KEO weighing 1.5 kg, is much better for this. Can cut thick branches up to 8cm diameter. And

It is worth changing the canvas in the tool, and you can saw not only wood, but also metal, stone, plastic, ceramics, glass, foam blocks.

The multifunctionality of the tool in use is simply amazing, it is useful for professionals in many professions and specialties.

A special narrow structure of the case and a long, flexible canvas allow you to saw where the angular grinder or jigsaw does not squeeze, cut the pipe or reinforcement flush to the wall, floor or other surface. The saber saws without sparks and does not scatter dirt from heating pipes, cuts pipes immediately with insulation, even cement. It is indispensable when cutting bodies, acidified bolts in cars.

The master can cut any part by weight, round the sharp angle or make a curved neckline.

The saw perfectly established itself in the production of dismantling. it easily cut door boxes, windows, sewer and heating pipes. Specially selected files saw wooden boards stuffed with nails without problems.

At the same time, it is safer and more convenient to work with electronics than grinder, circular and chain saws: sparks do not form, less dust when cutting bricks and foam blocks.

Top 10 Ways to Cut Metal WITHOUT an Angle Grinder. A Comprehensive Beginners Guide

Characteristic of the electric saw or how to choose and what to pay attention to

When choosing an electric hacksaw for the home, it must be borne in mind that they are classified into three main types of purpose: household medium and professional. The first two options are suitable for the house, and if you have to operate the tool daily, it is better to immediately buy a powerful professional unit. When buying any type of saw, you need to consider the following parameters:

-

Weight. usually the weight of saber saws does not exceed 8 kg. The harder, the more difficult it is to work, so the faster the fatigue occurs. For home, cottages and households, you need to buy tools weighing up to 5 kg. Such devices are suitable for working with different materials. There are also mini-files that are designed for small woodwork

A good and high.quality saber type hacks will cost quite expensive. That is why a decisive role in choosing a saw is played by a good tool, which will serve for a long time, and also will not let you down when performing different works, will cost at least 5-8 thousand.

How to cut electric saw?

Firstly, you should be particularly attentive to the surrounding area. Clean the site of the working area from stones, nails. Secondly, take a stable, convenient position for sawing. Thirdly, install the electric saw on the tree with a serrated emphasis and turn on the motor so that the saw does not touch the surface yet. Next, raising the rear handle and directing the front handle, enter the saw into the log, and then pull it back. The following movement: enter the saw even deeper, but do not make great efforts for this, as this may incur a quick breakdown of the tool or its wrong work.

Chain electric saws are suitable only for wood work: whether it was cut logs, woodwork, dried, branches, sawing boards and filled. Wood volumes can be different. However, it is worth noting that both the techniques of sawing and how to properly saw a certain diameter of the log is different.

What is a saber’s saw for

The equipment considered is used in many areas of human life. The use of a saber saw is advisable in the following cases:

- When cutting pipes, especially those made of metal.

- When cutting logs intended for heating.

- When cutting out figures from wood or plywood.

- Sable saw in the garden is indispensable in the saw of trees or their trimming.

A distinctive feature of the equipment is that for its operation it is not necessary to fix the material. The tool can work without support and in any position. It is worth noting that few professional tools have such a functionality. True, to cut the material, without fixing it, is much harder, due to strong vibrations.

The equipment in question helps not only neatly, but also cut a large number of materials in a short time. If you compare the tool with a hand hacksaw, the latter loses in many ways. This applies to the fact that the saber saw can cut in a straight line and the curve of the trajectory, which significantly expands its sphere of use, answering the question. why is a saber’s saw for. Naturally, to make curly cuts, experience is required, however, this can be quickly learned.

Cutting technology

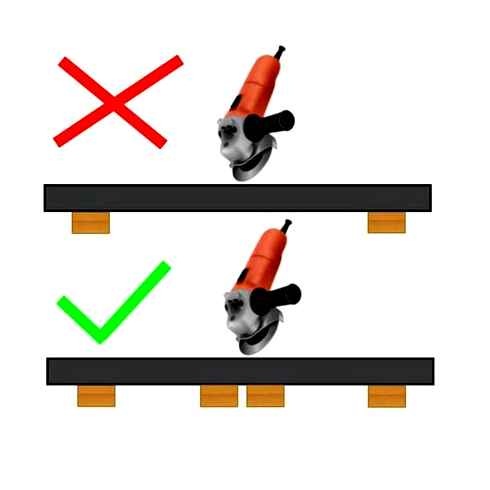

As a rule, the volumes and complexity of the work that are coming to the home master does not require the use of high.performance and expensive equipment of the production level. In the manufacture of the frame of the greenhouse, you can completely cut the pipes with a corner grinder or a traditional manual hacksaw.

Each type of cut has its own nuances, and some require special tricks.

At right angles

The accuracy of the cut is largely determined by a qualitatively made marking. Experienced craftsmen advise to marry the cutting lines not with a pencil, but with a painting tape, observing the following sequence of actions:

- Set aside the required size and put a small mark with a marker or pencil.

- Gently, applying to the mark, glue the part with masking tape in a circle. The edges of the paper must converge without a shift. This is a sign that the paper is sticking correctly. If the edges have not come down, the tape needs to be re.packed.

- Reliably fix the workpiece to exclude its movements and ponds during work. To fix, use a vice, clamps.

- A cut (smaller) piece of the workpiece should be left by weight so that it does not clamp a blade or disk.

- The incision starts from the upper part.

- Corner grinder disk (or hacksaw cloth) is carried out exactly along the edge of the painting tape, without deviating to the side.

This is allowed to cut off the required length.

If the diameter is large, then the marking is performed in the same way, but cut in parts, sectors of 30-60 °. After cutting the next fastening sector, weaken and turn the pipe. Then they fix again and continue to cut off from the place where the previous sector ended. To make it smooth, special attention should be paid to the beginning of the cut, avoiding steps and sickness.

Oblique section under 45 °

Cut the end of the pipe at exactly 45 ° is possible without the use of complex devices. It is enough to apply locksmith. You will need to do the following:

- Cut a paper sheet in the shape of a square.

- Fold the diagonal. The rectangular isosceles triangle will learn.

- Wrap the workpiece with a leaf so that the triangle has a perpendicular to the axis, and the hypotenuse forms an ascending spiral.

- Fix the sheet with tape.

- Fix the workpiece and cut off along the oblique edge of the sheet. It will turn out under 45 °.

There is another folk method. The end of the workpiece is immersed in a container with a liquid at the required angle. Cut off along the border of the dipped and dry sections.

If you need to cut off not perpendicularly, then it is better to use an old carpentry tool. a knock.

This is a P-shaped template, in the side walls of which slots are already made at the given corners. The pipe is rested on the far from the master, the wall was stuck and pressed there with a hand or a manual clamp. The canvas of the hand saws are made in the appropriate grooves and saw. If necessary, cut off from a different angle, you can make additional cuts in the walls.

Pipe cutting techniques at an angle

The techniques of non.perpendicular cutting depend on the processed material. Some techniques are suitable for plastic or thin copper. plastic and light materials in processing. Fat steel will require a more serious approach.

How to cut a pipe at an angle of 45 degrees

Small diameters plastic pipes can be cut using specialized scissors.

Steel pipes can be cut off with a corner grinding, but it is better to use a more accurate tool. a strip saw with a rotary table equipped with clamps. A desktop cut car is also suitable.

When using a general purpose tool, you will definitely have to use one or another equipment.

How to cut a pipe at an angle of 45 degrees

Calculation of cutting angles

A 45 ° cut pattern can be obtained by folding a square sheet in half. To form patterns for other bevels, you need to perform more or less complex trigonometric calculations. For those who safely left sinuses and mowers in high school and are not going to remember the formulas, there are many programs for calculating patterns for any necessary angle on the network. The program performs the calculation for the cutting diameter and angle given by the user and creates the image of the pattern that should be printed on your printer.

Important: in the print parameters you should select the “in full size” option and turn off the scaling of the image.

Pipe

To cut off at 45 ° evenly, you can independently make a paper pattern. This follows:

- Measure or calculate the length of the outer circle.

- From the corner of a sheet of paper for printer A4 format draw a fishing line for a trimmer at an angle of 45 °. If there is no transport, such a fishing line for a trimmer can be obtained by folding together adjacent to the corner of the edge of the sheet.

- Lay the length of the circumference on it.

- It will be a hypotenuse. Complete an isosceles rectangular triangle to it. One side will be the edge of the paper, the second should be omitted perpendicular to the second edge from the postponed point.

- Cut the resulting triangle. this will be a pattern for cutting pipes at an angle of 45 °.

It should be wrapped around the workpiece, combining the ends of the hypotenuse. Along the line of the legs and a cut will pass. The fishing line for the trimmer should be marked with a marker or paper tape. Further along the marked line, it will be possible to cut smoothly a piece with the required bevel.

The method is suitable for pipes with a diameter of up to 63 millimeters.

Pipe cutting

Carpenters have long been using a simple, but very useful device to cut off the ends of bars, rectangular, round and shaped at an angle. Plotnitskoye was good for drinking a plastic or not thick metal pipe.

You can use the finished, or you can make a knock with your own hands. Its advantage will be that it can be made exactly under the size of the pipe. For manufacture it will be required:

- Cut the board 40-50 cm long and width equal to the pipe diameter.

- Cut two boards of the same length, but wider to the thickness of the first board.

- Assemble boards on self-tapping screws, attaching the side to the base so that the P-shaped gutter is obtained.

- In the center, mark and make vertical cuts in the side boards to the base so that the straight line draws through them forms with a longitudinal axis of the structure of the corners of 90, 60, 45 and 30 °.

- If necessary, make cuts at other corners.

The side walls are best made of wood of more durable breeds. this will extend the service life of the equipment.

Such a knock not only determines and helps to withstand the correct fishing line for a trimmer of the saw and saw it evenly. It also serves as a means of fixing the pipe. It is enough to hold the pipe with your hand with the stupid. For each diameter, you will have to make a separate equipment.

During operation, the slots in the side walls are also worn out. It is necessary to ensure that the canvas of the hacksaw walks in them with a minimum play. In the case of wear, you can cut off new slots parallel to the old one, retreating from them at least 3 centimeters, or replace the side walls.

This knock has the following advantages:

- It is inconvenient to work with large diameters and wall thickness

- Binding of each equipment to its diameter

- compatibility only with a hacksaw for metal

Simple equipment for cutting

The universal cutting machine with a pendulum disc is perfectly suitable for evenly cut off the thick.walled pipes of large diameter at an angle, both round and rectangular in the cross section. Such devices operate in procurement areas of small industries and on construction sites, where it is required to exactly cut a large number of reinforcement in size.

The disk saw along with the electric motor is fixed on the pendulum lever and can with great accuracy be brought to the working area and then lead the cut in one plane.

Advanced devices are equipped with a hinge lever that allows you to change the direction of the cut. In the models of the lower and middle price segment, the orientation of the cut line is carried out due to the rotary table equipped with clamps for reliable fixation of the workpiece. In addition, the table can bend to the side to 45 °. The turning table and the lifting mechanism are equipped with transporters that allow you to set an angle with an accuracy of a degree.

For reliable fixation of the pipe at a given angle, a clamp and two steel corners with a side close to the diameter of the pipe are used. A short corner is fixed on a rotary desktop, using its standard screw clamps. The process of fastening and cutting by steps:

- Set the rotary table on the required angle of cut and fix it.

- Lay the pipe between the corners and pull them with hand.on.hand clamps so that the marked fishing line for the trimmer cut remains free.

- Run the engine.

- After a set of revolutions, smoothly bring the disk to the surface of the metal and smoothly cut off the workpiece. At the beginning and end of the cut, when the section of the cut metal is maximum, you should not make much effort to the handle of the pendulum.

How to work correctly with a saber’s saw

The saber’s saw itself is quite light, especially when compared with a chain saw, its weight is about two kilograms, which allows you to hold it with one hand. If you compare the saber plate with a disk saw, then the result is as in comparison with the chain saw. The advantage of the saber over these two saws is that for a chain saw you only need wood and thicker, and the disc saw works only within even mode, not allowing the ledges and cutouts. Thus, it is clear that each saw has its own area of application, exactly where it has no equal. Most often, saber saws are used when cutting pipes, window frames, to carry out rescue operations. In the choice of nutrition, they are acquired depending on the place where it will be applied.

In the convenience of use, the main point, is an anti.vibration system, the second most important is the function of the infestral replacement of the canvas for the saw, thus reducing the time for maintenance.

In terms of security, of course, the saber saw is the safest, as it has only one cutting side, while there is a protection against unwanted inclusion. Also, a saber saw is considered not a dusty tool and multifunctional, and can become a good assistant plumbers, rescuers, roofers. The use of such a tool significantly reduces the time compared to manual work.

How to choose: main characteristics

Answering the question of how to choose a saber’s saw, it is worth paying attention to the main criteria on which the choice should be based.

Power

This is the most important parameter that affects the choice of tool. The higher the power indicator, the heavier and more in size there will be a saw, and its performance will also be higher. Devices are presented on sale, the power of which is from 0.5 kW to 1.5 kW.

The choice of power depends on what a saber saw is needed for. often acquire a universal device, the power of which is from 0.9 kW to 1.2 kW.

Pendulum

This option is responsible for reducing the level of load on the canvas. The function will be very useful when performing a large volume of work, as it increases the productivity of the apparatus. If you choose between the instrument that has a pendulum course and a tool without a pendulum course, it is better to choose the first option, since this function is useful.

Please note: the pendulum will be needed only when working with certain materials. When buying a tool with this option, you need to understand why a saber saw is needed. So, when cutting metal, this option should be disconnected.

Adjusting the support shoe

In the process of sawing, this detail plays a large role. The support shoe allows you to conveniently fix the workpiece, so the cut will be more even and accurate. If there is a supporting shoe, it is more convenient to add great strength with a cut. The presence of a mobile shoe frame allows you to adjust the outlet of the tool and make a cut at any angle.

Steel saw shoe

Blocking from random inclusion and fixation of the launch trigger

Some models have a button that protects against randomly turning on the tool. The launch of the electric motor occurs only after clicking on such a button or lever.

Also, such models have a latch, which allows, starting the electrical appliance, release the trigger. Such an option is necessary for a more convenient retention of the device and the implementation of the exact sawing.

Speed adjustment

Changing the speed mode usually changes in two ways. In the first case, this happens using a slider or wheel. In the second case, the speed of the saber saw changes the degree of pressing the button. The latter method requires certain skills, so more often this method of changing the speed of work is found in devices designed for professional use.

Speed adjustment

Cut a Perfect Miter Joint/Corner Joint in Metal Tubing with a Handheld Grinder!!

The mechanism of replacing the canvas

The good quality of the connecting unit in professional models ensures the unnecessarity of additional tools in order to switch from wood to metal during the cut. When using cheaper models that do not have a “hot replacement” system of a hacksaw canvas, the necessary strength will be achieved only by the use of fasteners.

IMPORTANT: In order to avoid a trauma to be avoided during the operation of the saber saw, you must turn off the electric tool from the network during replacing the canvas.

Cracking protection

This option is built into all professional models, since in case of breakdown, their repair will cost much more than installing the security unit.

Cheaper models designed for operation in everyday life are most often not equipped with this option.

Smooth start and brake

Smooth start is necessary to protect the tool from breakdown. This option also increases the service life of the gearbox and electric motor. The electromagnetic brake allows you to place the saw on the surface after work without the risk of damage to the tool and coating.

These functions can only be found in more powerful professional models.

Double isolation of live nodes

This technical solution increases the service life of an electric unit and allows the operator to work from a socket that is not grounded. Sable saws equipped with such a protection system allow you to work even on the street in raw weather.

Saber saw: professional or household

If the use of the saw is limited only to solving household problems from case to case, it is better to choose a tool designed for operation in everyday life. Hobby class models from famous manufacturers no worse in quality. They have a set of all necessary options, and also differ in small weight and have a good cost.

The only thing to take into account is that such models are not intended for constant long.term use, so they are not suitable for a large volume of work.

Professional will be needed only by those who plan to use this tool regularly for a long time. Manufacturers have provided for the configuration of such devices many additional options that simplify the cuts, increase the performance.

Additional parameters that require attention when choosing

The quality of the tool depends on these parameters:

- With a high.quality connection of the file to the rod, the canvas should not hang out.

- The smaller the vibration, the more comfortable it will work with the saw, and the fatigue from work will not come so soon. It is very good if the saw is equipped with a special balancer, which extinguishes vibrations from vibration.

- Too much noise level during work can talk about poor.quality assembly. The less the tool rustles when included in the network, the better.

- High.quality units from well.known manufacturers usually have a network cord, the length of which is at least 3 m. The smaller the length of the cord, the more often you will have to use a special carrying, allowing you to turn on the saw at a considerable distance from the outlet.

- If you choose a device from the category of more expensive models intended for professional use, be sure to make sure that it will be convenient to hold it in your hands.

Saber saw characteristics

Use suitable blades

Cutting canvases for saber saws are of different lengths for many reasons. And if the blade is too long, then when sawing small details it is possible to appear strong vibration, it will not be comfortable to work, and the canvas may bend.

How to choose the right blade length? Yes, very simple-use the blades in length exceeding what you cut by only 4-5 cm.

How to cut it quickly

When sawing thick material, try to alternate the angle of inclination of the saw (in the photo below). This reduces the contact area of the cutting blade with the material, which in turn reduces friction and accelerates the process of sawing.

Try to press the sole tightly, which will help reduce vibrations.

The principle of operation of the piston saw

The main constructive feature of the saw is the pendulum trajectory of the canvas. In short, this mechanism includes the rise of the cutting edge when moving backwards, which significantly reduces friction and heating the blade. Thanks to this approach, the designers of the device achieved an increase in the service life of interchangeable saws, and also increased its performance compared to analogues, since the pendulum mechanism helps to automatically remove accumulated sawdust. Thus, there is no need to make excessive efforts during work, it becomes less tiring.

Devices are supplied with a special table, according to which you can change the speed of cutting the blade, depending on the characteristics of the processed material. A set of replaceable saws sharpened to certain properties of a tree also helps expand the scope of the tool. It is safe to say that the piston saw exceeds manual analogues in performance, accuracy and ease of use.

Varieties of hacksaw canvases

The versatility of the saber saw is provided by a variety of hacksaw paintings, each of which is used for a certain material.

The files are distinguished by the material, shape and size of the teeth, the size of the step. First of all, they pay attention to the size of the teeth. Large is cut faster, but the quality of sawed better in paintings with small teeth.

Files with divorced incisors and variable steps are used for direct cut on wood with nails.

The following marking is used to classify paintings:

- HSS. is used for cutting soft and non.ferrous metal;

- HCS-wood processing, wood-based, plastic;

- BIM. a bimetallic saw, with great flexibility and strength, saw the wood and metal;

- HM. hard alloy, necessary for cutting fiberglass, ceramics, steel.

The advantages of a saber saw

Sable saw has a number of undeniable advantages.

- Simplicity of use. In fact, this is familiar to a hacksaw with an electric drive. Both a woman and a teenager will be able to work confidently.

- Universality. Sable saw. an assistant both when cutting the bitch in the garden, and during construction, and when disassembling old buildings.

- High performance.

- The possibility of working in hard.to.reach places where you can’t get into either a jigsaw, or a chain or a disk saw;

- Possibility of working on weight.

- A wide range of sawed materials is possible to use an electric saw for metal, plastic, wood (including nails), concrete, brick and natural stone.

- Great safety compared to chain saws, grinder and disc saws, less dust and sawdust;

- Simplicity of service and large resource.

Compared to the above advantages, the shortcomings of the saber saw are represented by minor.

How to make the right choice

In order to make the optimal choice of a model of a saber saw from dozens of offered on the market, it is necessary, first of all, to clearly answer (and it is better to write down answers) to a number of questions:

- The purpose of the device.

- Terms of Use.

- Who will use the saw.

- What materials and what thickness is planned to be processed.

Knowing the answers to these questions, you will feel much more confident in a conversation with a consultant in a store. The consultant knows everything about the saws, but knows nothing about you. In addition, his task is not to choose the most suitable device for you, but to sell you the most expensive model. Only you, after listening to information about devices from the consultant, can compare them with your needs and make the best choice on the basis of this comparison.

The best battery

Roybi RRS 1801 M. Best Sabbat Battery Saw. The handle of this electro-burning D-shaped. The main difference is the presence of the battery. This will not look for an outlet. So you can work even in the room where there is no electricity, but you will need to stock up on batteries, since they only have enough for a short time. The length of the course can reach 22 millimeters, and their number is 3100 in one minute. It is possible to smoothly adjust the speed. The mass of the device is only 1.9 kilograms, which facilitates the work of the master. There is no pendulum course.

- Low weight;

- Work without a power grid;

- It works well with different types of wood;

- Good anti.vibration system;

- Metal canvas is included;

- The method of attaching the canvas. fast.packed.

The best saws with a powerful engine

Makita Jr 3070ct

This unit has large sizes, an electric motor is located inside it, the power of which is 1510 watts. Because of this, its mass reaches 4.4 kilograms. But if you need to overcome metal, plastic and wood without problems, then it will do it without difficulty. This apparatus can create a cut in wood with a depth of 255 millimeters, and in metal products. 130. There is a pendulum course in this unit. It is regulated thanks to the four.position switch. There is a good anti-vibration system, because of this, the master’s hands are practically not strained. But its price is great.

The advantages are such qualities:

- The case is present in the kit;

- The speed of the course is smoothly adjustable;

- The speed of the move under load is constantly maintained;

- It copes well with wood and metal;

- High number of moves;

- Vibration is practically not felt;

- The pendulum course has a four.speed adjustment;

- Power is almost maximum;

- The canvas can be replaced without additional tools.

Stomer SSS-1000

A relatively small saw, in which an engine with a capacity of 1100 watts is located. The mass of this unit is 3.85 kilograms. Its price is small, but there is no pendulum. From the governing bodies there is only a canvas frequency regulator. Also in this unit is not the best engine. This is proved by brushes that are included in the kit. There is no fast.packed cartridge, which means that the replacement of the canvas is carried out using the key.

Naturally, there is no plastic case for carrying equipment. But it can be additionally purchased if necessary. But the canvases for metal and wood are included. For steel, this unit is better not to use.

- Low price;

- A good number of strokes, which is 2500 units per minute;

- Comfortable design;

- There are two files in the kit;

- The presence of a system of smooth adjustment of the speed;

- It copes well with wood;

- Good engine power.

- There is no pendulum course;

- In the best way, this electric saber saw interacts with metal products;

- In order to replace the canvas, you need a key.

When choosing this tool, it is worth relying on its characteristics and customer reviews.