How to Cut or Correctly

For processing logs on a tape sawmill, it is necessary to adhere to the accepted technology. Thus, you can get the maximum amount of quality materials. Boards and timber. But first you should familiarize yourself with the basic rules of cutting.

Types of wood cutting

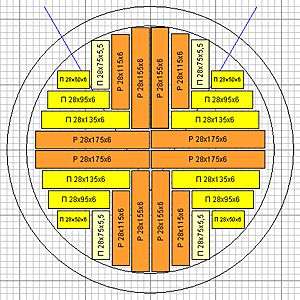

At the first stage, a carriage is formed from the log. To do this, cut on two sides. In some cases, processing is performed from four sides. A preliminary map of the tape cutting of the workpiece is pre-compiled, which indicates the dimensions of the components.

The determining parameter when choosing a scheme is the direction of processing of the log. In particular, the movement of the cutting edge relative to the annual rings. According to this, lumber of various quality is formed, having a unique appearance. Not only their aesthetic qualities depend on this, but also the price.

The following types of cuts are distinguished:

- Tangential. The cut is performed tangentially relative to the annual rings. As a result of this, elongated patterns are formed on the surface in the form of arches, rings;

- Radial. For its implementation, perpendicular processing on annual rings is necessary. Feature is uniform pattern;

- Transverse. Processing takes place across the fibers, the cut pattern is an even cut of the annual rings;

- Rustic. It can be done at any angle, it contains a certain number of knots, sapwood or other similar defects.

Often in the woodworking industry, waste from the band sawing of logs is used. A croaker. On one side is a flat plane, and the other remains untreated.

To make the most accurate cutting it is recommended to use special programs. They take into account not only the dimensions of the source material, but also the type of wood.

Sawing at the sawmill with 180 ° rotation of the log

To form the maximum number of boards, it is recommended to use a technology in which some tape processing processes rotate 180 °. This allows you to achieve the maximum amount of lumber with various types of cuts.

How to Cut or Correctly

The processing principle is to perform initial cuts along the edges of the logs, which are at an angle of 90 ° relative to each other. They will serve as the basis for further tape cutting. Work is carried out on equipment with a vertical arrangement of cutting elements. The diameter of the barrel should be at least 26 centimeters.

A phased order of work.

- Processing of the side with a cut chrome part. As a result of this, two boards are obtained.

- Turn the workpiece 90 °. The cut is performed from the opposite side. The number of products varies from 3 to 4.

- Repeated 90 ° turn. The processing of the main part of the source material. Depending on the planned, 7-8 blanks can be obtained.

Despite all its positive qualities, this method has one significant drawback. Low production speed. It is recommended to use it on equipment in which a block for automatically changing the position of the log relative to the cutting part of the machine is provided.

A detailed scheme is most often used for the manufacture of rustic boards, which are subject to reduced quality requirements.

Sawing at the sawmill with 90 ° rotation of the log

For the manufacture of tangential and radial boards, it is recommended to use a different technique. It consists in a planned tape processing of logs with a simultaneous analysis of defects. Thus, products of the required quality can be obtained.

After removing the twigs, the workpiece is placed on the feed bed of a sawing machine. Then you must perform the following steps.

- Removal of the primary croaker. It is carried out until the width of the base is 110-115 mm.

- Removing unedged boards about 28 mm thick.

- If the number of defects on the surface exceeds the required level, the material is rotated 90 °. With a sufficiently high quality of the board, the following is cut.

- Repeat operation.

A similar technique is applicable for processing plants that have one cutting surface or have the function of temporarily dismantling the rest.

With a sufficiently large number of defects, it is possible not to postpone the workpiece, but to perform its processing by a 180 ° turn method.

The above tape processing technique can be applied to create any configurations of wooden products. Often, the core region is used to form a beam, and the remaining parts are used to make boards. But there may be exceptions. It all depends on the desired shape of the blanks.

The quality of the work is affected by the current state of the sawmill, the level of sharpening of saws and the processing speed. These factors must be considered before starting the production process. If necessary, maintenance or repair of equipment is carried out.

The shows the method of sawing logs on a home-made tape sawmill: