How to Install a Chainsaw Starter Spring

A chainsaw is an indispensable tool in the construction and harvesting of firewood. Proper operation during moderate operation ensures a long tool life without breakage. However, troubles can arise completely unexpectedly and a working chainsaw loses its working capacity, and the malfunction can be completely trifling.

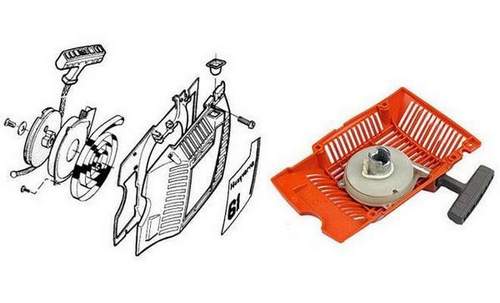

How to repair a chainsaw starter with your own hands

Presented is the repair of a chainsaw starter after a break in the starter cord. Without a starter cord, the chainsaw becomes completely inoperative; there is no other way to start the tool. The repair was examined using the Partner P350S chainsaw as an example; a tricky reliable start of this saw requires a minimum pulling of the start cord 4-5 times for the saw to work, therefore, probably, the first fault was a break in the cord. The cord does not tear immediately, the protective stocking of the cord threads breaks off at first and prevents the saw from starting. It is better not to wait for all the threads to break and fix the cord in advance. There is no need to invent anything, repair should not cause difficulties, but exact observance of the assembly conditions is necessary. A step-by-step instruction with a diagram of actions with photos ands is given below.

1. Unscrew the three screws securing the starter cover. The included candle wrench with a straight screwdriver is suitable for this process, but to speed up the work it is better to use a normal tool.

2. Remove the starter. The chainsaw is equipped with a soft start mechanism, it is located above the reel with a cord.

3. Unscrew the screw securing the soft starter and starter coil. Caution do not lose the puck!

4. We remove the soft-start mechanism.

5. We take out the cord winding coil.

6. We prepare a cord suitable for the diameter of 1.2-1.3 meters in length. For repair used kapron clothesline :).

7. We melt the ends of the rope over a fire so as not to dissolve.

8. Tied at one end of a complex knot. The assembly is required to be large in diameter, but should not protrude when mounted on a coil.

9. We fill the cord into the hole of the coil. Do not wrap the cord!

10. Insert the coil into place. Installation error may be made here. The coil has two slots, in one of which a spiral spring hook should fall. Install the coil so that it snaps firmly into place and the hook snaps into place. It is checked by turning the coil clockwise to determine the occurrence of a return force.

11. Install the soft starter. The protrusion of the mechanism should stand in the recess of the coil.

12. We fasten the fixing screw with the washer.

13. We fill the second end of the cord into the outlet.

14. Fill the cord into the start handle. We tie a large knot at the end of the rope. With a small knot, there is a chance of the rope slipping and the entire cord is wrapped in the starter and in order to get it out the starter will need to be removed again. Check the reliability of the node. See photo.

15. The most important moment! We release the loop of the cord inside the starter and begin to rotate the starter mechanism clockwise without winding the cord! For this saw, you must make a minimum of five turns. We fix the coil by hand. We pull the loop by the handle outward. Holding the cord and mechanism, we allow the cord to be wound on a reel. Watch a.

16. Check the operation of the mechanism.

17. Install the starter in place and fasten it with three screws. Repair done.

Repairing a tattered or damaged cord using step-by-step instructions takes 15 minutes, which is much faster and cheaper than contacting a service center.

If the instructions helped you, let me know in the comments.

Typical malfunctions

The most common tool breakdowns include the following:

In addition, it is necessary to carry out a visual inspection of the chainsaw before starting work and preventive measures. These include chain lubrication, control of the amount of fuel mixture, as well as the presence of the required amount of oil.

Each of the faults is eliminated by its technology. So, for example, repair of the fuel system of a chainsaw should begin with an inspection of the appropriate filter. After that, check the carburetor regulation, which is carried out using screws. Clearances must be set in strict accordance with the manufacturer’s instructions, which must be included with the chainsaw. To repair the ignition system include inspections of candles. If a strong deposit is detected, a change in the gap or other visible damage occurs, this element must be replaced.

Starter repair work

Problems in the operation of the starter may not ensure the launch of the tool. That is, after the cord is pulled, the chainsaw does not start to work.

The causes of the malfunction are:

- Broken or cracked pulley;

- Bursting spring;

- Rush trigger cable.

Before repairing the starter, it is necessary to prepare the tools with which to perform work:

- A set of screwdrivers or a special tool that is supplied with the tool by the manufacturer;

- Rope, which will be used as a replacement for a torn cord if necessary.

Before proceeding directly with the repair of the starter and finding out the causes of malfunctions, it must be removed from the tool body. To do this, unscrew several screws holding the side cover to which the starter is attached. This is done with a screwdriver or a specialized tool.

After the cover is unscrewed, it is turned over and inspected. Next, unscrew the screw with which the starter is fixed. After that, the clamp and spring are dismantled for a smooth start. Now the pulley on which the cord is wound is available for removal. After the knot on the rope is untied, it can be pulled out from the pulley and replaced with a new one. Provided that the starter’s loss of functionality is connected with a break, this may be sufficient to eliminate the breakdown. However, the remaining parts that make up this element of the chainsaw should be carefully inspected.

When examining the components of the starter, the following malfunctions can be identified:

If defective or partially damaged starter parts are found, they must be replaced with new ones. In this case, the new elements must correspond to the model of the saw being repaired.

After the repair is completed, the starter must be assembled correctly.

The pulley is mounted on top of the spring. In this case, it is necessary to check how much they interlocked with each other. To continue the repair, the pulley must be wrapped. This must be done so that during rotation, he pulls the cord into the starter. It is enough to make 3-4 turns to give the required voltage. Previously, the rope is passed through the hole in the lid of the chainsaw.

Practical recommendations

In order to match the holes for fixing the cord in the pulley and housing, you may need to make a few more turns. A new rope is threaded into the technological hole and a loop or knot is made: this will allow it to slip out of the pulley. The rope is set aside so that it does not interfere with further work. Next, fix the pulley.

First you need to replace the soft start spring. It can be used the same if no damage is found in it. Or new if replacement is necessary. On top of the spring set the starter clamp, which is fixed with a special screw. It reliably fixes the clamp for a long time, preventing it from skewing and swaying. After this, you need to make several turns of the rope and run it inward. The cover with the assembled starter is installed in place. Using screws, it is secured.

After the repair and assembly, you can begin to work. Self-repair of the starter does not take much time and does not require complex skills, but it saves time and money if you perform such work in the service center.

Chainsaw repair should be approached responsibly and promptly to carry out preventive examinations, monitor the quality of the fuel and oil used. These simple manipulations will increase the duration of the tool in working condition.

Device

The chainsaw starter device includes the following elements:

Key parameters of the chainsaw launch system:

- Power. From 2000 to 2500 W;

- Maximum number of revolutions per minute. 3000;

- Weight. 0.5 kg.

After pressing the power button, the flywheel begins to rotate with the magnet that is on it.

An electromotive force appears in the system. The appeared current with the help of an electronic unit is converted into electrical signals that are transmitted to the driving elements. A spark forms, which provokes the ignition of the fuel-air mixture.

How to repair a starter on a chainsaw

The cause of a malfunction in the chainsaw launch system can be:

Diagnostics

Diagnostics of the tool launch system is carried out as follows:

- Unscrew the fixing screws and remove the cover.

- The screw that secures the mechanism to the protective cover is loosened.

- Gently start the starter by removing the spring and clamps from it.

- To inspect for wear and defects, dismantle the coil with a cable.

- Check the fuel system for water in it. If there is water inside the system, the fuel fluid must be replaced.

- Inspect the power unit for overfilling with fuel fluid. In this case, you need to unscrew and dry the spark plug, pull the starter, dismantling the air damper.

- Check the spark plug for a spark.

Cord replacement

In order to replace the cord, the following tools will be required:

Replacing the starter cord is as follows:

- Unscrew the fastening screws that hold the side cover with a screwdriver.

- Then remove the starter from the tool body.

- After that it is necessary to turn the cover and carry out an inspection.

- Then dismantle the clamp and spring.

- Untie the knot on the rope.

- It is necessary to pull out the pulley on which the cord is wound. Remove the cord and replace it with a new one.

- Then put the pulley in place and tie the rope into a knot. Install the clamp and spring.

- Then tighten the cover with the fixing screws.

- At the end, reinstall the starter and tighten the fixing screws.

Spring repair

Procedure for repairing the launch system spring:

- Remove the starter from the tool body.

- Remove the protective cover.

- Wind the cord from the end of the pulley to prevent the mechanism from rolling.

- Thread the other end of the cord into the opening of the protective cover.

- Pull the cord 17-20 cm to check the rotation of the pulley of the spring mechanism.

- Check the operation of the spring after pulling and releasing the mechanism.

- Unscrew the pulley circle from the side of the generator by removing the 3 fixing bolts.

- Remove the pulley and cord.

- Check the condition of the parts for wear and damage and breaks. If the spring break is small, then the defect can be eliminated by welding.

How to put a spring

In order to install a new spring, you must perform the following steps:

- Carefully remove the clip of the mechanism.

- Inspect the inside of the cage, in which the spring mechanism is located near the C-shaped element.

- Lock and pull the upper part of the spring with your finger and pull the trigger handle to the side.

- Remove worn gear and wind new spring. Kinks and twists of the element should be avoided.

- Assemble a new spring mechanism. It is recommended to do this slowly so that the mechanism does not unwind.

- Fill the spring and insert it into the starter mechanism.

- Gently lock the clip.

Starter replacement

Procedure for replacing the chainsaw starter:

- Remove the assembly from the tool body.

- Unscrew securing bolts and dismantle side cover.

- Loosen the fixing screw that secures the starter.

- Remove the clip and the spring mechanism of the trigger system.

- Remove the pulley with the cord.

- Replace all worn and damaged items.

- Winding the pulley.

- Install a new starter.

- Replace the pulley with cord, clamp and spring.

- Screw on the side cover and install the assembly on the chainsaw body.

Before installing a new starter, it is recommended to inspect it for marriage, check the build quality and the presence of the guide sleeve.

Chainsaw starter device

The principle of operation of the starter for a chainsaw is as follows. A handle is installed in the groove of the housing through which a cable is passed. If the handle is sharply raised, the cable is pulled out and engages the drum of the ratchet mechanism which transmits movement to the drum with splines provided on the shaft. In this case, the crankshaft makes several revolutions, and the working mixture is compressed in the space between the piston and the cylinder head. Accordingly, when lowering the handle, the contact between the ratchet and the splines is lost, and the shaft stops.

With an increase in engine volume, the required amount of the fuel-air mixture necessary for its subsequent ignition also increases, so the number of jerks for the starter cable for saws with high power increases. Therefore, in order to accelerate the return of the drum, involuntary return springs made of steels with high elastic properties are used.

Facilitation of starting a chainsaw is implemented in the following ways:

- By preliminary enrichment of the working mixture, for which there is a special shutter in the carburetor design.

- By installing an automatic decompression valve, which reduces the working pressure in the cylinder of the chainsaw.

- The installation of an additional spring, which during the movement of the cable facilitates the unwinding of the crankshaft.

- The presence of some chainsaws (for example, Partner Series S, Maxcut, etc.) in the design of a primer is a pump that provides preliminary pumping of fuel.

Chainsaw starter repair

With frequent starts of the chainsaw, some parts of the starter are constantly subjected to dynamic loads. As a result, the cable may burst, several teeth of the ratchet will crumble, and the shaft will turn at a much lower speed. Therefore, the audit and even repair of the starter are operations that are sometimes carried out several times during the season.

Cord replacement

When it is pulled, there is a constant friction of the cable on the starter housing. For replacement, the assembly of the assembly is disassembled and the ratchet drum is carefully lifted in such a way as to prevent the return spring from jumping off its sockets. It is better to do this work together: the assistant fixes the spring, while the cable is being replaced. After fixing the cable in the handle and in the grooves of the drum, the cable is wound on the roller, and the body is assembled.

Spring repair

If the starter spring material is poor, the spring will burst (usually at the point of attachment to the drum, where it forms a loop). Replace the spring in this case is not worth it. It is enough to thoroughly clean its surface from dirt and traces of grease, carefully grind the place of destruction, and then release the spring at 600. 650 ° C (the spring steel should acquire a crimson color). It is necessary to cool the spring slowly, but at 100. 150 ° C it is already possible to carefully wrap its end in the form of a limiting protrusion on the inner surface of the drum (the steel will acquire the necessary plasticity) and put it in place. The elastic properties of the spring will not change.

The device and principle of operation of the chainsaw starter

Most well-known chainsaw manufacturers equip their products with starters that work on almost the same principle. Its essence is as follows: in the groove of the saw body there is a handle through which a cord is passed. With a sharp lifting of the handle, the cord is also pulled, which engages the drum, which is in the ratchet mechanism. By means of this, a drum with spitz, which is located on the shaft, is driven. During this, the crankshaft makes a couple of revolutions, which leads to compression of the fuel mixture, which at this moment is between the cylinder head and the piston. When lowering the handle, on the contrary, the ratchet and spitz lose their contact, which leads to a shaft stop.

With an increase in the power of the chainsaw, the amount of the fuel mixture increases, which must be ignited when the chainsaw is started. In this case, to start the engine, it is necessary to increase the number of jerks of the starter cord. To accelerate the return of the drum mechanism, manufacturers use a special steel recoil starter spring with excellent elasticity. To facilitate the launch of the chainsaw, leading brands use other methods:

- Pre-enrichment of the fuel mixture with a separate shutter;

- Installation of an automatic decompression valve, which provides a decrease in pressure inside the cylinder of the chainsaw;

- Installation of a primer designed for pumping fuel before starting the engine.

The use of one of these technologies greatly facilitates the launch and extends the life of the starter, which is especially noticeable at low temperatures.

Typical breaks and repair of a chainsaw starter

The appearance of various malfunctions of the starter leads to the inability to start a chainsaw. The most common starter breakdowns include:

- The starter pulley has completely burst, or cracks have appeared on it;

- The spring burst;

- The starter cable broke.

Do-it-yourself tools will be required to fix each of these malfunctions. You must have a set of screwdrivers and a spare cable with you. Remove and inspect the starter for the chainsaw in the following order:

- To find the cause of the breakdown, the starter from the chainsaw will need to be removed. To do this, unscrew the screws with which the protective cover is held with the starter attached to it;

- After removing the cover, you must carefully unscrew the screw through which the starter is attached to the protective cover;

- Then you need to try to smoothly start the starter. For this, remove the spring and clips from it;

- Further, a coil with a cable is removed from the starter for inspection.

As a result of inspection, you can find a number of typical malfunctions. These include:

- Various pulley damage in the form of tears or cracks mainly in the rear of the part. They interfere with the normal operation of the entire starter;

- Damage to the starter spring of a light start. In such cases, not only the spring itself can be faulty, but also the place of its fixation. This is the most vulnerable part of the spring;

- The starter flywheel dog is damaged.

In any case, any defective part must be completely replaced with a new spare part.

How to replace the chainsaw starter spring?

In order to replace the old spring in the disassembled starter, proceed in the following order:

- Before installing the chainsaw starter spring, you will need to remove the clip of the mechanism. This should be done very carefully so as not to break the part;

- Then you need to look inside the cage. In it you will see a spring wrapped around a C-shaped element. To pull out the spring, fix the upper part with your finger and slightly pull the starter handle to the side;

- After removing the old spring, wrap a new part. At the same time, try to avoid kinks and twisting of the new spring element;

- To assemble the spring of the starter of the chainsaw, you will need to act as carefully as possible, otherwise one incorrect movement can lead to unwinding of the spare part;

- After you have managed to fully insert the spring into the starter, you must carefully lock the clip.

At the last stage, it remains only to assemble the chainsaw starter and try to start the tool. It is possible that you will have to make 10 to 20 jerks. This is necessary in order for the spring to finally fall into place.

Today we will consider problems with malfunctioning chainsaw starter and we will eliminate them. This type of breakdown is not uncommon during heavy use of a gasoline-powered saw. And in our case. At logging, this happens systematically.

I had a chance to repair starters from the Ural chainsaw, with which we felled, working in the leshoz. I was still very young and understood the design for the first time, myself. The malfunction has arisen as a result of breaking the “tongue” of the spring, which is fixed in the drum (housing). I remember how I was all in graphite grease (hands and face) trying to tame the “snake” (metal tape), which “fell apart” into rings and did not want to gather in the bay))). I think who collected (twisted) the spring, remember as cramps the palm of the constant resistance of the spring. Compounding repairs and a metal cable. Nevertheless, I successfully coped with the task, although it took me a lot of time and nerves. On chainsaws of world brands, the design is not so complicated and capricious.

So, the chainsaw starter is designed to start the tool. On gearless saws, it is located in the side cover on the flywheel side (left side of the tool). This is a purely mechanical principle of action. But in order to correctly and properly repair the starter, it is necessary to understand the principle of its functionality (work). I propose a thorough consideration of this issue.

On top of the starter cover (housing), the handle is located in a special seat on the cover. The handle is connected to a cord, which in turn is wound on a pulley and the end of the cord is secured with a pulley. When the operator (the user of the chainsaw) jerks the handle up, the cord unwinds along the pulley (coil), bringing it into a “centrifugal” state. The pulley has a ratchet in its construction (on the back). It is a gear with teeth rounded to one side. The gear teeth (ratchet) are coupled with the “dogs”, which are located on the drum (flywheel) of the crankshaft. The crankshaft rotates, the fuel is compressed under the pressure of the piston and the head of the “engine”. The operator, meanwhile, lowers the handle, the return spring, which is fastened to the coil (pulley), wraps the cord in its original state (on the coil). The ratchet teeth, meanwhile, slip along the “dogs” of the flywheel, excluding contact with them, since they are already rotating in the opposite direction. I remind you that the ratchet teeth are rounded to one side. This principle allows engagement with the crankshaft splines. Rotating in the opposite direction engagement with the “dogs” is excluded.

But, as lumberjacks know, a pulley happens with a ratchet without characteristic teeth. Gears. These are classic professional chainsaws, the ratchet of which is either a steel “cup” of small diameter with side cutouts (protrusions), or plastic analogs (grips). For example, on Calm 361, the ratchet has grips in the form of “dogs”. It is with these “notches”, “grips” or “dogs” that the adhesion to the “dogs” on the shaft occurs. The principle of operation of the “doggies” splines, I think, is understandable. When the shaft accelerates in rotation, the “dogs” slip through the ratchet.

Let’s take a look at the general starter circuit.

In addition, the starter comes with a damper spring, the so-called “easy start” Smart start. On the model of a chainsaw with an “easy start”, the letter “e“(E.G. Husqvarna 340e) However, there are models of professional chainsaws without the letter “e”, since they have no analogues without the Smart Start system. The starter cover, with the presence of a damper spring, looks more convex. By the way, damper springs break quite often than the main spring.

Symptoms

So, you have “covered” the chainsaw starter. If the cord simply breaks, then the malfunction is “obvious” and should be replaced. Other characteristic symptoms of a starter malfunction are as follows:

- The shaft does not catch (the winding cord freely scrolls);

- After a jerk of the winding, the cord does not unwind;

- Starter jams

Chainsaw starter repair

First of all, it is necessary to twist and remove the cover, make a visual inspection. A breakdown of the chainsaw starter can be different. A bursting spring, a defect in the pulley (“coil”), a worn-out cord.

Next, we prepare repair tools. These are screwdrivers and pliers. In the event of a break, you will need a new cord. I think that lumberjacks have a cord for the starter in stock. If there is no possibility of acquiring a factory cord, then you can replace the “forced” with a clothesline, choosing the appropriate diameter.

In the event of a break in the cord

We turn out the starter mounting screw, remove the clamp and the damper spring, if any, on your brand of chainsaw. We dismantle the pulley with the cord, untie or cut off the cord assembly, and remove it. Since the cord is torn, the spring is discharged, and, in principle, you can not be afraid of falling out of the spring from the cover.

We take a new cord, select the appropriate length (focusing on the length of the old dangling cord), divide, melt the ends of the cord so that they do not “shake”. We insert a new cord into the coil, tie a fixing knot and “hide” it in a pulley for unhindered passage of the cord along the brook of the coil (on some chainsaw models the cord is tied around a ratchet. This is provided for in the design). Pass the free end of the cord through the hole in the starter cover and push it into the handle. We fix the cord in the handle with the help of a knot. We wind the cord onto the reel (pulley) in the corresponding direction. We place the pulley in the starter cover over the return spring (and over the damper if present) and make sure the spring is engaged with the coil. Slightly turn the coil in the corresponding direction. We fix the pulley with the fixing screw.

Next, you need to charge (cock) the spring. To do this, pry the free part of the cord with a screwdriver and pull it out. We grab the cord with your hand, put it in the technological half-hole, which is located from the edge of the coil. We make several turns by turning the coil (pulley) by the cord in the direction of tension.

How many turns do?

Too weak a tension will “break” the edge of the pulley housing, and too much tension will adversely affect the return spring. Pick up the tension yourself.

When the spring is charged, the starter is put in place. The cover is screwed to the chainsaw. During tightening, the mounting screws are slightly tightened, and the starter must be turned to fully fit and engage the pulley with the “flywheel” of the flywheel.

If the shaft does not catch

When trying to start a chainsaw, the jerk of the cord is “idle”, i.E. No gearing with the shaft. The operator inconclusively makes jerks of the starter, the cord is unwound on the pulley without resistance and rewound. What is the reason?

The malfunction is in a burst damper spring (“easy start”,”soft starter”). If you remove the starter cover, then the breakdown is detected without difficulty, since most often the spring bursts closer to the cover. However, not the damper spring itself, but its mounting location may break.

If the spring burst, then only a replacement with a new one will help to eliminate the malfunction. That is why, I am not a fan of chainsaws with a soft start system. Of course, I do not impose my tastes and opinions on any of my colleagues. Everyone has the right to decide his own preferences in this choice of chainsaw model.

Another reason for the lack of traction on the shaft may be a ratchet defect. We are talking about a ratchet model with a plastic gear, when the teeth for gearing have cracks and chips. In this case, it is also necessary to replace this unit. That is, the ratchet mechanism. And it is better to have a chainsaw model with steel ratchet.

By the way, the “dogs” on the flywheel shaft can also cover themselves. To burst the springs, which perform the return function and as a result, the clutch with the ratchet disappears. A similar malfunction has also occurred in my personal practice. The springs of the “dogs” were made from fragments of a cable (from cores). But it was worth an incredible patience, time and concentration. I am sure that you should not like to pervert and work out with another chainsaw.

Another reason when the shaft does not catch is the common mistake of collecting the starter again. Fixing it to the flywheel. This picture is observed in inexperienced lumberjacks. The reason is the lack of engagement of the coil with the “dogs”. The fact is that during the final fastening of the cover, the user of the chainsaw does not check the engagement by turning the starter and the ratchet lies on top of the “dogs”, and in this case there is no engagement. An inexperienced operator is perplexed and does not understand the cause of the malfunction. It disassembles and reassembles until it realizes (or until a more experienced colleague tells you) about the proper assembly of the starter.

If the starter sticks

The picture, when the starter is jammed, looks as follows: the operator jerks the cord by the handle, and the cord either does not move at all (the pulley does not turn), or with great difficulty “passes a short distance” and finally stops. Of course, no return movement of the cord to its original position occurs.

I am sure that most lumberjacks are familiar with this picture. The cause of the malfunction is the deterioration of the pulley, and more precisely in the support casing, which holds the cord in the “stream” of the pulley. The cord extends beyond the edges of the housing, creeps out, it is rubbed between the edge of the casing and the pulley, and the cord loses its ability to curl up to its original position.

To continue work, it is necessary to rewind the cord to the pulley, “charge” the spring. To start a chainsaw, it is necessary to “catch” the engagement, carefully pulling the cord by the handle up and only then pull it. The cord must be in a taut position when jerking to prevent it from falling out of the coil body. This method will help only for a short time using the tool, as the wear of the assembly is unremovable. It is necessary to quickly replace the starter coil with a new one.

Attention should be paid to one important nuance: during dismantling of the pulley it is important that the return spring (if it is intact) does not fly out of the seat. Otherwise, you get tired of collecting the spring in the bay and put it in place. In order to avoid the return spring falling out of the seat, it is necessary to discharge it first. This is done as follows: the cord (closer to the handle) is picked up with a screwdriver and placed in the technological half-hole of the pulley. Next, you need to pull the cord and make several turns in the opposite direction of winding, until the spring is loose. Another option is to unload the spring. Cutting the cord at the base of the handle, but by doing so you will sacrifice a small piece of the cord. When removing the pulley, you need to make sure that there is no clutch between the spring and the pulley.

If the return spring burst

The return spring is used to wind the cord onto the pulley and is located under the pulley. If it burst, and this depends on the resource (as a rule) of the tool operation, then there is only one way out in this situation. Replace the spring with a new one. It’s possible, of course, to distort and “blind” a fragment into a short analogue, but this is only when the “edge” is really necessary and the work on the cutting area needs to be completed. The end of the spring band will need to be annealed to take the form of a locking hook. Such forced absurdities occur, as a rule, on a shift and the “Russian peasant” has to “surprise the world” (or amuse) with his ingenuity. But in fact, to eradicate the need to feed the family.

If the spring burst, then for replacement we remove and discard its remains. In its place we install a cove of a new spring. We cover the spring with a protective cover.

The coil (pulley) is mounted on the spring (over it). After that, it is necessary to rotate the pulley, making sure that the coil engages with the return spring. Then we proceed in the sequence indicated in the chapter “In the event of a break in the cord”.

Write comments, supplement if I missed something, didn’t finish it, or made a mistake somewhere. I will be glad to our discussion.