How to install a starter on a trimmer

Removal and disassembly of the starter, replacement of broken parts

To repair the trimmer starter, it will be useful to disassemble it first, and then assemble it. This process is not particularly difficult. A screwdriver with a tip of a suitable shape is useful for performing work.

It remains for our client to do it carefully, observing safety precautions, mainly so that the spring does not injure the master in case of an accidental departure.

Lawn Mower / Lawn Mower Trigger Replacement

How to change the trigger on a lawn mower SUBSCRIBE / LIKE.

Which Trimmer To Choose For Home

How to choose an electric trimmer How to choose an electric trimmer for a summer residence Hello, dear friends! The choice of a trimmer for a summer cottage or a personal plot directly depends on the high-quality condition of this plot. To begin with, you need to assess the degree of vegetation congestion of the area of the site. after all, it can grow apart from ordinary lawn grass [.]

Starter assembly

Assembly starter unit is carried out in a series of steps:

- the coil is turned over, setting it so that the spring bend fits exactly into the groove of the body, as in the photo below;

- two washers are laid, between which a spring is placed;

- put a cup with antennae at the destination;

- tighten the screw (photo further).

When doing the described manipulations, it is imperative to put two washers. If this is not done, then the spring will damage the plastic cup over time, and when it is pulled, wedging will begin. Because of this, there is a feeling as if the spring has flown off. To remove such a defect, it is necessary to install this part of a greater length or an additional washer.

When there are no such spare parts, there is an option to simply unscrew the screw a little, and the starter unit will start working without wedging. Alas, this option is temporary. it is better to repair it superbly faster.

Starter repair: disassembly

We unscrew the screw with which the pulley is attached to the starter cover. We take out the antennae, the spring. We pull out the pulley itself carefully so that the spring does not bounce into the face. Even with the most careful disassembly, it usually immediately flies out of the coil and abruptly unfolds into a long metal strip or twists into rings.

Pull out the white starter coil carefully. do not get hurt by the spring!

If the spring bursts or one of its hooks breaks, then repairing the starter will not work simply and quickly. the spring needs to be replaced. In order not to spend money on buying a new starter, you can search only for it on sale.

If the starter spring simply breaks off, that is, one of the hooks is out of engagement, it is enough to insert it, if necessary, slightly tightening the hooks more tightly (just do not break it off!) Install the spring with an outer hook into the pulley groove and start twisting it, while holding with your fingers inside the coil and preventing it from jumping out of there.

Filling the starter spring Pressing the spring to the pulley, wind the spring inward in a circular motion

It may not seem so easy to insert the starter spring the first time, but everything comes with experience. With a little practice, you can easily wind the spring into the pulley in a maximum of a minute.

The starter spring is wound. It remains only to assemble the starter and charge the spring to the desired value.

Installing or replacing the starter spring for lawn mowers, motor-drill, trimmer

But what if everything is in perfect order with the rope, and the reel (pulley) of the starter does not unwind? Let’s consider this issue step by step using the example of the starter of the gasoline ADA GroundDrill motor-drill, which has a pulley with two metal antennae for 2 hooks.

In the case of other types of manual starters of a similar design, which are widely used in gasoline lawn mowers, trimmers and motor drills, the whole process of repairing a starter will look similar, differing only in some nuances.

Replacing a torn cord

A torn rope is replaced in the following sequence:

- the old cord is removed;

- choose a rope that is suitable in size (thickness and length);

- passing it through a special hole in the coil, tie a knot;

- cocking the spring, producing the required number of revolutions;

- fix the handle.

It is better to stretch the spring plate together with a partner so that the edge of the cord does not reel inside the starter mechanism.

Assembling the starter on the trimmer and winding the spring is not difficult, just do it carefully and carefully. For different models of lawn mowers, the breakdowns of the triggering devices are similar, therefore they are repaired in the same way. In this case, there are some aspects related to their design features.

How to put an electric starter on a tiller

If you cannot figure out how to put an electric starter on an agricultural unit, follow the recommendations below:

- To remove the engine flywheel, it is necessary to remove the tiller air filter to open access to the “native” manual starter for dismantling.

- Remove the protective cover of the unit, unscrew the fastening screws of the starter basket and dismantle the flywheel using a special wrench. Behind it is a key that must be unscrewed.

- Next, you need to install a generator for which there is a seat on the engine. All wires can be easily threaded through the hole in the wall of the motor housing.

- Place the generator magnets inside the flywheel so that the holes coincide, fix them in this position with the fasteners.

Heat the crown with a gas burner, and install the device. - The resulting assembly is installed on the internal combustion engine, the keys and the fixing nut are screwed in.

- Fasten the basket, replace the filter and protective cover.

- Install an electric starter, connect to the battery. In this case, connect the generator wires to the charging relay. Check the health of the system by running the tiller.

DIY repair and installation of a starter on a trailer

Many farmers ask how to install a starter on a tiller. When operating a motor-cultivator, starters are used: main and auxiliary.

How to repair the starter of a motor cultivator with your own hands

Consider how to repair a tiller starter with your own hands. Before you start repairing a recoil starter, you need to find its instruction manual, which contains a diagram of the device. Then you need to prepare a wrench to unscrew the mechanism.

Before starting to dismantle the device, it must be photographed in order to then correctly assemble all the parts and components.

After that, unscrew the washer, which is located in the middle of the body. Having opened the lid, you need to carefully inspect all the parts that are located inside the drum and determine which ones are damaged. It is necessary to inspect small parts very carefully and carefully so as not to accidentally spoil them and not lose them.

In most cases, repairing a kickstarter on a tiller consists of updating components that are out of order. For example, replacing the starter cord is performed if it is torn or frayed.

If a large spring fails, then you need to remove it from the drum. There are usually hooks where the spring is attached. If they are not in the design, then it is necessary to heat the ends of the spring and bend them in the desired direction. If the spring is completely out of order and there is pronounced metal fatigue, then there is no need to try to restore functionality to such a spring. In this case, it is best to replace it with another one. After that, we install the device in its place.

In addition to the manual starter, there is also a spring and electric starter for the tiller. The spring mechanism has a simple structure and is easy to start. The device starts up after shifting the handle of the cultivator. The motor accelerates by means of a semi-automatic spring operation. You can replace the manual starter with a mechanical one yourself.

The tiller’s electric starter is connected to the battery, from which it receives power. The electric start of the device is carried out using the start button. The battery determines the power of the electric starter and the duration of the operation of the device. Installation of an electric starter is carried out according to the electrical diagram of this design. Tiller with electric starter is durable, reliable, long-term.

Unfortunately, not all designs of manual cultivators can be converted into spring or electric ones. Therefore, before starting work on replacing the manual mechanism, you need to study the instructions and the capabilities of the tiller and find out if such an alteration is possible.

Farmers should be aware that at the beginning of work, all cultivators are working properly. Gradually, on the assembled unit, various components fail. In order to extend the service life of the tiller and all its parts and assemblies, it is necessary to regularly inspect the mechanism and properly maintain it. All assemblies and components must be periodically lubricated with machine oil and checked for performance. To increase the productivity of the cultivator and extend its service life, constant proper care of this technique is necessary.

Installing the starter on the tiller

There are various designs of starters:

- manual;

- spring;

- electric.

The most common is the manual starter for the tiller, since this device is very easy to put on the tiller, and its repair is easy to do on your own. If such a device is used correctly, then its durability is several years.

Consider what elements a starter for a tiller consists of:

- a drum-shaped body;

- springs: large and small;

- washers;

- coil;

- cord;

- reeds;

- fastener parts.

In the center of the drum there is a reel on which the cord is fixed. A large spring is located in the body around the axis and is designed to return the coil to its original position after scrolling.

The mechanism of this device is quite simple, you can assemble it yourself.

Tiller operation with a manual starter is carried out as follows. The driver starts the mechanism by pulling the handle of the device. In this case, the device starts to work and starts the engine. In order for the device to successfully transfer the initial rotation to the motor, the handle of the device must be pulled twice.

But despite the fact that the manual starter on the tiller is considered a reliable device, it also sometimes fails. If the structure breaks down, you can repair it yourself.

DIY electric starter on the tiller

In order to make an electric starter for a tiller with your own hands, you must:

- select the main structural elements: body, coil, small electric motor and cam mechanism;

- prepare wires, bolts, nuts and other fasteners to connect parts;

- according to the wiring diagrams and drawings of the factory device, connect the motor to the working elements by connecting it to a 12-volt rechargeable battery;

- after checking the circuit for operability, put all the components of the future starter into the case;

- install the resulting electrical device on the tiller and connect using wires.

How to make a manual starter on a tiller

As in the case of making an electric starter from improvised means, making a manual starter for a tiller (Neva, Oka, Cascade, Patriot and others) will be an easy task for a craftsman with the appropriate knowledge.

To assemble a homemade kickstarter, to the materials and procedure described above, you should add the installation of a handle for transferring force manually, which will replace the operation of the electric motor. The kickstand of the recoil starter can be made from a thin metal tube, which will need to be bent into the shape of the foot and installed in the hollow hole of the reel. After assembling the device, be sure to weld it.

What starter is installed on your tiller?

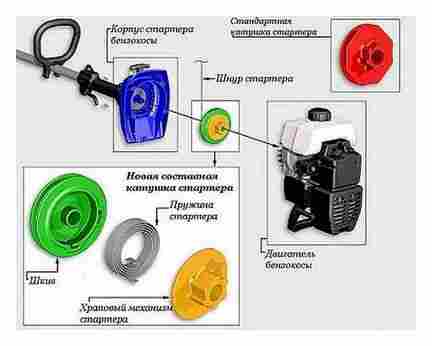

Disassembly of the starter unit

The launch mechanism is disassembled in order to install new parts instead of broken ones in the following sequence:

- unscrew with a screwdriver the screw fixing the pulley with the starter cover;

- take out the spring and antennae;

- carefully remove the pulley (you need to turn your head away or work, wearing glasses and gloves first);

- determine why the trigger is broken;

- if the spring has collapsed almost completely, then it is replaced;

- when the spring comes out of the hook, it is installed in its original place, bending the antennae in front of this (the photographs show the laying process);

- after the spring plate is installed inside the groove, carefully twist it.

To change the spring, you must work carefully and carefully: it can accidentally burst under the influence of the force caused by installing it in place. Even if you carefully remove the roller, the spring strip very quickly flies off the reel and can injure your hand with its sharp edges.

It is not always possible to immediately put the spring plate in its original place. It often slips, so attempts must be repeated until the desired result is achieved.

Chainsaw starter repair

The first step is to twist and remove the lid, make a visual inspection. Chainsaw starter breakage can be different. a broken spring, a defect in the pulley (“coil”), a worn winding cord.

Next, we prepare tools for repair. these are screwdrivers and round-nose pliers. In the event of a break, you will need a new cord. I think the lumberjacks have a supply of starter cord. If it is not possible to purchase a factory cord, then you can replace the “forced” with a clothesline, choosing the appropriate diameter.

The device and principle of operation of the chainsaw starter

Most well-known chainsaw manufacturers equip their products with starters that work on almost the same principle. Its essence is as follows: in the groove of the saw body there is a handle through which the cord is passed.

When the handle is suddenly lifted, the cord is pulled out, which engages the drum, which is in the ratchet mechanism. This drives the spitz drum, which is located on the shaft.

During this, the crankshaft makes a couple of revolutions, which leads to compression of the fuel mixture, which at this moment is located between the cylinder head and the piston. When the handle is lowered, on the contrary, the ratchet and the spitz loses their contact, which leads to a stop of the shaft.

With an increase in the power of the chainsaw, the amount of the fuel mixture increases, which should ignite when the chainsaw is started. In this case, to start the engine, it is necessary to increase the number of jerks of the starter cord.

To speed up the return of the drum mechanism, manufacturers use a special steel starter return spring, which has excellent elasticity.

Leading brands are using other methods to make it easier to start a chainsaw:

- Pre-enrichment of the fuel mixture using a separate flap;

- Installation of an automatic decompression valve, which reduces the pressure inside the cylinder of the chainsaw;

- Installing a primer designed to pump fuel before starting the engine.

The use of one of these technologies significantly facilitates starting and extends the life of the starter, which is especially noticeable at low temperatures.

Chainsaw starter: device, breakdowns and DIY repair

In the design of the chainsaw, the starter is responsible for the proper starting of the tool’s engine. Over time, owners of chainsaws are faced with the need to repair this important unit. And the sooner it is possible to eliminate the malfunction, the less other important parts and mechanisms of the tool will succumb to wear.

Chainsaw starter diagnostics

Due to the long-term operation of the chainsaw, the starting mechanism becomes unusable. After one or more jerks while pulling the starter rope, the crankshaft will not turn. This problem can be caused by the following reasons:

- cracked or broken drive pulley;

- the chainsaw starter spring burst;

- gust of launch rope.

Before starting work on diagnostics and repair of the launch mechanism, it is necessary to prepare the necessary tools and accessories, which will significantly reduce the time for operations. These include:

- A set of locksmith’s screwdrivers and a specialized set of proprietary tools included in the delivery of the chainsaw.

- Durable lanyard to replace worn-out starting rope.

Chainsaw starter spring

At the first stage of repairing a chainsaw starter, it is necessary to identify the nature of the problem. To do this, remove the side cover from the side of the starting mechanism, while unscrewing only a few screws. Depending on the manufacturer, this operation will require a specialized or conventional plumbing screwdriver.

How to Replace the Starter on a Trimmer

Next, we inspect the inside of the protective casing. In the absence of cracks and chips of plastic, we proceed directly to diagnostics of the launch unit.

We unscrew the central bolt of the starter and dismantle the spring. There should be no cracks or tears on its surface.

It is problematic to choose a spring similar in force and number of turns on your own, therefore you will need the help of specialized centers.

After removing the clip and the chainsaw starter spring, a pulley with a wound cord is available for dismantling. The integrity of the rope indicates that every detail of the launch mechanism needs to be carefully reviewed.

Spring repair

If the material of the starter spring is found to be of poor quality, the spring will burst (usually at the point of its attachment to the drum, where it forms a loop). In this case, you should not replace the spring.

Thoroughly clean its surface from dirt and traces of grease, gently grind the place of destruction, then release the spring at 600. 650 ° C (the steel of the spring should acquire a crimson color).

It is necessary to cool the spring slowly, and at 100. 150 ° C it is already possible to gently wrap its end in the shape of a restrictive protrusion on the inner surface of the drum (steel will acquire the necessary plasticity) and insert it into place. Simple repair of a chainsaw starter repair starter chainsaw how to properly pull the chain on. The elastic properties of the spring will not change.

The main malfunctions of the trimmer starter

It is not difficult to determine the cause of the breakdown of the triggering device. There are several main options:

- break of the cord (rope);

- when the spring breaks or disengages.

The above details are shown in the photo below.

It may happen that the starter mechanism is accidentally broken. The consequences will be disastrous if the broken rope is wound around the flywheel of a working internal combustion engine: then the spring will burst, the pulley will break.

But such cases, when a complete replacement of the starter unit is required, are extremely rare. In most cases, to fix the mechanism, it is enough to install a new spring or replace the cord.

Do-it-yourself gas drill starter repair, lawn mowers, trimmer

No matter how high-quality gasoline equipment you use, anything can happen to it during the construction process, and at the most inopportune moment for this. Difficulties often arise due to starter failure. Starter replacement petrol trimmer zigzag.

We will now consider a more widespread case when the breakdown is not so serious and will show how to repair the starter with our own hands, if the cord breaks off without any destructive consequences or does not unwind due to the fact that the spring inside just flew off, out of engagement. At the very least, at first there is a desire to believe in it. But in order to find out whether this is so or not, it will be necessary to disassemble the starter.

STARTER: INSTALLATION

In the fierce winter, instead of sleeping like everyone else, my friends and I decided to build ourselves a chopper. They “dug up” two “Urals”, “Dnepr” and. forward. To bring beauty, to chrome something. not a question, but to start with a button. yes! There were three problems, and we solved them in our shed.

The first is the starter ring. It was developed and produced in Rybinsk and is installed on the Buran snowmobile. We bought it without a snowmobile. individually, attached it to the flywheel, centered and marked the holes for attaching the crown to the pillars of the driving clutch discs. They drilled out and countersunk for the bolts “in the hole”. Outside holes

we drill the drive disc to the diameter of the racks (with an allowance of 0.5 mm).

| Fig. 1. Modification of the starter ring of the snowmobile “Buran”: 1.crown; 2. holes for attachment to the flywheel; 3. “extra” part of the crown. |

The second problem is the starter itself.

Here the unit from the starting engine of the T-170 tractor came in handy. You can also use a starter from the “Whirlwind-30” outboard motor. brand ST-367A.

| Fig. 2. Detail of fastening of the starter (welded to the crankcase). |

The third is to install a starter. First, we picked up the starter mounting bracket. In shape, it resembles a part of a bell, inside which you need to place the starter more tightly. We did not saw this part, but found a suitable one. part of the crankcase of the starting engine (therefore we do not give exact dimensions).

Then a cutout was made in the clutch housing for the starter mount, the motor was assembled for the final welding of the starter mount: a crankshaft and a flywheel with a crown are inserted into it.

Then the plug of the bendix was removed from the starter, and the bendix itself was fixed in the “on” position. The starter assembly with the fastening part was laid with the bendix gear on the flywheel crown, and “grabbed” by argon-arc welding. Rotating the flywheel, we checked the correct installation of the starter on the lateral engagement of the gears and the radial clearance between them. After adjusting the starter, the fastening part was finally scalded.

For a more reliable fixation of the starter, its rear part was compressed with a powerful clamp made of steel strip 3 mm thick. A plate is welded to the clamp, which is attached to the rear cover of the gearbox. Where necessary, we sawed down the stiffeners and fastenings of the air filter on the gearbox housing. That’s all!

So putting a starter on opposed turned out to be easier than steaming a turnip. And the measurer was not needed. The tools used were a drill, a file and a hacksaw. True, I had to take a ride to the regional center for argon, but this is not something to look for a jig boring machine.

text: Vladimir NESTEROV, Nugush village, Bashkortostan

drawing: Oleg VOYEVODOV