How to properly sharpen a chainsaw chain on a machine

Chainsaw sharpening angles and tooth configuration

To be able to sharpen the chains correctly, the first step is to figure out which functional elements a single link or cutting element consists of:

- Base. the lower part of the tooth, which has holes for connection with the rest of the chain elements and during operation hides in the guide channel of the bar. It is this part that is lubricated.

- A special stop is an element of the tooth structure that allows the cutter to remove only a certain thickness of wood chips in one pass. Thanks to him, the chain does not get stuck in the fibers, and the chainsaw does not wedge.

- The so-called tooth scapula is a cutter consisting of vertical and horizontal working surfaces that form cutting edges.

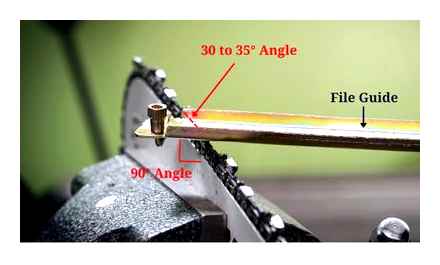

Tooth blades, or cutting edges, must be sharpened at a specific angle, otherwise it will be difficult to achieve optimal sawing characteristics of the chain. The upper blade (horizontal) has the function of plunging the tooth into the wood and forming a groove. Side or end blade (vertical) helps to trim fibers from the side.

The most important thing when sharpening a chainsaw is to achieve the correct upper blade angle, which should be between 60-50 degrees. The angle of the end blade is maintained within 85-60 degrees. It is also worth adhering to the angle in the plan (sharpening angle), namely, what is clearly visible when you look at the chain link from above. it departs from the side edge along the front mowing line and should be 10-15 degrees.

The productivity of the operations of sawing wood in the transverse direction increases if the angle of sharpening of the chainsaw chain is increased to the maximum possible and vice versa. Chains designed for longitudinal cutting of a tree trunk should be sharpened at an angle of approximately 10 degrees.

Under no circumstances should the depth gauge be touched once more: improper grinding can lead to vibration during tool operation. Its debugging is done according to a special template.

Manual file sharpening at home

A flat file can be used for the tooth stops. The sharpening template is attached to the sharpened element.

Stages of manual sharpening of a chainsaw chain at home:

- fix the chain (bar) so that it is completely motionless;

- do not change the sharpening angle during the entire sharpening;

- perform 2-3 forward movements with a file with light pressure;

- turn the file in different directions;

- sharpen to the size of the smallest tooth.

How to sharpen a chainsaw chain with a file with your own hands. about this video below:

Sets of necessary tools, templates and accessories for sharpening the chain

Most popular chain sharpening tools:

- round file;

- flat file;

- holder;

- depth gauge template;

- sawdust removal hook.

Sharpening filesChainsaw chain sharpening machine Sharpening angle control template

The sizes of files for sharpening chainsaw chains are different, but in everyday life for household needs and home use for sharpening chains with a pitch of ¼, 0.325 ″, 3/8 ″ and 0.404 ″, files with a diameter of 4.0 are recommended; 4.8; 5.2 and 5.5 mm. Some chains use cylindrical files with a diameter of 3.2 mm. For manual sharpening with your own hands, a file 200 mm long with a diameter of up to 5 mm would be ideal.

Some manufacturers sell these tools with sharpening kits, you can also purchase them separately. The round file is one of the most popular tools that many owners use to sharpen their chains as well as on machine tools. Each set is designed for a specific chain pitch and size. To find a set for sharpening chains, you need to know these two parameters.

There are markings on the holder. they help the owner of the chainsaw to determine the correct angle position for sharpening the chain. The holder is installed simultaneously on the upper part of the stop and the tooth, and the round file is placed under it immediately near the blade. The holder holds the file at the desired height, according to the norms, it should rise 1/5 above the blade.

To sharpen the chainsaw chain at home, the tire is secured with a vise or clamp. It is important to keep the tool still while sharpening. The holder is placed on the markings, and then the file is moved along the chain from itself 2-3 times. Each tooth is treated the same way. From time to time, the file is unfurled with the other side so that it does not grind unevenly.

For convenience, the teeth are sharpened evenly on one side, after which the saw is turned over and aligned on the other side.

HOW TO SHARPEN A CHAINSAW CHAIN.

Start sharpening with the smallest tooth, since the length of the remaining teeth must match it. When the blades are sharpened, the stops are processed. A template from the set is placed on the chain so that the stopper falls into the hole, all protruding edges are grinded with a flat file from the sharpening set.

Sharpening the chain with a file

The most common technology in the private sector, when the chainsaw is operated at an amateur level, and there are no special devices at hand. In practice, in everyday life, the simplest version of sharpening is realized. with a round file. Its recommended diameters: for chain size 1.3. by 4, for 1.6. by 5.

And if there is no ruler nearby, and it is impossible to measure the parameter exactly, up to mm? How do you know which file you need? There is such a selection rule. the tool in the middle part should not protrude above the tooth by more than 1/5 of its section. It is marked in the picture (on the left side).

But sharpening the chain with only one file, “by eye” is an extreme case, and then, if the employee has the highest qualifications, extensive experience in this matter, and the sharpening of the edges is done only 1. 2 times, no more. That is, when the chain only needs to be straightened. But for its systematic bringing into working condition, such a technique is clearly not suitable.

It is recommended to purchase a special chain sharpening kit along with the chainsaw. It usually contains 2 files (round flat), a link cleaning hook and a depth gauge.

(depends on the manufacturer). This will allow you to sharpen more correctly without violating the factory parameters of the chain. Taking into account the cost of the chainsaw, the costs are insignificant and quite reasonable.

Popular models of inexpensive sharpening machines

Popular manufacturers of inexpensive chain sharpeners: Dnipro, Einhell, Sadko, Vitals, Forte, Intertool, Eltos, Zenit, Grand, Stern, Temp.

Machine types

Manual. The most commonly used chainsaw machine is the manual one. This is a grinding wheel, the diameter of which varies depending on the size of the chainsaw. While the process of using the machine seems straightforward, it needs precision. Given that sharpening is done by hand, the user needs a high degree of control to maintain the correct sharpening angle of the chain.

Oregon 520-120 and 410-120 Electric Chain Grinder Instructions

Mechanical. Another popular chainsaw sharpener is the automatic option. When using a rod-mounted rail, the first step is to place the saw on a flat, stable platform such as a table. The operator then needs to attach the guide to the chainsaw, place it on the bar and secure it in place. Thereafter, various adjusters on the machine must be set in accordance with the sharpening requirements. This includes depth of field and feed angle. When using the guide, it is important to be careful with the chips that come off the blade. It can harm you and therefore it is best to work with protective equipment.

How to Sharpen a Chainsaw?

Electric models. A fairly popular option is an electric machine. Today it is one of the common tools used by professionals. An electric chainsaw chain sharpener differs from others primarily in terms of the time spent on the task. In fact, using an electric version of the saw is a quick way to sharpen a saw. In addition, there are a large number of electric sharpeners on the market. They come in a variety of sizes and fit every budget. As with mechanical models, protective equipment must be worn when using an electric machine. Gloves, goggles and overalls.

Using saw chain sharpeners can be beneficial as it will speed up the process. People choosing this method should be aware of the rules for using the machine and setting it up. Using the correct settings is of paramount importance as chains break easily when sharpened by a tank that is incorrectly set. In addition, operators must pay close attention to the amount of time the grinding wheel or stone is in contact with the teeth. Proper chain sharpening should be a part of every tool owner’s maintenance. This is necessary to improve the safety and efficiency of using the chainsaw.

Also check out our article on how to file a chainsaw chain. Simple, cheap and effective.

Tips and tricks for sharpening at home

“I noticed that different sharpening angles are indicated on the chain boxes, they differ for different chains. The factory angle, for example, is more than 25 degrees, everyone writes that it is not less than 35, and in order to cut pine well, I set the angle to 40 or 45 degrees. Some machines do not move the chain back and forth, so they don’t stand next to the factory sharpening at all! The thickness of the grinding wheel is also individually selected, and you constantly need to control the shape of its edge “.

“As a craftsman, my opinion is that file sharpening is the best in the world. Machine tools are, of course, good, but still heed the advice of an expert, I have been working with chains for ten years, no less. The machine will give you only 30 degrees horizontally and 45 degrees vertically for sharpening, and a file up to 10 degrees horizontally. The vertical of the file in degrees is the same, but the shape of the cutting edge does not change, and the working blade becomes wider. No other attachment will do this! Second: the machine always overheats, which is bad for steel, but the file does not. Third: the file spares the teeth, if you use it, the chain will last about six sharpenings, two longer than after the machine.

The main disadvantage of work is that you need to train to work with a file! Practice and only practice “.