How to properly sharpen a hacksaw on wood with a file

Important nuances

Not every master can sharpen the tool correctly. To do this, you need to know the technology well and have considerable experience behind you. Do you want to comprehend plumbing? We assume no.

For home sharpening of a hacksaw, it is enough to learn a few rules:

- A hacksaw for wood with fine teeth is sharpened with a file with a sharpening angle of 30 degrees, and with large ones. 75 degrees. They should have a coarse or fine velvet notch. Optimal use of a new sharp file.

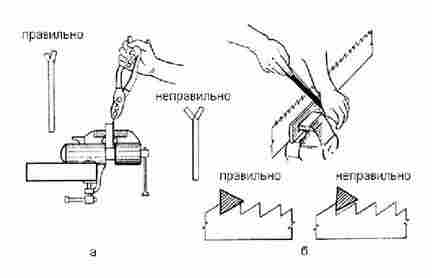

- When spreading the saw teeth, it is necessary to ensure that the bend is symmetrical along the entire cutting edge. For cutting dry material, the optimal setting width is 0.3–0.5 mm, for raw wood. 0.5–1 mm (in each direction). The bend is made from the middle of the tooth, and not from the base. So less likely it will break off.

- The teeth must be of the same height. Press the cutting end vertically against a flat board lined with paper. You will see which teeth are protruding. Fit them flush with the other teeth. If a few teeth are sharpened more than others, leave it as it is. In a situation where all the teeth are out of order, they are approximately equalized.

- Sharpen the tool correctly in a vise or other clamping tool. In addition, protective gloves should be worn. These are basic safety rules, you should not neglect them.

- Movements with a file should be done only in one direction. away from you. At the same time, they need to carry out smoothly, if possible with even pressure.

- If burrs have formed on the teeth, remove them from the side edge of the blade with a wet whetstone. Otherwise, they will chip off. and the cutting edge will quickly become dull.

Sharpening a hacksaw is a painstaking job that requires 100% attention. It is recommended to perform it in silence and solitude. Distracted by conversation or music, you risk cutting the wrong area or getting injured.

Sharpening a hacksaw with a file step by step

To quickly return the hacksaw to working condition, arm yourself with pliers and a file. Progress:

- First you need to inspect the cutting edge. The saw teeth look in different directions through one. If any of the teeth bent, we return it to its place with the help of pliers.

- Now you can sharpen the hacksaw with a file. Install the tool tilted away from you (approximately 45-50 degrees).

- Find the first tooth that points outward.

- We draw a file on it from ourselves several times. We sharpen the tooth on both sides so that it looks like a shark’s tooth. This is how it should look like:

- Skip the next inward tooth.

- We sharpen the third tooth following the example of the first. We process all the teeth (through one) to the end of the hacksaw.

- We turn the hacksaw over to the other side and again set it at an angle from ourselves.

- We sharpen all the teeth directed outward.

When moving the file, it is important not to overwhelm the edges of the teeth. They are positioned at optimal angles from the manufacturer’s point of view. It is not recommended to change them without a good reason.

Grandfather taught how simple and easy it is to sharpen a hacksaw with a file

It is not worth explaining how important a good, serviceable tool is for a craftsman. At home, the easiest way is to sharpen a hacksaw with a file. Half an hour of time. and she will cut wood like butter.

A simple tool to help

It is difficult to sharpen a hacksaw with high quality without special devices and a machine, by eye. You have to constantly inspect the teeth to make sure that they do not deform, but become sharp.

Tooth setting

The setting of the teeth is required to prevent the blade from getting stuck in the cut. The process consists in bending the teeth relative to the blade in two directions at the same angle and distance. As a result of correct routing, free gaps should be formed, which will help to simplify the movement of the blade in the cut when cutting.

The standard is considered to be wiring at a distance of no more than 2 mm. Depending on the features of the application, the bend is made as follows:

- for processing dry wood. from 0.3 to 0.5 mm;

- for raw wood. from 0.5 to 1 mm.

The selection of the bend angle is carried out on the basis of the following principle: a larger angle will allow you to cut with a wide kerf, and a smaller one. with more effort, but a smaller cutting width.

For bending, special devices are used. The canvas is clamped in a clamp, installed on the work surface. Then the teeth are carefully bent with a metal die to such a distance so as not to break them.

The wiring is done step by step as follows:

- Cuts are made as marks to determine the thickness of the web.

- The prong is fixed in the hole made and bent with a die to the marked stop point.

- A similar procedure is performed with all remaining teeth.

Height leveling

After the setting has been made, the hacksaw must be checked for the same height of the teeth. Since the force could be applied unevenly to it, there is a chance of the appearance of teeth with less wear, which will protrude above the rest.

To identify these teeth on a hacksaw, you can use a simple method. It will need thick paper or cardboard along the length of the cutting blade. The sheet must be laid on a flat surface, for example a table, well leveled, and then forcefully press the cutting part of the blade against it. Prongs that are knocked out of the general row will make deeper dents in the surface.

This makes them easy to spot and correct before sharpening. To remove excess height, various files are used. During this work, you should strive to preserve the shape of each hacksaw tooth as much as possible.

Why and when you need to sharpen?

Qualified specialists know the following signs indicating an imminent saw failure:

- when sawing wood, the hacksaw starts to sound different;

- visually it becomes noticeable that the tips of the teeth are rounded, have lost their sharpness;

- the color of the teeth changes;

- sawing force increases;

- the direction of the saw is poorly maintained;

- there are frequent jamming of the teeth in the wood.

Breeding the teeth must always precede the sharpening process. When breeding, a deviation of the teeth from the plane of the hacksaw to the left and right at a certain angle must be achieved. Too small a tooth deflection angle will cause the teeth to “sit” in the tree. Conversely, a too large angle of deflection of the teeth makes the cut too wide, increases the amount of waste (sawdust) and requires too much muscle energy to pull the hacksaw. The purpose of sharpening teeth is to restore the following tooth geometry:

- step;

- height;

- profile angle;

- bevel angle of cutting edges.

We suggest that you familiarize yourself with Oak. a tree from the Northern Hemisphere To sharpen with minimal loss of time and quality, you need to use such special devices and tools as:

- Workbench;

- locksmith vice;

- pliers;

- sharpening bar;

- sandpaper;

- protractor and caliper;

- hammer;

- it is possible to use equipment that allows you to fix the hacksaw blade with an angle of 90 or 45 degrees.

Be sure to use the following files:

- with a triangular section;

- with a rhombic section;

- flat;

- set of files.

Throughout the entire sharpening time, the file / file must move without jerks, it is necessary to ensure constant pressure, the movements must be made without deviations from a constant angle. The sharpening process goes only with the movements of the file “away from you”. Return the file / file by air, while there should be no contact with the hacksaw.

When sharpening such teeth, a fine-cut triangular file is used. The direction of movement of the tool is an angle of 60 degrees. The hacksaw is fixed in the device at an angle of 45-50 degrees to the workbench. The file / file must be driven strictly horizontally (keeping an angle of 60-75 degrees to the hacksaw), starting from the first left tooth.

You need to start with “setting the movement of the hand with the tool”, for which they are held along each left edge of the odd row of distant teeth, which will give the hand movements the necessary automatism. After that, the same is repeated, sharpening the right edges of the odd teeth to complete the sharpening of the cutting edge and sharpening the tops.

The teeth of hacksaws for longitudinal sawing have an angle of less than 60 degrees, therefore they use files with large notches or a fine-cut file with a rhombic section. In this case, it is absolutely not recommended to use triangular files. For sharpening, the hacksaw is vertically fixed in the device. There are two methods for sharpening a hacksaw, which differ in giving different sharpening angles.

Straight. The file / file is placed at a 90 degree angle. It is given a direction parallel to the hacksaw, sharpening both the rear and front cutting surfaces of each tooth. This is repeated for the entire distal row of teeth. Then the hacksaw is turned over in the clamping device 180 degrees and the same operation is repeated for the other teeth, which will make up the far row.

Oblique. This method differs from the straight one only in the angle of the direction of the tool movement to the plane of the blade. the sharpening angle decreases from straight to 80 degrees. The process is exactly the same, but the teeth after sharpening resemble the teeth of a bow saw.

How to sharpen a hacksaw

To sharpen a hacksaw for metal or wood with your own hands, you need:

- Perform preparatory work.

- Determine for what purposes the saw is used.

- Grind with parameters that take into account the intended purpose of the tool.

Sharpening the saw with a file

Do-it-yourself hacksaw sharpening

If the exact parameters are not indicated in the instructions for the blade, the wiring is done according to the general rules: The overhang of the cutting edge in width should be 1.5. 2 of the blade thickness. A wider set is made for wet wood, or in the case of sawing along the grain. If, when processing such wood, the width of the teeth is small, the blade will jam in the cut.

Conversely, with wide layouts, it will be inconvenient to process normal wood across the grain. The cut will be uneven and you will have to work harder to pass the saw.

There are handy setters that can be used to straighten a long blade in a matter of minutes. However, such mites are expensive.

Most do-it-yourselfers use the old-fashioned traditional timing plates, with manual setting and stop.

The canvas is clamped in a vice, or pressed against the workbench using a long bar and clamps. The teeth are aligned through one, first one side, then the other.

Then you need to align the height of the cutting edges. To do this, a sheet of paper is placed on a soft flat board, and the canvas is vertically pressed against it (by the cutting part). The print will show which teeth have different heights.

Sharpening a hacksaw on wood with your own hands video from the master handyMEN

It is advisable to adjust the size to one level, otherwise you will have to make more effort when cutting. Of course, if one or two teeth are sharpened more, it is unreasonable to level the rest to this height. If the majority of the incisors are inconsistent, it is necessary to equalize their sizes as much as possible.

How to Sharpen Any Hand Saw Manually with a File | Ripsaws

After leveling, you can start sharpening the hacksaw on the wood. A hacksaw with a large tooth is the easiest to maintain. For sharpening, you can use a fine-cut file and a regular vise.

How to sharpen a hacksaw with a file

The use of a file is still relevant today, so let’s try to figure out how to properly sharpen a hacksaw at home.

Let’s start by installing the canvas.

It must be fixed, as already mentioned above, in a clamp or vice.

The vise cheeks must be made of wood, with a jaw width of at least 200 mm.

The movement of the file should be uniform, and the pressure on the teeth is made only when moving “forward”.

It is necessary to move the hand with the tool to the starting point freely, without effort on the incisors.

In one working pass, an even layer of metal is removed, this will preserve the step, height and profile of the edge.

The sharpness of the cutter can be reduced by the formation of burrs on the surface and irregularities after the passage of the abrasive.

A file cannot perfectly sharpen a hacksaw, but you can get high quality. after sharpening, the smallest file or a file and a touchstone will come in handy.

Burrs are removed by selective cleaning with a fine abrasive, and the edges are smoothed with a wet donor along the side base of the blade.

Having set a goal to sharpen the hacksaw correctly. pay attention to the preservation of the tops of the teeth. The same cutter height and correct setting affect the wear resistance of the tool and the quality of the cut. The same cutter height, correct setting affect tool wear resistance and cut quality

The same cutter height, correct setting affect tool wear resistance and cut quality.

Tooth setting

So that the tooth does not break during wiring, do not bend it completely.

Before sharpening the cutting element, it is necessary to check and correct the setting of the teeth. The quality of the wiring is checked visually and by measuring the width of the wiring.

The teeth of the hacksaw are diluted using a special tool. setting. Basic wiring is a small metal plate with a handle. A slot is made in the plate, a bit wider than the thickness of the hacksaw blade. To improve the quality of breeding, use a set with an emphasis, which, using a wing nut and a screw, is set at the desired distance and, thus, controls the amount of bend.

The breeding of the teeth itself is carried out in the following sequence. The saw is clamped in a vise so that only the teeth are above the vise jaws. They are alternately captured in the routing slot and bent in the middle at a predetermined angle in the desired direction. When using a set with a stop, the teeth are first bent to one side. Then the emphasis is rearranged, and the other group is bent in the opposite direction. The bending of the tooth is made in a smooth motion.

The quality of the tooth setting is checked visually and by measuring with a vernier caliper. A simple test is recommended to check that there is no excessive bending of individual elements. The saw, after setting, is pulled between the jaws of the vice, spread apart to a width equal to the setting width. Excessive bending of the tooth will prevent the blade from moving.

Tooth setting

The teeth deviate from the plane of the blade in a checkerboard pattern, for example, all even ones to the left, all odd ones to the right.

Only very experienced carpenters are able to cut wood saws by eye. This skill comes after several hundred diluted saws. Less experienced craftsmen are better off using a special tool. wiring.

The simplest version of the tool is a flat plate made of strong metal with a slot, into which the blade fits in, with a minimum clearance.

The saw blade should be clamped in a locksmith’s vice. The teeth should protrude slightly due to the jaws. The teeth, one by one, are clamped in the groove of the tool of the plate and bent in the middle part. The routing angle must be constantly monitored. First, all even teeth are bent in one direction, then all odd ones are in the other. At the end of the wiring, you can spread the sponges to the width of the wiring and stretch the canvas between them. If any of the teeth are bent more than necessary, they will touch the vise. They need to be fixed.

Canvases with hardened teeth are not subject to spreading.

General requirements for sharpening

On the basis of wood measuring 2 × 5 cm from a bar with a thickness of 2 cm or more, two rectangular isosceles triangles and a steel plate 20 × 3 mm are attached. A support plate-support made of plywood or OSB with a thickness of one and a half centimeters with dimensions of 15 × 40 cm is attached to the triangles and the same clamp plate is fixed to it from below on hinges. The plates are tightened with screws or studs with wing nuts. If installation at an angle of 45 ° is required, the plates are fixed to the hypotenuses of the support triangles, and if 90 °, then to the legs.

Hacksaw sharpening rules

To sharpen the saw, you will also need several files that differ in section and pitch of the notch. All of them must be serviceable, without knocked down or clogged with dust notch lines. To sharpen a saw on wood, the file must be moved smoothly, with constant pressure and at a constant angle. The working movement of the file is carried out “from oneself”. It should be easily pulled onto itself, practically without touching the metal surface.

Height leveling

With different cutting tine heights, the efficiency of woodworking is greatly reduced. The higher ones take on a greater load and are subject to accelerated wear, while the lower ones do not participate in cutting. The broach becomes uneven, jerky. Both the accuracy of the cut and the quality of the cut surface are reduced.

The alignment of the height of the teeth should be carried out before sharpening the blade. The height is checked as follows: the canvas is pressed against a sheet of paper lying on the table. The profile is printed on the sheet, and the height of a particular tooth can be determined from the print. To align teeth of different heights, the blade must be clamped in a locksmith’s vice. Prongs protruding above others must be filed down.

Tool for leveling the height of the teeth

How to sharpen a hacksaw on wood with a file

For sharpening, the hand saw blade must be clamped between the plates of the equipment in such a way that the teeth rise above them by one and a half to two centimeters. For different types of blades, sharpening a hacksaw on wood is carried out in its own way.

Fixing the saw sharpening file

To properly sharpen the cross hacksaw, the blade should be set at 45 °, the file should be selected with a triangular cross-sectional profile.

To ensure the proper quality of sharpening, the following sequence of actions must be observed:

- sharpen the left edges of the even (farthest from the master) teeth;

- turn the canvas over;

- sharpen the left edges of the even teeth;

- form sharp cutting edges and sharpened tops of teeth

Sharpening your hacksaw correctly

To sharpen a longitudinal or universal hacksaw, it must be fastened at a 90 ° angle. This requires a file with a diamond-shaped cross-section. The file moves in the plane of the desktop. The sequence of sharpening the teeth is the same as for the cross-cut saws.

In the course of work, burrs usually appear on non-sharpened edges, larger or smaller, depending on the thickness of the hacksaw blade. They should be smoothed with a “velvet” file or an abrasive bar of minimum grain size. Sharpening quality can be checked in two ways:

- To the touch. Should feel sharp, should not feel burrs.

- By color. No x glare occurs on properly sharpened edges under illumination.

The quality is also checked by a trial cut. The hacksaw should not be pulled to the side, the cutting surface should be smooth, without soaked wood fibers.

Requirements for wiring a hacksaw

The spreading width of the tops of the teeth corresponds to the kerf. Experimentally, it was found that the best width of the setting exceeds the thickness of the blade by one and a half to two times for hard varieties of wood and two to three times for softer ones. Considering the most popular saw blade thickness for wood, one millimeter, we get a divorce value of up to half a millimeter for hard varieties and up to a millimeter for soft.

Saw teeth in various shapes

When setting, it is also very important that all teeth bend at equal angles. Teeth set wider than the rest will increase pulling resistance and wear out quickly. The teeth that have already been set apart will not participate in the sawing process, and their tops will slow down the broach and reduce its uniformity, making it difficult to work.

Attention: the bending of the teeth is carried out starting from the middle part. An attempt to bend the tooth at the base leads to a decrease in the strength of the blade and to its destruction.

How to determine when it is time to sharpen a hacksaw

An experienced carpenter can tell when the saw is ready to sharpen by:

- the sound of sawing wood changes;

- teeth change shade.

A number of signs are also available to the less experienced:

- increased material resistance;

- it is difficult to maintain the perpendicularity of the cut;

- the blade does not adhere well to the mowing line of the cut, the line is deflected or bent;

- the blade gets stuck in the wood.

Before sharpening the saw, it is imperative to separate the teeth, that is, to ensure that they are deflected from the plane of the blade at a certain angle. Correctly set teeth ensure a kerf wide enough to prevent the blade from getting stuck in the material. If the teeth are too set, the kerf will be too wide, this will increase the loss of material, the pulling force, and also reduce the accuracy.

If you sharpen the saw correctly on wood, it regains its working qualities.

During sharpening, the following geometrical characteristics of the teeth are restored:

- step;

- height;

- profile angle;

- bevel angle of cutting edges.

Important: Blades with hardened teeth must not be sharpened. They are easy to distinguish. they are black with a blue tint. Regular blades can (and should) be sharpened in a timely manner.

How to sharpen a hacksaw on wood

Despite the widespread use of circular saws, reciprocating saws and electric jigsaws, the traditional wood saw is preserved in the workshop of every household. With a small amount of work or in hard-to-reach places where it is impossible to crawl with a power tool, a hand-held hacksaw still helps out. In order for the tool to work with sufficient performance, accuracy and quality, it must be sharpened on time.