How to put a mower on a single tractor. How to make a mitch for a mini-tractor yourself?…

Segment mower for a walk.behind tractor

The rotary mower to the walk.behind tractor is a type of attachment equipment, the function of which is to mow weeds and bushes in meadows and fields. This device successfully copes with the removal of grass in large areas, the soil of which is not treated with herbicides.

Often, the rotary mower is also called disk. this is due to the principle of its operation and constructive features. Depending on the method of connection with the walk.behind tractor, such a mower can be half.waist, hinged or trailed. Also hinged equipment of this type is classified by the location of the cutting elements in relation to the used motoblock. Therefore, the factors distinguish rotary mowers with the front, rear and lateral arrangement of cutting knives.

During operation on the site, the rotary mower is set in motion through the transmission and wheel of a motor block. The design of such attached equipment is extremely simple. one or more cutting discs along with the support wheel are fixed on the frame. As soon as the support wheel begins to move, the discs that make the mowing of vegetation begin to rotate with it.

Areas the use of rotary mowing is quite extensive. it can be used in pastures, meadows and large gardens. At the same time, the more discs are included in the design of the equipment, the greater the processed area can be.

What is a segment model of a mowing?

A segment mowing can be used for mowing soft and solid grass and stern. She easily copes with mowing both on a flat area, and repeats the complex relief of the fields. The cutting elements evenly cut the grass, even in the most dense and overgrown areas.

Segment mowel Neva KN- 1.one

The design of the segment mowing

The design of the segmented mower is not complicated, so it breaks less often and does not require special knowledge from the operator. A segmented mower of the frame and cutting elements, segmented knives that are fixed between two bars consists. When making progressive movements from the motor.block drive, the knives cut the grass like scissors. One segment of mowing with cutting fingers is in constant motion. left and right, the second is motionless. When the grass gets between the fingers, its stems are evenly cut off.

Thanks to the streamlined device, cut grass is evenly distributed in two directions from the walk.behind tractor. Uniform shafts are obtained, which are easily removed using rake and forks.

The entire structure is located on wheels and is attached to the walk.behind tractor or MTZ mini.submarine. From the edges of the structure there are special slopes that make it possible to adjust the height of the mowing. Of course, such a baby cannot cope with big lands, but to stock up hay for the winter of livestock in a private courtyard.

The design of the segment mowing

The main difference between a segmented mower and a rotary is its working organ (fingers). Due to its design, a segmented mower can work on areas with the most difficult relief. Deviation of the knife part of the mowing in relation to the walk.behind tractor can reach 20%. Among the various models of the segmented mowing, models for the Neva, Salute and Cascade motor blocks, MTZ, Dofan mini.tractors are distinguished. Popular include KNS 0.8, KN- 1.1, km- 0.5, which are produced by Automash in the city where motoblocks and MTZ ministers are gathering.

Self.manufacture

Surely the reader has already matured the question “but whether to make a mower to the Neva motornote with your own hands?”Well, nothing is impossible in this. Only in order to create a truly high.quality and relatively safe device at home may need months of hard work, plus tools and materials.

The main thing that needs to be made first is a strong metal frame. For this, iron corners are suitable that can be welded to each other. After that, you need to decide on the configuration of the future braid for grass and start working on the tool itself.

Variant of a homemade rotary mowing

- Two working discs are removed from the old grain tractor seeder, and a chain and a gearbox from a chainsaw are used as a drive.

- It is necessary to separately make blades with your own hands and, using the holes pre.drilled in the disks, fix them on the disks.

- The knives should be mobile so that there is less risk of damage if the braid for the grass “finds” a stone or another hard obstacle in your meadow.

- It should be noted that the discs of the braids should rotate towards each other. Otherwise even herbal rolls will not work.

As a result, something similar to this photo should be obtained.

How to make a finger mowing

- You will need to take two metal beams up to one and a half meters long and drill a dozen holes in them for bolts.

- The bolts between the bars will need to be fixed by the separately made rail with cutting edges.

- This whole design should be attached to the hard frame and stayed with two guides.

- Just like for the rotary unit, you will have to make a belt drive with pulleys and bearings.

Of course, the work is interesting for the Samodelkin, but the factory attachment equipment is almost always more profitable than its own.

If you want to choose a mower for the Neva MB 2 single tractor, study all the features of those areas on which you need to work. Universal tools, as practice shows, in this category there is no.

The most reliable criterion for choosing can only be the experience of those who themselves used such devices. In any case, the mechanization of the haymaking, especially if it is conducted in significant volumes only by one person, this is a significant plus for a personal economy.

Popular models

Domestic manufacturers produce these units in various configurations. A common braid is the one that is produced under the Zarya and Zarya 1 brand. the product of the Kaluga OJSC Kadi.

This multi.purpose model. It is distinguished by high production indicators, ease of management, ease of installation and maintenance. The mechanism of attaching the braid frame to the rotary node of the motor block is simple and universal, approaches almost all domestic cultivators.

Another model widely used by farmers is KR-80. It is suitable for operation in combination with the motoblocks “virgin lands”, “Neva”, “cascade”, “Oka”. You can mow grass, coarse shrub, cereal crops.

Similar characteristics are possessed by the rotational suspension mower KRN-1. Produced in the territory and Belarus. Installed on most leading units. It has modifications designed for industrial field processing.

Before acquiring an installed addition to the walk.behind tractor, it is necessary to find out the characteristics of their compatibility. Daewoo Daewoo Daewoo Cultivator is sometimes sold with additional nozzles from the same company. They easily combine with its leading mechanism. Cosocosers of other manufacturers may constructively differ, which will prevent or nullify the attempt to connect a walk.behind tractor with a suspended unit

When buying this or that agricultural equipment, it is worth paying attention to this issue

Classification of braids

There are several main types of mowers that are different in their functionality and characteristics. The main differences are manifested in the nature of mowing elements. For self.assembly of equipment, it is necessary to determine the type of equipment required.

Rotary

Rotary options are considered the simplest and most common. Main parts:

- support frame;

- cutting wheels fixed to the frame (2-3 pieces);

- Side Slacks for Adjusting Affairs of the Superior Superior and Movement.

Important! Any rotary device does not require significant knowledge during operation. Also, such equipment has minimal requirements for the walk.behind tractor according to its characteristics and power.

Among the common options are “dawn”. There are also many special and universal models on the market. Manual creation of a rotary type mowel is the simplest.

Segmented

The segment design of the equipment for the bevel of grass has several differences from the rotary version. Main parts:

The main advantage of this type of mowing is considered the performance and uniformity of the bevel. There is a protective casing that is located directly above the working part.

Important! The segment type is demanding on the power of the unit. It is intended for dense grass and thick thickets of weeds.

Various types of motoblocks have their own unique equipment models, which are designed specially. Less often on the market there are universal options.

Pitch-brewery

The punching pitch is considered a special option that is used for heavy motoblocks. Application is possible for both the bevel of grass and cleaning ice and snow. You can use the technique at any time of the year. This type of equipment is used for large volumes of operation.

Production of a mower: step.by.step instructions

In the manufacture of any type of equipment, the initial stage will be a selection of all tools. After that, a drawing is created by which you can determine the main required elements and details. Next is the process of assembling the device. For each type of mower it is his own.

- discs are taken in the amount of two pieces from any device. The chain can be taken from the chainsaw. A gearbox is prepared;

- The diameter size of the pipe for the axis is needed within 1 centimeter. The axial shaft is delayed;

- discs are fixed on the frame, which is connected to the sewing shaft drive. Disks have rotation towards each other. This allows you to make small grass rows.

The assembly process of segment equipment:

- Bars are prepared with 12 identical holes for the bolt with the marking “M8”;

- There should be a guide rail on a bolt mount. Its length is 89 cm. Also on the rail, teeth and knives are previously fixed;

- Rights and scenes are created on both sides of the bars;

- A small wheel is installed from below the frame;

- The haymaking of the seno.block is connected to the motorcycle unit through the power shaft.

The creation of a homemade mowing mowal has several stages. Step-by-step instruction:

- A metal sheet is placed on the frame;

- Further on the frame, two canning cans without a bottom are fixed;

- Disks are installed on banks. External discs should have a diameter section of 20 cm, and internal. 17 cm;

- there is a pair of disks with the help of bolts;

- The blades to the disk are attached at the same distance from each other;

- The drum part is inserted into the sleeve and fixed to the frame;

- A leaf made of steel angles on the frame is installed;

- drums are connected by transport tape;

- The fasteners of the lower type of lower type are carried out;

- The corners are fixed to the drum.

Facilitate your work with a mowing on a single tractor

After the creation, you need to connect the device to the walk.behind tractor.

It should be borne in mind that any connection with homemade technology is made only in reverse mode. It will be necessary to connect the devices through the lifting nest. After that, the connection is stopped by a shkworm and springs. Before the initial run.in and checking, it is necessary to unload the walk.behind tractor, since excess weight will affect performance.

A haymaking on a single tractor can be either purchased or made on its own. If necessary, you can create any type of mechanism. It is required to comply with all the requirements and rules regarding the compatibility of the device and the motor.cultivator.

The creation of a mowing of any type is on a special instruction that must be observed.

Segmented

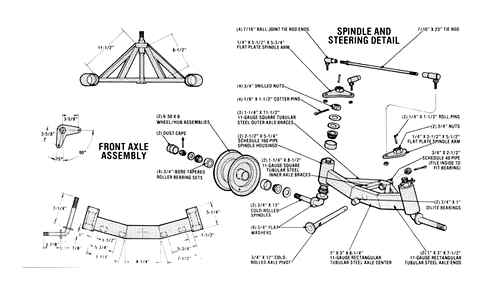

A segmented mower for a walk-behind tractor is a frame installed on a wheelbase and equipped with a cutting element of many knives that make reciprocating movements during operation. The height of the bevel is adjusted using lateral slopes.

Segmented mowers are not only more productive, but also safer than rotary analogues thanks to the protective casing located above the working part. The same.based tractor equipped with such a mower evenly mowing the grass, regardless of the relief and the density of thickets.

Under specific specifications of the motor blocks, segmented mowers with the function of neat laying of the grass in rows were developed for the convenience of subsequent cleaning.

Below are the technical characteristics of segmented type KN 1.1 mowers for Neva walk.behindists. To date, they are produced only in weigh such mowers about 45 kilograms, mush grass with stripes of 110 centimeters wide, a beard height. from 40 millimeters. During the hour of operation, it is possible to process an area of about 0.35 hectares with an average advanced speed of 5 km/h.

Today, there are many instructions in the public domain describing the process of making a mower for a walk.behind tractor with your own hands. As a rule, the main motive for the independent manufacture of a mower is the desire to save. Such a desire is normal, but it is only appropriate if you have the necessary materials and welding equipment.

If you need to buy or rent any of this, the point of making a mower with your own hands is lost. And spending 10-15 thousand on a reliable device created for work in almost any conditions, it seems no longer such a reckless solution. It should also be taken into account that the homemade device is several times more dangerous than the factory manufacturing unit. even for the simple reason that old parts from agricultural machinery are usually used to assemble it.

I FLIPPED MY TRACTOR. how I got it upright

General information

Hinged braids intended for motoblocks are divided into two modifications: rotary and segment. If a person has not previously used such units, he may have difficulties in choosing.

In this regard, we decided to make a brief overview of each species, and highlight the main advantages and disadvantages.

Rotor mower

This is a simple design that is two rotating disk. Is in high demand among farmers due to a relatively low cost.

Keep in mind that due to design features, rotary models are suitable for relatively even surfaces. The maximum allowable deviation is up to 20 degrees.

Among the advantages of such models, good performance, ease of maintenance and repair is highlighted. In addition, rotary braids put bevels in the rolls, which greatly simplifies further cleaning and drying.

The disadvantages include high injury hazard. Rotating knives do not have lateral protection, so if safety precautions are not observed, you can get a serious injury. In addition, rotating elements receive mechanical damage in a collision with stones or rhizomes of trees.

Segment mowing

In appearance resembles a fat saw. During operation, the elements make reciprocating movements, ensuring maximum removal of vegetation.

The required force is transmitted from the motor.block engine shaft. Unlike the previous model, segment mowers have a larger width of coverage. up to 1.1 meters.

In addition, the equipment is suitable for processing sections of various areas and relief. Of the advantages, an emergency shutdown mechanism can be distinguished, adjusting the angle of inclination and the lack of vibration during operation.

There are also many disadvantages of the product. This includes the high price of a mower, difficulty in repair, large dimensions and structural weight.

Knowing these features, you can choose a suitable model of attachment equipment. If there is no desire to spend money on the purchase of factory models, we will tell you how a mower is done for a walk.behind tractor with your own hands.

DIY pitch

In order to collect a mower of this type, the following materials will be required:

- metal corners for assembling the frame;

- four wheels (the larger diameter they will, the less damage to the lawn will cause);

- sheet (metal or plywood) 80 × 40;

- Two tin banks (ceremonial);

- 8 metal disks;

- 4 knife;

- sleeve;

- drum;

- transport tape;

- Fasteners.

The set of tools will be required the same as to assemble other types of mowers. Next, you need to perform the following actions:

- Collect the frame from the corners and fix the metal sheet on it.

- Remove the lid and Dona from the cans and fix it on the frame. At the bottom of the bottom on each jar, place the discs: from the outside with a diameter of 20 cm, from the internal. 17 cm.

- Combine the disks in pairs.

- Install the knives on the wheels at the same distance so that they can rotate freely.

- Install the sleeve in the drum and fix it on the frame.

- Connect the drums using a transport tape.

- Fasten the lower bushing bushing.

- Attach corners to the drum.

- Make sure there are protective elements on the knives.

- Install the device on one.axle tractor.

This is interesting: a mower for a motornote salute 5.

Rotor.type mower

This equipment can be used for cutting the Luja, as well as to cut fresh herbal cover into hay

However, it is worth taking into account that such a haymaking hay of high vegetation cuts off, and low grass simply crushes small grass. Equipment can be seen on this video

The main working elements of the device are knives, which are installed on the working discs by means of Shinka. The braid is driven by the power shaft, and sliding is carried out due to the rotation of the lower discs.

To make a rotary mowing frame with your own hands, you can use old metal corners or scrap metal, which is probably available on each craftsman. In order to save time for knives, you can use a tractor rotor. However, in this case, to improve traction and efficiency, it is advisable to reduce the length of the rotor from two to four centimeters, depending on the power of the unit used.

For the manufacture of the rotor, you need to make 2 round plates with a diameter of 390 mm from a sheet of metal or use the bottom for these purposes from an unnecessary tin barrel from machine oil. Exactly in the middle of these circles to weld the legs with which rotation will occur. The welded joint must be made durable.

Using kids tractors to plow dirt and cut hay compilation | Tractors for kids

For the lower support, you can take the disk from the luschtor, but its diameter should not be more than 450 mm. For the axial shaft, a pipe with a diameter not exceeding 30 mm can be used, and bearings 80, 106 will still be needed. On it to make a hole for attaching the lower bearing, and the second bearing is installed on the pulley. Put a device with knives on the axis, and then weld the pulley to the shaft. The rotation of the working discs will be carried out using two bearings.

Such a modification has a capture of 1100-1150 mm and the speed of rotation is 1500 about./min. The entire design of the braid is required to mount on the chassis boiled from a steel corner. For the safety of operation, it is necessary to install a protective casing on a homemade device. To simplify the structure, you can weld the lower drives of the rotary mowing on the frame by welding.

This homemade mower is able to cut off the vegetation cover at a speed of 8-12 km/h. At high speed, the grass is more crushed, and with a low one. integral. Such rotary type equipment can cut off vegetation 60-80mm and is used not only for mowing grass, but also for harvesting a personal plot from weeds.

Tool and materials

- welding machine;

- fasteners;

- metal corner;

- the bottom of the old metal barrel;

- eight cutting plates;

- wheel axis;

- two wheels.

Service and storage

The duration of the uninterrupted operation of the mechanism of a motor.block braid for grass directly depends on regular maintenance. Within the framework of the service work, the device is cleaned from herbal residues, dirt and dust. The degree of tightening of the threaded joints is checked. the weakened are pulled up. The tension of the belt is measured. Knives of the cutting mechanism should be sharply sharpened. To do this, they must be periodically removed and undermined. In a hinged position, it is forbidden to do this. Adjustment of the balancing mechanism is carried out after each fact of operation. Its spring part is checked and regulated.

Details of nodes subject to high friction are subject to regular lubrication. The conical gearbox, the section of the cutting timber and bearings, especially need it, especially. Lubrication is carried out only through the corresponding oil openings.

It is not recommended to pour oil or apply thick lubricating material in the rubbing areas not equipped with oil.liner traffic jams. This will lead to the sticking of dust and dirt in greased places, increase the degree of wear of parts and reduce their service life.

The procedure and list of works carried out for preparation for long.term storage is determined by typical characteristics. The main nuances of such preparation include cleaning of dust and dirt, removal of moisture from metal surfaces, coating parts with special anti.corrosion solutions. An important factor is the right choice of suitable storage location. It should be dry, protected from mold, drafts and other aggressive influences.

Additional information on how to prepare a rotary mower for the off.season storage is in the operating instructions from the manufacturer.

Look at the rotary mower on the Neva walk.behind tractor in action in the next video.

The price of a rotary mower to a walk.behind tractor

Price scatter, as well as a list of manufacturers, is quite large. For example, and a similar, but less powerful Aurora Grass 1000 unit will cost 13 thousand.

Homemade mowers for a walk.behind tractor

Consider several varieties.

DIY rotary mower

This variety of mowers is used under the haircuts of the lawn and for mowing grass on hay. It is important to remember that the model only cuts high plants, it only crushes low grass into small pieces.

The assembly of the mower is shown on the Neva walk.behind tractor and similar structures. The following elements will be needed for work:

Knives are made by their hardened alloy for 65 g. Four knives go to a separate disk. On each of the disks, a slot with a diameter of 6 millimeters is made using a fortified drill. The knives are attached using Shinka, it is fixed over the couch, regardless of the main knife mounting design. There is a small gap between the blade and the tire, about 2 millimeters more than the thickness of the blade. Such a constructive solution is necessary that while working with a mowing on a single tractor, the centrifugal force spread knives and they cut plants. It is important that the design can rotate freely in a circle (360 degrees). This is necessary to protect the knife when hitting hard soil, stones.

Making an adapter for a walk.behind tractor will help you move around the site faster.

The axis axes of the knife part are made of strong carbon steel, its diameter should not be less than 8 mm. The disk is to the end tightly, so that nothing interferes with the movement of the knife part. Photo of a rotary mower:

Then the frame of the rotary mower is cooked on a single tractor. Disks are installed on the finished basis and connected to the drive from BOM (additional elements of the walkover mechanism). This version uses gears with a checkpoint from a VAZ car. Drink rotation is performed in a counter position, against each other. Thanks to this, the grass squints through the rows. The last step is to install a protective element on the drive.

DIY segment mower

For the manufacture of a segment mower for a walk-behind tractor, you need a metal pipe with a cross section of a rectangular type of 1200-50-15 millimeters or a standard segment for grass. It is made on it 12 holes of 10 millimeters at an equal distance from each other. They are needed to install m8 fixing bolts. In the future, they will be fixed on them a guide metal strip (length 0.89 meters) with teeth and blades installed on all sides of the rectangular pipe.

The segmented mowing knives have backs with sections and clips of the drive lever. On a metal basis on both sides, presses and scenes are also mounted. The main wheel is installed on the chassis of the model. The working mechanism of the mowing operates due to the movement of the shaft of the development of the current motor. Drawing of mowers:

The segment mower is suitable for tops of potatoes and neat mowing of plants without grinding.

Homemade pitch-brey

The mechanism consists of 2 drums, they are attached with a frame and a fixation tape. The cart is made of cooked pipes and metal corners. Plywood and wheels falls on the base-frame. Plywood needs thickened (you can take a sheet of metal).

The tape is easy to make from a strip of rubber, it is connected in a ring using duralumin plates by 2 millimeters.

Another version of the drum braid to the walk.behind tractor is welding of metal parts:

Competent installation of a mower on a single tractor

The newly acquired product must be correctly installed on the equipment to provide the desired performance and quality of execution. Consider the approximate procedure for assembly and installation on the example of the rotary version:

- We check the supply package (from the model to the model, the set may differ, but, as a rule, it is a drive belt, frame, fitting, fasteners, rotor cover, hydraulic shuttle, supporting slopes, hydraulic cylinder, a drive belt tension system, rotors with knives, SIPs);

We mount the frame to the mounts of the walk.behind tractor so that it makes up with a vertical plane of 45 degrees and so that the slotted details look up;

We install the rotors on the frame so that their knives are located below. It is important that they are completely planted on a slot;

We attach the rotary cover to the same slot;

We fixed with the attached shplints and nuts;

We mount the tension system, pulling out the shoplint and unscrewing the counter.hack on the pulley. The next step, carefully knock out the pulley so that the key does not get lost. With a properly installed system, its handle will be directed up and fixed with bolts from SIPs;

Next, on the frame, we fix the slide with bolts from SIP so that their concave part looks inside;

We draw the rifs of the frame. they should be located outside the frame of the walk.behind. After that, we finally connect to the second mower;

We throw a drive belt on the pulley in the direction of movement. It is important that the one.axle tractor and mowing remain aligned;

We mount the hydraulic cylinder system. hydraulic shows (if the connection is provided on the walk.behind tractor).

At the end of the assembly, the product must be prepared for work:

- Activate a reverse on motor vehicles;

- remove cargo from the wheels (if there were);

- put the motor for small speeds;

- make a test launch on an even area without interference, checking the quality of the result and, if necessary, adjusting the knives and speed.

How to make a mower for a walk.behind tractor with your own hands?

It often happens that for some reason the manufacturer does not have a special mower on sale, specifically for this model, or that it does not suit her characteristics. In this case, it is easy to work on a homemade option. Full production on the basis of its economy will be demonstrated by the example of segment variation.

From spare parts, first of all, you need to take a rectangular pipe 5×1.5 120 cm long. An ordinary piece of old braids for grass is also suitable. About 12 holes are drilled on the pipe along the same distances, as drawings are shown.

You should prepare a frame from cooked corners and pipes, the frame can be covered with plywood and attached wheels to it. The tape is made by rubber ring.shaped. It is convenient to fix it with duralumin plates. Shrings are also welded on the frame to install the cutting strip. For the latter, a strip with metal blades is attached to a pipe prepared in advance with holes in advance.

Operation of mowers

The technique must be constantly lubricated. The frequency of this process depends directly on the frequency of use. The knives that are responsible for mowing the grass should be changed periodically.

Understand that it is not difficult to replace. Firstly, the technique will begin to work worse, and, secondly, in the state you can run a finger

It is important to check the territory before starting work. Since, if, for example, a collision with a stone occurs, the mower can be badly damaged.

The consequence for such an incident will be the replacement of the disk. The most common injuries that occur when using mowls are those that are obtained when it is included. Therefore, in no case can you start inspecting the equipment without turning it off in advance.

Correct connection of the mower

Subject to all recommendations, you can create a technique that, by neither in its life, or in terms of performance of the work required from it, will not be inferior to a single acquired model.