How to Remove the Gear from the Shaft of the Drill

There are several features when removing cartridges:

- You need to get to the fixing bolt, for this you need to spread the cams all the way.

- You need to unscrew the fixing bolt, then you need a head with a thin wall so that you can reach the bolt.

- It is necessary to twist, but not in the usual direction, since there is a left-hand thread, it is necessary to unscrew it clockwise.

- Since the fixing bolt is installed on the thread sealant, here two options are to unscrew it, or to heat the connection, but you can spoil the plastic elements, or a sharp blow, for this, an air or electric wrench with an impact mechanism is best suited.

- After the bolt has been unscrewed, it is necessary to unscrew the chuck, it’s good when there is a groove there, you can hook the tool on it and the chuck will unscrew, it is more difficult if there is no groove, then we clamp the bolt into the cams and unscrew it, gripping the bolt head with a wrench.

The moderator chose this answer as the best

add to favorites link thank

Under the brand name “Bosch9quot; (Boch), just a huge amount of tools are produced including screwdrivers.

In the beginning, it is necessary to determine how specifically the cartridge is mounted on the shaft, it can be a threaded mount and a conical one, and this and that is practiced in the Boch9quot; tool.

If threaded, then additionally the cartridge is attached to the shaft with a screw.

The screw head is most often a curly screwdriver.

We raise the cams of the cartridge until it stops.

Now we see the same screw.

The thread there is left and it is unscrewed clockwise.

Next, put the screwdriver in the “reverse rotation” position (reverse), the revolutions are minimal.

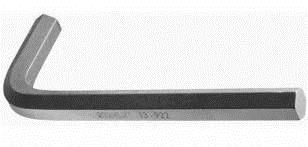

We clamp in a cartridge here such a six-sided “G9quot; shaped key

(naturally short end in cartridge).

And then everything is at your discretion, you can hit the key with a hammer, tear the cartridge from the thread.

If there is a sturdy table nearby, or a vice, then next to them we hold the same clamped key and turn on the screwdriver for a short time, the key hits the workbench, the cartridge is unscrewed.

To remove the cartridge from the screwdriver you need to spread the cams of the cartridge to the maximum, in the depth you will see a bolt for fixing the cartridge. It can be with a Phillips or flat head screwdriver, it can be with a head or special keys (sprockets, hexagons, etc.).

This means that there is a left-hand thread on it, that is, you need to unscrew it clockwise. It is necessary to hold the cartridge and unscrew the bolt.

Next, you need to unscrew the chuck itself from the screwdriver shaft, for this you need to clamp the knob into the chuck and hold the shaft with the key by the groove on the shaft (between the chuck and the body, usually this is a 14 key). If not, then you can use the power of rotation of the screwdriver to unscrew the chuck.

That’s all, reassemble in the reverse order; experts recommend dropping on a fastening bolt (the one inside), any compound for fixing the thread (you can even sealant or rubber glue).

It is quite easy to remove the cartridge from the screwdriver, you need to carry out some actions to unscrew the cartridge. Most screwdrivers have a screw inside the chuck that secures it to the shaft. To get to it you need to spread the jaws of the cartridge as wide as possible and there will be a screw inside that has a reverse left thread. Unscrewing it is not easy, especially if you have been using a screwdriver for a long time, it can stick and you will have to make a lot of effort to unscrew it, after that the cartridge must be turned counterclockwise with effort and it will be removed.

Add to favorites link thank

Bosch screwdriver. A reliable tool, indispensable for construction and repair.

Add to favorites link thank

02/11/2015 0 comments 6,545

Even the highest quality reliable and professional screwdriver wears out over time and each time it starts to keep getting worse with drills, nozzles and bits. To restore the instrument to its former power, let’s look at how to remove a cartridge from a screwdriver and what nuances are worth paying attention to.

How to disassemble a screwdriver chuck

To disassemble the chuck of a screwdriver, no special equipment is required, it is enough to have a few keys, a screwdriver, a hammer and, if possible, a vice on hand.

The design of the cartridge is an empty metal cylinder with a special ring and a sleeve for its adjustment. Inside the cartridge there are cams, fixing drills or special nozzles. The cartridge itself is worn on the shaft of a screwdriver. The cartridge may have a thread or cone, depending on the type of mounting on the shaft. With proper guidance, disassembling a screwdriver’s chuck will not take much time.

Before unscrewing the chuck on a screwdriver, you need to find out what type of fastening is in front of you.

Methods for attaching a chuck to a screwdriver

- Morse cone. The method is named after the inventor Stephen A. Morse in 1864. The essence of the method is the conjugation of two surfaces in the form of a shaft and a part with a hole, which have the same taper with an angle from 1 ° 25’43 ″ to 1 ° 30’26 ″ depending on the size. This method is quite widespread and has established itself as a simple and reliable.

- Threaded method. A thread is cut inside the screwdriver’s chuck, exactly the same thread is made on the working shaft of the tool. To tighten the cartridge, you just need to tighten it all the way, like a nut and a bolt.

- Fixing screw. Used for additional fixation of the cartridge on the shaft.

Types of Screwdriver Chucks

How to find out which way to mount the cartridge

To find out what type of chuck attachment your screwdriver needs to carefully inspect the marking of the tool. The inscription of the form: 1-6 B10 (may differ slightly). Means that the cartridge with a Morse cone. Numbers 1-6 indicate the diameter of the shank of the drill or nozzles, and B10 the size of the Morse cone.

The cartridge with a threaded connection is marked with the numbers: 1.0-11 M12x1.25. Symbols M12x1.25 mean the size of the metric thread, and 1.0-11. The diameter of the shank of the drill, similar to the Morse cone.

On imported models of screwdrivers, the thread is measured in inches, so do not be afraid to see the type marking: 2-13 mm ½-20 UNF.

Both types of cartridges perform their task equally well, the only difference is in the convenience and speed of changing nozzles from a screwdriver.

Marking on the screwdriver chuck

How to remove a chuck from a screwdriver

There are several ways to remove the cartridge from the screwdriver, we will analyze the first:

- We take a hex key about 10 mm;

- Clamp the key with the short end in the cartridge;

- We turn on the screwdriver for a couple of seconds so that the clamped key hits the second end on the table;

- We turn the key and unscrew the screwdriver’s chuck.

The second way that professionals recommend:

- First you need to completely unclench the cams of the cartridge;

- There must be a screw inside the cartridge, if it is not visible, it may be covered with dirt;

- It is necessary to unscrew this screw clockwise;

- Hold the hex key in the chuck;

- Turn the key sharply counterclockwise;

- The cartridge should be easily unscrewed, if not. You can lightly hit the hammer at the end of the key.

If none of the above methods work, you will have to disassemble the screwdriver and remove the spindle and gearbox together with the chuck from it. To do this, hold it in the tees and unscrew the cartridge with an adjustable wrench. On some cartridges there are special turn-key undercuts, which greatly simplifies this process.

To remove a cartridge from a screwdriver on a Morse cone, you need to knock it out with a hammer blow on the body.

These methods are suitable for disassembling the cartridge for all types of screwdrivers, drills and perforators. We also recommend watching a on how to disassemble a screwdriver’s chuck.

It has long been no secret that it is more convenient and faster to loosen and tighten the screws with a screwdriver.

Any tool has the ability to wear out and fail. This is especially true for moving and frequently used parts. In a screwdriver, such a component is a chuck. An element that is completely out of order should be replaced. But first you need to understand how the cartridge is removed. To do this, you need to know a little about the technical characteristics of the device. To carry out repairs, you will need a hammer, screwdriver, vise and some keys.

Methods of mounting a cartridge

Cartridges are most often attached to the shaft in the following ways:

- By Morse Cone

- Threaded way

- With fixing screw

Morse cone is one of the easiest and most practical methods that has been used since the 19th century. The plane of the shaft is processed in the form of a cone with the assigned parameters. A similar cone is in the middle of the cartridge. When they are combined, an operational and strong connection of the components occurs.

The following method is equipped with a thread that is cut at the edge of the power tool shaft.

The fixing screw is used for additional connection of the twisting cartridge on the shaft. Typically, a screw has a head for a Phillips screwdriver as well as a left-hand thread. It is necessary to unscrew the cams at the cartridge to the maximum in order to see it.

How to determine the method of attachment to a screwdriver

The fastener method is easy to learn if you carefully examine the details. The cartridge of the Morse cone variety will have the following inscription: 1-6 B10. This means that in the cartridge, attachment of nozzles with a shank diameter of 1-6 mm is permissible, and B10 is a pointer to the value of the Morse cone.

The cartridge, fixed with a threaded fastener, has the markings:

- Metric thread (domestic products). 1.0-11 M12x1.25

- Inch thread (foreign production). 2-13 mm ½-20 UNF

How to remove and change the cartridge

If you are faced with replacing the cartridge, initially, you should understand the method of fastening it. To carry out the procedure with a minimum of effort, experts do not recommend overloading a screwdriver in everyday use. If you operate the tool without interruption for fifteen minutes, the rotating parts may overheat and lock tightly into the socket. Then it will be more difficult to replace. Experts recommend proven cartridge removal methods described below:

Cartridge removal: Makita screwdriver

Typically, Makita brand power tools are equipped with a threaded fastener with an auxiliary lock using a left-hand screw.

A number of actions should be followed:

- Unscrew the fixing screw (clockwise).

- Activate the spindle stop button.

- Wrap the casing with a tight cloth and squeeze in a vice.

- Grip the hexagon in the fists.

- Hitting a hammer on the free plane of the key, the cartridge scrolls and then retracts from the shaft.

Chuck removal: Boch screwdriver

Bosch screwdrivers are usually equipped with a fixing screw.

- We put the key in the cams and tighten it for a couple of clicks.

- The tool is placed on the edge of the table.

- Pressing the stopper button, remove the cartridge lock on the shaft.

- The cartridge is removed against the clockwork.

All actions require special attention and consistency during disassembly / assembly.

After gaining theoretical knowledge about the types of cartridges, it will be easier for you to repair the Interskol, Hitachi, and other manufacturers screwdrivers yourself.

(1 ratings, average: 5.00 out of 5)

Did you know that screwdrivers appeared in our world thanks to space technology? Yes, indeed, the tool was invented for construction and installation work in open space. After some time, the engineers so liked the usability of the device that it was decided to create a special model range of screwdrivers and put it on open sale. Today, these devices are literally clogged with the construction market, and often even people who do not understand anything about this undertake to repair the devices themselves. Most often, the repair concerns the cartridge. Let’s look at how to disassemble a cartridge from a screwdriver.

What is a screwdriver chuck

A cartridge is called a solid cylinder, inside of which there is a sleeve or ring. The part is attached to the main shaft of the tool. For this, there is a special hole inside the cartridge. This is a tapered recess with a thread cut inside.

The upper part of the cartridge serves as a place for attaching the screwdriver nozzles. As you know, this part is one of the main ones in the whole instrument.

How to remove a cartridge from a screwdriver?

This question often baffles users. The fact is that there is nothing in the instructions about this, but the cartridge is a part that often breaks. To replace it, you must first remove and disassemble the hollow cylinder. Fortunately, you do not need special knowledge and skills for this. It is enough to include logic and ingenuity. So, for example, an ordinary ten millimeter hex key will help you solve this problem.

This is a banal and even slightly primitive method, but, as practice shows, it is precisely it that works today without fail and is much more effective than everyone else. So, hold the chuck at the small end of the key. Next, you will have to turn on the screwdriver, but pre-calculate the optimal speed of your tool.

Stand parallel to the table and bring the screwdriver a few centimeters to the surface. Next, turn it on. The task is to make the key hit the edge of the table and independently unwind the cartridge under pressure. Please note that it is necessary to hold the screwdriver as tight as possible. Otherwise, you have the opportunity to drop it from subject to even greater damage.

How to disassemble a chuck from a Boch screwdriver

German technology is quite sensitive, so we recommend you a safer way. To do this, first unscrew the screw that secures the chuck to the shaft of the screwdriver. It is mounted on the left-hand thread, so you have to turn it clockwise. The difference between the method is that you have to remove it manually. Using the same principle, hold the key in the chuck and pull it as sharply as possible counterclockwise. If you did everything correctly, the cartridge will disconnect the first time.

How to disassemble a cartridge from a Makita screwdriver

rude actions are allowed here, but you should not risk taking a hit on the table either. Carry out the same process with the screw, unscrew the cartridge, hold the key and hit it sharply. In this case, most likely, it will not work to do all the work by hand. To simplify the task, we recommend using a hammer. To do this, it is better to lay the tool on the table so that the key is located at a convenient angle for impact.

Similar articles

Regardless of the type of food and design, all screwdrivers are divided into two main types. Professional and household. The second type is also often called home screwdrivers because of the simplified features and capabilities. Assortment of mouth

Cordless screwdriver is one of the most convenient tools on the modern construction market. The master is completely independent of any wires, outlets, and so on. In principle, this comfort is displayed at the cost of

A person seeks to simplify any work as much as possible. This is our nature. And this is normal. Fortunately, the developers of modern building tools allow us to facilitate many tasks. Screwing and unscrewing various screws. Odi

© 2005-2012 Art-n-House St. Petersburg

Lining, block house, construction of houses from glued beams. Imitation of a bar.

(812) 927-09-39. Molded products

(812) 927-09-49. Construction of houses

In our country, screwdrivers as a household and industrial tool appeared not so long ago. For the first time they began to be used in the space industry, and then screwdrivers found application in ordinary human life.

Among the main parts of this equipment, a mechanism consisting of a hollow cylinder, an adjusting sleeve, and pressure cams can be distinguished. This mechanism is called a cartridge.

Disassembled cartridge

It is important!

Attachment of the chuck is carried out using threads on the tool shaft, and counter thread in the chuck or cone on the same parts.

Types of cartridges

Today, two main types of cartridges are on sale:

Keyless chucks have another classification:

This type of part can be tightened or unscrewed with two hands, because one clutch adheres and the other rotates when removing the equipment.

Two coupling cartridge

Work with this product provides the same actions, they are only performed with one hand. This is possible due to the fact that the design of such products provides for automatic locking of the shaft when removing the snap.

It is important!

Keyless chucks are characterized by the fact that with their help you can insert any device for working with the tool and there is no need to use an additional tool, for example, a key.

Such cartridges are made of two types of material:

The use of a plastic product is a good opportunity to reduce the weight of the equipment used, but this material is not reliable enough and does not have resistance to shock loads. Keyless chucks can be used for both domestic and professional tasks.

Cam cartridges have greater reliability, durability and are able to withstand a large shock load. Not unimportant for screwdrivers with a punch function.

How to fix a cartridge

There are several ways to attach a cartridge. Among them stand out:

- Thread;

- Morse Cone;

- The fixing screw as an addition to the above;

One of the simplest and most reliable methods is the cone, which began to be used in the 19th century. The shaft is specially sharpened for the parameters of the cone, which is available in the cartridge. When two elements are connected, a strong connection is obtained.

You can see the thread on the main shaft of the screwdriver on which the chuck is mounted

If we consider a threaded connection, then its whole point is to apply thread to the cartridge and shaft. According to technology, to connect the parts, it is enough to simply wind the product.

It was not uncommon to use a fixing screw, which acts as an additional fastener. As a rule, his head is made in the form of a Phillips screwdriver, and the thread is cut to the left. You can only see the screw if you untwist the cams of the cartridge as much as possible.

It is easy enough to determine which method of fastening is used on a screwdriver, for this you just need to inspect it. If it is a Morse cone, then 1-6 B10 will be written on the cartridge like this.

Such an inscription is deciphered as a shank diameter from 1 to 6 millimeters, and B10 is the cone dimension, which can be found in any reference to a machine builder.

On a threaded connection, marking is also put, for example, 1.0-11 M12x1.25. M12x1.25 means metric thread, and values of 1.0-11 tell us about the dimension of the tail of the nozzles. If it is a tool of a foreign manufacturer, the inscription will be indicated in inches.

How to remove a cartridge

There is nothing difficult in unscrewing the chuck of a screwdriver. For this you need a hex key 10

- The key is clamped in the cartridge with a short end

- The screwdriver turns on for a time sufficient so that, turning, the key hits the table

As a result of this blow, the cartridge should turn on the left-hand thread, with which it is attached to the shaft.

This is one way, but it is not the only one.

- The cams of the cartridge must be fully released, if there is a screw on the bottom of the cartridge, this is an additional fastening to the drive shaft

- Turn the screw clockwise

- We hold the hexagon and try to sharply turn it counterclockwise

- The cartridge should move, but if this does not happen, you need to apply a light blow with a hammer at the end of the key

It happens that none of these methods helps, then the only way out is to completely disassemble the tool and pull out the spindle with the chuck and gearbox from its design. This design is installed in a vice and only after that the cartridge is removed using a key.

On some models of screwdrivers there are special grooves that help simplify the task. Unfortunately, this is a rarity for a modern instrument.

A problem with the chuck can occur if the tool is very hot, so you need to let the screwdriver rest from time to time.

Device and screwdriver malfunctions

All screwdrivers are arranged approximately the same. They consist of the following functional units:

- Start button;

- Pulse width regulator;

- Electric motor;

- Transistor;

- Planetary reductor.

All components of the device are in a strong and aesthetic case, which has a rubberized handle, control and adjustment buttons, as well as a slot for installing the battery (if the screwdriver is designed only for 220 V operation, it does not have a battery).

When you press the start button, the screwdriver may not be squeaking. This is a normal occurrence of DC motors at startup and at low speeds.

Why and how to adjust the ratchet

A ratchet screwdriver is a clutch designed to limit the force during rotation of the chuck. Its presence in the power tool can be determined by a rotating ring with numbers. Some users do not understand the meaning of the coupling and do not touch it. Using a ratchet, you can adjust the screwing depth of the screw. In too soft material, the fastener cap is easily recessed and can pass through. When using small fasteners, very high torque can destroy it. A ratchet prevents the cutting of a slot from self-tapping screws and the wear of a screwdriver bit. To determine the desired value on the control ring, make several passes, starting with the minimum.

Each number on the ratchet corresponds to a certain value of the twisting force. The larger the number, the greater the force and vice versa

If the screwdriver has a drilling mode, then the last icon on the coupling will be the icon with the image of the drill. In this position, maximum torque is used.

Frequent screwdriver malfunctions

Since all modern screwdrivers have a standard device layout, their malfunctions, as a rule, are also typical. The main defects of this tool include:

- Battery malfunction;

- Brush wear;

- Button breakage;

- Runout of a cartridge;

- Lack of response to attempts to turn on or off;

- Interruption work.

You can fix all these failures yourself if you have experience working with measuring and soldering devices. In some cases, you will have to change the components completely, since not all parts are sold separately. If repairing the gearbox or motor is too complicated for you, these elements can be completely replaced or taken to the workshop.

DIY screwdriver repair

To eliminate most of the malfunctions of a screwdriver, it needs to be disassembled, that is, removing the case and disconnecting the main components from each other.

How to disassemble a screwdriver

The screwdriver is disassembled in the following sequence:

- Remove the battery.

- Remove the screws connecting the two halves of the housing.

The case of the screwdriver consists of two parts connected by a fairly large number of screws. In order to disassemble it, you need to find all the attachment points - Remove its top.

- Take out the contents.

- Disconnect the button.

The screwdriver button is integral with the switching mechanism, which is connected to the engine, so when separating the button from the socket on the case, you must be careful not to break the wires - Remove the gear selector.

- Disconnect motor, gearbox, adjuster, and chuck.

In order to disconnect the gear of the screwdriver from its engine, it is necessary to unscrew the four screws located at the contact point of the two plastic casings

Cartridge Repair

The chucks in different models of screwdrivers may differ slightly from each other. They can be attached to the shaft in three ways:

- Morse cone.

- Threaded connection.

- Threaded connection with fixing screw.

To determine the method of attaching the cartridge, you need to read the inscription on its sleeve:

- The marking “1–6 B10” means a Morse cone. Used nozzles with a shank diameter of 1 to 6 millimeters. The coding “B10” indicates the size of the cone. Take a hammer and knock out a cartridge by striking the body;

- Inscriptions like “1,0–11 M12x1,2” or “2–13 mm ½-20 UNF” mean metric and inch threads.

If the cartridge is threaded, you must perform the following steps:

- Release the cams of the cartridge.

- If there is a screw inside, unscrew it clockwise (the screw has a left-hand thread).

- Take a 10mm hexagon wrench.

- Insert the short edge into the cartridge and tightly clamp in the fists.

- At low speeds, start and immediately turn off the screwdriver so that the long edge of the hexagon hits the table. Instead of turning on the device, you can simply hit the key with a hammer. The thread moves and the cartridge is unscrewed.

In order to remove the cartridge, you need to hold the hex key in it and start the engine at low speeds until the key hits the table

If these methods do not help, disassemble the screwdriver and remove the gearbox assembly. Take the L-shaped tubular wrench (most often 19 ”) and unscrew the chuck, holding the gearbox securing bolts on the back with the cap wrench. She will give the necessary emphasis, with which you can unscrew the cartridge by hand.

To disassemble the cartridge, you need to remove the cap at its base. The plastic plug is gently poked with a knife. Metal. Knocked out by hammer blows on the base of the cartridge:

- Take a large bolt, insert it into the cartridge and slightly tighten for alignment. The bolt head should protrude above the cartridge for two to three centimeters.

- Hammer the bolt head. The cartridge will pop out of the case.

Common cartridge malfunctions:

- Crookedly pinches bits;

- Play between bits and cams;

- Cams jerk out.

To find out the reasons and eliminate them, follow these steps:

- Disassemble the cartridge.

- Remove the flare nut, which consists of two parts.

- Unscrew the clamping jaws.

- Check the condition of the threads on the nut and on the cams, replace the defective parts.

In the process of working on cams or a flare nut that controls their work, a thread may develop or crumble, then these parts must be replaced - Assemble the cartridge in the reverse order of disassembly.

Battery Repair

Three types of batteries are used in screwdrivers:

- Nickel Cadmium (Ni-Cd). They can be charged many times, but they have a memory effect. If you do not wait for the full discharge and begin to charge the battery, then its capacity will gradually decrease. Swing the battery before first use. Discharge and recharge it three times to maximize capacity.

- Nickel Metal Hydride (Ni-MH). A feature of such batteries is a less pronounced memory effect, but a high self-discharge current. If you intend to store a screwdriver without use for more than a month, be sure to fully charge its battery.

- Lithium-ion (Li-Ion). These batteries charge quickly, but do not tolerate frost. They can be charged when convenient.

Store all types of batteries separately from the screwdriver and charger. For long periods of non-use, they need to be recharged once a month.

If the battery does not hold a charge, disassemble it. It consists of several batteries. Check the voltage tester in each. The value of the operating voltage is indicated on the housing (it is the same for all elements). Replace broken batteries.

The battery of a screwdriver consists of several elements, which you can call and find and replace those that have failed

If the battery cannot be removed, the locking button is most likely stuck. It is necessary to remove the upper part of the case, disconnect the battery, disassemble it and adjust the button.

Charger Repair

Frequent damage to the charger:

- The fuse is on;

- Network cable breaks;

- The primary winding of the transformer breaks;

- Diodes break through.

If we disassemble the charger of the screwdriver, then we will see a step-down transformer and a board. Through the mains voltage is supplied to the primary winding of the transformer. The thermal fuse is connected in series with the network winding, so it overheats first and prevents the winding from breaking. From the secondary winding, the voltage passes to the diode bridge. If charging transmits current, yellow is formed around the diodes. Transformer windings overheat, diodes break through.

The charger of the screwdriver consists of a step-down transformer and a board with electronics

- Measure the resistance on the primary winding with a multimeter. If it is not there, it means that the circuit is disconnected and the voltage does not reach the primary coil. The fuse is located beneath the transformer insulation next to the wires connecting to the network. Check it with a tester.

- If the fuse is intact, check the power cord; it may be broken.

- If the wire is OK, check the windings. In case of breakdown, replace the transformer.

Button Issues

A malfunction of the start button can lead to the following malfunctions of the screwdriver:

- Self-propelled guns appear;

- The device does not turn on;

- The device is unstable.

From the button, two wires go to the battery terminals and two to the engine. If there is a transistor, then it is connected by three wires. Make sure the problem is in the button:

- Connect the battery. Press the button and tester measure the voltage at its output, it should be absent.

- Remove the battery and remove the upper motor wire from the button housing.

- Connect the motor directly to the battery. To do this, take two wires of the required length and connect them to the battery terminals. Connect the other ends of the wires to the motor housing and to the wire that was inserted into the button. If the engine is running, then the button is faulty.

Button repair sequence:

- The wires coming from the button do not need to be soldered. Carefully, so as not to damage the base, remove the push part of the button that does not fall into the interior of the case. This should not be done in a jerk, but slowly rotated and pulled towards yourself.

- Remove the protective cover. Take a knife and a flat screwdriver. Pry and release all latches. Pull out element number 1 and remove the cover of the inclusion compartment under number 2. If the contacts are slightly burnt, they must be cleaned. But if they burn out completely, then the button is best replaced. It is sold complete with wires. If the contacts are intact, then move on.

- Holding the spring, carefully remove the trigger mechanism. Look inside. Perhaps, due to the poor quality of the metal, the contact pads wiped off and dust formed, which settled inside the plastic box. Accordingly, dielectric surfaces began to conduct electric current. This is one of the reasons for spontaneous operation of the device. The second reason is a failed transistor. Remove metal dust with a cotton moistened with alcohol. Contacts can be scraped off with a knife, but not with sandpaper, so as not to spoil their surface. Now reassemble everything in reverse order. Replace the burnt transistor. Turn on the tool.

The cause of the malfunction of the button may be burnt contacts, metal dust or a burnt transistor

Inspection and repair of the force regulator

Behind the cartridge is an adjusting ring with a spring that controls the force and snaps the cartridge away from the gearbox. This spring presses on the balls, which abut against the protrusions of the ring gear of the gearbox. Disassemble the ratchet, check the integrity of all its elements. Remove dirt with a rag dampened with alcohol, grease balls.

Gearbox disassembly and repair

The main elements of the gearbox:

They are made of metal and plastic. An annular gear is a cylinder with internal teeth along the entire circumference. Satellites move along the teeth.

The first carrier has two gears at both ends. The first solar is the engine drive gear. She enters between the satellites of the first carrier. The second solar on the opposite side sets between the satellites of the second carrier. In a two-stage gearbox, the second carrier is connected to the shaft on which the cartridge is worn. The three-stage gearbox has another mechanism. All these parts are located inside the ring gear.

The engine transmits the rotation to the first stage satellites through the sun gear. The first carrier rotates the second stage of the satellites. If there is a third step, then the second carrier will rotate it. Satellites of all stages rotate inside the ring gear. The last carrier rotates the cartridge shaft. With each transmission of torque, the speed drops.

Gearbox disassembly sequence:

- Cartridge removal.

- The unwinding of the body.

- Disconnecting the gearbox from the motor.

- Plate removal.

- Removing all parts from the chassis.

When disassembling the gearbox, all parts are removed sequentially: first satellites of the first stage, and then the second - Unscrew all bolts that connect both halves of the gearbox.

- Correction of spring diameter using pliers to improve gear engagement.

- Disassembly of the coupling by removing the retaining ring, washers, bulk bearing.

- Shaft removal

Arrange all the parts of the disassembled gear in order, so that later it is easier to assemble.

- If a rattle is heard during the operation of the screwdriver or it twitches, then the gearbox has defects. During operation, you have to make lateral pressing and heavily load the tool. Because of this, the gearbox shaft bends and a noticeable runout occurs. In this case, the assembly changes assembly.

- If the support sleeve and shaft bearing are worn, they can be replaced with similar ones.

- Breakage of the pin of the satellite is accompanied by the start and instant stop of the engine. Replace the carrier or gearbox.

- Wearing gear teeth also requires replacing the gearbox.

Often, gearbox repair is reduced only to cleaning and lubrication. Do not overdo it with grease, otherwise the device will work poorly.

Brush replacement

Graphite brushes are located at the end of the engine on the connection side with the button. They can be located inside the engine housing under the rear cover or outside. If at least one of the brushes is worn by 40%, change both. Check your contacts. The following signs indicate wear on the brushes:

- The engine runs jerkily;

- Sounds unusual for normal operation are heard;

- Sparking;

- The smell of burning.

When removing and installing the brushes, you need to hold the holders, otherwise, under the action of the spring, they can scatter quite far

Engine repair

The screwdriver uses a DC motor in a cylindrical case with magnets. Inside is an anchor with windings and brushes. To check the motor, disconnect the gearbox and the wires leading to the button, and measure the resistance of the armature winding with a multimeter. Lack of readings indicates a break, and a very low value indicates a short circuit. The collector resistance is measured on the shaft and each plate. It must be zero. Faults in the anchor lead to shutdown during operation, loss of power, sparking and smoke.

Often when the engine fails, the gear remains intact. Since in most engines it is pressed onto the shaft, its removal takes place with some difficulties. Buy a special puller or use the tools at hand. Do not try to do this with pliers or a nail puller. You will bend the shaft and spoil the gear teeth.

- Take a piece of profile or channel. Make a longitudinal groove angle grinder.

- Insert the shaft into the groove perpendicular to the profile and pry off the gear.

- Lay the profile on two hard surfaces so that the engine hangs between them.

- Take a nail and gently tap the edge of the shaft with a hammer. The gear will slip easily.

- Put the gear onto the new engine with a hammer and a hard surface.