How to rewind the stator drill at home. Types of electric motors and repair features

Repair the drill. Stator calculation step.by.step instructions for rewinding the electric motor with your own hands

Many household devices and homemade structures use small power electric machines as a drive as a drive. Despite the high reliability of electric motors, their failure for a number of reasons is not uncommon. Given the relatively high cost of these devices, it is more practical to repair them, and not replacement. We offer to consider the possibility of rewinding electric motors at home.

As a rule, in everyday life, direct current collector engines and blessed asynchronous motors of alternating current are used in everyday life. It is the repair of these drives that we will consider. Information on the principle of action and design features of asynchronous and collector machines can be found on our website.

As for synchronous drives, they are practically not used in everyday life, so this topic is not affected in this publication.

Features of the repair of asynchronous machine

Problems with an engine of any type can have a mechanical or electrical nature. In the first case, strong vibration and characteristic noise may indicate a malfunction, as a rule, this indicates problems with the bearing (usually in the end cover). If the malfunction is not eliminated in time, the shaft can jam, which will inevitably lead to the failure of the stator windings. In this case, the thermal protection of the circuit breaker may not have time to work.

Based on the practice, in 90%, the failure of asynchronous machines arise problems with the stator winding (cliff, inter.flip circuit, short circuit on the case). In this case, a short.closed anchor, as a rule, remains in working condition. Therefore, even with the mechanical nature of damage, it is necessary to check the electrical part.

Features of the process

For rewinding electric motors with your own hands, it is necessary to have at least minimal concepts about the methods of connecting engine windings. If rewinding is carried out for the first time, you need to study this issue well. Particular attention should be paid to the polarity of the windings and the direction of movement of the turns.

In some factory coils, the wire is first wound in one direction, and then returned back. When disassembling it, it is necessary to unwind turns 10 by the place, freeing the coil from insulation, and then accurately determine and write down the direction of the turns in the winding.

Work with the stator

First, they make up the location and connection of the electric motor windings. If the engine is three.phase, then carefully compiles a coil circuit for each phase. They are usually wound with one wire. Only after a good study and proper compilation of the connection diagram of the windings can you begin to disassemble and remove them. It is better to mark windings with different paint and photograph. You also need to check whether it is possible to figure out the photographs and schemes.

Before rewinding the electric motor stator, the template is made by its size. The width is equal to the size between the grooves in which the coil will be laid. To insulate the stator from the winding into the grooves, inserts of cardboard or special insulating material are inserted into the grooves. When laying a coil in the grooves, a wooden or plastic shoulder blade is used. tamping.

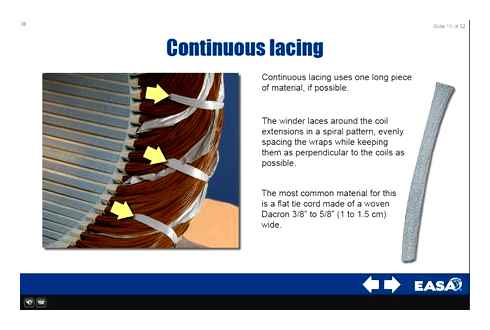

After winding one coil, the wire is not bought out, the coil is laid in the grooves and continued to wind it on the template. All the coils of the same phase are shaking with a whole wire without a snack. First rewind all the turns of one of the phases, alternately laying them. The coils for the rest of the phases are shaken and laid down and lay. The upper part of the winding in the stator grooves is covered with plates of the same insulating material as in the stator grooves themselves.

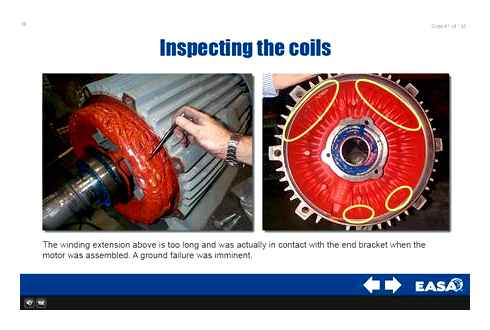

After winding and laying the coils of one of the phases, they must be binded and the coils are formed in even bundles, trying to ensure that the turns are in the same connection and do not touch the stator corps. If the coil is too big and touches the case, then the cut Cambrick is put on it, after which they tied it. The touch of the wires of the case outside the isolation is unacceptable, since with vibration from the electromagnetic field the varnish can be rubbed, as a result of which the coil will be closed to the case. After laying, the resistance is checked by an ohmmeter.

The number of turns in all coils must be precisely observed in order to avoid overheating of some windings. Particular attention and accuracy are necessary to avoid overlaps of turns in the winding. In addition, it is necessary to ensure that the wire is not tied to a shaft node and is not with wiped insulation. All elements going beyond the grooves of the grooves are carefully tamped.

Conclusions from the coils are tucked into insulating tubes. Cambrics. They should not only be made of material with good isolation, but to have resistance to wire heating. In order to avoid melting, a class of isolation is necessary not lower than previously used. Classes of insulation resistance to temperature:

- Y. with a limit of 90 ° C, materials. paper, cotton whip, silk and yarn without impregnation.

- A. with a limit of 105 ° C, the same materials, but with impregnation.

- E. with a limit of 120 ° C, materials. organic and synthetic film.

- B. with a limit of 130 ° C, materials. fiberglass, mica, asbestos with organic binders.

- F. with a limit of 155 ° C, the same materials, but with synthetic impregnating and binding materials.

- H. with a limit of 180 ° C, the same materials, but with siliconic soaking and binding materials.

- C. with the limit above 180 ° C, materials. glass, ceramics, quartz, mica with inorganic binders or without them.

How to rewind the stator drill

Change of brushes. Frequent type of breakdown, this is the wear of the brushes of the motor, the change of which is made without the help of others with their own hands. From time to time, the brushes are certainly replaced without disassembling the drill housing. In some models, it is enough to turn the plugs from the installation windows and install new brushes. Other models, for the change, requires disassembling the case, in this case you need to carefully get the brush holders and extract worn brushes among them.

No need to expect the brushes to be small. This is fraught with the fact that the gap increases between the brush and collector plates. As a result, an overstra.formation occurs, the collector plates are very warm and there are variations to “retreat” from the base of the collector, which will lead to the need to change the anchor.

Find the need to change brushes is an option on high sparking, which is visible in the ventilation slots of the body. 2nd method of determining, it is a random “twitching” of a drill at one time.

Network cord. The cord is checked by an ohmmeter, one probe is connected to the contact of the network fork, the other to the cord. The lack of resistance shows the cliff. So the repair of the drill is reduced to the substitution of the network wire.

Diagnosis of the electric motor. In 2nd place, by the number of breakdowns of the drill, there is an option to put a malfunction of the motor parts and in most cases anchor. A breakdown of anchor or stator occurs for two reasons. Incorrect operation and poor motor wire. Domestic manufacturers with global naming use an expensive motor wire with double insulation with heat.resistant varnish, which significantly increases the reliability of the engines. Accordingly, in cheap models, the quality of the isolation of the coil wire is not sufficiently developed. Incorrect operation comes down to frequent overloads of the drill or long.term work, without interruptions for cooling the motor. Repair of a drill independently rewind the anchor in another stator, in this case, without special devices by non.partial. Only the change of the element is quite (only experienced repairmen will rewind the anchor or stator at home).

Stator rewinding at home

To change the rotor or stator, you need to disassemble the case, disconnect the wires, brushes, remove the drive gear as necessary, and remove the engine completely, coupled with the supporting bearings. Replace the faulty element and install the engine in the area.

Find a malfunction of the anchor of course by the corresponding smell, an increase in sparking, in this case, sparks have a radial movement in the direction of the anchor movement. Pronounced “burnt” windings can be met with visual inspection. If the power of the motor fell, but there are no above signs, then you should contact the measuring devices. ohmmeter and megammeter.

Windings (stator and anchor) are subject to only three damage. Interpreter electronic breakdown, breakdown on the “case” (magnetic circuit) and a break in the winding. The breakdown on the case is determined quite easily, it is enough to touch with a megammeter to be touched to at least what kind of winding output and magnetic circuit. Resistance of more than 500m shows a lack of breakdown. It should be noted that the measurements should be carried out with a megammeter, in which the measuring voltage is approximately 100 volts. When making measurements with a simple multimeter, you can not find exactly that there is definitely no breakdown, but they are determined that the breakdown is definitely found.

The interitic breakdown of the anchor is not easy, if, of course, it is not visually visible. For this purpose, you use a special transformer, which has only the primary winding and the gap rupture in the form of a gutter, to install an anchor there. With all this, an anchor with a personal core becomes a secondary winding. Turning the anchor, so that the workings would be alternately in the works, we apply a narrow iron plate to the anchor of the anchor. If the winding is short.closed, then the plate begins to rattles very much, with all this, the winding tangibly heats up.

rewinding of the stator of the power tool

Often, the inter.seal circuit is located in visible sections of the wire or an armature shirt: the turns happen bent, crumpled (t.e. pressed together), or they usually have any or conductive particles. If so, then you need to remove these circuits, by correcting the bruises of Shinka or extracting foreign bodies, respectively. Also, you will like the closure more found between the adjacent plates of the collector.

Find a break in the anchor winding of course, if you connect a milliammeter to the adjacent anchor plate and rotate the anchor evenly. A certain monotonous current will appear in the entire windings, the broken one will show or increase the current by another complete absence.

The breakdown of the stator windings is determined by the connection of the ohmmeter to the disconnected ends of the windings, the absence of resistance shows a complete break.

Revolutions and reverse regulator. The presence of the voltage at the input terminals of the inclusion button and the absence on the weekend shows the contacts of the contacts by another component of the circuit of the revolutionary control regulator. To disassemble the button of course, gently picking up the clamps of the protective casing and pulling it off the button case. The visual inspection of the terminals will allow us to judge their performance. Blackened terminals are cleaned of soot with alcohol or small sandpaper. Then the button is collected again and check for the presence of contact, if nothing has changed, then the button with the regulator must be replaced. The speed controller is made on the substrate and is quite flooded with an insulating compound, therefore it is not subject to repair. The next corresponding fault failure is the erasing of the working layer under the slider of the rheostat. A simple way out. The change of button is completely.

Repair of the drill button at home is likely only if there are certain abilities. Remember that after opening the body, some parts of switching will simply fall out of the body. You can prevent this from a smooth lift of the cover at first and the desirable sketch of the location of contacts and springs.

The reversal device (if it is not placed in the button case) has its own cracking contacts, therefore it is also subject to the disappearance of the contact. The disassembly and cleaning mechanism of the same, as well as the buttons.

When making a new revolution regulator, you should make sure that it is designed for a drill capacity, so at a drill capacity of 750W, the regulator must be designed for a current of more than 3.4A (750W/220V = 3.4A). And when, the regulator at the drill in the photo is not native, and so that it climbed into the case, the lower part of the trigger was cut off.

rewinding from A to Z.

To understand the difference in new batteries compared to the old version, it is necessary to test under load.

The batteries were subjected to comparative tests:

L1215, Article 4932 3526 58, 1.5 Ah, 18 VTH, based on the INR18650-15M L1220 banks 4932 430165, 2.0AC, 24W, on the base of the INR18650-20R banks, technical data from the manufacturer to the banks: accumulative battery is equipped with a board Protection: Testing Results: 1.compared to the old version of 1,500 tankers in the declared psosts 33.3 %. According to the test results, the superiority of the new battery is more than 50 %. T.e. the difference is really greater than stated. 2.The new battery has a lower internal resistance, and as a result: a higher voltage under load. more than the power of power, which is reduced to heating the battery. Summary: a new battery on the basis of the cells Inr18650-20R noticeably surpasses the old version and at a comparable price is preferable when buying.

And how much does Nm actually need ? The necessary theoretical retreat.

From sopromatam (torque) = τ (voltage in the rod) W (polar moment of the section equal to πd3/16)

The bolt strength class means the following: 1 digit. 1/100 of the nominal value of the strength of the strength, in MPa 2 digit. the ratio of the limitation limit to the strength of the strength t.e bolt of the strength class 6.8 has a 600 MPa strength limit, and the fluidity limit 6000.8 = 480 MPa is confirmed by the acquisition of the obtained numbers. The experience conducted in the training center: the M6 bolt 8.8 begins to “swim” (irreversible plastic deformations arise) at 17 nm, and when the torque is reached, moment at 23 nm, destruction occurs. We will make a similar calculation for screws and screws: for the calculation, the full diameter is taken, the minimum section is much less! Conclusion: To use the most popular fasteners with PH2 and PZ2 slots, a tool with a torque of not higher than 6 nm for a diameter of 4.2-4.5 mm is tapped, in rare cases up to 10 nm for fasteners with a diameter of 5.0 mm. Exceeding these points leads to damage to fasteners and screwdriver (bats). 13 self.tapping screws Ø4.5 x70 mm are twisted into a “pie” 121 mm thick at 3.0 nm, developed by the Makita DF010DSE screwdriver, enough for confident wrapping the self.tapping screw Ø4.5 x70 mm for the entire length. If to prevent the destruction of screws and screws, you need a torque of 2-3NM, rarely 5-6NM, and in exceptional cases up to 10NM, then for which the moment is 20.30.50NM on an electric screwdriver? And what else can a drill-shurupert ? If the drill is known to drill! And what torque is needed for drilling? Theoretical retreat Consider the drilling of steel as the most severe metal drilling in load. The torque is calculated by the MKR = 10cmDQSYKP formula, where the D-diameter of the drill, S-handle, the rest of the signs are correction factors. For steel C against: CM = 0.0345, Q = 2.0, Y = 0.8, KP = 1.0, we take the drilling rate of 20-25 m/min (with coolation of the spray), we enter the corresponding turns in 4.The column. Torque, rotation speed and power on the shaft are related values. The value of the required capacity on the shaft is entered in 5.Ty column. We look at the numbers: to drill the holes Ø10-13 mm, torque 8-15 nm is required. At the recommended drilling rate 720.550 rpm for this you need a power from 570 to 850 watts. And what is the power of the battery drill ?

In the usual drilling cartridge, 3 holes are not in vain: for reliable fixation, the cartridge must be used alternately through all 3 positions of the key. In a cartridge, tightened through one hole, a drill Ø10 mm is turned with a torque of 13.5 nm, and after 3 holes (as expected) at 23 nm. And to the drill Ø13 mm when drilling steel, you need to transfer the torque

15 Nm. T.e. With a cartridge pulled through one hole, the drill will turn! The power of the battery drill (consumed) = voltage of the accumulator current current consumed for powerful models is 20-25 amperes Thus, the power for the battery tool will be: for 12 volts: 240–300W 14.4 volts: 290–360W 18 volts: 360– 430W Twisting the moment for the most powerful (18 volts) drill will be: at a speed of 1500-1700ob/min: 2-3nm at a speed of 300-400 RID/min: 8-14nm drilling steel up to Ø7mm drilling steel Ø10-13mm is the value of the torque at maximum power.(in drilling mode) when overloading the engine when wrapping hard fasteners (for example bolts), the amount of torque reaches 30-40NM. It is these values that are indicated in the characteristics as the maximum soft/hard moment.They do not have practical significance! If when working, the tool requires a torque of large values, then you need a specialized tool specifically for this work. Summary: it is enough for an ordinary user to have a torque of 3-6NM in a battery/electric screwdriver controlled by a ratchet for working with standard fasteners with a head of size to pH/PZ2, and up to 10NM for PH/PZ3. For drilling steel, plastic, wood with drills with a diameter of up to 10mm, a torque is enough at 10-12nm. Twisting more than 15 nm requires the use of a specialized tool and should not be included in the sphere of use of a universal drill-electrical screwdriver.

How to call

For high.quality diagnosis of an angular grinder stator, a complete disassembly of the power tool should be performed in order to eliminate all other structural elements, including the rotor to ensure free access to all its parts. At the initial stage, it is necessary to perform a visual inspection. For a more complete picture, it is necessary to check the presence of defects using electrical devices. What devices and how to call the stator of the corner grinder is described in detail at the link “How to call the stator of the corner grinder”.

Frequent type of breakdown, this is the wear of the brushes of the motor, the change of which is made without the help of others with their own hands. From time to time, the brushes are certainly replaced without disassembling the drill housing. In some models, it is enough to turn the plugs from the installation windows and install new brushes. Other models, for the change, requires disassembling the case, in this case you need to carefully get the brush holders and extract worn brushes among them.

No need to expect the brushes to be small. This is fraught with the fact that the gap increases between the brush and collector plates. As a result, an overstra.formation occurs, the collector plates are very warm and there are variations to “retreat” from the base of the collector, which will lead to the need to change the anchor.

Find the need to change brushes is an option on high sparking, which is visible in the ventilation slots of the body. 2nd method of determining, it is a random “twitching” of a drill at one time.

The cord is checked by an ohmmeter, one probe is connected to the contact of the network fork, the other to the cord. The lack of resistance shows the cliff. So the repair of the drill is reduced to the substitution of the network wire.

In 2nd place, by the number of breakdowns of the drill, there is an option to put a malfunction of the motor parts and in most cases anchor. A breakdown of anchor or stator occurs for two reasons. Incorrect operation and poor motor wire. Domestic manufacturers with global naming use an expensive motor wire with double insulation with heat.resistant varnish, which significantly increases the reliability of the engines. Accordingly, in cheap models, the quality of the isolation of the coil wire is not sufficiently developed. Incorrect operation comes down to frequent overloads of the drill or long.term work, without interruptions for cooling the motor. Repair of a drill independently rewind the anchor in another stator, in this case, without special devices by non.partial. Only the change of the element is quite (only experienced repairmen will rewind the anchor or stator at home).

Stator rewinding at home

To change the rotor or stator, you need to disassemble the case, disconnect the wires, brushes, remove the drive gear as necessary, and remove the engine completely, coupled with the supporting bearings. Replace the faulty element and install the engine in the area.

Find a malfunction of the anchor of course by the corresponding smell, an increase in sparking, in this case, sparks have a radial movement in the direction of the anchor movement. Pronounced “burnt” windings can be met with visual inspection. If the power of the motor fell, but there are no above signs, then you should contact the measuring devices. ohmmeter and megammeter.

Read Repair of the Corner Grinding Stator with DIY

Windings (stator and anchor) are subject to only three damage. Interpreter electronic breakdown, breakdown on the “case” (magnetic circuit) and a break in the winding. The breakdown on the case is determined quite easily, it is enough to touch with a megammeter to be touched to at least what kind of winding output and magnetic circuit. Resistance of more than 500m shows a lack of breakdown. It should be noted that the measurements should be carried out with a megammeter, in which the measuring voltage is approximately 100 volts. When making measurements with a simple multimeter, you can not find exactly that there is definitely no breakdown, but they are determined that the breakdown is definitely found.

The interitic breakdown of the anchor is not easy, if, of course, it is not visually visible. For this purpose, you use a special transformer, which has only the primary winding and the gap rupture in the form of a gutter, to install an anchor there. With all this, an anchor with a personal core becomes a secondary winding. Turning the anchor, so that the workings would be alternately in the works, we apply a narrow iron plate to the anchor of the anchor. If the winding is short.closed, then the plate begins to rattles very much, with all this, the winding tangibly heats up.

rewinding of the stator of the power tool

Often, the inter.seal circuit is located in visible sections of the wire or an armature shirt: the turns happen bent, crumpled (t.e. pressed together), or they usually have any or conductive particles. If so, then you need to remove these circuits, by correcting the bruises of Shinka or extracting foreign bodies, respectively. Also, you will like the closure more found between the adjacent plates of the collector.

Find a break in the anchor winding of course, if you connect a milliammeter to the adjacent anchor plate and rotate the anchor evenly. A certain monotonous current will appear in the entire windings, the broken one will show or increase the current by another complete absence.

The breakdown of the stator windings is determined by the connection of the ohmmeter to the disconnected ends of the windings, the absence of resistance shows a complete break.

The presence of the voltage at the input terminals of the inclusion button and the absence on the weekend shows the contacts of the contacts by another component of the circuit of the revolutionary control regulator. To disassemble the button of course, gently picking up the clamps of the protective casing and pulling it off the button case. The visual inspection of the terminals will allow us to judge their performance. Blackened terminals are cleaned of soot with alcohol or small sandpaper. Then the button is collected again and check for the presence of contact, if nothing has changed, then the button with the regulator must be replaced. The speed controller is made on the substrate and is quite flooded with an insulating compound, therefore it is not subject to repair. The next corresponding fault failure is the erasing of the working layer under the slider of the rheostat. A simple way out. The change of button is completely.

Winding scheme, how to choose the thickness of the wire

Bulgarian stators have a very similar design and differ in the size of the details in which the magnetic flux is formed, the number of turns into the windings and the diameter of the wire. The standard connection diagram of the Bulgarians is shown in the following figure.

Here L1 and L2 indicate the coils of the stator.

Important: the coils after rewind should be installed according to the above scheme, where the beginning and ends of the windings are diagonally, as shown in the figure:

The burned winding is removed, while it is necessary to collect information about the old coils: determine the number of turns, the diameter of the wire, the beginning, end of the winding and the required direction during diverse work. The number of turns is determined by the direct account of the delays after cutting out the coils of the coils.

The diameter of the wire should correspond to the replaced windings as close as possible. Therefore, as a measuring tool, the most suitable is a micrometer with an accuracy of measurement up to 0.01 mm. The measurement is carried out on the surface of the wire of the burned coil on the surface of the surface of the wire.

Dismantling of corner grinders

To check the closure at the stature and rotor, you need to disassemble the engine of the household tool. Consider the implementation of this operation to search for a malfunction of the corner grinder.

- Remove the protective casing by unscrewing one screw on the clamp;

- unscrew 4 screws and disconnect the gearbox with the engine from the handle of the corner grinder;

- Then, from the side of the gearbox, we unscrew 4 bolts and disconnect the gearbox, along with the engine rotor;

- The stator has remained in the case connected to the power button and power.

Having dismantled and disconnecting the parts necessary for checking, we proceed to their external inspection for the intervaling check.

Visual inspection

A malfunction can be detected with uneven heating of the tool body. Touching your hand, you feel the temperature difference in different places of the case. In this case, the tool must be disassembled and checked by the tester and other methods.

In case of short circuit of stator turns and the search for malfunctions, we are primarily inspection of the turns and conclusions. As a rule, when closed, the current force passing through the windings increases, and their overheating occurs.

There is a greater short circuit in the stator windings and the insulation layer is damaged. Therefore, we begin to determine the malfunctions of a visual inspection. If there are no burns and damaged isolation, then we proceed to the following stage.

Perhaps the cause of the breakdown of the voltage regulator that occurs with an increase in excitation currents. To detect the problem, brushes are checked, they must be extended evenly and not have chips and damage. Then you should check with a light bulb and 2 batteries.

Checking the winding

In most cases, the problem can be found in appearance and characteristic smell (see. rice. one). If the malfunction cannot be established with an empirically way, we proceed to the diagnosis, which begins with the call to the cliff. If one is detected, the engine is disassembled (this process will be described separately) and a thorough inspection of the connections. When the defect is not detected, you can state a break in one of the coils, which requires rewinding.

If the call has not shown the cliff, you should proceed to measure the resistance of the windings, while taking into account the following nuances:

- The insulation resistance of the coils on the case should strive for infinity;

- At a three.phase drive, the windings should show the same resistance;

- In single.phase machines, the resistance of the starting coils exceeds these readings of the working windings.

In addition, it should be borne in mind that the resistance of stator coils is quite low, so it is pointless to use its low.class accuracy devices for its measurement, most multimeters include these. You can fix the situation by collecting a simple circuit on a potentiometer with the addition of an additional power source, such as a car battery.

Scheme for measuring the resistance of windings

The measurement methodology is as follows:

- The drive coil is connected to the scheme presented above.

- A potentiometer is set to current 1 A.

- The resistance of the coil is calculated according to the following formula:. where Rk and Upit were described in Figure 2. R is the resistance of the potentiometer. the drop in the voltage on the measured coil (shows a voltmeter in the circuit).

It is also worth telling about the technique that allows you to determine the place. This is done as follows:

The stator released from the rotor is connected through the transformer to a reduced diet, having previously placed a steel ball to it (for example, from the bearing). If the coils are workers, the ball will cyclically move on the inner surface non.stop. In the presence of an interval short circuit, he will “stick” to this place.

Testing with a steel ball

Full Pitch and Short Pitch Winding (Worked Example)

Causes and signs of stator breakdown

Manual grinding machines, popularly called “grips” can fail for various reasons. The most common problem is to break off the stator turns that occur due to the overly strong load on the device. Now such a malfunction can be corrected independently. correctly rewind the stator.

There are frequent cases when the cause of the breakdown becomes an failure of the electrical part of the device. Various factors lead to this:

- water gets to the surface along which the current passes;

- voltage surges;

- sharp pulling out a fork from a socket;

- high overload and, as a result, overheating.

There is an opinion that it is impossible to rewind the stator yourself. In fact, just understand the design of the device. If there is experience of such work and the necessary knowledge, the repair of a three.phase launch device can be carried out at home. Given the preparatory work, the process can take several hours.

Often the engine fails due to a breakthrough of the magnetic circuit, winding or anchor collector disturbances. With an increase in voltage, an abrupt increase in the force of sparks is noted. This is usually observed only on one brush. This phenomenon leads to the destruction of the insulation of wires on a stator coil. If when turning on, the disk accelerates very quickly and is gaining momentum, this indicates a vitkov short circuit of the stator.

drill machine field coil rewinding

Sparks arising during the work of the collector signal the occurrence of violations in the balancing of the anchor. Checking the work of the collector can be carried out in this way: when turned on, the sound should be intensified gradually with an increase in voltage. There should not be vibrations. If a resonance is observed, the electric motor of the corner grinder requires repair.

Dismantling, inspection and preparation of the stator

Rewinds can be performed with your own hands or send an electric motor for repairs. Since the last option often requires large cash costs and is not always realized in small cities, it is best to rewind the winding yourself. In a home workshop, this is quite feasible. Now three.phase alternating current electric motors with a short.closed or phase rotor are widespread. Therefore, the process of rewinding electric motors of this type will be considered below. Rewinding, as well as replacing most other engine parts begins with its disassembly.

Having completed all safety preparations (turn off the power, disconnect the drive and more), the electric motor is thoroughly cleaned and laundered in order to minimize dirt from the entry of dirt inside.

Then several fan bolts and its casing are unscrewed, and then, fixing the bearing shields. They are located on the end parts of the engine.

After disassemble the engine, they begin to extract an old winding. For this, its protruding parts (frontal) are handed over from the end of the conclusions of the windings.

The frontal part is cut down throughout the circle of the stator.

After that, they are knocked out of the grooves of the wedge, which fix the winding in grooves, and then remove it.

In small.sized electric motors, as a rule, there is no remaining winding can be immediately pulled out with pliers.

Having released the stator from the damaged winding, it must be carefully examined, cleaned, and if it is possible to blow out air. So, often after closing to the case, copper, burrs and other metal defects remain in this place in this place.

Most of them can be removed with sandpaper with fine granularity.

Dismantling of the motor

Do.it.yourself repair of an electric motor involves an independent disassembly of the motor, which is carried out in various ways. Sometimes it is enough to turn the engine where exactly depends on the place where it is installed. There are times when it is necessary to disconnect the cable of power, while be sure to place the phases, otherwise when repeated the connection will have to be guessed which wire where to connect.

Use the puller to remove or pull off the half.wrap.

Inspect the body, pay attention to the condition of the side covers, whether there are a stirring lubricant on them, when detected, remove them. If there are no traces, you can start removing the covers, fasteners, as a rule, there are from 3 to 5.

Unscrew the bolts on the lids, slightly tap with a small hammer on the lid on one side, while providing another tension. Exploring tapping carefully so as not to break the “ears”, which will inevitably entail additional expenses. What will be needed to repair the engine is the accuracy and skillful actions of the master.

Throw off the lids to determine whether you need to get the rotor from the body, or all repair work can be done in place. When the engine power is less than 17 kW, the rotor is simply pulled out and put aside, and if above, then the repair is done in place.

After you dealt with the shaft, take up the removal of the bearings, remove the fully leaked grease with aviation kerosene. When the lubricant flooded the winding, it will need to wash and dry it, 1 or 2 bulbs or a calorifier are used for drying.

The types of repair work of the electric motor are divided into account the type of malfunction, for example: the bearing “gone” to the shaft, in other words, its landing is weakened, it is necessary to fuse the shaft using electric welding and punch it on a lathe. If the bearing has a number below than 309, it is soldered with tin, such a repair has quite good results.

Consider an engine with a power of up to 100 kW equipped with rolling bearings when the engine operates in disrepair, at a critical temperature, if thermal protection does not work, the link bursts.

Faced with a similar problem, follow the following actions:

- Remove the remains of the winding.

- Make the bandage again and apply a layer of varnish on it, then the link will stick to the windings, it will not hang out during operation and last longer.

Ringing the stator of the corner grinder with your own hands

408-317 Stator for Bosch GWS7-125/GWS7-115 Hammer. Photo 220 volts as an electric drive in the grinder, an asynchronous collector engine is used. One of the main nodes of its design is the stator, which always works paired with the rotor and creates a magnetic field with which it rotates.

In case of a malfunction of the stator, the corner grinder fails and is subject to repair. You can repair the stator in the main two ways. either replace a defective stator with a new one, or using rewinding the burned winding changes to a new one.

Such repair with independent execution requires certain knowledge and skills

Corner grinder and stator device

Stationary asynchronous electric motors usually have a special case where the stator and rotor are securely attached.

In the grinder, the role of the supporting element for the main units of the electric drive is played by the actual case of the power tool itself. It is usually made of high.strength plastic, into which the stator is tightly inserted.

This design significantly reduces the weight and overall characteristics of the corner grinder, which is important for manual household devices.

The causes of breakdowns

408-105 Stator for angular grinder Hitachi G18SE3 and Hammer. Photo 220 volts

The most common reason for the failure of the stator of the corner grinder is a violation of operating conditions. Asynchronous engines have the ability to maintain speed, regardless of the value of the active load. This is both a dignity and a disadvantage.

The ability to perform work at high loads is accompanied by overheating of the tool, which contributes to prolonged operation to the occurrence of malfunctions in the winding and stator windings. Under the influence of high temperature, the protective layer of the insulating coating is burned out, which leads to the failure of electric nodes.

The main malfunctions

The main malfunctions of the stator are the following:

How to call

For high.quality diagnosis of an angular grinder stator, a complete disassembly of the power tool should be performed in order to eliminate all other structural elements, including the rotor to ensure free access to all its parts.

At the initial stage, it is necessary to perform a visual inspection. For a more complete picture, it is necessary to check the presence of defects using electrical devices.

What devices and how to call the stator of the corner grinder is described in detail at the link “How to call the stator of the corner grinder”.

Winding scheme, how to choose the thickness of the wire

Bulgarian stators have a very similar design and differ in the size of the details in which the magnetic flux is formed, the number of turns into the windings and the diameter of the wire. The standard connection diagram of the Bulgarians is shown in the following figure.

Here L1 and L2 indicate the coils of the stator.

Important: the coils after rewind should be installed according to the above scheme, where the beginning and ends of the windings are diagonally, as shown in the figure:

The burned winding is removed, while it is necessary to collect information about the old coils: determine the number of turns, the diameter of the wire, the beginning, end of the winding and the required direction during diverse work. The number of turns is determined by the direct account of the delays after cutting out the coils of the coils.

The diameter of the wire should correspond to the replaced windings as close as possible. Therefore, as a measuring tool, the most suitable is a micrometer with an accuracy of measurement up to 0.01 mm. The measurement is carried out on the surface of the wire of the burned coil on the surface of the surface of the wire.

Necessary tools

Locabulary whole.hand hammer 500 g. Inforce. Photos all tools.RU

- Various hammers: metal, wooden, several sizes.

- For manipulations with coils, pliers, round.liners, pliers are used.

- Stripping the surface surfaces from pollution and isolation is performed using a metal brush.

- The required cleanliness of the surface of the stator can be obtained using an electric drill with appropriate nozzles.

- In addition to a micrometer, a caliper and a ruler are used for less critical measurements.

- Control the electrical parameters of the coils after rewinding can be by multimeter.

- Cambrows, insulating cardboard, bicopic tape special varnish for impregnation. auxiliary materials for repair technology.

How to rewind at home, stages of work

Repair begins with the removal of the failed old winding. With the help of pliers (pliers, round.liners) from the old winding, the grooves of the stator are freed.

Important: be sure to remove data on the number of turns and the diameter of the wire of the removed coils. Clean the surface of the stator from the old burnt isolation, rinse it and dry it.

Next, the rewinds of the stator coils are performed. It can be performed on a special manufactured template or directly into the grooves of the stator core. It depends on the depth and width of the space for laying the wire.

Important: determine the beginning and end of the winding, direction of laying wire. In the case of manufacturing the template, do not forget to give a allowance for isolation and width of the future coil (about 3-5 mm).

The wound coil is installed in the stator with mandatory positioning of the onset and end of the winding wire, as described above in the text.

The winding is fixed in the stature with withstanding all the clearances (consolidation options will be discussed further in the video presented below). The stator is heated in the furnace to about 80 ° C. 110 ° C.

With the help of a brush, varnish or pre.prepared epoxy resin with hardener is applied. When applying, it is important to achieve the deepest penetration of the impregnation.

Practical tips for rewinding the stator windings are given in the following videos.

Checking a multimeter

You can make sure that the stator can be used using the device. multimeter. This is a universal measuring device. Of course, they measure several electronic values: voltage, current, resistance. The device consists of a case where there are a screen, switch and nests, and 2 cords with probes (plus and minus). The minus probe is always connected to the lower nest, and the plus to the middle or upper, depending on the current strength in the test device.

Corner grinder (angular grinder) should be set on the multimeter of the resistance value from 20 to 200 Ohms and alternately bring the probes of the measuring device to the windings. If the resistance everywhere has a similar value, then the coil is working. When the device indicates another resistance in certain points, then in the winding of course the Kutzue close is another break in one book from the turns. Similarly, the stator is checked by an ohmmeter. Its difference from the multimeter is only about the fact that this device can only measure the resistance.

Where to begin?

Since the installer device is simple, the repair of the Makita peorator must be started with its disassembly. The disassembly of the peorater is best done by already verified order.

- Remove the back cover on the handle.

- Remove electrical coal brushes.

- Disconnect the body of the mechanical unit and the stator case.

- Disconnect the rotor from the mechanical unit.

- From the stator body, extract the stator.

Remember, the body of the stator is green, the body of the mechanical block with the black rotor.

Disconnecting the rotor from the mechanical unit, we proceed to determine the nature of the malfunction. Rotor Makita HR2450 poses.54; Article 515668-4.

How to find a short circuit in the rotor

Since you are making independent repair of peorators, you need an electrical circuit of the Makita 2450, 2470 peorator.

Makita 2470, 2450 Poorators use collector electric motors.

Determining the integrity of the collector engine begins with a general visual inspection. The faulty rotor has poses.54 traces of burnt winding, scratches on the manifold are visible, traces of Gary on the Lamel of the collector. A short circuit can only be determined in the rotor, in the chain of which there is no break.

To determine a short circuit (short circuit), it is best to use a special IK-32 device.

Checking the anchor on the short circuit using a homemade indicator

Having made sure, using the indicated device or a home.made device, that the rotor between the turns of the turns of a short circuit, proceed to its disassembly.

Rotors before disassembly

Before disassembly, be sure to fix the winding direction. This is done very simple. Looking at the end of the rotor from the collector, you will see the winding direction. There are two windings of winding: clockwise and counterclockwise. Fix and write down, you will definitely need this data with independent winding. The rotor of the makita peorator direction is a clockwise winding, right.

How to repair asynchronous engines

If there are problems in the engine, then these are problems of either a mechanical or electrical nature. In the first case, the breakdown may be accompanied by strong vibration and characteristic noise. This usually indicates problems with the bearing. usually in the end cover. Do not eliminate the breakdown on time. and the shaft can jam, and as a result, the stator windings will fail. At the same time, it may not have time to work out the function of thermal protection of the circuit breaker.

Practice shows that about 90% of the asynchronous motors malfunctions of the asynchronous type, problems appear in the stator winding. in the form of a cliff, inter.flip circuit, KZ per body. At this time, a short.closed anchor most often continues to function properly. Thus, if the damage to the engine has a mechanical cause, the electric part should be checked.

Most often, the problem can be identified by external signs and characteristic smell if the breakdown was not found in the empirical way, then we resort to diagnosis and make a call to the cliff. If we find it, carry out the disassembly of the motor (we will talk more about this more details) and carefully examine the compounds. When the defects are not detected, we can say that we have a cliff in some kind of reel. Therefore, you need to rewind.

If after the call the break is not fixed, then we measure the resistance of the windings, while taking into account the following nuances:

It is necessary that the resistance of the insulation of the coils on the body strove for infinity; It is necessary that the three.phase drive of the winding be shown the same resistance; It is required that in single.phase models the resistance of the starting coils exceed these parameters of the working windings.

You also need to remember that stator coils have a very low resistance. Therefore, to measure it, it makes no sense to use devices that have a low accuracy class. this is most of the multimeters. You can solve the issue if you assemble a simple circuit on a potentiometer by adding an additional power source. for example, a car battery.

We connect the drive coil to the circuit, which is presented above; Using a potentiometer, set the current 1 A; We calculate the resistance to the coil using this formula: where R k and u pit are described in rice. 2. R is the resistance of the potentiometer. the drop in the voltage on the measurement coil (the voltmeter shows the circuit).

Tags: automatic, asynchronous, sconces, type, choice, switch, hysteresis, engine, house. replacement, protective, star, sign, isolation, cable, as collector, design, contactor, circuit. bulb. magnet, installation, power, multimeter, load, voltage, face value, lighting, soldering iron, rule, principle, wire, launch, vacuum cleaner. Work, size, calculation, rib, regulator, relay, repair, row, garden, resistance, means, term, scheme, tenders, type, current, transformer, triangle. Photo, shield, electric motor, anchor