How to saw smoothly with a hand saw. Hacksaw – simplicity and safety

techniques of even cutting with a circular saw with and without accessories, and also what you can cut and how to use it correctly

You do not need any special skills to work with a manual circular saw. It’s enough to try for the first time, then in a few cuts the user will understand the capabilities of the tool: how quickly it saws, how much pressure not to “choke” the engine, how an electric saw behaves when starting, how the cord is stretched to prevent it from getting under the saw. It concerns the simple sawing, for example, of firewood.

It is a little more difficult to make even cuts and achieve a precise carpenter’s cut (plus/minus 1mm or degree). Greater accuracy with such a tool is difficult to achieve, although in principle it is possible. But such tolerances in most cases are acceptable, given that the wood is capable of drying and swelling, changing the volume and dimensions with a large amplitude (up to 10%). Other tools are used for jeweler’s precision, including fine-toothed hand hacksaws.

What to cut fiberboard?

Depending on the thickness of the sheet of fiberboard should choose a tool for cutting it. It is better, of course, to get a special machine that can cope with the material of any thickness. But for a single solution, for example, if you need to repair a couple of drawers in a furniture cabinet, no one will get precious equipment. Therefore, for such works performed at times by their own hands, suitable follow-up tool:

The ruler for a manual circular saw or how to saw smoothly.

The jigsaw is very straight if it has a laser direction indicator. Perfect evenness is also observed when working with a circular saw. It must be said that the electric jigsaw and circular saw are quite popular tools in the household, so these methods are quite relevant and accessible to home handymen.

If fiberboard is not more than 3 mm thick, it is easy to cut some parts with a regular sharp knife. It is not uncommon to find a milling machine in garages, so milling will come in handy for making small workpieces out of fiberboard. For uncomplicated straight workpieces, you can saw a sheet of fiberboard with an angle grinder.

In special cases, take the right tool for rent, which is inexpensive, or turn to specialized companies.

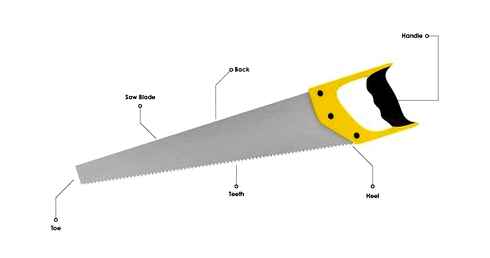

How to work a hand saw

The saw must be driven, otherwise it will start to “walk”. This should be taken literally.

Wood is a living material and its behavior is unpredictable.

Hard annual rings, knots, cracks, high humidity and resin can make sawing very difficult.

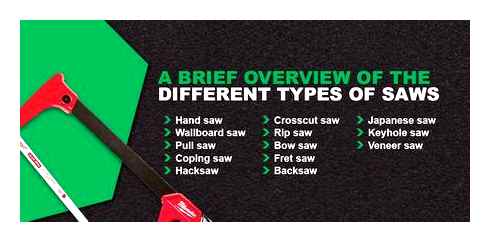

For this reason there is no universal tool that can account for all the vagaries of wood, but there are many different special saws.

It is not the material of the saw blade that determines the shape and the order in which the teeth are set, but the purpose of the saw.

Some tools can only cut in a straight line, other, on the contrary, are better suited for circular sawing.

When sawing only the saw moves, the log must be secured in place. You therefore need a solid support.

For example, a workbench or a sawhorse. Clamp or hand-hold the workpiece, and use a knee to hold particularly large workpieces.

Sawing begins and ends with repeated light pulling of the saw in the opposite direction, i.e. a “trace” is laid. At the end of sawing, hold the remainder firmly so it doesn’t break off along with the piece of main wood.

Sawing is one of the most common processes in wood processing. A clean, even cut. no problem if you have the right tool and know how to use it.

Here is a photo from top to bottom of the photo: a large and small hacksaw; a backsaw; a saw with a narrow blade. Next to left is the fi nishing saw.

A hacksaw is fast, but the wide tooth pitch leaves a coarse mark in soft material. It would, on the other hand, be difficult to saw thick logs with a coping saw.

In short, material and tool have to fit together. Only then you can count on high-quality work and obtaining an even, defect-free piece.

Here is a brief guide: What kind of wood you have to work with what saw?

Any saw (especially its cutting edge) must not come into contact with other tools during storage. It can quickly go out of order from such proximity.

If the saw does not have a cover, a simple way to protect its teeth from damage is to.

A cut in a piece of hose of the required length is made, and then the hose is put on the saw blade.

The best method is to use a rigid hose wrapped in cloth on the inside. It is held tightly on the saw blade even after repeated use.

This is the first and the second: the information that can be taken from the texts in the frame is not understandable for a beginner and useless for a professional.

Making a Cross-Having Joint // woodworking basic skills

There should be at least three or four saws of different types in any home workshop.

- Saws with a wide blade for rough cuts in large parts and workpieces. The longer the blade, the faster the work. But for the same reason the mobility of the blade increases, which makes the saw tend to move sideways, as they say. That’s why it is important to keep a close eye on the sawing line and not let it deviate from the marking. A novelty in recent years is the Teflon coating of the hacksaw blade, which greatly facilitates the cutting of fresh wood and also protects the saw from rust.

- Saw blades with a back plate differ from conventional hacksaws not only in that they have a rigid tang that damps the blade, but also in that the teeth are much finer and closer together. Such a saw makes it possible to make a clean and narrow cut.

- Finishing saws produce a clean cut.

- Saw blades with narrow band saw blades for cutting out rounded pieces and large holes. The basic rule for every chainsaw is to keep the blade dry and clean at all times. The teeth of the saw. even if hardened. should be sharpened regularly.

A look at tree species in the Middle zone: A list of conifers and deciduous trees

Always saw from the cutting side, close to the marking line. This includes rough cuts with a hacksaw as well as precise cuts with a fine-toothed saw.

Next, it is very important that the workpiece has a stable support in the form of a workbench top or an ordinary work table.

For large-sized workpieces it is best to use a sawhorse.

While sawing workpiece must be held firmly by hand all the time (even with knee on large-size workpiece). in other words, only saw has to move.

Sawing begins with the first short cuts at an angle of 30 to 45 degrees. Only after the saw blade has entered the wood and become anchored in it, can you start working with the saw to the full length of the blade.

Near the edge of the cut, only make short, sharp jerks. This avoids chipping on the underside of the workpiece.

Sawing along the grain is always a “critical” situation, especially if the wood is heavily piled.

The saw naturally wants to take the path of least resistance and if it is not held back it will start to wander.

That is, the saw in such cases has to be pressed harder than usual, which, in turn, requires the most stable position of the workpiece.

For big cross-cuts a conventional hacksaw might get jammed.

In such cases it is better to use a rip saw with teeth set very far apart.

But remember that the bar will be much thicker than the saw blade.

getting the saw ready for work

It is easier to saw fresh or wet timber if the saw blade is lubricated with wax or soap.

hacksaw for longitudinal sawing of wood

The workpieces are pressed firmly against the lintel, with its right edge guiding the saw.

Tsulaga

When working small workpieces, the zulagas in the pictures below are of great help.

To make it, you will need a piece of joinery board about 20 x 30 cm and 2 mm thick, as well as two strips of wood to be fastened to the board as shown in the picture. To prevent warping and breaking of the board, the laths must be positioned across the direction of its core layer.

Working with a circular saw

Step-by-step instructions for working with the circular saw

When working with a hand circular saw

The following algorithm should be followed:

- Connect the saw to the power supply before beginning work. Use an extension cord if the power supply is far away. The saw must receive sufficient electrical power for normal operation. Check cable insulation before plugging in. Switch on saw must be off.

- The wood to be sawn must be securely secured by placing it on a level surface.

- Then set the cutting depth. Use the scale on the tool to determine the cutting depth. Always keep the circular saw blade within the material, otherwise you will damage the table. Experts recommend that the cutting depth be set a little lower than necessary to avoid damaging the workbench.

- After checking the setting of all the mechanisms, turn on the cutting mechanism. Begin the cut during the acceleration of the rotating saw blade. Keep a smooth, even motion along the kerf.

- When you finish your work with the saw turn off the switch and unplug it from the mains.

Saw a sheet of plywood with full support from underneath

This is best done on the floor. Of course you can do it on these sleds, but if you want to get the best quality cut you better do it on the floor.

Lay a few boards under the plywood sheet and, after measuring the material to be sawn off, lay the guide on top of the plywood and secure it with clamps. This method will give you a guarantee that at the end of sawing a piece of plywood will not break off, and it will not move anywhere in the process.

Boards should be of the same thickness and should be placed across the saw, as in the photo on the right. Yes, you have to sacrifice a few boards, but the kerf in them is not deep, and why, read the following tip.

Sawing safety

The high saw blade rotation speed of circular saws can be very dangerous for the operator. Above all, narrow and small workpieces can be caught and thrown off by the rotating blade. In order to avoid this, jamming of the circular saw blade and tilting of the workpieces must be avoided.

A blade jamming is counteracted by a wedge-shaped blade opener that is available on most circular saws. The riving knife can only be removed in exceptional cases, e.g. when making plunge cuts. Always ensure the correct position of this safety device.

When working with a circular saw it is also necessary to ensure that the parallel stop is used correctly. When close to the circular saw blade the limit stop must be set back in order to avoid tilting the workpiece between the blade and the limit stop. This can cause it to be thrown out to the side of the blade rotation, with fatal consequences for the person standing there.

Working with a jigsaw

This electrically powered tool is designed for cross, lengthwise and shape cutting of wood, plastic, metal. It is easy to work with it, but some subtleties you need to know. And when working with a jigsaw, you need to wait until the jigsaw stroke reaches maximum speed and only then start sawing. So put the front edge of the base plate on the workpiece, turn on the motor and, when the motor starts at full speed, drive the saw into the material. Modern jigsaws have a pendulum function that moves the saw head in two planes. up and down and back and forth.

Due to this the efficiency and speed of sawing increases significantly. But the proportion of scoring around the edges increases as well. So if you want a clean and neat cut you should set the stroke control to “0”. Changing the saw blade in modern jigsaws is a keyless operation. This is considerably easier than with circular saws.

Always check before use that you are inserting the saw just right for the material you are cutting. If a circular saw blade has worn down, you recognize it first by its slower running speed and secondly by the teeth in the midsection of the saw shorter than usual.

When buying new saws check if the shank of the saw fits your jigsaw model. In order to saw at an angle the body of the tool needs to be tilted relative to the base of the jigsaw. For this purpose there is a adjuster with screw on the bottom of the base plate. However, it is still better to use crosscut saws for high-precision cuts at an angle, because it is quite difficult to keep the jigsaw perfectly straight when sawing at an angle.

How to saw plywood without chipping with a circular saw?

It is recommended to make the cut on a flat floor. A sheet of plywood is laid on wooden bars of equal thickness, placed perpendicular to the mowing line of the cut. Full support at the bottom ensures that the corner of the sheet will not break off at the end of the cut. A metal or wooden guide rail is placed on the top, which is held in place by wire clamps.

In order to cut laminated plywood neatly and without chipping, it is necessary:

- Setting a minimum cutting depth. On the opposite side of the sheet, the teeth must protrude 2 to 3 mm. With this cutting depth setting the blade does not cut, but rather gently cuts through the wood.

- Choosing the right circular saw. For a more gentle cut, use a blade with a minimum size and a high number of teeth (e.g. 40).

- Low feed rate of the cutting blade when moving without stopping. In this case, the teeth do not chop, but gently cut the wood without chipping. For a good cut of laminated veneer we also recommend to set the blade speed to maximum. Disadvantage of the method: the carpenter risks overheating the blade.

- Laying of adhesive tape on the kerf. The use of masking tape that does not leave marks on the surface of the sheet is recommended for this purpose. Once work is complete, the band is removed at a 90 o’clock angle, moving toward the cut.

If laminated plywood is to be processed, it is recommended to tape the sole of the circular saw also. This avoids scratches on the front surface of the sheet.

For cutting such material is suitable both an electric jigsaw and a circular saw. The first option is indispensable in the case of a curved trajectory of the cut.

To saw thick plywood without chipping with an electric jigsaw, it is recommended to use either of the two types of blades:

For even cutting a sheet of plywood, an ordinary circular saw is also suitable. It is enough to install a blade with a fine tooth (for example, 40), to adjust the depth of cut in the range of 12-13 mm and lay the sheet on flat wooden bars. It is recommended to make cuts in the guide rail, at slow feed speeds and without interruptions.

If the front surface of the sheet is laminated, then the place of the cut should be pre-glued with masking tape.

If you are not sure about the best saw for plywood we recommend to address a specialized company with laser nesting and professional equipment for cutting.

In the manufacture of various finishing works or furniture, the use of plywood is common practice. In this case, craftsmen at home face a choice: what to cut the plywood and how to achieve a perfect cut without chipping. There are some difficulties when cutting such material: the sheet is large in size, and the structure of its base makes it difficult to cut. Knowing some specifics, it is possible to achieve excellent results when working with an electric jigsaw, hand saw or circular saw. The main condition is to make sure that the plywood is firmly fixed.

Plywood is a practical and easy-to-handle material

Electric hand saw

- Saber. It is an alternative to the jigsaw, but is more suitable to quickly cut the excess without forming a smooth and accurate edge.

- Circular. Used most often, as it ensures performance of large-scale work. The disadvantage of the device is that the sawing is only possible in a straight line.

Sabre saw is not designed for precise cutting, so it can only be used for rough cutting of plywood, while the circular manual circular saw is considered one of the best options for such work

Cutting plywood to a given size is better performed with the last option, taking into account some peculiarities of application:

- The possibility of setting the plunge depth minimizes damage to the edges.

- Small-sized carbide discs with frequently spaced serrations are suitable for the job.

- Easy to use. The tool does not weigh much and does not need a special platform for installation.

Top 3 Circular Saw Projects || 3 Best Circular Saw Ideas

When choosing the right saw blade pay attention to the setting of the teeth: a slight divergence is good for thin material, a larger divergence for thicker boards.

There is only one thing left to do

Next, you need to set the exact size of the saw cut (remember, first run at 5 cm, and now set it at 4 cm). In this case you should press one clean side, which acts as a base, to the saw table, and the second base to the clamping table and saw off the excess evenly (the uncut sides should be behind the saw blade and on top).

Let’s go again with the circular saw. It remains to run one more side, and that’s it, your bars are ready! In addition, you should never forget about safety precautions when working with a circular saw, because it is better to measure 7 times than to cut off a finger at once.

What electric jigsaw allows to make a perfectly smooth cut

High-quality cuts in any material are made by electric jigsaws with an additional guide for the saw. Among them it is possible to allocate:

Use of additional clamping device instead of support roller allows to minimize saw blade backlash and ensure optimal cutting quality.

We also recommend to read about the best jigsaws of this year and how to choose the right one.

The electric jigsaw is an indispensable tool in the home and professional workshop. It allows you to make quick and qualitative cutting of any material, as well as to perform profiling. After reading the article, everyone will be able to understand how to properly make straight and curved cuts with it.