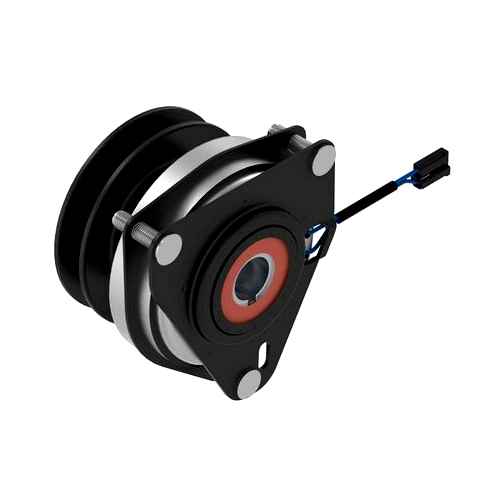

Lawn mower clutch assembly. Lawn mower clutch assembly

Hustler 791251 Lawn Mower Clutch Pigtail Harness OEM Why buy this Hustler Lawn Mower Clutch Pigtail Wire Harness from us? Because this is an OEM Hustler replacement kit that will boost your Zero Turn lawn mower, outlasting the competition with its.

Decrease Quantity of Hustler 791251. Lawn Mower Clutch Pigtail Harness OEM Increase Quantity of Hustler 791251. Lawn Mower Clutch Pigtail Harness OEM

HUSTLER 604244K. CLUTCH KIT. HUSTLER genuine Part Number 604244K

Part 604244K. CLUTCH KIT. HUSTLER genuine Part Number 604244K. This is an authentic part from HUSTLER TURF EQUIPMENT. We are experts on Hustler mowers parts, accessories and services being a Gold dealer and proudly representing Hustler and leading the.

Decrease Quantity of HUSTLER 604244K. CLUTCH KIT. HUSTLER genuine Part Number 604244K Increase Quantity of HUSTLER 604244K. CLUTCH KIT. HUSTLER genuine Part Number 604244K

HUSTLER 366765. ANGLE CLUTCH ANCHOR MM. HUSTLER genuine Part Number 366765

Part 366765. ANGLE CLUTCH ANCHOR MM. HUSTLER genuine Part Number 366765. This is an authentic part from HUSTLER TURF EQUIPMENT. We are experts on Hustler mowers parts, accessories and services being a Gold dealer and proudly representing Hustler and.

Decrease Quantity of HUSTLER 366765. ANGLE CLUTCH ANCHOR MM. HUSTLER genuine Part Number 366765 Increase Quantity of HUSTLER 366765. ANGLE CLUTCH ANCHOR MM. HUSTLER genuine Part Number 366765

HUSTLER 120838. GUARD RAPTOR CLUTCH CE. HUSTLER genuine Part Number 120838

HUSTLER 120838. GUARD RAPTOR CLUTCH CE Part 120838. GUARD RAPTOR CLUTCH CE. HUSTLER genuine Part Number 120838. This is an authentic part from HUSTLER TURF EQUIPMENT. We are experts on Hustler mowers parts, accessories and services being a Gold dealer.

Decrease Quantity of HUSTLER 120838. GUARD RAPTOR CLUTCH CE. HUSTLER genuine Part Number 120838 Increase Quantity of HUSTLER 120838. GUARD RAPTOR CLUTCH CE. HUSTLER genuine Part Number 120838

HUSTLER 606936K. CLUTCH KIT CMS250. HUSTLER genuine Part Number 606936K

HUSTLER 606936K. CLUTCH KIT CMS250 Part 606936K. CLUTCH KIT CMS250. HUSTLER genuine Part Number 606936K. This is an authentic part from HUSTLER TURF EQUIPMENT. We are experts on Hustler mowers parts, accessories and services being a Gold dealer and.

Decrease Quantity of HUSTLER 606936K. CLUTCH KIT CMS250. HUSTLER genuine Part Number 606936K Increase Quantity of HUSTLER 606936K. CLUTCH KIT CMS250. HUSTLER genuine Part Number 606936K

HUSTLER 605777K. CLUTCH KIT 605777. HUSTLER genuine Part Number 605777K

HUSTLER 605777K. CLUTCH KIT 605777 Part 605777K. CLUTCH KIT 605777. HUSTLER genuine Part Number 605777K. This is an authentic part from HUSTLER TURF EQUIPMENT. We are experts on Hustler mowers parts, accessories and services being a Gold dealer.

Decrease Quantity of HUSTLER 605777K. CLUTCH KIT 605777. HUSTLER genuine Part Number 605777K Increase Quantity of HUSTLER 605777K. CLUTCH KIT 605777. HUSTLER genuine Part Number 605777K

Hustler 601801K. Clutch Kit OEM

Hustler 601801K Clutch Kit OEM Why buy our Hustler 601801K Clutch Kit? Because this is an genuione Hustler replacements kit that will provide you the best fixes to your Zero Turn Mower‘s clutch, outlasting the competition with its great performance.

Decrease Quantity of Hustler 601801K. Clutch Kit OEM Increase Quantity of Hustler 601801K. Clutch Kit OEM

HUSTLER 114052. KIT CLUTCH CONN. REP HUSTLER genuine Part Number 114052

HUSTLER 114052. KIT CLUTCH CONN. REP. Part 114052. KIT CLUTCH CONN. REP HUSTLER genuine Part Number 114052. This is an authentic part from HUSTLER TURF EQUIPMENT. We are experts on Hustler mowers parts, accessories and services being a Gold dealer.

Decrease Quantity of HUSTLER 114052. KIT CLUTCH CONN. REP HUSTLER genuine Part Number 114052 Increase Quantity of HUSTLER 114052. KIT CLUTCH CONN. REP HUSTLER genuine Part Number 114052

HUSTLER 601311K. CLUTCH KIT. HUSTLER genuine Part Number 601311K

Part 601311K. CLUTCH KIT. HUSTLER genuine Part Number 601311K. This is an authentic part from HUSTLER TURF EQUIPMENT. We are experts on Hustler mowers parts, accessories and services being a Gold dealer and proudly representing Hustler and leading the.

Decrease Quantity of HUSTLER 601311K. CLUTCH KIT. HUSTLER genuine Part Number 601311K Increase Quantity of HUSTLER 601311K. CLUTCH KIT. HUSTLER genuine Part Number 601311K

HUSTLER 113347. CLUTCH ANCHOR. HUSTLER genuine Part Number 113347

Part 113347. CLUTCH ANCHOR. HUSTLER genuine Part Number 113347. This is an authentic part from HUSTLER TURF EQUIPMENT. We are experts on Hustler mowers parts, accessories and services being a Gold dealer and proudly representing Hustler and leading the.

Lawn Mower Clutch Problems: Their Quick And Easy Fixes

Lawn mower clutch problems can be a nuisance when using a riding-style mower for lawn maintenance. A clutch is a particularly sensitive part of the mower equipment that is easily prone to get damaged.

This article lists all the probable reasons your clutch might not work properly. You will also learn practical methods for checking for problems and solving them yourself.

What Are Some Common Lawn Mower Clutch Problems?

Some common lawn mower clutch problems would be the releasing mechanism, the worming out of the input. On the other hand, it can also be due to the solenoid not working, and the clutch not being properly lubricated.

On the other hand, the clutch of gas-fueled and electric lawn mowers might have problems because of a defective releasing mechanism or a worn-out input shaft. A faulty or fused solenoid is one of the most common reasons, and it provides a variety of symptoms.

– The Releasing Mechanism

The releasing mechanism of an electric PTO clutch gets damaged quite easily. This would be the result especially when the machine is used improperly on a bumpy surface. The latter is because the machine is made to work on smooth surfaces, with no uphills or crusted bumps on the edges.

When these are present, the machine will become weaker, because it is not made for these reasons. The dysfunctionality will be represented by the mower’s weird noises when the clutch engages or disengages. This would indicate that the mechanism has been messed up, and the clutch is not in the right position as it should be.

What you must do in this case is to turf off the engine and then press and release the clutch. If the release mechanism has been affected, the peculiar noises will continue even with the engine being turned off.

The mechanism is the one that is responsible to adjust the proper functionality of the machine and how it would be running throughout the time. Remember that if this is damaged, then the whole thing will have a major issue when it is aiming to do the work.

– Worn Out Input Shaft

A clutch input shaft connects the engine to the clutch and transfers rotational forces to it. Naturally, the bearings around this shaft might wear off after years and years of mower use. The shaft is what will be gripping well the clutch, and as a shaft gets worn out, or weakened, the clutch would start seeing different problems. This is an aspect that you wouldn’t think of, because this issue is not an obvious one.

However, it might also occur due to bad PTO clutch use when you overexert your riding lawn mower and its clutch, which would get damaged as the years would pass by. As a result to the latter, you can very obviously, tell that the problem lies in the input shaft when the mower makes whirring or chirping noises in a neutral position, but the sounds go away when the clutch is depressed.

– Clutch Solenoid Is Not Working

A PTO solenoid, in layperson’s terms, is simply a switch activated when the engine engages with the clutch. Once the clutch, in turn, connects with the external shafts of mower tires, this solenoid gets deactivated.

The clutch will stop working whenever there is something wrong with this solenoid; on the other hand, it may also be due to the wrong calibration of the solenoid, which is not properly adjusted, as a result you will feel like the machine is not doing its job right.

A lot of mower clutch problems arise because of a dysfunctional clutch. Sometimes, this solenoid turns into a bad fuse and must be taken care of, or else the machine would get tired so quickly.

At other times, the solenoid might be working all right but is not getting the right voltage from the battery, so the battery needs to be fixed, and this is a matter of reverse standardization, where one would effect the other.

When the mower is not stored properly, someplace dry, the solenoid rusts. Dust can get stuck in the mower engine, affecting the sensitive electromagnet from which the solenoid is made. When the solenoid gets fused, damaged, or corroded, you have no other option but to replace it.

– The Clutch Is Not Lubricated Properly

When the electric clutches are not lubricated properly as part of regular mower maintenance, problems would begin to arise. As a result of lacking of oil, the machine may start showing you signs such as a squeak of noise coming out, or a challenge when trying to work through the task.

To elaborate further, the friction in the clutch parts might cause it to become stuck while working or not turn properly. You will feel resistance in the mower movement even with the engine at full throttle and the clutch fully engaged, as a result the problem would be relevant and obvious.

A lack of power is not the only thing that happens when lubrication of riding mower clutches needs to be taken care of. When friction starts to occur, then it will cause the clutch components to wear down quickly, and this might end up damaging the mechanism of this machine on a permanent scale. In addition to this, sometimes, fluids might start leaking into the clutch from lack of lubrication.

Lastly, the resistance and friction between these parts will increase the heat production in the clutch. The temperature of the whole engine will be raised, which is a dangerous thing to happen in any machine.

How To Solve Lawn Mower Clutch Problems?

To solve the lawn mower problems with the clutch, you must first test the clutch well, and make sure you would replace the electromagnetic solenoid. In addition, you should also replace the battery, and invest in better lubricating oil, and remove the defected clutch and replace it.

To fix your problematic PTO clutch, you need to see what is wrong with it and then fix it accordingly. In case the clutch is completely damaged, take it out and then replace it with a new one.

– Test The Clutch First

The first step is to carry out extensive clutch troubleshooting for the pto switch clutch. after which it can be fixed. This will help you pin the issue right from the start, it will tell you and signify what is really going on.

First and foremost, you must make sure that the mower’s engine has been turned off and cooled before working. This is when you must push a mower jack underneath it and lift it using two rear jacks and two front ones.

Then, make sure you try to lift the hood to expose the battery and disconnect its terminals. Use a millimeter to read the volts on the battery. If the voltage falls below 12.4 volts, the inadequate voltage is why the clutch is not engaging, and this is the way you would start to tackle the problem.

Next, check the fuse in-line and see if it has blown or is black with soot. It will have to be replaced if it is damaged. See that nothing is jamming the belt and the pulley system of the mower, like broken twigs or tree branches.

Put in the ignition key and turn the engine off to check the working of the clutch. Before turning the engine, engage the lever and disengage it after turning it on. If the pulley is slowing down during this, then this means that the clutch has fused with the plates.

Which means that you should take the matter into a closer look, and fix this situation by replacing it, or adjust it properly.

– Replace the Electromagnetic Solenoid

Many problems can go wrong with a mower clutch, and each needs to be addressed individually. However, if you check that the clutch is not sitting right, then you should try to work with fixing the solenoid.

If the problem lies with a faulty solenoid, this electromagnet will have to be replaced by a new one. This is something other than what we recommend doing yourself, and it’s best to ask for professional help instead.

When it sits right, after you have replaced it, you won’t go through so much difficulty, because after adjusting, it won’t show you any issues. Sometimes, it is just the switch that is defective and in need of a replacement, this would be upon the situation, of course.

Your local hardware store will give you a brand new one that must be bolted in place of the old one.

– Replace The Battery

When the problem lies with the battery voltage, there is no need to mess with the clutch anymore, don’t go any further and try to put yourself in a chaos of a situation. The battery only needs to be cleaned and get IRS electrolyte refilled, and it will be fair to get it done.

When the machine has been set with a really old and worn-out battery will have to be replaced by a new one, and as you try to turn it on after you have replaced it, you shouldn’t face any clutch problems.

– Invest in Lubricating Oil

Lack of lubrication will produce undue friction and generate heat from the clutch plates getting stuck together. Invest in a premium-quality lubricating oil and use it on the engine. If the problem persists, the clutch has been damaged already and requires a replacement.

When you invest in a quality lubrication oil for your lawn mower, and spread it to the right amount that is given, it will run in a smooth way, with no further complications, and no noise. This would show that the clutch is functioning very properly.

– Removing and Replacing the Defective Clutch Effectively

Put on your best rubber gloves and take a screwdriver and a socket wrench set. You do not need any other additional tools for this.

Once the engine has been switched off, and the ignition key is taken out, wait for the mower to cool down. Then remove the protecting covering of the spark plug and use its wrench to remove it as a precautionary measure.

Then you must place a jack under the mower and pull it upwards to access the deck and the pulleys. Remember that it is important to have a plastic coating is usually protecting the mower belt that must be removed.

Loosen the belt using the screws holding it in place on both sides to gain access to the clutch underneath. Once the belt has been loosened and removed, you can see the clutch connected to two wires. These wires connect the clutch to the engine and the blade, make sure this step is done neatly.

Ask someone to help you remove the bolt that connects the clutch to the top of the mower. Once this screw is loose, remove the flywheel cover and screw it back on. Remove the clutch as the final step and replace it with a new one.

Put everything back as you did before and restart the engine to see if it works, and adjust the grip, and make sure you turn it on and now see the way that it would be running.

Conclusion

Now that we have discussed the problems and the solutions associated with faulty mower clutches, here is a brief recap before we go.

- A faulty solenoid that is either fused, not getting the right voltage, or corroded might cause clutch problems and must be replaced.

- The clutch might get overheated from friction when not lubricated regularly and will not engage properly.

- When the releasing mechanism of the clutch is affected, the clutch stops working properly.

From the steps we have mentioned, you must first figure out what is wrong with the clutch. Once you know what is wrong with the clutch, you can take the necessary steps to fix it through our guide.

What Are The Symptoms of bad PTO Clutch?

PTO clutches are generally used with outdoor power equipment that used for start the rotation of and implement a cutting blade. Also, It helps to slow down the implementation when the clutch is turned off.

You’re here because you wanted to know what are the symptoms of bad PTO clutch. Don’t worry, the dedicated article is on this topic. You will learn some common signs of bad PTO clutch in the following post. Plus, The solution to those problems.

What Are The symptoms of bad PTO clutch?

Hard To Start

Usually, the common symptom of a bad PTO clutch is taking time to engage. In the beginning stage, It takes several seconds for the blades to engage. It will be getting hot after running for a while.

Noise:

The PTO clutch will make some awkward noise when engaging or disengaging. If you hear such type of noise when your release or depress the PTO clutch, or both at the same time when the engine is off, It’s probably a problem with the PTO clutch and Its release mechanism.

Also, When the transmission is neutral, the car makes a chirping, whirring, or grinding sound, but the sounds go away by depressing the clutch pedal that indicates the PTO clutch problem. The possible reason behind it is the noise is coming from a worn-out input shaft bearing.

You can use noise to understand that is the clutch has any defect or not. For this, first, disengage it and turn it on and off few times. If you notice that the power takes off slowing down or stopping and won’t make a disengagement noise, It indicates the PTO clutch galled together fo heat or slip ring has jammed.

Engine won’t turn over

The blades will not engage if the PTO clutch solenoid is defective for this clutch won’t get any power. Also, The engine won’t get any power if the switch has any defect.

How to solve bad PTO clutch symptoms?

There aren’t a single solution to solve the PTO clutch problems. For example, If your PTO clutch solenoid is defective, then you need to replace the clutch. But, If the problem occurs on a switch, the problem will solve by replacing the switch.

Also, Adjusting the PTO clutch, especially electric clutches, are mandatory for getting the highest performance. Otherwise,You will notice the gap between contact plates that reduces magnet power and complexity to hold them together. For this, with a heavy load, the contact plates may slip, which will cause heat from the friction of lowering.

Sometimes, Adjusting the PTO clutch from time to time can solve some common issues and provide optimal performance.

Here are some common issues and solutions you may apply to solve the PTO clutch problem:

How do I Test A PTO clutch?

Follow this quick guide to test a PTO clutch:

- First, Use a floor jack to lift the vehicle up and use two jack stands under the rear frame and two in the front frame to provide clearance to look at clutch drive assembly.

- Read the volts using a good engine source. If you find output below 12.4 volts or equal, then charge the battery because it won’t engage without enough voltage.

- Then, Check the in-line fuse. If it turns black or blown, replace it with the same amper fuse rating as the original.

- Active the engine and carefully check the blade operation. If it makes noises, first replace the ignition key and unplug the battery cable.

- Remove any type of broken branches that jammed into the drive belt and the pulley.

- Again plug in the ignition key and negative cable with a socket. Turn on the clutch engagement lever and disengage it after starting the engine. Then, turn it on and off several times. If the pulley is slowing down and stopping frequently, It’s the sign that plates and clutch have galled together. For this, you need to remove the clutch and inspect the internal issue.

How Do You Remove A PTO clutch?

Fortunately, We don’t need any type of special tools and equipment to remove a PTO clutch. Just a screwdriver, a socket wrench set, and a pair of good-quality gloves are enough. After you collect those tools, let’s jump into the removing part:

- To reduce the risk, first, disconnect the spark plugs.

- Then, You will have to take off the plastic covering from the pulley, which protects the belt from any sort of damage.

- Then loosen the blade belt to access the clutch.

- After removing the belt, you’ll find two sets of wires which directly connect with the PTO clutch. Disconnect those wires before releasing the clutch.

- In this step, A assistant must be needed. There is a bolt connected with the top of the mower or vehicles. At the same time, unscrew the bolt, the assistant help you to keep the nut in place, and he used a screwdriver to take off the flywheel cover.

- Finally, You can remove the PTO clutch after the bolt is out.

Final Words

The power takeoff clutch is a piece of important equipment used on small tractors that activate mower tillers or blades. It’s used electricity to produce a magnetic armature to rotate the blade. But, to get the optimum performance, you need to keep it in regular maintenance.

So, Knowing some common Syndrom of bad PTO clutch helps you do the maintenance process easily and find out any problem quickly. In the above guide, You find some common syndrome and how to solve those, which might help you identify the problem and solve it.

s:

What is the Blade Brake Clutch on a lawn Mower? Guide to Replace Repair

The blade brake clutch is a safety feature on your lawnmower. While it is a great idea to purchase one, it is first important to understand how it works.

What is the purpose of a blade brake clutch?

A lawn mower equipped with a blade brake clutch offers an additional feature that is not found in regular mowers. So what is a blade brake clutch on a lawn mower?

The blade brake clutch allows the operator to disengage the mower blade rotation without stopping the engine. This comes in handy when you need to cross the gravel or a paved path, empty the mower bag or wish to stop mowing to remove some obstacles on the way. A mower with a blade brake clutch saves you from switching off the mower and starting the engine again and again during a single session.

How to operate the blade brake clutch?

The process of operating the blade brake clutch is similar in most mower models. Here are the steps to follow:

- Start the mower engine.

- The throttle should be adjusted to the highest setting.

- The stop button is usually found on the right-hand side. Push and hold this button to stop the blade.

- Now pull the lever used for blade control towards the direction of the mower handle and hold it in its place.

- To engage the blade, release the blade stop button.

- These actions enable the rotation of the mower blade.

- To immediately stop the blade rotation, release the blade control lever. This will trigger the blade brake clutch.

While it is Smart to buy a lawn mower with a blade brake clutch for added safety, you should be well aware of how this additional feature works.

If the blade break clutch starts to make a noise, this signal of a mechanical malfunction. Immediately stop using the blade brake clutch.

Before you resume your routine mowing, delve deep and find out the reason for the noise. An improper operation may also create noise. It is important to educate yourself about it and take the necessary steps.

What are the different kinds of noises that a blade brake clutch makes?

You may hear various kinds of noises that may arise because of a mowers blade brake clutch problem. Anything different from the usual noise should be taken seriously.

Here we list down a few common noises that a blade brake clutch could explain the possible reason for the same.

- Clanking or rattling sound may indicate a broken or a loose part that is hitting against the various metal components in the mower.

- A squalling noise may either indicate that the blade brake clutch parts need lubrication or that some parts may have worn out or may have shifted from their original position.

- A grinding noise usually is a warning of a metal rubbing against another metal.

Repairing and Assembly of the Blade Brake Clutch

There are varied designs of the blade brake clutch manufactured by different manufacturers. In most cases, it consists of a couple of drums or plates that get together when the clutch is engaged. A linkage brings the clutch sides together, and a brake is used to stop the blade. This is also where the problem usually starts.

Most issues are found in the blade clutch linkage that is used to engage the clutch. The cables and springs could break, or the bracket could bend. The clutch drum and plates could wear after sometime when it starts to slip not locking well together. The blade brake wears, causing a slight drift in the blade even though the clutch is not engaged.

There are varied designs, so the repair steps differ widely. Here are some standard steps that should be followed:

- Get access to the clutch and inspect it. This can be found above the blade and under the mower.

- You will notice a cover on the clutch. Remove this.

- Some clutches are self-contained, where you can remove the clutch and the linkage as a single unit. The others could have the clutch located under the deck.

- The linkage is spread across the mower deck. There are some components placed under and some above the deck.

- To diagnose the issue, spot any missing or broken springs, power, or metal savings that indicates metal on metal wear. There could be misaligned or loose parts.

- Once you diagnose the problem, the repair involves removing and replacing the worn or broken parts.

It is an overwhelming task to repair a blade brake clutch which is best left to an expert unless you are a mechanically inclined operator.

Problem with the break blade clutch cable

If there is trouble with the engagement of the lawnmower’s blade, then this could be because of a faulty cable.

The cable is attached between the blade clutch and the blade bail. It is made of a metal cable with a plastic sheath, cast metal ends, and one or two mounting brackets. The majority of the problem with the engagement cable arises because of the metal cable itself.

The cast end which connects the cable to the clutch and the bail is prone to severe breakage after many years of use. The steel cable could break or fray, which is accelerated because of rust.

There could also be an issue with the cable kink, which occurs when the cable gets snagged on a fence or a shrub. The metal cable that is kinked does not slide smoothly through the plastic sheath that makes the operation finicky, not letting the cable move. Suppose the steel cable gets corroded or rusted. In that case, it seizes inside the plastic sheath, which is commonly seen in mowers that are kept exposed to the weather elements. Water seeps inside the plastic sheath, and with no easy escape, it starts to corrode and rust the clutch.

To replace a blade engagement cable

- Remove any mounts attached and cut the cable ties that secure the mowers handle and the cable.

- Thread the cast end out from the hole and remove the cable.

- Now remove the next end of the cable from the blade clutch. For this, you will have to top the mower to one side. The carburetor should face up when you tip the mower so that there is no fuel spillage.

- There could be a few covers on the underside. Remove them so that the clutch can be accessed.

- Once you access it, just remove the cast cable end and replace it with a new cable following the steps above in reverse order.

- Replace the covers that you have removed, install the new cable ties that hold the cable in place securely, adjust the cable as required, and the task is done.

- You may not have to adjust all the blade engagement cables, but if you have to, then check the rotating adjuster or the clamping bracket to ensure proper adjustment.

- Refer to the manual to understand the proper procedure for adjustment.

Replacing the blade brake clutch

The clutch does wear off with time and would eventually need adjustment or replacing to get it back to its proper working condition. An expert will diagnose the clutch for which he will need to disassemble the mower. The condition will be closely inspected to see if it can be repaired or needs to be replaced.

If several components are broken that restrict the clutch from rotating, there is no option but to replace it. In such a case, refer to the owner’s manual to cross-check the replacement part number should you need a new clutch.

There is some blade brake clutch which is a single pre-assembled unit. It saves the mechanic from removing and replacing various parts. Replacement is the only option if there are issues with this model of blade brake clutch.

Ensure that you buy the right assemble for the mower model and tighten the component securely before starting the mower and taking it on a test run.

Conclusion

A mower with a blade brake clutch is a Smart purchase. The clutch is placed under the engine that is attached to a crankshaft. The crankshaft runs right through the center of the brake clutch and a belt attached to the clutch and powers the blade once it starts to rotate. The clutch does not let the mower blade spin even though the engine is running, thus giving complete control to the operator.

Knowing its integral parts and the proper operational procedures of a blade brake clutch lets you be aware of any signs of breakage, enabling you to make the right decision of either replacing or repairing it.