Lawn mower coil replacement. How does Lawn Mower Ignition Coil Works | Everything You Need To Know

How to Test a Lawn Mower Coil With a Multimeter? Step by Step Guide

Mowing is an important activity if you have a lawn and intend to keep it clean and low. A mower is by far the most crucial tool for lawn maintenance. A lawn mower is designed to last for decades with the proper care and service, but sometimes, it may leave you a little disappointed when you want to use it.

You notice the grass is tall and needs mowing, you try to put on your mower to do the work, but it just wouldn’t come on. At first, you think, oh, it may have something to do with the starter; after all, it’s winter where it is common to have starter problems. But then you realize it is something more.

Typically, when you’re having issues starting your lawn mower, it might be an issue with one of the following: fuel/oil, spark plug, or induction coil. If you’ve checked the fuel and spark plug, and they don’t seem to be the issue, you’re most likely facing a coil problem. Here, a multimeter set at ohms reading can help you test the coil to know if the coil needs replacing.

If you don’t know how to use a multimeter to check the coil of a lawn mower, do not worry as a lot of people struggle with this too, this is why we’re creating a guide with simple steps you can follow.

Use of a Coil and Continuity Testing

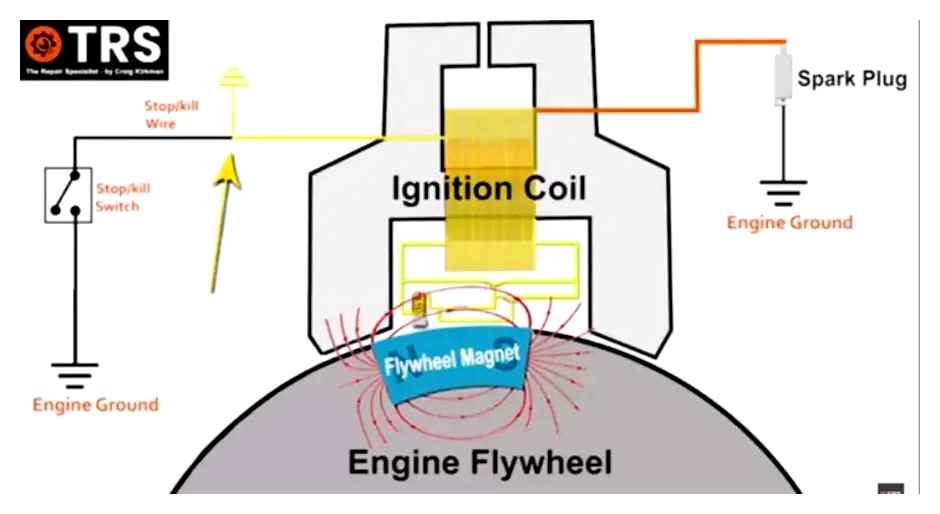

The coil of a lawn mower is located close to the flywheel. The flywheel spins as you pull the starting rope, while the magnet attached to the flywheel near the coil generates a voltage by induction. Before the engine starts, there has to be a spark that ignites the combustion chamber.

The coil goes round a hold over a thousand times which makes removing it to check for any break impractical. Continuity testing is employed to check for breaks without removing the coil. When you test for continuity and get a finite number, usually around 2500 to 5000, the coil is intact and is not broken. When you get an infinite number, it shows the coil is broken and needs to be replaced.

Why Use a Multimeter?

A multimeter is a device used to measure multiple quantities, including ohms, as in this case. The multimeter can test for continuity and let us know if the coil is bad and needs replacing.

Typically, using a multimeter to check the coil is like a fault detector. Before you can be sure of the fault, you have to test, and this is where the multimeter shines. If you’ve replaced the spark plug and successfully checked the fuel and air circulation, it may be time to bring in that multimeter.

Things to Check Before Testing Ignition Coil

The ignition coil is hardly the first troubleshooting your lawn mower gets if it is having problems starting. There are some other, often specific things you can check first before proceeding to the coil if the issue persists.

#1. Check Fuel, Fuel Filter, and Air Circulation

If you’ve not used the engine for a long time, the fuel might have gone bad and needs changing. Replace the fuel in the tank with fresh fuel and dispose of the old fuel. Fuel additives can help clean out debris from the carburetor.

Check that the gas cap is open and there is no debris clogging it. The gas cap will typically have vents that allow for proper ventilation and improve the carburetor flow.

The fuel filter traps dirt in the fuel as it moves from the tank to the carburetor. Throughout its job as a fuel sieve, it will become clogged with dirt which will then reduce the optimum flow of fuel into the carburetor. When this happens, you need to replace the fuel filter.

You should also check the air filter that serves as a sieve removing dirt from the air entering the engine. With time, even this filter itself becomes clogged and cannot work effectively. In this case, replace the air filter.

#2. Check Spark Plug

The spark plug is the next thing to check after examining the air filter and fuel. The plug is often overlooked and gathers black soot over time which shows that it has been overworked and spark plug needs to be changed.

Remove the spark plug by raising the spark cover and twisting the plug till it comes out. Examine the plug for black soot. Replace the spark plug if you find black soot on it. Luckily, it is very affordable.

#3. Check Oil

Too little oil, too much oil, and bad oil can all cause your mower problems. Check the oil and examine its color. Black oil shows the oil is bad and needs replacing. Remove the bad oil and replace it with fresh oil. Ensure you use the recommended oil.

Sometimes, the oil is depleted, which causes problems. In this case, top up the oil but ensure not to overfill the tank.

#4. What You Need to Check Ignition Coil

Here are what you will need to check your coil:

- A multimeter that can read resistance (ohms)

- A wrench to get access to the coil

- Your lawn mower owner’s manual

- Leather gloves

Steps to Check Coil With a Multimeter

If you’ve gone through the other tests without any luck, it may be time to check the ignition coil with a multimeter. Here are simple steps you can take to test your coil:

-

Open the Mower Before you can access the coil, you have to open the mower, and this is where your wrench comes in as you work your way into the mower.

Ignition coils are made to last for a really long time, but this is not often the case, with several factors increasing the likelihood of a break somewhere along the coil. As earlier mentioned, it is impractical to check the coil for a break or burnout manually, so using the multimeter is a better option.

To test the coil using the multimeter, touch the positive multimeter probe to the spark plug and the negative probe to the metal extending from the second terminal you’ll find on the ignition coil. Bear in mind the positive probe is red while the negative probe is black.

Conclusion

Trying to use your lawn mower only to discover it won’t start can be so frustrating. Most times, it can even cause you to use extreme force to pull the starting rope and break it in the process. Luckily, this article shows you an easy and effective method to test your ignition coil with a multimeter.

How does Lawn Mower Ignition Coil Works | Everything You Need To Know

Every lawnmower comes with an ignition coil. By maintaining the voltage, keeps the system up and running. The ignition coil works as source for the spark plug to acquire voltage from the battery. This makes the mower continue to run by producing the spark.

But the question is, how does lawn mower ignition coil works?

Most new lawnmowers have a Magnetron ignition system. There is a common principle for all modern lawnmowers that use ignition coils. The spark plug is powered by the ignition coil, which provides a high voltage to achieve a spark.

In this post, we are going to go for an in-depth explanation of how does lawn mower ignition coil works. After going through this article, you will have a clear idea about how does lawn mower ignition coil works. Let’s dive in!

- How Does Lawn Mower Ignition Coil Works?

- Electro-Magnetic Induction

- Increasing Voltage

- Transistor Switching Mechanism

- Operation of a Magnetron Ignition

- Problem Diagnose

- Check Damage

- Inspect Spark Plug

- Supply Of Voltage To The Ignition Coil

- Primary And Secondary Coil Circuits

- Step 1 – Turn off The Ignition Switch

- Step 2 – Apply Some Tune-up Grease

- Step 3 – Slide the Intact Coil into The Case

- Step 4 – Recheck

- Step 1 – Disconnect The Ignition Boot

- Step 2 – Make the Connections

- Step 3 – Start The Lawnmower

- Step 4 – Check The Intensity

- Defective Spark Plugs

- Overheating

- Fuel Inefficiency

- Lawnmower Stalling

- Quality Deterioration

- Lawnmower Backfiring

- Excessive Vibrations

- Defective Plug

- Defective Wire

- Defective On/Off Switch

- Defective ignition coil

- Insufficient Fuel Supply

- Spark Issues

- Low Compression

- Power Supply Issues

- Unfresh Gasoline

- Dead Battery

- Dirty Components

How Does Lawn Mower Ignition Coil Works?

Are you wondering how does lawn mower ignition coil works? During the 1980s, most lawnmowers used to run on induction ignition systems mainly. Over time lawnmower was updated, and the Magnetron ignition system replaced the induction ignition system.

Magnetron systems can create current without the help of mechanical points. The spark plug receives this current to produce sparks.

So, how the Magnetron ignition system produces current without the help of mechanical points? A transistor pair controls the switching and ensures current for the spark plug.

So, why latest lawnmowers have a Magnetron ignition system instead of other ignition systems? Compared to other ignition systems, the primary benefit of the Magneto ignition system is that energy is generated without the need for external sources.

Electro-Magnetic Induction

Everyone knows that without an ignition system, you can’t run a lawnmower. The ignition system of a lawnmower helps produce sufficient electric current to leap over the space between the electrodes of a spark plug and run it smoothly. Finally, sparks are produced for the ignition of fuel in the combustion chamber by this system.

As part of knowing “How does lawn mower ignition coil works?” you should also know which component helps the ignition system to do it. Can you guess?

Well, by using the phenomenon of magnetic flux or flux density, the system can operate. A physicist named Michael Faraday found out this theory in 1831.

He also explained the relationship between magnetism and electricity and detected magnets could generate electric current when they pass over coils of wire. The current is basically a result of pushing the electrons back and forth in the cable.

The coil works as a medium to pass the electric current from a corollary. At last, a magnetic field is developed from the system, which can induce a current in the next coil.

Increasing Voltage

As you already know, each latest lawnmower is equipped with a Magnetron ignition system, and a flywheel supports a Magnetron ignition system.

A flywheel makes contact with the engine crankshaft, and its job is to provide power from the motor to the machine smoothly.

The sluggishness of the flywheel resists and calms variations in the speed of the machine.

The edge of the flywheel is joined with a sole fixed magnet. When the flywheel rotates every single time, a coil of copper wire is sent by the magnet, which helps produce an electric current in the engine.

However, you have already known there is a space between the spark plug electrodes to ensure proper voltage. The electric current generated due to the flywheel rotation is not strong enough to pass this gap.

That’s why the ignition system features a transformer, which transforms voltage. It works as a secondary coil while rotating more to pass the electric currents. As a result, more voltage is generated because more rotation occurs in the second coil.

Transistor Switching Mechanism

As a part of knowing “How does lawn mower ignition coil works?” it is necessary to learn how transistor switching system works.

The ignition system of a lawnmower features a switching mechanism. It helps to turn off the power to the plug and not constantly spark and disrupt the piston cycle. So, the primary task of a magnetically sensitive transistor switch is to control the flow of power.

The transistor switch inside the lawnmower includes a spinning breaker. This component makes a fleeting contact with a single electrode to shut down the circuit.

On the other hand, if your lawnmower has a magnetron system, it is mainly supported by a Darlington transistor. This transistor combines a pair of transistors, which delivers a very high DC current gain.

When the trigger winding occurs, the first transistor identifies the current. Then, it helps open the second transistor, and a free flow of current occurs from the second transistor to the main coil.

Operation of a Magnetron Ignition

While wondering about “How does lawn mower ignition coil works?” do you know the basic principle of a Magnetron ignition? A lawnmower that has a Magnetron ignition system includes a heavy wheel. It spins continuously, either manually or electronically, for storing rotational energy.

Each spin helps to generate voltage, and it directly enters inside the main coil. Once the voltage goes to the secondary coil, the voltage increases. The reason is that the turn increases more than 53 times from the main coil to the secondary coil.

The increased voltage generates approximately 10,000 amps, and it is enough to pass over the gap between the spark plug electrodes.

Once the piston compressed the fuel-air blend, the generated spark ignites the fuel. Then it causes the piston to move and push the flywheel through additional revolution. It will ultimately create a self-sufficient cycle to fuel the engine.

These are the most crucial points you want to note down about “How does lawn mower ignition coil works?”

How Do You Check A Lawnmower Ignition Coil?

How do you check a coil? Fixing a small ignition coil is not a hassle as you think. By looking at its conditions and checking its internal functions, you can figure out whether the ignition coil has become faulty or not.

Just follow the steps to get a clear view of this question: — how do you check a coil?

Problem Diagnose

If you have any Diagnostic equipment, use it to check out Diagnostic trouble codes and identify a particular problem area. Now, give a comparison of the value between the faulty coil and a well-function coil.

Check Damage

Now inspect the internal coil conditions if you can see issues, such as —

Inspect Spark Plug

Spark plugs are one of the primary components of a lawnmower. That’s why you want to take out the spark plug and examine its current conditions. Make sure you notice their cables and whether there is a perfect gap between the spark plug electrodes.

Supply Of Voltage To The Ignition Coil

Now, use a multimeter to measure the supply of voltage to the ignition coil. You should note down if the voltage surpasses 10.5V.

Primary And Secondary Coil Circuits

Now, use the multimeter again to check out the circuits of the primary and secondary coil. For the primary coil, it should have resistance between 0.5 and 1.3 ohms. However, for secondary coil, it should have resistance between 2,500 and 5,000 ohms.

The coil is shorted if you notice zero reading. If it exceeds the ohms rating, it means an internal open circuit exists. Most times, if the coil becomes damaged, it will have less than 0.5 ohms. In that case, replacing the components is the best decision.

Those are all the important points you want to consider while wondering about “How do you check a coil?”

How Do You Fix An Ignition Coil On A Lawn Mower? Step by Step Guide

Are you wondering about this question: how do you fix an ignition coil on a lawnmower? We have already discussed how to check an ignition coil condition.

What did you find out? Is your ignition coil gets damaged? If yes, you want to replace it. Unless you change it, there is no point in knowing about “How do you fix an ignition coil on a lawnmower?”

Plus, we are assuming you are not a professional expert to fix the different parts of the ignition coil of a lawnmower.

Hence, you need to either take it to a nearby shop store to repair the ignition coil or replace it of your own with a new one. Since an ignition coil has a low price, replacing it is better to make your lawnmower fully functional.

Here we mention how to replace an ignition coil as you want to learn about “How do you fix an ignition coil on a lawnmower?”

Step 1 – Turn off The Ignition Switch

First of all, you want to turn off the ignition switch and give your hands to the ignition coil. Loosen all the nuts and bolts before removing them from the engine.

Also, don’t forget to disconnect the power connector. Now, it will be easy to take out the ignition coil from the engine.

Step 2 – Apply Some Tune-up Grease

Do you instantly place the new ignition coil, or is there something that needs to do? Before installing it, you want to apply some tune-up grease at the coil’s base, which will fight off greatly against moisture and prevent corrosion. If you notice your spark plug also gets damaged or is not working properly, it will be better to replace them together.

Step 3 – Slide the Intact Coil into The Case

Next, you want to slide the intact coil into the exterior case. Tighten the nuts and bolts appropriately without overdoing it. After that, fasten the electric connector to start the mower.

Step 4 – Recheck

The answer to the question of “How do you fix an ignition coil on a lawnmower?” is already cleared. But to become 100% confirm about it, you want to recheck whether any faulty code is still appearing. Also, do other tests to ensure no issues in the engine system.

So, these are all the steps you want to check while wondering about “How do you fix an ignition coil on a lawnmower?”

How Do You Test A Lawn Mower Ignition Coil? Step by Step Guide

Are you wondering about this question: how do I know if my lawnmower ignition coil is bad? You can figure out whether your lawnmower ignition coil is bad or not by looking at its conditions.

One of the most common symptoms you will notice is that your lawnmower is becoming hot while operating it. It may also shut off automatically after running it for a few seconds.

You cool it down and start the mower again. When the engine gets hot again, it turns off automatically. So, you must be thinking, how do I know if my lawnmower ignition coil is bad? Right?

The only option to know whether your lawnmower ignition coil is bad or not is by testing it. So, how do you test a lawn mower ignition coil?

If you don’t know how to test a lawnmower ignition coil, check out these steps:

Step 1 – Disconnect The Ignition Boot

First of all, you want to disconnect the ignition boot (

) from the spark plug and attach it to a spark tester.

Step 2 – Make the Connections

Now, make a connection between the open-end side of the tester and the spark plug boot by plugging the wire. Make sure you connect the boot properly. No loose movements!

Step 3 – Start The Lawnmower

Now, start the lawnmower while it is at normal temperature. Check out the display of the tester to find out its performance.

Can you see a normal spark while the engine is on? In addition, cutting some grass to check the mower’s performance is another thing you can do. Did your lawnmower shut off again while cutting the grass?

Step 4 – Check The Intensity

Check out the intensity of the spark plug while you are cutting the grass—a particular dissimilarity between when the mower is cold and when it is hot.

If you don’t see any spark or too little spark, you want to replace the ignition coil. However, if there is a decent amount of spark, your lawnmower might be having some other issues, which prevent it from running smoothly.

It is the perfect method to test a lawnmower ignition coil. Hopefully, you have learned about this question: how do I know if my lawnmower ignition coil is bad?

What Causes A Lawn Mower Coil To Fail?

Are you failing to figure out the main cause of your lawnmower coil failing? What causes a lawnmower coil to fail? The failure of a lawnmower may occur for several reasons. Here are the few common reasons you can note down:

Defective Spark Plugs

Defective spark plugs will force your lawnmower engine to run on increased output. Hence, you want to make spark plugs free from damage. Otherwise, it may cause an ignition coil failure.

Overheating

Have you experienced any overheating issues in the lawnmower engine? It may prevent the ignition coil from supplying electricity.

Fuel Inefficiency

Have you noticed if your mower engine is consuming more fuel than before? This is called fuel inefficiency, which may lead to ignition coil failure.

When this happens, your mower struggles to run itself smoothly as an insufficient amount of power reaches in the spark plug.

Lawnmower Stalling

An ignition coil failure may lead to lawnmower stalling. When this happens, you will notice your lawnmower is sparking irregularly to the spark plugs. As a result, the engine may shut down automatically after starting it.

Quality Deterioration

It is important to keep your lawnmower ignition coil in a fresh condition. Degradation of insulting may occur between the primary and second coil over time because of ignition coil failure.

So, these are all the main points you should consider when you want to know about “What causes a lawnmower coil to fail?”

Lawnmower Backfiring

Do you feel bucking, jerking, or stumbling while running your mower? So, when does a lawnmower backfires? Generally, a combustion event is supposed to occur inside the combustion cylinders. If it happens outside, it may be because of ignition coil failure.

Excessive Vibrations

Does your lawnmower vibrate excessively? The ignition coil insulation and windings might be broken because of it.

What Causes No Spark On Lawn Mower?

If your lawnmower doesn’t fire any spark, you can’t run the machine smoothly. So, what causes no spark on lawnmowers? It may happen for several reasons:

Defective Plug

Are you 100% confirmed if your spark plug doesn’t have any issue? No worn-out issues! If your lawnmower spark plugs are damaged or broken, they won’t fire to generate sparks.

How will you know your lawnmower has spark plug issues? In that case, you want to use the spark tester to check out whether it is firing spark while the engine is on.

If not, replacing the component is essential. We have already mentioned how to test spark plugs conditions above.

Aside from here are the most common issues you will see in a bad spark plug:

Defective Wire

Have you checked whether your spark plug connector and cable are okay or not? If the terminal connector of the spark plug wire is damaged or has become loose, it will cause no spark on the lawnmower. Keeping your lawnmower free from defective spark plug wire will ensure regular spark.

Defective On/Off Switch

Each latest lawnmower is equipped with a bail level at the handlebar to turn off or on the engine within seconds. There are five parts to the bail level. Various kinds of problems may occur in these parts. Here are they:

Defective ignition coil

An ignition coil either works smoothly or doesn’t work at all. However, sometimes you may see it works for seconds and turn off automatically. When the engine becomes hot after a few seconds or minutes, it shut down mechanically.

In that case, you can test out the ignition coil using a tester. We have already mentioned how to test ignition coil conditions above.

So, these are all the possible things you want to consider if you are wondering about “What causes no spark on lawnmower?”

Why Is My Lawn Mower Turning Over But Not Starting?

A lawnmower is supposed to start after turning it over. If not, there might be some issues. So, why is my lawnmower turning over but not starting? It can be related to several problems, which may be unknown to you.

Here are we are mentioning all the possible causes of “Why is my lawnmower turning over but not starting?”

Insufficient Fuel Supply

Have you ensured enough fuel supply for the mower? If the fuel filter becomes damaged or clogged up, it will prevent a smooth flow of fuel. As a result, the mower may turn over but fail to start due to lack of fuel supply.

Spark Issues

Is your lawnmower getting sufficient spark from the engine? If not, you may struggle to start the machine.

So, why does sparking deficiency occurs? It will happen for different reasons, such as —

- Defective spark plugs

- Bad ignition circuit

- Broken ignition switch

- Unbalanced security system

Low Compression

All lawnmower engines include cylinders, which should have a sufficient amount of pressure. If they have low compression, you will struggle to start the engine.

Low compression may occur due to a blown head gasket or mower valve. Stopping the leaking gases issue is essential. In that case, you want to change the leaking part.

Power Supply Issues

If your lawnmower has a bad or failing starter motor, you may struggle to start the engine. A bad or failing starter motor consumes a large number of amps to crank the engine.

As a result, the remaining amps are not enough to support the ignition system and fuel injectors. When this happens, abnormal sounds appear after turning it over.

Unfresh Gasoline

How long have you used the same gasoline? Unfresh gasoline deteriorates its quality and lacks combustibility when it remains idle for a long time. After a certain time, it will lead to a clogged carburetor.

So, how long can gasoline stay fresh? As per professional mechanics, it is better to change gasoline after 30 days. It will ensure optimal performance for the engine and prevent the clogged carburetor issue.

Dead Battery

Most lawnmower batteries are durable and long-lasting. But you may don’t know when they become dead due to no early signs. In that case, you can use a voltmeter to see the battery’s performance.

So, how will it measure its performance? For example, if your lawnmower battery has 12 volts, the reading should be close to 12 volts. If it is too less, you want to replace the battery soonest.

Dirty Components

Lawnmowers include various components. Though you can’t clean all parts, some parts need to be regularly cleaned, especially if you used them heavily.

Parts like spark plugs, carburetor, air filter, and fuel filter are necessary to clean daily. If not, dirt, grease, and other contaminants will build up inside the parts and prevent them from functioning smoothly.

So, these are all the possible causes when you want to know about “Why is my lawnmower turning over but not starting?”

What If I Don’t Replace An Ignition Coil?

We have already learned how does lawn mower ignition coil works? But do you know what will happen if you don’t replace it when it is necessary?

The first step you need to do knows when it is the perfect time to change your lawnmower ignition coil.

Delaying the replacement will hamper the overall performance of your mower engine. In addition, it will lack sufficient power and won’t run smoothly or not at all.

over, using a defective ignition coil for a prolonged time causes various issues for other components.

In fact, many garden experts recommend not using your lawnmower if you think it has some problems with the ignition coil. It may seriously damage the engine, and even professionals can’t repair it anymore. Hence, you have no option but to buy a new one.

Wrapping Up

Like other vehicles, a lawnmower has so many components, and an ignition coil is one of the most important parts of this machine. It is important to know how does lawn mower ignition coil works.

Knowing how does lawn mower ignition coil works will help you to decent any issue that occurs inside it. As a result, you can take quick action and save the machine from any extra damage. Hopefully, you have earned enough knowledge to know everything about lawnmower ignition coils. Thanks for reading!

Last update on 2023-01-28 / Affiliate links / Images from Amazon Product Advertising API

Lee Safin was born near Sacramento, California on a prune growing farm. His parents were immigrants from Russia who had fled the Bolshevik Revolution. They were determined to give their children a better life than they had known. Education was the key for Lee and his siblings, so they could make their own way in the world. Lee attended five universities, where he studied plant sciences and soil technologies. He also has many years of experience in the U.S. Department of Agriculture as a commercial fertilizer formulator.

Thoughts on How does Lawn Mower Ignition Coil Works | Everything You Need To Know

Lawn Mower No Spark – Fix Easily in Seconds

Winter has finally passed, and you can now start thinking about getting the garden back into Spring and Summer condition. Being a responsible owner, you decide to check that the lawnmower is running well before you need to put them to use.

If a lawn mower doesn’t have a spark, it can only be one of four wrong things. The spark plug is damaged or faulty, the high-tension wire connecting the spark plug to the ignition system fault is broken, the start/stop switch is not working, or there is a problem with the ignition system.

You fill the lawn mower with fuel check that the blades are good enough to give a good cut for another season.

When you are ready, you set the choke, pull the cord, pull the cord, and pull the cord. After straining your patience and your back, you sit down to consider what could be wrong.

How To Fix A Lawn Mower No Spark?

Internal combustion engines need three things, delivered at the exact time to work. These are.

If any of these is not present or is delivered to the cylinder in the wrong sequence, the engine won’t start.

In a nutshell, these are the factors a mechanic would check to find out the cause of the problem.

For this article, we will assume that fuel and air issues have been ruled out, and a test has shown that the lawnmower has no spark.

To start the engine, you need the ignition system to send a sufficient electrical charge through the high-tension cable to the plug, which will, in turn, set off a spark.

As in all electrical circuits, there must be no breaks or unintentional changes in resistance to cause the ultimate spark.

The four elements which need to be investigated are.

- The Stop/start switch and the wiring connecting to the ignition system

- The ignition system

- The Spark Plug itself

- The Spark Plug Wire

If any of these items are broken, the circuit won’t close, and the plug will not create a spark.

How To Check The Stop/Start Switch And Its Components?

The stop/start assembly includes the following components.

- Bail Throttle Control Lever

- Cable

- Stop/Start switch

- Flywheel brake assembly

- Coil control wire

Bail Throttle Control lever

This lever can become disconnected from the throttle cable, either because the adjustment is out of whack or, more likely, the control lever itself is broken. To fix this, source a new one and replace it on the machine.

The Cable May Be Broken

If the throttle cable is broken or stretched, it will not close the circuit, and a spark will not be produced.

The Flywheel Brake Assembly May Be Faulty

If the flywheel assembly is faulty, it could very well just be an adjustment issue where the cable is out of spec.

If this happens, the bail lever won’t move the switch to the off position, and therefore no spark will be generated.

The Stop-Start Switch Itself

Most lawnmower engines have a start-stop switch that connects directly to the flywheel.

When the Bail control lever is activated, it pushes on the stop/start switch and closes the circuit to the coil; this allows the engine to start.

If the switch has broken, a spark will not be generated.

You can test the switch by carrying out the following steps.

- Attach the spark plug lead to the spark tester and connect the tester’s ground lead to the engine (to ground it).

- First, turn off the switch.

- Pull on the cord or turn the starter motor over and watch for a spark in the tester window.

- If you see a spark in the tester, the switch is not switching off.

- Move the switch to the ON position and repeat step 3.

- If you don’t see a spark, the switch is not closing the circuit and needs to be replaced.

How To Check The Ignition System?

The ignition system sequences the spark exactly when the gas and air mixture is in the combustion chamber.

If the spark is not generated or occurs at the wrong time in the combustion cycle, the engine won’t start.

Most modern lawnmowers have ditched the old contact breaker ignition system in favor of solid-state unis; It has no moving parts, and the machine’s reliability is increased. Solid-state units use a tiny transistor positioned in the coil or armature to close the electrical circuit that travels through the spark plug leading to the spark plug(s).

First Test The Coil

If your lawnmower is not producing a spark, you should test the coil; this is very quickly done as follows.

- Clip the spark tester to the ignition cable and the cylinder head.

- If it sparks, the coil is working, and you can move on.

Check The Solid-State Ignition Unit

With no moving parts, these units are very reliable. If it does fail, it is probably because of incorrect fitting, which has caused it to get too hot.

If you have tested everything else and this is the last potential culprit, we suggest that you take the lawnmower to a dealer who will have the necessary equipment to find out what is wrong.

How To Check The Flywheel Brake Assembly?

The main issue which affects lawnmower flywheels is a sheared flywheel key.

The flywheel key’s function allows the flywheel to move on the crankshaft when your mower blade hits a hard obstruction, such as a root or metal outpost.

If the mower blade is loose, it may generate enough shock energy to shear the flywheel key.

To check the flywheel key, follow the manufacturer’s instructions and replace it if necessary.

How To Check The Spark Plugs?

The spark plug must be in good order and set to the correct gap to generate the spark required by the engine.

In a real-life situation, we would not wait until this late stage to check the plug because they are easy to replace and reinstall.

- When checking the plug, make sure that there are no carbon build-ups between the ground and center electrodes.

- Check that the ceramic insulator is not cracked or chipped.

- Check that the gap between the ground and center electrodes is within the lawnmower manufacturers’ specs.

Spark plugs are not expensive, and if you have any doubt about the one fitted in the lawnmower’s engine, buy a new one with the exact specifications.

If this doesn’t fix the problem, it is elsewhere on the engine, but you have eliminated one factor.

Checking The Wires To The Coil

There usually are three wires which lead to the coil.

- The High-Tension Spark Plug Lead.

- The power wire connected to the ignition unit

- The ignition switch wire.

If any of these are broken, the ignition system will be disabled, and there will be no spark.

Conclusion

In this article, we have discussed all the possible reasons why a Lawn Mower has no spark. Likely the cause will be relatively simple, and when investigating, we recommend checking the most straightforward possibilities before investigating the more complex possibilities.

If in any doubt, ask a qualified lawnmower technician to diagnose the problem for you.

Author

Jason is an expert writer and is passionate about Smart Homes and Home Improvements writing as well as lifestyle and Lawn Care. He spent the past twelve years living in Hawaii, where he worked closely alongside event planners and resort owners to perfect his knowledge of luxury products and aesthetics. He discovered his passion for DIY projects and home improvement there. Currently, he lives in Washington D.C with his family and 2 pets. View all posts

Mower Won’t Start No Spark (This Is Why)

Pulling and pulling and nothing, a mower without spark, is useless. In this post, we’ll cover all the most common ignition system failures.

Mower won’t start any spark? Common reasons a lawnmower has no spark include:

None of these tests are difficult, and twenty minutes from now, you’ll know why your mower has no spark.This post will have you covered, but if you need video help diagnosing no spark or help to fit a new coil, check out “Mower won’t start video.”

Checking Lawnmower Spark

Since you’ve checked the spark already, I’m guessing you know the procedure. However, it’s worth pointing out, getting this test wrong can lead to misdiagnosing and replacing the ignition coil or other parts unnecessarily.

Spark testing is, as you know, a simple test, you won’t need any special tools here, but a spark testing tool does make the job easier and totally foolproof.

If you need video help, check out the mower “Mower spark test video,” where I cover the whole process.

Tools needed

For these tests, you’ll need a plug spanner, insulated pliers, screwdrivers, and a spark plug is useful. You’ll also need a helper, as we’re not using a spark testing tool. It can be difficult to crank over the engine and, at the same time, check for spark. With all the tools gathered and a helper on hand, we’ll get right to it.

Spark Testing

As we’ll have a helper cranking over the engine, that means the blade will be spinning, and even though the engine’s not running, it can still remove body parts, so, you know!

You must use insulated pliers (plastic/rubber-handled pliers) to hold the plug as the voltages produced are enough to give you a jolt, which isn’t pleasant.

Tools – Plug spanner, insulated pliers, and a spark plug will be needed.

Spark test tools

Step 1 – Remove the spark plug wire by twisting and pulling, then using the plug tool, remove the spark plug.

Step 2 – Reattach the spark plug wire to the plug. Using your insulated pliers, hold the plug threads firmly against the metal of the engine. This is known as grounding. If the plug doesn’t make good contact with the metal of the engine, you won’t get a spark.

Step 3 – While you watch for spark, have the helper hold the bail lever as normal and yank on the pull cord.

If you have no spark, swap out the plug and test again.

If you still have no spark, it is most likely a failed coil, but best to check the on/off switch assembly first.

Common Spark Plug Faults

A healthy spark plug is essential for reliability, power, and smooth running. Plugs have a tough job. They carry high voltages and live at the heart of the engine where it’s hottest.

Making matters worse for the plug is its location – right out front of the engine. So getting shoved into fences and trees is all part of a spark plug’s life, and you thought you had it hard!These are the most common spark plug faults:

- Wrong plug type

- Dirty plug

- Bad plug gap

- Cracked spark plug insulator

Wrong Plug Type

Plugs areas you know are graded; each engine will have a particular plug code. So even though a plug fits, it doesn’t mean it’s correct. Plugs are graded by heat. The plug should get hot enough to burn off contaminants but not so hot that it pre-ignites. Wrong plug types can cause all types of problems, from hard starting, rough running, hot start failures, etc.

Plug type – Check your plug type with your mower engine maker.

An incorrect plug type will lead to intermittent problems.

Dirty Plug

Self-explanatory, it’s a plug that’s contaminated by too much gas (flooding), carbon, or oil. All of these will prevent the plug from doing its job. Flooding may be caused for a few reasons – blocked air filter, faulty choke, overuse of choke, tipping mower over on its carburetor side, and carburetor fault. Check out the video “How to fix a flooded engine.”

Carbon build-up in the engine is a normal condition. Fuel type, oil type, maintenance, and plug type all affect how quickly it builds.

Oil on the plug is also common. It’s caused by too much oil, blocked crankcase breather, head gasket fault, engine wear, and wrong plug type. Check out the video “How to clean a plug.”

Bad Plug Gap

A spark plug function is obviously to create a spark, and it can only do this if the electrode gap is correct. The coil has been designed to create a sufficient spark to jump a pre-determined spark plug gap.

- No gap, means no spark

- Gap too small means poor running or no start

- Gap too big means no start and risks damaging the coil

A plug gap tool is used to set the spark plugs gap. The electrode is manipulated to the correct size by simply bending it with pliers. Check out the video “How to gap a plug.”

Plug gap – The gap is important. Too small or too big can lead to no starts or poor running.

Cracked Plug Insulator

Self-explanatory too. The insulator is the white ceramic material of the plug’s body, and as said earlier, plugs are at risk of being damaged by bumping into obstacles. If the insulator breaks or cracks, the plug stops working.

Common Spark Plug Wire Faults

A spark plug wire has a few particular problems that affect them, depending on a few variables, like how and where they’re stored.

The common faults I see again and again include:

Loose Terminal

Caused by our old friends, the trees, shrubs, and fences. The plug wire terminal that clips to the spark plug becomes loose, and that can cause no starts, poor running, and intermittent starting/running.The fix here is simple, squeeze the terminal body using pliers to tighten it.

A loose terminal will cause the engine to misfire or not start at all. The quick fix here is to squeeze the terminal until it fits snugly on the plug.

Faulty Terminal

Because this cap was loose, it created arching, which burnt the metal of the terminal cap.

Faulty terminal connector – It’s different but related to a loose connector. A loose connector will often turn into a faulty one as the spark starts to jump inside the terminal, burning it or setting up conditions for corrosion to take hold.

The outcome is the same, no spark or poor running. A replacement terminal can be purchased and fitted to solve this issue.

Damaged Plug Wire

Plug wire rubbing off the engine cover can cause the insulation to wear and the coil to ground. But more often than not, a damaged plug wire means rodents. Mice love wiring insulation, and unfortunately, our furry friends have cost us a coil.

Sure, you can wrap them with insulation tape, but it’s only a quick fix. The long-term repair is to replace.

Damaged wire – Mice love to chew on the wiring insulation.

Common Stop/StartAssembly Faults

Most mower owners are familiar with the bail lever at the handlebars, which must be held to start the mower. Most mowers will use this type of stop/start system; other manufacturers may incorporate the stop/start function with the throttle lever. But apart from this difference, all other components will be very similar.

The main components of the stop/start assembly include:

- Bail/throttle lever

- Cable

- Flywheel brake assembly

- Stop/start switch

- Coil control wire

Bail / Throttle Lever

Common faults here include disconnected, out of adjustment, or broken levers.

Cable

The cables break and stretch, so it’s not uncommon for the bail lever to work, but because the cable has stretched, it doesn’t move the brake assembly to the start position.

Stop / start cable

Flywheel Brake Assembly

Common faults here include cable out of adjustment, meaning the bail lever doesn’t pull the brake to the off position.

Flywheel assembly

Stop/Start Switch

This is the on/off switch. It’s fitted at the flywheel brake assembly. When the bail lever pulls the assembly, it pushes on the switch removing the ground connection to the coil. This allows the mower to start.

On /off switch

Coil control – Here’s a different mower coil control switch. It’s a very simple connection; the contact points must separate before the coil and plug will create a spark.

The Coil (also known as Armature)

The control wire is connected from the stop/start switch on the flywheel brake assembly to the coil, which is fitted to the engine. The coil and plug won’t produce a spark so long as the control wire is connected to the ground (Metal of the engine).

A common fault is the chafing of the control wire on the engine (shorting to the ground); this effect is the same as releasing the bail lever – turns the engine off.

Check coil control wire for chafing, especially anywhere the wiring turns sharply around the engine.

Coil control wire – Coil control is a single wire with a push-on connection. Often they’ll come loose, and when they do, the mower won’t turn off.

Common Coil Faults

Coils generally work, or they don’t. Occasionally, you’ll get a coil that works when it’s cold and stops when the engine heats up. Coils are solid-state units – they can’t be repaired. Testing a coil and fitting a new one is easy; I wrote a whole post about it right here “Push mower hard to start when hot”.

Or check out the video here; it covers spark checking, diagnosing, and replacing the coil. If you need to replace the coil, check out the great deals on the Amazon link below.

Coils – Lawnmower coils give lots of problems; I replace tons of them.

Related Questions

Can a spark plug have a bad spark? Spark plugs wear out. A spark plug should be changed once every year at the start of the new season. You can check the spark plug for spark by removing it, connecting the plug wire, grounding it off the engine, and turning over the engine.

Hey, I’m John, and I’m a Red Seal Qualified Service Technician with over twenty-five years experience.

I’ve worked on all types of mechanical equipment, from cars to grass machinery, and this site is where I share fluff-free hacks, tips, and insider know-how.

And the best part. it’s free!