Lawn mower control bar. How Do You Start a Lawn Mower? 6 Simple steps

US4704847A. Control mechanism for walk-behind mower. Google Patents

Publication number US4704847A US4704847A US06/806,531 US80653185A US4704847A US 4704847 A US4704847 A US 4704847A US 80653185 A US80653185 A US 80653185A US 4704847 A US4704847 A US 4704847A Authority US United States Prior art keywords bale handle bar members mower control assembly Prior art date 1985-12-09 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Expired. Fee Related Application number US06/806,531 Inventor C. Austin Greider Timothy E. Berry Current Assignee (The listed assignees may be inaccurate. Google has not performed a legal analysis and makes no representation or warranty as to the accuracy of the list.) Murray Inc Original Assignee WESTERN INTERNATIONAL Inc Priority date (The priority date is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the date listed.) 1985-12-09 Filing date 1985-12-09 Publication date 1987-11-10 1985-12-09 Application filed by WESTERN INTERNATIONAL Inc filed Critical WESTERN INTERNATIONAL Inc 1985-12-09 Priority to US06/806,531 priority Critical patent/US4704847A/en 1985-12-09 Assigned to WESTERN INTERNATIONAL, INC., 3811 MCDONALD AVENUE, DES MOINES, IOWA 50322, A CORP. OF IOWA reassignment WESTERN INTERNATIONAL, INC., 3811 MCDONALD AVENUE, DES MOINES, IOWA 50322, A CORP. OF IOWA ASSIGNMENT OF ASSIGNORS INTEREST. Assignors: BERRY, TIMOTHY E., GREIDER, C. AUSTIN 1987-11-10 Application granted granted Critical 1987-11-10 Publication of US4704847A publication Critical patent/US4704847A/en 1995-10-23 Assigned to MURRAY, INC. reassignment MURRAY, INC. MERGER AND CHANGE OF NAME Assignors: MURRAY OHIO MANUFACTURING COMPANY, THE, MURRAY OUTDOOR PRODUCTS, INC., NOMA INDUSTRIES, NOMA OUTDOOR PRODUCTS, INC., Western International Incorporated 2000-11-20 Assigned to GENERAL ELECTRIC CAPITAL CORPORATION, AS AGENT reassignment GENERAL ELECTRIC CAPITAL CORPORATION, AS AGENT SECURITY AGREEMENT Assignors: MURRAY, INC. 2005-12-09 Anticipated expiration legal-status Critical Status Expired. Fee Related legal-status Critical Current

Images

Classifications

- A — HUMAN NECESSITIES

- A01 — AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01D — HARVESTING; MOWING

- A01D34/00 — Mowers; Mowing apparatus of harvesters

- A01D34/01 — Mowers; Mowing apparatus of harvesters characterised by features relating to the type of cutting apparatus

- A01D34/412 — Mowers; Mowing apparatus of harvesters characterised by features relating to the type of cutting apparatus having rotating cutters

- A01D34/63 — Mowers; Mowing apparatus of harvesters characterised by features relating to the type of cutting apparatus having rotating cutters having cutters rotating about a vertical axis

- A01D34/67 — Mowers; Mowing apparatus of harvesters characterised by features relating to the type of cutting apparatus having rotating cutters having cutters rotating about a vertical axis hand-guided by a walking operator

- A01D34/68 — Mowers; Mowing apparatus of harvesters characterised by features relating to the type of cutting apparatus having rotating cutters having cutters rotating about a vertical axis hand-guided by a walking operator with motor driven cutters or wheels

- A01D34/6806 — Driving mechanisms

- G — PHYSICS

- G05 — CONTROLLING; REGULATING

- G05G — CONTROL DEVICES OR SYSTEMS INSOFAR AS CHARACTERISED BY MECHANICAL FEATURES ONLY

- G05G5/00 — Means for preventing, limiting or returning the movements of parts of a control mechanism, e.g. locking controlling member

- G05G5/005 — Means for preventing, limiting or returning the movements of parts of a control mechanism, e.g. locking controlling member for preventing unintentional use of a control mechanism

- A — HUMAN NECESSITIES

- A01 — AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01D — HARVESTING; MOWING

- A01D34/00 — Mowers; Mowing apparatus of harvesters

- A01D34/01 — Mowers; Mowing apparatus of harvesters characterised by features relating to the type of cutting apparatus

- A01D34/412 — Mowers; Mowing apparatus of harvesters characterised by features relating to the type of cutting apparatus having rotating cutters

- A01D34/63 — Mowers; Mowing apparatus of harvesters characterised by features relating to the type of cutting apparatus having rotating cutters having cutters rotating about a vertical axis

- A01D34/67 — Mowers; Mowing apparatus of harvesters characterised by features relating to the type of cutting apparatus having rotating cutters having cutters rotating about a vertical axis hand-guided by a walking operator

- A01D34/68 — Mowers; Mowing apparatus of harvesters characterised by features relating to the type of cutting apparatus having rotating cutters having cutters rotating about a vertical axis hand-guided by a walking operator with motor driven cutters or wheels

- A01D2034/6843 — Control levers on the handle of the mower

- A — HUMAN NECESSITIES

- A01 — AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01D — HARVESTING; MOWING

- A01D2101/00 — Lawn-mowers

Abstract

A control assembly associated with a walk-behind mower having a handle bar that is attached to a rear portion of the mower body and is formed with opposite side portions and a rear cross portion extending between the side portions. Forming the control assembly, are two curved bale members juxtaposed in a side-to-side relationship with one another and pivotally connected between the side portions of the mower handle bar. A first control cable connects one of the pivotable bale members with an operator zone engine kill/restart assembly and a second control cable connects the other bale member with the wheel clutch so that these assemblies can be independently actuated by consecutive movement of the bale members to actuating positions. In a first preferred embodiment, each of the bale members includes a transverse portion conforming to the peripheral shape of the cross portion of the handle bar whereby the handle bar cross portion is received in the bale transverse portion when the bale is in an actuating position to operatively form a unitary member therewith.

Description

The present invention relates in general to control mechanisms for walk-behind mowers and more specifically relates to double actuating control mechanisms for such mowers to comply with federal safety standards.

Numerous safety standards have recently been federally enacted for the protection and safety of operators using walk-behind mowers. The primary purposes behind these regulations are to prevent the engine of the lawn mower from operating if the user of the mower is not in a proper operator’s position to prevent rocks and other debris from being thrown by the mower against the operator’s body, and to make it difficult, if not impossible, for the operator to come in contact with the cutting blades of the mower while they are in motion.

To achieve the above purposes in connection with power driven walk-behind mowers, federal regulations require separate means for actuating the engine kill/restart control and the wheel clutch. To meet these requirements, a control system that has been used almost industry-wide was developed. This control system utilizes a single-control bale associated with the handle bar of a mower and a trigger mechanism releasable by the bale. In operation, the control system is designed so that when the bale is in a forward (neutral) position with respect to the end of the mower handle bar, the engine kill/restart control and wheel clutch are disengaged. Upon movement of the bale to its rearwardly most position, the engine restart is engaged to permit the engine to be started. Once the engine is started, the trigger mechanism is then manually cocked by the user to engage the drive clutch and the mower is then in normal operation. Disengagement of the engine kill/restart and drive clutch occur as the bale is returned to its neutral position. However, disengagement of both does not occur simultaneously. Instead, as the bale is partially returned to the neutral position, first the drive clutch is disengaged to stop the self-propelled action of the mower. As the bale reaches its neutral position, the engine is then killed by release of the engine kill/restart. In this way, it is possible for a user to stop the self-propelled action of the mower without killing the engine in instances when it is necessary to turn the mower around or prevent it from hitting objects, etc.

Although the above type of control system is used almost industry-wide, it has a major deficiency making it difficult to properly control the mower because it is difficult for a user to discern the proper forward movement of the control bale to disengage the self-propelled drive but yet not turn the mower off. Thus, users must pay careful attention to the degree of bale travel while they are using a mower with such a control mechanism.

The present invention provides an improved mower control assembly with independently actuated bale members for separately controlling engagement of the engine kill/restart and engagement of the drive clutch.

The present invention provides a dual function manual control assembly for actuating two independently controlled mechanisms of a power driven lawnmower having a handle bar attached to a rear portion of the mower body. The control assembly includes a first bale member pivotally associated with one side of the handle bar, a second bale member pivotally associated with the opposite side of the handle bar, and connecting means for pivotally connecting the opposite ends of each of the two bale members in association with the handle bar. The bale members are connected to the handle bar in such fashion that either of the bale members is independently pivotable from a normal nonactuating position to an actuating position in which the bale members lie adjacent the handle bar. The control assembly further includes means for connecting the bale members to their respective controlled mechanisms so that one of the mechanisms is actuated by pivotal movement of the first bale member and the other of the two mechanisms is actuated by pivotal movement of the second bale member.

In the preferred embodiment of the invention, each of the bale members includes a transverse portion conforming to the peripheral shape of the cross portion of the handle bars. Thus, the handle bar cross portion is receivable in such transverse portion when the bales are in their actuating positions whereby the handle bars and bale operatively form a unitary member.

It is an object of the present invention to provide a control assembly that can be easily and effectively operated to properly control a self-propelled lawn mower. A further object of the present invention is to provide a control assembly that is relatively simplistic in construction but yet will meet all requirements of the existing federal regulations. Other objects and advantages of the present invention will become apparent from the following more detailed description when taken in conjunction with the attached drawings in which all similar elements are like numbered.

FIG. 1 is a rear side partial perspective view of a walk-behind mower on which a first preferred embodiment of the control assembly of the present invention is employed;

FIG. 2 is an enlarged perspective view of the handle bar and control assembly of FIG. 1, which assembly is shown in a partially actuated condition;

FIG. 3 is a perspective view of a bale member forming a portion of the control assembly in FIG. 1; and

FIG. 4 is a perspective view of a second preferred embodiment of the control assembly of the present invention mounted on a mower handle bar.

Referring now to the drawings and with reference first to FIG. 1, a typical walk-behind self-propelled lawn mower is partially shown generally at 10. The only difference between the mower 10 and power mowers presently being used is that the mower 10 includes a first preferred embodiment of a dual bale mower control assembly of the present invention shown generally at 11.

The mower 10 includes a blade housing 12 for a rotary cutting blade (not shown) driven by the conventional gasoline engine 14. Steering of the mower 10 is accomplished by a handle bar 15 that is attached to the rear of the mower body to extend upwardly and rearwardly therefrom. Preferably, the handle bar 15 is formed from two tubular opposite side portions 17 and 18 and a tubular cross portion 19 that extends between and connects the rear ends of the side portions 17 and 18.

The engine 14 is adapted through drive trains and clutch mechanisms (not shown) to serve as the power source for both the mower blade and drive wheels of the mower 10, which drive wheels may either be the front wheels (not shown) or rear wheels 21 of the mower 10.

The control assembly 11 is adapted for mounting from the handle bar 15 to provide for independent actuation of the engine 14 and the drive clutches. The control assembly 11 includes a pair of bale members 24 and 25 that are a mirror image of one another and are journaled on an axle 26 extending between the side portions 17 and 18 of the handle bar 15. The bale members 24 and 25 are generally of a U-shaped configuration (as shown in FIG. 2) and each include a partially curved side 27 adjacent one of the handle bar portions 17 or 18, a straight side portion 28 and a transverse rear side 29, all of which sides 27, 28, and 29 form the bale members 24 and 25 in unitary fashion.

As shown best in FIG. 3, the bale member rear side 29 is arcuately-shaped to conform to the tubular configuration of the handle bar cross portion 19. Thus, the cross portion 19 is receivable in the arcuate rear bale side 29 of either of the bale members 24 or 25 when they are moved to their fullest rear position as indicated by bale 24 in FIG. 2.

The bale members 24 and 25 are preferably spring biased in their forward most position by spring assemblies (not shown) associated with cable control means 31 and 32, as are well known in the art, attached respectively to bale members 24 and 25. As indicated by FIGS. 1 and 2, the cable assemblies 31 and 32 are connectable respectively to the bales 24 and 25 by means of two vertically spaced apart appertures in the sides 27, and the particular apperture utilized is dependent upon the amount of stroke desired for the bales 24 and 25. Preferably, the bale member 24 is associated with the operator zone engine kill/restart and the bale member 25 is associated with the drive clutch. Consequently, to start the engine 14 requires the bale member 24 to be pivoted from its forward most neutral position to its rearward most (actuating) position in which the bale member rear side 29 is adjacent the handle bar cross portion 19. It should be noted, that the bale members 24 and 25 each include a limit of movement abutment prong 33 extending outwardly from the free end of the bale member curved side 27 in orthogonal fashion thereto to ensure that the bale members cannot be pivoted beyond their engagement with the handle bar cross section 19.

Once the engine 14 has begun running, engagement of the drive wheels of the mower 10 is simply accomplished by moving the bale member 25 to its rearward most (actuating) position. This places the mower 10 in its self-propelled mode and normal cutting operation is initiated. It should be easily recognized, that if it is desired to stop the self-propelled action of the mower 10, all that is required is release of the bale member 25 by the user to permit such bale member to return to its forward most (neutral) position thereby deactuating the drive clutch.

Referring now to FIG. 4, a second preferred embodiment of the control assembly of the present invention is shown generally at 35. The operating principle of the assembly 35 is identical to that of the assembly 11. The only differences between the assemblies 11 and 35 is that the assembly 35 has bale members 36 and 37 that are of a different shape than the bale members 24 and 25 and are connected in a different fashion to the handle bar 15. Similar to the bale members 24 and 25, the bale members 36 and 37 are a mirror image of one another and include a tubular-shaped side 38 adjacent one of the handle bar side portions 17 or 18 and a tubular-shaped rear side portion 39. However, the bale members 36 and 37 differ from the bale members 24 and 25 by having the side 38 terminating in a prong 40 and a curved truncated side portion 41 that extends only a short distance out from the rear side 39 and has a pronged end 42.

The bale members 36 and 37 are pivotally connected to the handle bar 15 by means of the prongs 40 and 42 on the ends of the sides 38 and 41. The prongs 40 and 42 extend into corresponding apertures 43 and 44 in the handle bar side portions 17 and 18 and a connecting means 48 to serve as axles for the bale sides 38 and 41. The connecting means 42 is attached to the medial portion of the handle bar cross portion 19 to pivotally connect the truncated sides 40 of the bale members 36 and 37 to such cross portion.

Thus, the present invention provides a dual bale mower control assembly that is relatively simplistic in construction and operation but yet fully and effectively meets all federal regulations for providing dual control of the starting and driving functions of a self-propelled walk-behind mower. Not only is the control assembly of the present invention easy for a user to become familiar with, but moreover, the control assembly can thereafter be used for operating the mower 10 in almost troublefree fashion.

Claims ( 4 )

A dual function manual control assembly for actuating two independently controlled mechanisms of a power driven lawn mower having a handle bar that is attached to a rear portion of the mower body and is formed with opposite side portions and a rear cross portion extending between said side portions, said assembly comprised of:

(a) a first bale member having one end pivotally associated with one of said opposite side portions and an opposite distal end;

How the auto choke works on a Briggs and Stratton lawnmower engine

(b) a second bale member having one end pivotally associated with the other of said opposite side portions and an opposite distal end adjacent to the distal end of the first bale member;

(c) means for pivotally connecting said opposite distal ends of said bale members in association with said handle bar in such fashion that either of said bale members is independently pivotable from a normal nonactuating position to an actuating position in which said bale member lies adjacent said handle bar;

(d) means connected to said first and second bale members and said controlled mechanisms so that one of said mechanisms is actuated by pivotal movement of said first bale member and the other of said mechanisms is actuated by pivotal movement of said second bale member; and

(e) each of said bale members includes a transverse portion conforming to the peripheral shape of the cross portion of said handle bar whereby said cross portion is received in said bale transverse portions when said bales are in their actuating positions to operatively form a unitary member with said cross portion.

A control assembly as recited in claim 1 wherein said connecting means for said opposite ends of said first and second bale members is formed by connecting means positioned on a medial portion of said handle bar cross portion.

A control assembly as recited in claim 1 wherein said pivotally connecting means is formed by an axle member extending between and attached to said opposite portions of said handle bar and said ends of said bale members are pivotally attached to said axle member.

A control assembly as recited in claim 1 where said one ends of said bale members each includes an abutment member for engaging said handle bar to limit the movement of said bale members.

US06/806,531 1985-12-09 1985-12-09 Control mechanism for walk-behind mower Expired. Fee Related US4704847A ( en )

Priority Applications (1)

Applications Claiming Priority (1)

Family Applications (1)

Cited By (24)

Patent Citations (8)

Cited By (31)

Similar Documents

Legal Events

Owner name: WESTERN INTERNATIONAL, INC., 3811 MCDONALD AVENUE,

Free format text: ASSIGNMENT OF ASSIGNORS INTEREST.;ASSIGNORS:GREIDER, C. AUSTIN;BERRY, TIMOTHY E.;REEL/FRAME:004492/0986

Effective date: 19851122

Free format text: PAT HLDR NO LONGER CLAIMS SMALL ENT STAT AS INDIV INVENTOR (ORIGINAL EVENT CODE: LSM1); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY

Year of fee payment: 4

Free format text: PAYOR NUMBER ASSIGNED (ORIGINAL EVENT CODE: ASPN); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY

Year of fee payment: 8

Owner name: MURRAY, INC., TENNESSEE

Free format text: MERGER AND CHANGE OF NAME;ASSIGNORS:NOMA INDUSTRIES;NOMA OUTDOOR PRODUCTS, INC.;WESTERN INTERNATIONAL INCORPORATED;AND OTHERS;REEL/FRAME:007666/0694

Effective date: 19870908

Free format text: PAYER NUMBER DE-ASSIGNED (ORIGINAL EVENT CODE: RMPN); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY

Free format text: PAYOR NUMBER ASSIGNED (ORIGINAL EVENT CODE: ASPN); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY

Effective date: 19991110

Owner name: GENERAL ELECTRIC CAPITAL CORPORATION, AS AGENT, IL

Free format text: SECURITY AGREEMENT;ASSIGNOR:MURRAY, INC.;REEL/FRAME:011333/0036

Effective date: 20001005

Free format text: PATENT EXPIRED DUE TO NONPAYMENT OF MAINTENANCE FEES UNDER 37 CFR 1.362

How Do You Start a Lawn Mower? 6 Simple steps

Starting a mower is a straightforward procedure. But before you start your mower, it’s always a good idea to check the fuel and oil levels. Do a quick check over, looking for any loose or damaged parts. Turn the mower over, carburetor side up, and check for grass build-up and blade condition.

How do you start a lawnmower? To start a lawnmower successfully, you need to:

In my experience, many nonstarts are caused by a simple issue, something a homeowner can easily take care of.

This post should have you covered, but if you need video help, check out “Common causes of a no start mower video”. The video walks you through the lawnmower starting process and how to check all the common simple causes of a no-start mower.

Simple Starting Procedure

First, pick a suitable location to start your mower. You don’t want tall grass catching the blade as your try to pull start the mower. If you have a throttle lever-type system go ahead and move the lever to full choke. If you have the primer bulb type, press three times.

1 Check Oil – Best to check the oil before starting the engine. A low oil level will often prevent the engine from starting. The upper mark is the correct oil level. Check out this guide to help check oil level.

2 Gas – Is there enough gas in the tank? A low gas level may cause hard starting.

3 Gas “On” – Gas valves are not fitted to all mowers. They are used to stop the flow of gas to the carburetor. The gas tap should be turned off when the mower is in storage. Click here for help finding your gas tap.

4 Choke – If you have a throttle lever-type system go ahead and move the lever to full choke.

If you have an Auto choke, you can go straight to yanking on the pull cord.

Primer bulb – Your mower may have a primer instead of a choke lever. If so press it 3 times.

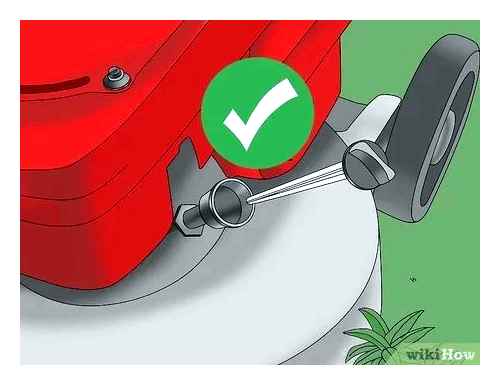

5 Bail Lever – Now hold the Bail lever also known as the dead man’s lever, this is the bar at the top of the handlebars usually marked with a stop symbol. The other lever is the self propel lever.

The Bail lever is a safety feature that modern mowers must have. Its function is to stop the blade from spinning and kill the engine within 3 seconds of bail lever activation.

Pull Cord – Now grab the pull cord handle and give it a good yank, the engine must turn over at 350 rpm minimum in order to produce a spark strong enough to ignite the fuel.

If you find the pull cord very stiff to pull, make sure the blade isn’t obstructed by dry grass on the deck, and check that the bail lever is working properly.

Try Again – Most mowers don’t run with the first pull so don’t be disappointed. It may take two or three pulls. If it takes more than three pulls you may flood the engine with too much fuel. If this happens, just leave it to sit for thirty minutes and try again, but this time don’t apply the choke.

6 After Starting – As soon as your engine has warmed up, move the throttle lever to fast/run (If manual choke fitted). A warm engine running continually on a choke will give off black smoke, run poorly, and will shorten its life.

Oil Check Adding Oil

Oil is best checked on a cold engine, I check the oil level every time I fill the gas tank. Most mowers will be happy with 10w30 car engine oil and from empty, take about.65 of a quart (.6lt). Why not go ahead and give your mower a tune-up, a lawnmower should be serviced at least once a year. The beginning of the new season is the best time to tune up your mower. This guide will help you service your mower in under an hour – “Lawn mower tune-up”.

Add Oil – Add small amounts and then check. Too much oil is almost as bad as too little.

Common Lawn Mower Fuel Problem

If this is the first start of the season, consider the fuel quality. Gas that’s been in the mower since last year is probably bad. So if your mower is hard to start or won’t start – try draining the gas tank and filling it with fresh gas. If the problem persists then a carburetor clean will fix the gremlins. This easy-to-follow guide will walk you through the whole process – “Carburetor cleaning”.

Fuel Stabilizer – Last season’s gas is the number one reason for lawnmower no starts. We all do it – put the mower away, not knowing for sure if that was the last cut.

Before you know it, it’s spring, and guess what? The mower won’t start, now you’ll need to clean out the fuel system.

To prevent this from happening next spring – add a stabilizer to the gas before the season’s end. I use Sta-bil gas treatment,1 ounce treats up to 2.5 gallons, it prevents gumming and cleans the fuel system. It can be used in all gas-powered kit including 2 stroke engines. Check out the video on fuel stabilizers, it covers mixing and adding.

What Is A Choke?

The Function of a choke or priming bulb is to enrich the fuel mixture, so a cold engine starts smoothly. Gas engines run best when the ratio of air to fuel is 14.7 to 1. Meaning 14.7 parts air to 1 part fuel, also known as an air-fuel ratio (AFR). Using the choke or priming bulb enriches the fuel mixture which counteracts the lean condition caused by the dense cold air. Engine manufacturers commonly use two system types to achieve smooth cold starts.

Choke Plate – The Choke Plate type, usually controlled by a lever. Some of the latest choke plates are thermostatically operated meaning they are an automatic system. This choke plate reduces the amount of air and increases the amount of fuel supplied to the engine.

Primer Bulb – The second type is the Primer bulb. This is very simple and easy to use, it creates a fuel-rich condition by squirting extra fuel into the engine. You do this by pressing a rubber primer bulb, mounted at the carburetor

Choke – Choke set to full to start a cold engine, after the engine warms up move the choke to the fast setting.Some mowers use a snowflake symbol for the choke.

Related Questions

How can I start my pull-start lawnmower if I’m not strong enough to use the starter cord? You can tune up your engine and adjust the valve lash, this will reduce the amount of strength needed to turn over and start the mower. In addition, have a starter motor and battery fitted.

How to start a lawnmower in one pull? To start a mower in one pull, make sure your gas is fresh, prime the engine, put the bail lever on, and now one good pull.

Hey, I’m John, and I’m a Red Seal Qualified Service Technician with over twenty-five years experience.

I’ve worked on all types of mechanical equipment, from cars to grass machinery, and this site is where I share fluff-free hacks, tips, and insider know-how.

And the best part. it’s free!

How to Use a Self-Propelled Lawn Mower

David Beaulieu is a landscaping expert and plant photographer, with 20 years of experience.

Jessica Wrubel has an accomplished background as a writer and copy editor, working for various publications, newspapers and in public libraries assisting with reference, research and special projects. In addition to her journalism experience, she has been educating on health and wellness topics for over 15 years in and outside of the classroom.

Self-propelled lawnmowers work on a vehicle-like drive system that requires the operator to squeeze a bar (called a bail) on the handle to engage the mower. Squeezing the bar causes the cutting blades on a self-propelled rotary mower to spin and makes the mower take off. After that, the mower moves forward independently, not requiring your pushing power. You only need to control the direction it goes.

If you release your grip on the bar, the mower stops moving, and its blades stop spinning. You may be familiar with this type of device if you have a hand-guided self-propelling vacuum cleaner; it has its drive doing a lot of the moving for you.

If you’ve ever wondered how self-propelled lawn mowers work and if they’re worth considering for your lawn, read on to learn more.

What Is a Self-Propelled Lawnmower?

A self-propelled device means it has a drive and doesn’t require your strength to operate it. You still need to steer the lawn mower since it’s not an autonomous robot, but it can save you time and energy.

Self-Propelled Lawn Mower vs. Push Mower

Self-propelled lawn mowers are motorized and drive independently, only requiring you to steer and move along with the device. The machine does the heavy lifting while you guide it along.

Lawn Mower Will Not Start?.This is Probably Why! ‘Simple Fixes’

On the other hand, a push mower tells you in its name that you will need to use your body strength to push it. Push mowers can vary widely from non-motorized reel push mowers to motorized push mowers powered by battery, gas, or an electric plug. Here are two different types of push mowers:

- Reel mowers: Best suited for small, flat lawns; using no power, only your push strength to turn the axles that push the blades and wheels; least expensive and lightest to transport, requires some effort to wield; not the best for all situations

- Motorized push mower: Uses gas, battery, or electric plug to run its motorized blades; still requires your pushing power to move the mower; requires less strength than a reel mower; a better option than a reel mower for larger, uneven lawns

- Heavier

- expensive

- Require less body strength and effort

- Best for large lawns and uneven surfaces

- Feels like less of a chore

- Requires gas or electric energy source

- Lighter in weight

- Cheaper

- Motorized types still need power

- Reel types require more strength and energy

- Reel types are safest; no mechanized parts

- Reel types are most eco-friendly option

Parts of a Self-Propelled Lawn Mower

A self-propelled mower uses many parts in the mower’s drive and transmission system, including engine parts, blades, pulleys, belts, a power source, and the safety bail. Much like a car, these parts need regular maintenance and occasionally replacement. The list goes on, from bearings and bushings to axles and air filters. These mowers can offer speed controls, height adjustments, discharge bag attachments, and even cup holders.

Some higher-end models may have a special feature like a blade override system that makes the blade stops spinning when you release the bar, and the unit stops moving, but it does not entirely shut off. This feature is convenient for two reasons: You can move the mower from point A to point B using its drive but not cutting grass along the way, and you don’t have to restart the mower every time you release the bar.

Safety Considerations

The bail or squeeze bar safety feature is the norm nowadays, even on mowers that are not self-propelled, like a battery-powered push mower.

This safety feature works great to prevent accidents and avoid hazards in your line of sight, like giant holes on the lawn or sprinklers, rocks or boulders, children running around, or pet mishaps. If you slip and lose your footing, there’s less chance of spinning blades coming into contact with your body. Also, while sidestepping things in the way, you don’t have to fiddle with a switch to try to shut the mower off; you only release the bar.

Buying vs. Renting

You can get a decent self-propelled lawn mower starting at about 300. The price goes up from there. If you rent a lawn mower, it can cost you around 40 a day or 150 a week for a name-brand lawn mower that is listed for 450. Most lawn mowers will last many years and most good models come with a 2- to 4-year warranty. If you have any size lawn—whether small or large—it will require mowing. And, during the growing season, from spring to fall, you might need to mow it once or twice a week.

Rentals only work in your favor if you’re saving money to get a new machine, your mower is being serviced, or you want to try a newer model before buying it. Ultimately, purchasing the device is less expensive than renting it.

Keeping the Self-Propelled Lawn Mower Maintained

Your lawn mower will need a tune-up once a year. You can do this maintenance or call for a service to maintain your machine. Annual maintenance includes changing the engine oil, adding a fuel stabilizer to the fuel system or removing the gas from the system if it’s old or at the end of the season; replacing the spark plug and air filter; sharpening and balancing the mower blades; cleaning the housing; and winterizing your engine. Also, check your belts for wear and tear.

When to Replace Your Self-Propelled Lawn Mower

Most lawn mowers have replaceable parts that can help you extend the life of your machine. Do the required maintenance, such as changing air filters and getting new gas and oil. But, as the years wear on, your costs to fix a problem may be more than buying a new one.

If your machine chugs, sputters, or makes a loud unexplainable noise, the rule of thumb is the costs of repair should not come close to buying a new model. If the motor, transmission, or crankshaft is gone on your machine, it’s probably time to look for a new lawn mower.

The Best Zero-Turn Mowers of 2023

These achieve the rare feat of making lawn mowing fun.

By Roy Berendsohn Published: Mar 1, 2023

When it comes to yard work, zero turn mowers do the impossible. They make lawn mowing fun. They accomplish this by putting unprecedented speed, control and maneuverability at the disposal of the person mowing the lawn. The so-called “zero turn” feature of these mowers converts a grass cutting machine into something akin to an amusement park ride. You steer the machine with two levers—the left lever controls the left wheel, the right lever the right wheel. With that steering setup, you can zoom over the landscape cutting straight lines, curves, or pivot the mower into and out of a corner. What’s not to like?

Read on to understand how these agile grass cutters work, how we go about testing them, and see some candidates that we’ve recently tested as well as some that we haven’t but that we think look particularly promising.

How Zero-Turn Mowers Work

A zero-turn riding mower consists of an operator platform, a frame and wheels, an engine (or battery bank), transmissions (or motors), and a pair of control levers commonly known as lap bars. In gas mowers, the engine powers a pulley system. One group of pulleys drives the blades, another group powers a pair of transmissions–one at each rear wheel. When you move the lap bar forward or back, you are directing the transmission to go faster, slower, or even turn the opposite way. When one drive wheel turns clockwise and the other counter clockwise, the mower pivots. When the wheels rotate at different rates, the mower turns in an arc-shaped path. When the lap bars are in the neutral position, the mower stops. Aside from a parking brake, there’s no other braking mechanism. Battery-powered zero-turn mowers work the same way, but have separate motors to drive the rear wheels and one for each blade inside the mower deck.

When it comes to transmission, most mowers have a Hydrogear EZT—a well-known and cost-effective residential-grade transaxle with a reputation for durability.

Some mowers use a deck stamped from one piece of steel, others use a deck fabricated from multiple pieces and welded together. A fabricated deck can be built from thicker steel at a lower cost than it would be able to be built otherwise. Once you’re talking about stamping metal as thick as 10 gauge (about 1⁄8 inch thick), the cost of stamping such a deck would push up the mower’s price beyond what most people are willing to pay. The decks in the mowers below range from 42 to 52 inches, a typical size in this class of product. When powered by these engines and the Hydrogear, these mowers will deliver a decent cut quality at their rated top speed of 7 mph. Note, however, that cut quality declines steeply if you maintain that speed in very thick grass or on uneven terrain.

As to the electric mowers, they represent the leading edge of the technology in this category. These are remarkable and expensive mowers powered by large-voltage lithium-ion batteries. If you’re interested in reducing mowing noise and simplifying your maintenance routine by eliminating gas and oil, they’re worth a look.

Selecting a Zero-Turn Mower

Everyone would like to select the biggest possible zero-turn mower with the hope of whittling a big grass cutting job down to size as quickly as possible. Reality usually intercedes because these machines are expensive and the wide range of options available today quickly drive up the cost. Roughly speaking, you start somewhere in the range of a mower with a 42-inch deck costing in the vicinity of 3200 to 3500 and move up in increments of 1000 to 1500 until you reach entry-level commercial-grade equipment that costs 7000 to 8000.

Again, speaking in terms of approximation, a mower with a 42-inch deck will cut a two-acre lot (that takes into account that the house, driveway, outbuildings and various landscape features are taking up some of that space). Use a mower with a larger deck to cut anything over two acres. But here’s the caveat. That entry-level ZTR mower (3200, say) with a 42-inch deck will wear out faster and need more maintenance than a mower with a 50-inch deck, a heavier frame, larger engine and higher quality transmissions, and thicker deck with more robust blade spindles, costing 4500.

In the simplest possible terms, you can cut a smaller area with a larger mower and expect more longevity out of the machine (not to mention a nicer mowing experience) or you can cut a larger area with a smaller machine and encounter more maintenance and a mowing experience that will be, we might say, a bit more rugged.

But there are still other factors to consider, in selecting a mower other than deck size and your budget. Larger mowers take more space in a garage or outbuilding. And a mower with a 50-inch or even 60-inch deck, as useful as it might be in getting the job done more quickly, may not fit through a fence’s gate, and it might be more difficult to maneuver in tight spots without creating scalp marks on the lawn from a lot of close-quarter pivoting.

Carefully consider all these factors when shopping for a mower: your budget, maintenance and whether you will perform that work yourself, mowing speed and time, maneuverability and trimming in tight areas, the importance that you place on your comfort while mowing, cut quality, longevity, storage, and access to the landscape.

How We Select and Test

There’s only one way to test a mower, and that’s to cut grass with it. But we also do more than mow.

We raise and lower the deck and adjust the seat. We look at service point access (the air filter, the spark plug, and the oil filter) and how easy it is to remove the deck. We mow approximately an acre with each mower, considering cut and mulching quality while running uphill, downhill, across washboard, and along sidehills. (On sidehills, we’ll mow surfaces pitched up to approximately 20 degrees; manufacturers generally recommend not going steeper than 10 degrees, but we like to be thorough.) We evaluate power and speed relative to cut quality—we investigate whether the mower delivers a decent cut mowing at full speed. When mowing in damp conditions, we look at whether the mower’s tires accumulate grass and how effectively it discharges moist clippings. Finally, we test maneuverability (these machines are, generally, very nimble) and how readily they come to a stop when you back off the lap bar control levers.