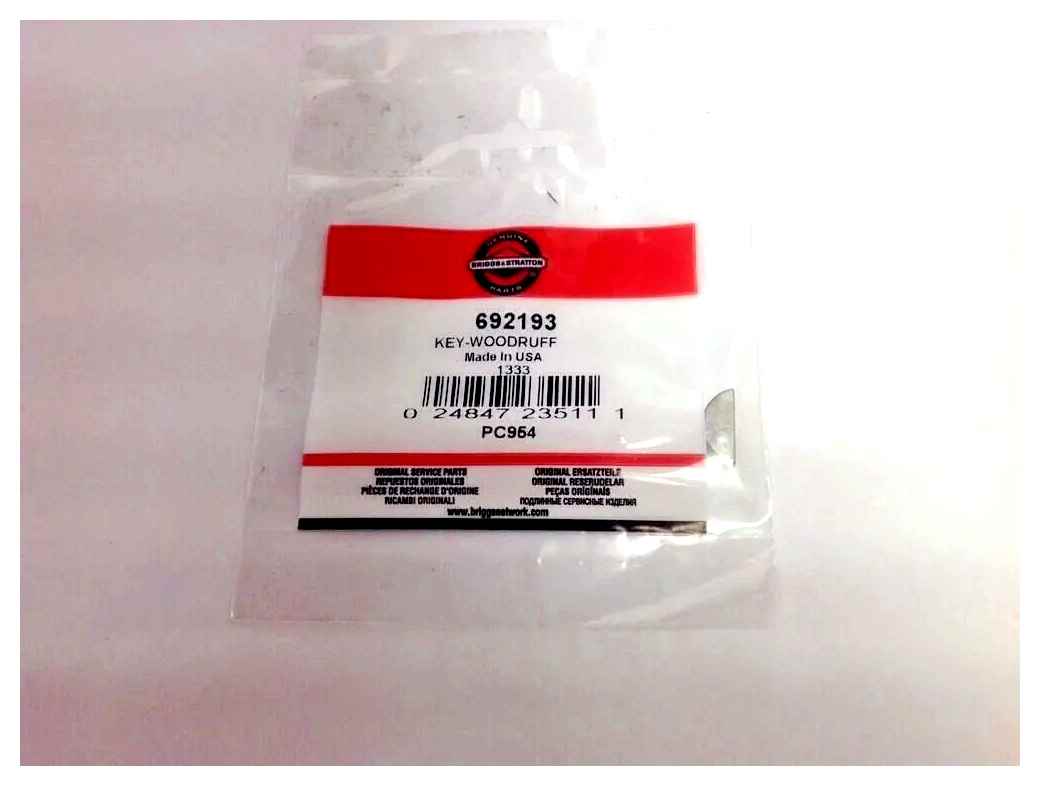

Lawn mower crankshaft key. Briggs & Stratton 19HP Lawnmower Engine (EX1900 Series)

Briggs Stratton 19HP Lawnmower Engine (EX1900 Series)

Briggs Stratton 19HP Lawnmower Engine (EX1900 Series) is backordered and will ship as soon as it is back in stock.

We Offer Delivery Australia Wide. Delivery Estimate is available on the Cart Page and calculated on the Checkout Page.

Description

The Briggs Stratton EX1900 Series 19Hp Vertical OHV engine with electric start delivers top reliability, performance and durability to meet the demands of professionals. This Briggs Stratton series engine is a ideal replacement engine for most ride on mowers on the market.The Briggs EX1900 Series 19Hp engine features a pressure lubrication system with an automotive full flow style spin on oil filter that cleans contaminants from the oil. This model engine has Briggs and Strartton’s latest AVS antivibration system which elimates side to side motion of a traditional counter and rotating balance system. Typical Applications :- This Briggs Stratton series engine is a ideal replacement engine for most ride on mowers on the market. It is a ideal replacement for all previous Briggs Stratton 14. 21Hp models.

Key Features

- Automotive Style Dipstick

- Briggs Model 33S877

- Electric Start

- Super Quiet Muffler fitted as standard

- Dura-Bore cast iron cylinder sleeve

- Over Head Valve Engine (OHV)

- Full-Pressure Lubrication w/ Spin-On Oil Filter

- Advanced Debris Management System

- Float-Feed Carburetor Mechanical Governor

- Electronic Ignition

- 1 inch Diameter / 3.5/32′ Long Keyway Shaft

- Vertical Shaft

- 19 (in) x 16.5 (in) x 13 (in) (LxWxH)

- 2 Year Warranty. Australia Wide

Specifications

Engine Series

Briggs Stratton EX1900 Series

Engine Style

Engine Type

Cooling System

Charging Circuit

Cylinder Bore Type

Starting System

Ignition System

Oil capacity

Air Cleaner

Crankshaft Rotation

Crankshaft Type

Crankshaft Diameter

Crankshaft Length

Crankshaft End Tapped Size

Crankshaft Keyway Width

483 (mm) x 419 (mm) x 330 (mm) (LxWxH)

Payment Security

- American Express

- Apple Pay

- Generic

- Google Pay

- Mastercard

- PayPal

- Shop Pay

- Union Pay

- Visa

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Briggs Stratton 19HP Lawnmower Engine (EX1900 Series)

Description

The Briggs Stratton EX1900 Series 19Hp Vertical OHV engine with electric start delivers top reliability, performance and durability to meet the demands of professionals. This Briggs Stratton series engine is a ideal replacement engine for most ride on mowers on the market.The Briggs EX1900 Series 19Hp engine features a pressure lubrication system with an automotive full flow style spin on oil filter that cleans contaminants from the oil. This model engine has Briggs and Strartton’s latest AVS antivibration system which elimates side to side motion of a traditional counter and rotating balance system. Typical Applications :- This Briggs Stratton series engine is a ideal replacement engine for most ride on mowers on the market. It is a ideal replacement for all previous Briggs Stratton 14. 21Hp models.

Key Features

- Automotive Style Dipstick

- Briggs Model 33S877

- Electric Start

- Super Quiet Muffler fitted as standard

- Dura-Bore cast iron cylinder sleeve

- Over Head Valve Engine (OHV)

- Full-Pressure Lubrication w/ Spin-On Oil Filter

- Advanced Debris Management System

- Float-Feed Carburetor Mechanical Governor

- Electronic Ignition

- 1 inch Diameter / 3.5/32′ Long Keyway Shaft

- Vertical Shaft

- 19 (in) x 16.5 (in) x 13 (in) (LxWxH)

- 2 Year Warranty. Australia Wide

Specifications

Engine Series

Briggs Stratton EX1900 Series

Engine Style

Engine Type

Craftsman Mower Flywheel Key: Intact

The mower tried to eat a protruding root, emitted a horrible crash, and ran poorly until I shut it off, after which it refused to restart. Hoping against hope that the flywheel’s aluminum key had sheared, I pulled the cover, removed the starter, and found:

Alas, the key is in fine shape. I made the two diagonal scratches to confirm it really is aluminum.

After letting the mower sit for a day, it started and ran briefly, blatted a giant backfire that probably startled the neighborhood (because I had the exhaust aimed into the garage, which served as a wonderful resonator), died a sudden death, then made clanking sounds whenever I pulled the rope. Something is definitely broken inside, but I suspect diagnosing fixing it will require more time and money than is justified.

I no longer form deep emotional attachments to lawn mowers, so I ordered a similar one online and the local Sears had it ready for pickup in an hour.

If I had to pull the flywheel, I’d tap the two obvious holes (one behind the shaft in the picture) and gimmick up a puller with two matching screws around a central bolt that does the heavy lifting; I can’t justify the Special Service Tool I’m sure it requires.

The old mower lasted an hour at the foot of the driveway with a “FREE – Engine probably severely broken” sign affixed to its handle; both parties got a great deal on that transaction!

thoughts on “ Craftsman Mower Flywheel Key: Intact ”

Works pretty nearly every time, too! Just looking at that key, though, I flat-out don’t understand how the flywheel could apply enough shear force to break the key without twisting the shaft beyond repair. Which is apparently exactly what happened… I wanted to autopsy the engine, but that looked more complicated than just popping the top to peek inside; I wasn’t going to build a flywheel puller just for that.

Yeah, even my curiosity has its limits. Luckily, I have the remains of an old steering wheel puller that works fine as a flywheel puller. I’ve lost the weird multi-threaded bolts it came with, but to use it, I just have to find a couple of bolts with whatever threading there is on what I want to pull. As we both know, things tend to cold-weld themselves in place, so even a puller doesn’t guarantee things will go smoothly or easily. I did pick up some Kroil last time, it is as good as I remember.

Kroil is good stuff, as is PB’laster (or however that’s punctuated). Maybe if I’d spritzed that flywheel, it would have just lifted off. Ya never know!

The Lucas Electrics (Prince of Darkness) design philosophy. 30A fuse on the headlight circuit, and a 10A switch. The sheet metal cable clamps were also a nice touch… Had to replace some wire and the switch, but the fuse shrugged it off.

Tapping two holes and using a puller works well but that is “the hard way.” This is the easy way… Remove the large nut which holds the flywheel in place, and also the large washer. Screw the large nut back onto the threaded tip of the crank, just enough to make its top surface flush with the tip of the crank. This is done to protect the threads. Put a large pry bar (or tire iron) under the flywheel and pry upward gently (maybe ten pounds of lift). Using a 3-pound hammer, strike the tip of the crank downward with considerable force. The flywheel pops off after 3 hits (sometimes after only one hit). Fast, easy, effective, no special tools, satisfaction guaranteed!

Without the pry bar lifting the flywheel, the force of the hammer blows would be taken by the bearings. There is a small amount of vertical “play” in the crankshaft of the engine. The pry bar moves the crank to the highest position of this normal travel. The hammer blow suddenly moves the crank to the lowest position of the travel. Inertia (and not the pry bar) keeps the flywheel from moving whilst the crank moves 0.001 inch, breaking that tenacious taper fit. Ideally, the bearings feel little or no shock. There once was a K-D tool (now discontinued) called a Bingo Puller which worked in this manner. I have one and have used it many times. It is a hardened steel sleeve which fits over the crank nose to protect the threads from a mis-aimed hammer blow.

Sounds good to me! When this mower seems ready to hop off the wheel of incarnation, I’ll give it a whack just to see what happens… [grin]

Engine Kicks Back When Starting – Check this first!

When you experience kickback, you won’t mistake it for anything else. Kickback is when you pull start your mower, and the pull cord is snapped from your hand. It can sometimes whip you as it does so, which is Oouch.

A lawnmower engine commonly kicks back when the shear key breaks. The shear key commonly breaks because the blade has kit a solid object and come to a sudden stop. Common symptoms of broken shear key include:

Before I describe the repair, it may be helpful to know a little about engine timing, don’t worry, I’ll keep it short.

Engine Timing

Timing maintains a mechanical set relationship between internal engine components and firing the spark plug at the optimum time. When the timing is out/off, you run the risk of severely damaging the engine.

Timing is vital for a few reasons. When the timing is out a lot, the mower won’t start. If the timing is out a little, your mower may run but run rough. A broken shear-key is, as you now know, the most likely cause of engine kickback. The repair procedure isn’t complex, but a few techniques need to be followed to nail this repair successfully.

If you need video help, check out “Shear-key replacing video”. It walks you through the whole process step by step, from checking the shear-key, tapping removing the flywheel, fitting the shear-key, torquing the flywheel, and setting the armature air gap.

Kickback – The recoiling of the pull cord stings a lot.

What Is A Four Stroke Engine?

Most lawn mowers are fitted with a four-stroke engine, and like all engines, they have a set sequence of operation. The main components involved with timing the engine are crankshaft, piston, flywheel, camshaft, valves, coil, spark plug.

Four-stroke engines are more reliable, live longer, quieter, and cleaner than two-stroke engines. So-called four-stroke, as it has four distinct stages in a complete cycle.

How To REMOVE a FLYWHEEL on a Briggs and Stratton Riding Lawnmower engine motor

How does four stroke Work?

First Induction – piston travels down the cylinder and draws air/fuel mix in through the open inlet valve.

The second Compression – the piston starts to travel back up the cylinder and closing the inlet valve, creates a sealed, air/fuel compressed cylinder.

Third Power – the piston is now past Top Dead Center (TDC) and starting to turn back down the cylinder as soon as the piston is past TDC, the spark plug fires which sends the piston down the cylinder under power.

Forth Exhaust – the piston turns back up the cylinder, the exhaust valve opens, expelling the spent gases out the muffler, and the sequence starts over.

Valves – Rockers open and close valves as the engine moves through the cycle.

When Engine Timing is Out

So when the timing is out, lots of things don’t happen when they’re supposed to. Valves don’t open or aren’t closed. But most importantly, the plug doesn’t fire at the correct time. The engine is designed to run clockwise and fire the plug only when the piston is past TDC (third stroke power).

Firing the plug before TDC causes the piston to try and go back down the cylinder, working against clockwise crankshaft momentum. That’s when the pull cord is snapped from your hand. This has the potential to bend or break internal engine components not to mention your arm.

Firing too soon – When the timing is off, it means the plug is firing outside its narrow window of operation.

It’s firing too soon and that causes the piston to reverse, causing the crank to turn counterclockwise and snap the pull cord from your hand as it does so, Ouch!

What Is A Shear Key?

The Shear key is a small block of aluminum, so-called a key because it fits in a slot (keyway) cut from both the crankshaft and flywheel (see pic). The whole point of a shear key is to shear (break) when needed. Sounds odd I know.

Keyway – Crankshaft and flywheel keyway

When a mower blade, attached to the bottom of the crankshaft, hits something solid, the engine stops dead. The flywheel attached to the top of the crankshaft has mass and inertia will force it to turn, it’s at this point the shear key does its job and uncouples the flywheel from the crankshaft by shearing.

If the shear key wasn’t fitted, the crankshaft would most likely twist, this puts the timing out and the only fix is to replace the whole crankshaft. This isn’t a small job and really the engine is junk.

Shear key – New and damaged

How To Replace The Shear Key

Now the good news, the flywheel shear key is probably the cheapest part you can buy for your mower. The fact the key has sheared means your engine has been saved. Of course, the timing will need to be reset, and fitting a new shear key will sort this.

Fitting is mostly straightforward. However, you’ll need a socket set, torque wrench, and a flywheel puller. While it is possible to remove the flywheel without the pullers, it risks damaging the engine and isn’t always successful. In any event, a puller isn’t expensive, and you can find a link to a quality Briggs Stratton puller here on the “Small engine tool page” or check out the Amazon link below.

Wire Off – Remove the plug wire to disable the mower and turn off fuel. Remove plastic engine cover, couple of screws usually.

Remove – Remove engine cover and blower housing assembly.

Paint – Mark the nut in relation to the crankshaft. This lets you know how far to tighten if you’re not going to use a torque wrench. (A torque wrench is preferred)

Block – Use a block of wood to wedge against the blade to prevent the engine from turning as you loosen the flywheel nut.

Alternatively use an impact tool or use a piston stop tool, you’ll find all these tools on the “Small engine tools page”.

Loosen – Loosen the flywheel nut, and remove, using a socket set.

Check – At this point, you can confirm a shear key is your problem, the key ways don’t align. However, I’ve worked on mowers with kickback and found the shear key to be good. This, unfortunately, means that the crankshaft has twisted, it’s rare. Replacing a crankshaft may not be economically viable for some mowers.

Spray the keyway with WD40 and let it soak while you remove the coil.

Remove – Remove the coil by removing two bolts. Set the coil to one side no need to remove the wire connector. When reassembling, an air gap must be maintained. It’s all covered here, check out “Fitting a Coil”.

Pullers – Time to use the pullers. The pullers thread into the flywheel, however, some flywheels aren’t tapped, meaning an extra step is required to tap threads into the flywheel. A pain? Yes, but I have you covered with the “Shear key video”.

Tighten – Now go ahead and tighten the pullers, give the puller bolt a tap with a hammer if it’s not playing ball.

Remove – Remove the flywheel and remove the old shear key debris from the keyway. Check also the keyway on the engine.

Fit – Align flywheel and crank keyways, now push the new shear key into the keyway. Nice!

Tighten – Tighten nut to your mark. Or use torque wrench. You’ll need to swap the block of wood the other way to prevent the crank from spinning while tightening.

Torque to spec – Usually around 60 ft. lbs. / 80 Nm. Need help using a torque wrench, check out “Setting a torque wrench video”.

Briggs & Stratton Lawn Mower Small Engine Flywheel Key 222698S

You’ll find a link to the Teng torque wrench I use here on the “Small engine tolls page”.

Fit coil – A special procedure is needed to fit the coil, it’s not difficult, it’s all covered here “Fitting a coil”. Alternatively, it’s all covered here in the “Shear key fitted video”.

Blade – Check your blade and blade boss (blade mount) for damage. Make sure it’s secure. A common symptom of a bent blade is excessive vibration. Check out the blade replacing video here.

Related Questions

Will a lawnmower start without a blade? Most mowers won’t start without the blade. The engine requires the force of the blade turning (inertia) in order to run as designed.

Lawnmower string won’t rewind? The pull cord recoil spring is worn or broken. A new spring can be fitted, often replacing a complete pull assembly is easier.

Hey, I’m John, and I’m a Red Seal Qualified Service Technician with over twenty-five years experience.

I’ve worked on all types of mechanical equipment, from cars to grass machinery, and this site is where I share fluff-free hacks, tips, and insider know-how.

And the best part. it’s free!

How to Remove a Woodruff Key

This article was co-authored by wikiHow Staff. Our trained team of editors and researchers validate articles for accuracy and comprehensiveness. wikiHow’s Content Management Team carefully monitors the work from our editorial staff to ensure that each article is backed by trusted research and meets our high quality standards.

There are 7 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 155,659 times.

A woodruff key is installed in the hub of a pulley or gear so that the pulley or gear does not slip off the shaft it is attached to or spin freely. These keys are found in motorized devices such as lawn mowers, motorcycles, and cars and are held in place by a threaded fastener. By removing a key, you can remove and modify other parts of your vehicle or replace a bad key to improve performance. [1] X Research source

Removing Keys by Hand

Apply penetrating oil. Put this directly onto the pulley and shaft area to loosen any corrosion that will make the pulley hard to move.Those that come in spray bottles are handy and will still be effective for getting into and breaking up rust on metal.

Remove the threaded fastener. This holds the pulley in place and can be undone with a tool such as a crank remover or wrench. If the threads are damaged, more tools and methods will have to be utilized, such as pliers. [2] X Research source

Clean the shaft. If there is any rust or dirt on the shaft, lightly sand or brush it. The hub of the pulley usually is fit well to the shaft, so the debris can prevent a loosened pulley from sliding off.

Loosen the pulley nut. Do whatever you can to stop the pulley from turning, then use a tool such as a socket or ring spanner on the nut until the pulley can be removed. [3] X Research source

- Use a soft-faced hammer to avoid damaging the components. If you use a normal hammer, hold a wood block against the fastener and shaft.

- Tap the pulley shaft with the hammer. Don’t use too much pressure. For steel hammers, insulate the shaft, nut, and bolt before striking.

- You can try tapping a nail on one end of the key, drilling into the center of the key and removing it with a nail, or even heating the key up with a blowtorch and letting it cool repeatedly to loosen it.

- Remember that damaging the key is a far better alternative than damaging the shaft or other part around the key.

Using a Gear Puller

Fit the arms. Once the gear puller is set, the center bolt should engage the pulley shaft in proper alignment to prevent slippage. Adjust the arms so that the puller’s jaws are set at about right angles against the pulley or gear. [6] X Research source

- You can strike the exposed end of the gear puller with a hammer to try to loosen the pulley. [7] X Research source

- Try tapping down on one end of the key with a hammer and nail. Another option is to drill into the center of the key and remove it with a nail.

- Rapidly heating the key with a blowtorch and letting it cool can help loosen it.

- Remember that these keys are cheap and readily available online or at hardware and auto part stores, so causing damage to it may be necessary. Damaging the parts around it is a more costly idea.

Community QA

You can try to tap out the key with a chisel or pin puncher. You can also quickly heat up the key with a torch and try to remove it again when it cools. You can also drill into it and use a screw or other device to take it out. Whatever you do, avoid damaging the shaft around the key.

Thanks! We’re glad this was helpful. Thank you for your feedback. As a small thank you, we’d like to offer you a 30 gift card (valid at GoNift.com). Use it to try out great new products and services nationwide without paying full price—wine, food delivery, clothing and more. Enjoy! Claim Your Gift If wikiHow has helped you, please consider a small contribution to support us in helping more readers like you. We’re committed to providing the world with free how-to resources, and even 1 helps us in our mission. Support wikiHow

Thanks! We’re glad this was helpful. Thank you for your feedback. As a small thank you, we’d like to offer you a 30 gift card (valid at GoNift.com). Use it to try out great new products and services nationwide without paying full price—wine, food delivery, clothing and more. Enjoy! Claim Your Gift If wikiHow has helped you, please consider a small contribution to support us in helping more readers like you. We’re committed to providing the world with free how-to resources, and even 1 helps us in our mission. Support wikiHow

Lawnmowers have a shear key, which prevents damage to the crankshaft, located in the hub of the flywheel or magneto. These often cause the engine to refuse to run but are easily replaced when you learn how to remove them.

You Might Also Like

How to Set and Use a Torque Wrench

How to Easily Load a Packing Tape Gun

About This Article

This article was co-authored by wikiHow Staff. Our trained team of editors and researchers validate articles for accuracy and comprehensiveness. wikiHow’s Content Management Team carefully monitors the work from our editorial staff to ensure that each article is backed by trusted research and meets our high quality standards. This article has been viewed 155,659 times.

Woodruff keys are found in motorized devices and are installed in the hubs of pulleys or gears so they don’t slip off the shaft or spin freely. If you need to remove a woodruff key, you can do it using pliers. Start by removing the threaded fastener that holds the pulley in place, loosening the pulley nut, and prying off the pulley with a pry bar or screwdriver. Then, grip the key, which is the semicircular piece inset into the shaft, with pliers and pull it off. You can also use a gear puller to remove the key. Adjust the arms so its jaws are at right angles against the pulley or gear. Tighten the forcing screw until the pulley slides free and you can locate the key. Then, remove it with pliers. To learn how to remove dirt and grime that may make the pulley hard to move, keep reading!