Lawn mower engine mods. How to Create a Go Kart with a Lawnmower Engine

How to Create a Go Kart with a Lawnmower Engine

wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 52 people, some anonymous, worked to edit and improve it over time.

There are 9 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 686,047 times.

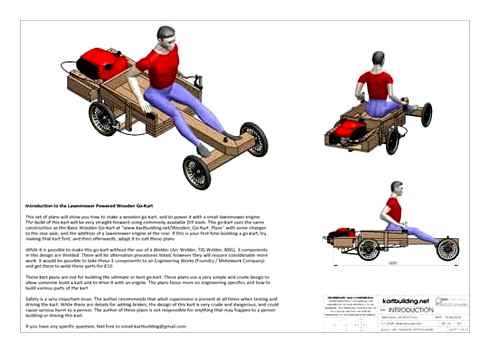

Though go-karts traditionally use horizontal mount engines, with a little modification, you can install a vertical shaft lawnmower engine to be the driving force behind your homemade racing machine. Taste again the speed, freedom, and exhilaration of the open road when you convert your lawnmower engine into the go-kart you’ve always wanted.

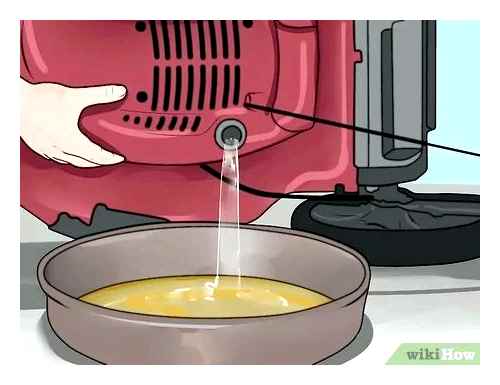

Removing a Lawn Mower Engine

- It’s best to drain the oil from an engine when it’s slightly warm, as the heat allows for a faster flow than when cold.

Drain the gas. Loosen the fuel hose clamp before you start draining your fuel. You can do so by tracing the route of the fuel hose from the engine to the base of the gas tank. Notice where the hose attaches to your lawn mowers carburetor. [2] X Research source Using your pliers, squeeze the clamp loose and slide it upwards on the hose. Now you can detach the hose and drain your fuel into a bucket.

Locate the throttle linkage. You can usually find the throttle linkage beneath the carburetor. There will be a cable that should connect to the throttle, and by removing the screw that holds the cable in place, you can easily remove the throttle linkage. [3] X Research source

Find the starter. This part is on the side of the engine and will have the shape of a small can. [4] X Research source Electric-start lawn mowers will have a red battery cabled attached. Use a wrench to unfasten the cable from the starter.

Remove necessary nuts and bolts. At the base of your mower engine is the mower house, which is where the engine is seated normally. Using your wrench on the bolt and another to hold still the nut below the mower house, unscrew the bolts holding your engine in place.

Take off the drive belt. You will find the drive belt on pulley on the crankshaft beneath the engine. Incline the engine slightly forward and pull the drive belt from its pulley. [5] X Research source

Remove the engine. Taking the engine firmly with both hands, lift the engine from the mower house and place it carefully off to the side in a safe place.

Preparing to Install

- Larger engines in the 13 to 22 horsepower range, which you can find on riding mowers, may destroy the transmission or kart. [7] X Research source

Pick a suitable go-kart frame. You will want one that can support both your vertical shaft engine and lawnmower gearbox comfortably. Your gearbox should will need to have non-trans axle set-up.

- Most frames have a width that varies between 1/3 and 2/3’s the wheelbase of your go-kart, with wider models giving better stability. [8] X Research source

Assembling the Frame

- Always use proper protective gear when welding. Failing to do so can result in significant harm to yourself.

Put in a floor. A 16 gauge sheet metal piece should be sufficient for the floor of your kart. Using your plans from earlier, drill holes in the sheet for the fastening bolts for your seat.

Weld a brace for your seat. You should brace both outer sides of the go kart frame with flat, 3/16 gauge steel. This is where you will install the bench for your seat.

Assembling the Steering Column, Tabs, and Spindle Brackets

Cut and install you steering column. You should cut a section of 3/4 x 11 gauge tubing and weld it to your steering tabs. Insert an additional 1 spacer loosely by the shaft near the steering hoop, grinding the shaft slightly near the hoop if too tight. Drill a three hole pattern with the holes equidistant from the center of the washer at the end of your shaft.

Add resting tabs for brake and throttle. These 2 long 3/8 diameter tabs keep your pedals in their resting and full forward positions. The closest tab to the center of the frame should be fixed a max of 1/2 after the crosswise piece your to which your steering column is attached. The second tab should be installed 1 3/8 after the first tab.

Attach spindle brackets. You will weld these to the front axle of your go-kart. The spindle should have a 1 clearance above the front axle.

Give yourself a foot rest. Use a 3/8 rod in a vise to bend it with a hammer into the shape of your passenger footrest if applicable. This will keep your feet from resting on tie rods.

Don’t forget your brake Band stud. This stud will serve as the pivot for your brake Band. Weld a 3/8 round bar to the frame 1 1/2 after your axle.

Assembling Motor Mount, Brake Rod, and Accessories

- The motor mount should be welded as the final step to building your kart.

- Your mount should be able to hold your lawn mower engine in the horizontal position.

Attach the throttle cable guide tab. About 4 away from the middle of the throttle pedal bolt hole, weld this tab to your kart on a 45 degree angle.

Put in the brake rod guide tab. Take your brake rod and insert it through the tab, bending it to adjust it to the brake Band. Next, take the tab with the rod inserted and weld it to the kart.

Bend your brake rod into shape. Bend this 1/4 round rod so that it angles to meet your brake pedal assembly. Cut the length of your brake rod as needed, and weld eyelets to the rod with a return spring installed brake pedal.

Give yourself a seat. Many go-kart kits do not bolt seats directly to the kart. If this is the case for you, use a simple frame and bolt this into the seat braces. Your seat should be cut at a 37.5 degree angle for a 105 degree incline for your backrest.

Weld motor mount and attach accessory parts. Having finished with the body of your go-kart, you can now weld the mount to your frame. Upon completing your weld, you can add tires, seat padding, and all other necessary hardware to your vehicle.

Installing the Vertical Motor and Gearbox

Bolt down both motor and gearbox to the mount. The location of your motor is not as important as that of the gearbox. [9] X Research source To properly install your gearbox, align it with the gear on the rear axle, and then bolt it into place.

Change the sprocket size for the gearbox. A sprocket is a gear toothed wheel inside your gearbox that controls the gear ratio for your transmission, which is another name for the gearbox. Your target gear will be about 16 teeth.

Attach a throttle cable to throttle linkage on carburetor. Now you can clean off any residual oil from your kart, but do so with care. Always allow for sufficient time for the materials you are working on to cool, like the engine or solder, before using a cleaner.

Community QA

Speed mostly depends on three factors, engine RPM, tire size, and gear ratio. So that question is not easily answered. Most 5-7 HP yard go-karts go 17-35 mph, with 25 mph being common. 8-13 HP go-karts with torque converters and large tires top out at around 40 mph. Race karts can go much faster as they use modified or two stroke engines that rev higher, so you could see speeds of 50-60 mph in those. Enduro and high end race karts can go much much faster.

Thanks! We’re glad this was helpful. Thank you for your feedback. As a small thank you, we’d like to offer you a 30 gift card (valid at GoNift.com). Use it to try out great new products and services nationwide without paying full price—wine, food delivery, clothing and more. Enjoy! Claim Your Gift If wikiHow has helped you, please consider a small contribution to support us in helping more readers like you. We’re committed to providing the world with free how-to resources, and even 1 helps us in our mission. Support wikiHow

As long as the engine is from a decent brand (and therefore good quality), it won’t explode out of nowhere. You’d really need to damage it to make it explode.

Thanks! We’re glad this was helpful. Thank you for your feedback. As a small thank you, we’d like to offer you a 30 gift card (valid at GoNift.com). Use it to try out great new products and services nationwide without paying full price—wine, food delivery, clothing and more. Enjoy! Claim Your Gift If wikiHow has helped you, please consider a small contribution to support us in helping more readers like you. We’re committed to providing the world with free how-to resources, and even 1 helps us in our mission. Support wikiHow

Thanks! We’re glad this was helpful. Thank you for your feedback. As a small thank you, we’d like to offer you a 30 gift card (valid at GoNift.com). Use it to try out great new products and services nationwide without paying full price—wine, food delivery, clothing and more. Enjoy! Claim Your Gift If wikiHow has helped you, please consider a small contribution to support us in helping more readers like you. We’re committed to providing the world with free how-to resources, and even 1 helps us in our mission. Support wikiHow

How to Make a Lawn Mower Go Faster (9 Tricks!)

Mowing the lawn is time-consuming, that’s no secret. Maybe you don’t particularly enjoy the activity, or maybe you’re just in a hurry. It’s only natural to look for ways to make a lawn mower go faster so you can get back to enjoying your afternoon. There are a few simple tweaks you can make, as well as some more complicated projects and modifications that’ll get your mower cutting as efficiently as possible. In this article, I aim to show you some of the most common ways of how to make a lawn mower go fast.

How to Make a Lawn Mower Go Faster (9 Tricks!)

If you’ve been wondering how to mow the lawn faster, one way is by making modifications to parts of your mower, such as the governor spring, tires, and pulley wheel. These modifications can increase the speed of your mower. You can also make it go faster with some simple additions to your lawn mower maintenance routine such as checking the oil and keeping the tank topped up. Some of these tricks are easy to implement, taking only minutes (after a trip to the hardware store, but I love those). Others are complicated projects that should be started at your own risk. Are you ready to make your lawn mower go faster? Great—read on to find out how!

Changing your Mower’s Air Filter

The first and most simple way to make your lawn mower go faster is to replace the air filter. Over time, these get clogged up, allowing dirt and refuse to enter your engine—causing damage, and startup problems of various kinds. Also, a clogged filter will prevent your engine from getting enough oxygen flow, causing it to run inefficiently, which in turn makes your lawn mower slow.

A fresh air filter will increase the speed of your lawn mower, especially if you’ve owned and used it for a long time. You can find new air filters for your lawn mower at your local hardware store or online—check your owner’s manual for reference.

Checking and Changing the Oil

Check the oil level and quality regularly. This is an important step in keeping your mower’s engine running at maximum efficiency. This is because oil degrades with time and use, and will eventually start damaging the engine if left unchecked.

For a push mower, it’s recommended to change the oil every season, or after roughly 50 hours of use – whichever comes first. The same goes for riding mowers, though they will run for around 100 hours before needing an oil change. I’d also recommend changing the stock oil of your mower for something of higher quality after the first 5 hours of use.

Not sure how to check your mower’s oil level? Don’t worry – it’s easy. First, unscrew the dipstick from the oil reservoir. Wipe the readings and replace the cap. Always top up the oil by pouring slowly, being careful not to overfill the compartment. For a full oil change, it’s best to consult the owner’s manual for their intended method, though for most push mowers you simply tip the machine on its side and place a plastic dish to catch the oil in before disposing of it responsibly (recycle if you can!).

Changing the Length of the Governor Spring

Something else you can do is change the length of the governor. It’s a small spring that controls the fuel flow to the engine. Increasing the spring’s length will allow for more fuel to flow to your engine, thus making it go faster.

Similarly, removing the governor entirely will significantly increase your lawn mower’s horsepower. To adjust the governor, you may need to remove the starter insert and flywheel housing (don’t forget to replace these, that’s important). Once the spring is removed, bear in mind you are now operating the machine outside of its recommended use-case scenario. Be cautious and stay safe.

Keep the Tank Topped Up

This may sound obvious to some, but it’s good to know that if your tank isn’t full, your mower isn’t operating at maximum capacity—so keep it topped up. This is because as your tank empties, the available volume of air in the tank is increasing—and fuel fumes are evaporating into this air—decreasing fuel efficiency. Just don’t overfill the tank.

You can also opt for some high-octane fuel, just make sure you empty the tank before using a different kind of fuel. As usual, always refer to the owner’s manual to gauge the types of fuel that are compatible with your lawn mower.

How To Make A Riding Lawn Mower Fast

How about riding mowers specifically? There are a few tips specifically suited to making a riding mower go faster.

Sharp Blades

The most important thing you can do to increase the speed of your riding lawn mower (any mower, really!) is to keep the blades sharp. This sounds simple, but it’s easy to forget. A sharp blade cuts with less resistance, leading to less friction as well as helping prevent grass buildup on your blades as you mow for extended sessions.

Bigger Tires

One of the most common tweaks is to install bigger tires. With bigger tires, you cover more ground per wheel rotation, translating directly into increased speed. You should make sure the tires on the mower are the same width. This will make the mower respond quicker and maneuver smoothly.

Go Kart From Lawn Tractor

Better Airflow

In addition to making sure the air filter is clean, you can opt to remove the hood of your riding lawn mower entirely! Doing so will drastically increase the airflow to your engine, giving it some extra juice.

Reduce Weight

As an added bonus for removing the hood from the previous trick, you have now significantly reduced the weight of your machine, which helps it go faster. Remember to replace the hood between uses to help keep the engine clean, especially if you keep it outside.This trick doubles as a legitimate argument for why my older teenager should be mowing the lawn for me sometimes. He’ll be faster at it because he’s smaller than me, it’s simple physics!

Bigger Pulley

The real modification, however, is the infamous pulley mod. By changing your pulley to a bigger one, you can substantially increase the speed of your mower.

Is A Bigger Pulley Going To Increase My Mower Speed?

You can change the size of the engine pulleys on your riding mower to increase the speed. This is a relatively complex procedure—more of a weekend project than a quick tweak. If you’re considering this, you should definitely consult your manual, as well as have a wide selection of tools on hand. Every mower is different, and you may need to make some major modifications.

One pulley is connected to the engine, and the other pulley is behind it. By installing a bigger pulley (and matching belt), you will increase the speed of your mower—just bear in mind this will most likely void your warranty. Not to mention, there are obvious safety concerns when operating your machine outside of its intended range.

That’s all Folks!

All in all, it’s completely possible to increase your lawn mower’s speed. You can do so with some simple additions to your maintenance routine, or you can venture into the more advanced methods such as adjusting the governor spring or looking at increasing the size of your pulley wheel. If you’re unsure about your ability to make these modifications yourself, or if you’re concerned about the safety of it all, you can consult a professional to make the modifications for you. If you have any other tips tricks on how to make your lawn mower go faster, share them with the community in a comment below!

About Tom Greene

I’ve always had a keen interest in lawn care as long as I can remember. Friends used to call me the lawn mower guru (hence the site name), but I’m anything but. I just enjoy cutting my lawn and spending time outdoors. I also love the well-deserved doughnuts and coffee afterward!

Leave a Reply Cancel reply

Copyright © 2010. 2023 LawnMowerGuru.com, All Rights Reserved.

Affiliate disclosure: As an Amazon Associate, we may earn commissions from qualifying purchases from Amazon.com. You can learn more about this here.

Kicking Grass: The Sport of Lawn Mower Racing

“Who hasn’t looked at a lawn mower and thought Gee, what if I was sitting on that doing 80 miles an hour?” That’s the thought process of Joe Troyer, a man who’s been racing lawn mowers for about 20 years now.

Troyer – and his fellow lawn mower racers around the world – are a unique breed. Most of us who didn’t grow up around lawn mower racing had no idea this grassroots motorsport even existed. But it’s international, and it’s been around for decades.

Go ahead and laugh. Even the most die-hard lawn mower racing enthusiasts know you have to have a sense of humor to be involved in something like this. But what you may not know if you’ve never experienced the sport up-close and personal is how much work and how much love goes into it.

“You can watch videos, you can read about it, and all that stuff,” says Kerry Evans, president of the U.S. Lawn Mower Racing Association, but you won’t truly understand “Until you’re standing beside that track, and you hear that loud motor coming by and feel that vibration, and say, Man, I’ve never seen a lawn mower go that fast.“

Lawn mower racing might sound like a joke at first, but take a look under the hood. You’ll find a supportive community of people who love what they do – and love helping newcomers get involved, too.

So, what exactly is lawn mower racing? Who are the people racing lawn mowers? We’ve got all the dirt.

The Roots of Lawn Mower Racing

The first lawn mower race took place in 1963 in a tiny town called Twelve Mile, Indiana. But that race, dubbed the Twelve Mile 500, was only the beginning.

In 1973, a group of motorsports enthusiasts in the UK got together and started the first national mower racing league, the British Lawn Mower Racing Association (BLMRA). Word spread, and in 1992, the U.S. followed suit with its own United States Lawn Mower Racing Association (USLMRA).

From the beginning, this sport was far more wholesome than you might imagine. The whole point of that first lawn mower racing league in Britain was to create an equal playing field for everyone, no matter where they come from or how much money they make.

Lawn mower racing has never been about the money. All the proceeds of those early races went to local charities, and most races today still give their profits back to the local community.

Want to know more about how lawn mower racing came to be? Check out LawnStarter’s History of Lawn Mower Racing.

Lawn Mower Racing Today

While the original spirit and core values of the lawn mower racing community have persevered through time, the sport itself has come a lawn way since those early days. Watch any YouTube video that pops up when you search “lawn mower racing,” and you’ll see feats people couldn’t have dreamed of in the ‘60s and ‘70s.

Mowers speeding at more than 100 mph, races that last for 12 hours straight, young kids racing alongside their parents – it’s insane, and it’s beaut-turf-ful. These are just a few highlights of what today’s lawn mower racing looks like, but there’s a whole world to explore if you want in on this wild ride.

The Machines

If you’ve ever cut your grass with a riding lawn mower, you know they usually move at about 6 or 7 mph, maybe 10 mph if you really push it. So … how on turf do the mowers in these races go so fast?!

These aren’t your garden-variety lawn mowers. They started out as the same models you can find at Lowe’s or Home Depot, sure, but they’ve been modified since then, usually by the racers themselves.

For many participants, building impressive engines is as important to the sport as the racing itself.

Kerry Evans owned a small engine repair shop before he ever even heard of lawn mower racing. He got involved for the first time when a customer came in asking him to build an engine for a racing lawn mower. 25 years later, building lawn mower racers is still his favorite part.

“To me, the fun of the sport is that I start with an old, junky lawn mower and make it go fast,” he says.

Many others got into the races the same way Evans did. They’re mechanics, gearheads, and tinkerers who love the challenge of turning a tool made to cut grass into a mean, green speed machine.

With so many inventive minds in the mix, the results are astonishing.

Speed Demons

In 2010, Evans helped driver Bobby Cleveland build the mower that broke the world record for the fastest lawn mower ever reported. Its top speed? An incredible 96.529 mph.

Like any great artist, though, Miller says he’ll never really be “finished” with that mower. He’s driven it at speeds up to about 70 mph, but there’s always something he can do to make it a little better, a little faster.

Now that he’s older, the new FOCUS of his modifications is making the mower a little easier to handle so it’s not as hard on him.

The first Troyer to get involved with the race was Larry, who worked as a pit crew member for a friend back in the ‘70s. In the ‘80s and ‘90s, his brothers Gary, John, and Randy all decided they wanted to sit in the driver’s seat, one-by-one.

Randy Troyer says his logic behind wanting to race was simple: “Well, everybody else is doing it, so I might as well do it, too.”

The next generation, Zach and Joe, worked as pit crew until they were finally old enough to race themselves in the early 2000s. Now, the Troyers have more than 20 wins under their belt collectively, and they’re well known among locals.

“If I meet somebody I don’t know from anywhere in the surrounding counties,” says Joe Troyer, “They’ll say, ‘Oh, Troyer – are you the ones that race the lawn mowers?’”

Helping Other Lawn Mower Racers

Along with the racing itself, the Troyers are well-known for their generosity. They use their mechanical background to help out anybody who wants to race but doesn’t have the expertise to rig their own mower.

“I don’t think there’s one of us that races that wouldn’t help somebody build a mower,” Zach Troyer says.

In the lead-up to race day, they’ll have seven or eight mowers in Joe’s body shop that they’re working on for other people. Even on the day of the race itself, they’ll help the other racers with final adjustments. It makes for a more fun and competitive race, they say, when everybody’s mowers are running at the top of their game.

Lots of Data and ‘a Sense of Humor’

John Troyer, who has an engineering background, describes his approach to the race as more scientific and analytical than you might expect. He constantly wants to improve, so he tracks race data and other information in an Excel spreadsheet as a way to know what he needs to work on for next year to race even better.

He even talks about diagramming which muscles are sore in the days after the race so he can work out those muscles and get them in better shape for the next time around.

Even with all the thought he puts into his races, though, John still doesn’t take himself too seriously.

“It’s a little different than most other sports,” John says. “The chief prerequisite is that you have a sense of humor.”

That seems to be the case whether you’re in the Twelve Mile 500 or a national series race. If you’re not out to make friends and crack jokes about what you’re doing, lawn mower racing isn’t the place for you. Of course, that’s not to say the competitive spirit isn’t serious. Racers might pal around and poke fun at themselves in between races, but on the track, they’re in it to win it.

“We put on the helmets,” Chuck Miller says, “and it’s a whole different ballgame at that point.”

The Races

So, what does a lawn mower race actually look like? That depends on where you go. There are races all over the U.S. and UK every year, and each one has its own rules and setup.

No matter how different they are, all lawn mower races have at least one thing in common. Call it what you will, the rush, the excitement, the thrill of the game, but it’s always thick in the air when the engines start and the green flag goes up.

“It’s not professional like NASCAR,” Chuck Miller says, “but when you get out there on that mower, and you’re whipping around the track at 10 miles an hour or 40 miles an hour, it’s all the same. You’ve got the adrenaline pumping and the competition in your veins, and it’s just like the real thing.”

There’s no way to shine a spotlight on all the races that happen every year without writing a whole book, but to give you a taste of how intense and exciting this sport can be, here’s a rundown of some of the biggest races in the world.

The 12 Hour

The 12 Hour is an endurance race hosted by the British Lawn Mower Racing Association each year in England. During this race, teams of three race overnight for 12 hours straight.

Imagine, half a day of non-stop roaring engines! The race starts at 8 p.m. on Saturday night, and it isn’t over until 8 a.m. Sunday morning. Speeding around an uneven, ever-shifting track at 50 mph in the dark adds a whole new thrilling (and terrifying) element to the sport.

Despite an apparent decline in interest in recent years, anyone who knows anything about lawn mower racing could tell you that it isn’t going anywhere any time soon. Not as long as there are people out there who crave the thrum of an engine, the adrenaline in their veins, and the satisfaction that comes from turning a simple grass cutter into so much more.

Main Photo Credit: François GOGLINS / CC BY-SA 4.0 / Wikimedia Commons

Jordan Ardoin

Jordan Ardoin is a writer, editor, and classical literature student based in Colorado. When she isn’t reading or writing, she enjoys goofing off with her cats and spending time in nature.

Yard work at the click of a button.

As seen in Forbes, CNBC and USA Today, LawnStarter makes it easy to schedule service with a local lawn care professional.

Enjoy your beautiful lawn.

Do you want a BEAUTIFUL LAWN?

Get easy-to-understand, actionable yard tips that will give you the greenest grass on the block.

Rider Mower

Riding mowers racing began in the 1960s as a form of novelty. Since that time they have grown into a serious form of low-cost racing.

Rider Mowers typically used for racing have the cutting blades removed, the CG height lowered and the transmission geared up to give speeds of approximately 45 mph (72 km/h). To keep the racing low-cost, entry-level classes retain many stock components while most open classes allow customization of the powertrain and chassis.

Racing is generally held on small dirt tracks to keep the racing competitive and close. Racing takes place in the Americas, Europe and Australia.

Design and Construction

Race Car Models of This Type

There are numerous models of stock mowers that qualify for racing or as a donor for a customized machine.

Knowledge Level

Rider mower racing does not permit extensive modifications in the entry-level classes, so a basic working knowledge of handling is useful. As you develop your mower into more of a purpose-built racing machine, it will be helpful to have a working knowledge of powertrain and chassis, as most modifications will center around these areas. In addition to a small engine repair manual, it will be useful to have resources around customizing the transaxles.

Design Challenges

Weight Distribution: The rider mower‘s weight is relatively well distributed front/rear with it being a front engine/rear drive short wheelbase machine.

For racing purposes, the lower the CG (Center of gravity) the better, but there are limits to seat height as well as chassis and mower deck ground clearance.

Suspension: There is generally no suspension allowed on rider mower racers. Tires provide the absorption of bumps and their types and pressures are usually regulated. Rear axle and front wheel brakes are worth consideration. Brakes other than that provided by a transaxle are required in the top classes.

Widths of the machines are regulated, but using the maximum allowed width will generally give the best handling. The exception perhaps is in situations where there is very little grip (such as a slick wet surface). In this case, narrower tires and track width could be helpful in getting corner bite.

Throttle, brake and clutch controls are critical to smooth operation of the mower. The most natural configuration for you is the one to build. Some designs use a hand throttle attached the steering wheel, while others use traditional car-like pedal arrangements. In the case where a hydraulic disc brake is used, there will need to be separate clutch actuation because many rider mowers combine the brake and clutch into one pedal.

Chassis: Depending on the class, modifications may be made to the chassis and body work. Modifications might include strengthening a weak chassis, altering CG if allowed, changing the wheelbase if allowed, and welding the front suspension as a fixed beam.

Powertrain: Using aftermarket filters and racing exhaust may be a consideration if permitted by the regulations. Modifications must be made to stock transaxle gearing for higher speeds to be reached. Most transaxles have a limit to the input RPM, and so adjusting the gearing inside the transaxle enables output speeds to be increased. In top classes the powertrain regulation is open so far more flexibility is available in final drive configuration (ie. Centrifugal clutches, Chain drive, live axle)

Safety: Consideration should be given to securing critical fasteners with locking mechanisms (Castellated nuts, safety wire, cotter pins, etc.) to prevent failures of brakes, loss of wheels, or drivetrain components. A spring-loaded throttle close system should be included to close the throttle in case of a control cable failure. An ignition kill switch should also be included to quickly kill the motor in an emergency.

If you intend to race under a sanctioning body, always read and understand the regulations of your chosen racing class before designing or building any race vehicle.

Design Resources

Download our free race car design aids to assist you designing your race vehicle.

Construction Challenges

Having sufficient space around your mower for the build is important, as a cramped workshop can be difficult to work in.

The tools to modify the chassis (ie. welder, metal working) can add considerably to the cost of your project if you don’t already have a workshop, but borrowing or renting items is also an option.

Build Costs

Donor mowers can be had used for low prices, provided the state of the engine and transmission is still good. Because of the limited size and power, most parts are OEM or fairly low cost to fabricate.

Build Effort

Due to the unique nature of each rider mower brand and model line, modifications will usually require OEM/off-the-shelf part replacements. Customizing beyond that will require metal working or creative part scrounging.

Racing Cost

Very, very low. Tire replacement, except in the case of damage is infrequent.

Transportation and Support Equipment

Can be loaded into the back of a pickup truck or onto a small trailer. Support equipment can be carried in the transport vehicle.

Why Are Lawn Mowers So Loud? Causes solutions

Yea, I hear ya, the sound of a mower at full tilt, especially early in the morning can feel like an attack on the senses. Surely if they can make a truck quiet, they can make a mower quiet, right?

So why are their lawnmowers so loud? Mowers are loud because mufflers fitted to most engines are a cheap basic type known as – Absorptive type mufflers, they create very little gas flow restriction which is great for power but bad for noise.

Manufacturers could make a mower less noisy, but they don’t because they don’t want to sacrifice cost and engine power.

The Outdoor Power Equipment Institute (OPEI) which is the association of outdoor equipment makers, decided voluntarily back in 1974 to set a noise level target of 95dcb for mowers.

Noise Source and Solutions

Although the engine makes most of the noise you associate with a mower, a surprising amount comes from a spinning blade, much like the blades of a helicopter cutting through the air. Next time you see an electric mower stop and listen, most of the noise you hear is the blade cutting through air and grass. Electric mowers are not as quiet as you might think.

Anyhow mower noise comes from four main sources, listed below are possible solutions for excessive noise. If looking to go below 20 decibels, I suggest a donkey.

Exhaust/Muffler – Exhaust heatshields become loose and baffle inside become loose also. To test, give the muffler a tap with the handle of a screwdriver and listen for the tell-tale rattle.

Check your Muffler for damage, these guys get very hot and are prone to cracking and corrosion.

You already know mowers cause lots of vibration, and stuff just comes loose, that’s why it’s a good idea to check over your mower regularly looking for loose stuff. The baffles live inside the muffler and sometimes break free causing a thin metallic-sounding rattle. Mufflers get really hot and vibration can cause them to crack. They can be repaired by your local muffler shop.

Gaskets – Gaskets are used to mate the muffler to the engine. They create a seal, and as you can imagine when it breaks down you get lots of noise and fumes. Gaskets are easy to replace.

Blade Noise – Blades make a surprising amount of noise. Blade tips cut through the air at over 200 mph and most lawn tractors will have 2 and maybe 3 blades.

Bare Metal – The underside of mower decks is just painted. Debris thrown against the deck resonates like a bell.

You can DIY this one, at the auto parts store you can buy spray-on bed liner which adds sound deadening and metal protection to your deck.

Just make sure the deck is clean and dry before painting outdoors. You can check out a video on that subject right here.

Also, try sticking sheets of self-adhesive bitumen car sound deadening material in a few places on the deck topside. You can pick these up in an auto parts store. Sure it might look a little odd, but it does help.

Engine – Obviously the engine is a major contributor to noise levels. Valves, rockers, camshaft, crankshaft, and especially the fan (located on top of the engine) can be considerable. There are things you can do to help minimize the noise. Valve lash should be checked and adjusted every year, it doesn’t take long. Not only will it cut down on noise, but it’ll also give you more power and better gas mileage.

Engine Fan – Most small engines don’t have coolant they are air-cooled and so they need a fan to pull cool air across the engine, and fans are noisy.

Check out “Valve lash adjustment”, it’s for a walk-behind mower, but the process is the same for any OHV engine. Engine oil is another opportunity to help reduce noise. When oil gets old it gets thin which causes engine ratel. Your mower needs a tune-up at the beginning of every season. Check out “Tractor mower tune-up”.

Valve Lash – Valvetrain will be noisy if there’s excessive lash.

Of course, your engine may rattle because it’s worn, if you think that may be possible, try using a thicker oil or try Lucas oil treatment, it’s great stuff, you will notice a quieter engine, I promise. The engine fan is needed to cool the engine, so it’s got to stay. But try putting self-adhesive bitumen on the underside of the hood, really does help reduce noise.

Body – Body panels, deck linkages levers, etc. will rattle and squeak as the engine and blades cause them to vibrate. Greasing all-metal deck arm contact points will reduce noise, spraying with WD40 will help also.

Check your hood and seat rubber stops, replace them with a DIY fix if needed. Run a blade down some old rubber hosing, great for pushing onto the edge of a rattling hood, MacGyver style.

Linkages – Keep all the metal-to-metal links well-greased, it helps dampen rattling and squeaks. Check that the rubber hood and seat stops are in place.

Muffler Types

The two main types of exhaust mufflers are – Absorptive mufflers and Reflective mufflers. Most mowers are fitted with the less expensive absorptive type muffler. So what is the difference between the cheap one and the more expensive one? Design, materials used, and execution.

Absorptive Mufflers

An absorptive muffler is a very basic muffler, probably the one fitted to your mower. It doesn’t use any clever engineering, it does a poor job of noise reducing. It will usually incorporate a spark arrester, which is a mesh screen that catches any sparks that might exit the engine.

This muffler causes a very little restriction to gas flow which is great for power, that’s why racing cars are so noisy. This type of muffler is fitted to most lawnmower engines.

Reflective Mufflers

Reflective mufflers or resonators – Engineered to kill noise using clever acoustic engineering. Sound waves are pushed through perforated baffles in resonating chambers where some noise is canceled out, known as Destructive interference. Special acoustic suppression temperature resistant material (not unlike rock-wool) is sandwiched between the chambers and the exhaust outer casing, this further suppresses noise.

How to make a racing lawnmower I.T. Creations

The larger the muffler the quieter the motor, that’s why high-end luxury cars have very large mufflers. The downside to this type of muffler is flow restriction – the baffles and chambers cause restriction to the flow of gases which in turn causes backpressure, and backpressure reduces the power of the engine.

Super Quiet Lawn Mower Mufflers

Here’s a possible solution it’s the Super Trapp Quiet Muffler, I haven’t used it so I can’t comment first hand, but doing some research, it seems to do the business. Check out the YouTube video below. The Super Trapp is a Reflective muffler type, it uses witchcraft and wizardry to make an engine as quiet as a cricket.

Mufflers – Some makers do a better job than others, John Deere mufflers do a first-class job.

Lawn Mower Louder Than Usual

Mowers create a lot of noise and vibration, the engine and spinning blades set up vibrations that over time will start to pull your mower apart. A lawnmower can make many different types of noises, they can be squeals, squeaks, constant howls, cyclical noise, or just a general harsh roughness. Some noises are just impossible to describe and I know describing noises may not be useful to some.

What is useful, is to see when the noise is present, is it present as soon as you start the mower, or only when you are driving, or maybe only when the blades are engaged. This kind of detective work will help you find and fix the problem quickly.

If you need a new muffler check out the Amazon link below.

Check

If you feel your mower is louder than normal, you can check a few of the more common noise sources. Some of these won’t apply to walk behind mowers but most will.

- Oil level ok?

- Blade(s) loose (cyclical noise)

- Muffler or brackets loose (loud roar/rattling)

- Muffler gasket leaks (loud roar)

- Muffler cracked or broken (loud roar)

- Hood loose or contacting the body (rattling)

- Seat brackets loose or rubber bushing worn/missing (rattling)

- Debris caught in the drive line (cyclical noise)

- Belt pulley bearings worn (harshness/howl)

- Blade spindle bearings worn (harshness/howl)

- Belt worn/damaged (cyclical noise)

- PTO clutch worn (harshness/howl) (Tractor/Ride-on)

- Deck carrying arms loose/dry (rattling)

- Wheel bearings dry (squeal/Squeak)

- Steering dry (squeal/Squeak)

- Transmission worn (harshness/howl)

This isn’t a complete list, and as you can imagine there are many possibilities, but these are the more usual causes of noise.

Blade Spindle

Blade spindles transfer the power to the blades. They are bolted to the deck and have bearings on top and bottom to provide smooth spinning.

The bearings wear out and can cause a howling roar when the blades are on. The bearings can be replaced, but often replacing the whole spindle makes more sense.

Pulleys

Pulleys are used to drive and route belts around the chassis. Most will have bearings and they’re the ones that cause trouble. They’re a common source of noise.

Generally, if you have a worn-out belt, then chances are one or more pulleys are also worn, and vice versa. Pulleys are fitted to the driving belt and also to the cutting deck belt system.

Most pulleys employ integrated bearings but some are replaceable.

Belt Wear

Belt wear or damage will cause a cyclical noise as the damaged area contacts the pulleys. Damaged cutting deck belts will also cause lots of vibration.

Hey, I’m John, and I’m a Red Seal Qualified Service Technician with over twenty-five years experience.

I’ve worked on all types of mechanical equipment, from cars to grass machinery, and this site is where I share fluff-free hacks, tips, and insider know-how.

And the best part. it’s free!