Lawn mower rpm tester. Best Small Engine Tachometers 2022

Best Small Engine Tachometers 2022

The term “tachometer” came from two Greek words, namely: tachos which means speed; and metron which means “measure.” Hence, etymologically, the word “tachometer” means “measure of speed” or “speed measurement.” Well, the etymological meaning of tachometer tells something about what it does, for a tachometer basically measures the rotational speed of a disk or shaft. It shows this measurement in revolutions per minute (RPM) on an analogue dial, although digital tachometers are increasingly becoming popular and common. The tachometer is also referred to as revolution-counter, rev-counter, RPM gauge, and tach.

The tachometer is specifically a device that indicates the angular speed or rotary speed of any rotating shaft. However, the term sometimes only refers to the electrical and mechanical instruments that show the instantaneous values of speed in RPM but do not indicate the average values of speed for a given interval.

Cheap Small Engine Tachometer Hour Meter

How To Use Tachometer on Small Engine?

Since the tachometers used on aircraft, cars, and other vehicles only indicate the rate of the engine’s crankshaft’s rotation, but they can surely show the safe range of rotational speeds. With the data a tachometer provides, a driver can readily select the specific gear and throttle settings for any given driving experience and condition. Thus, the tachometer can prompt a driver to slow down when he/she is continuously moving at high speed, for prolonged rate use of crankshaft at high speed can surely cause problems like overheating, inadequate lubrication, damage to sub-parts of the engine. The onset of these damages can eventually lead to the partial or total breakdown of the engine.

Drivers whose cars are with manual transmissions, for example, would surely benefit from the data provided by the tachometer. The analogue tachometer, for example, would prompt a red signal on the gauge area indicating that the driver is operating at unsafe speed. On the other hand, in cars with automatic transmissions, the presence of the red zone is already superfluous because automatic vehicles are already equipped with a revolution limiter that electronically prompts or limits the engine speed when the car is speeding beyond its engine limitation. Thus, you would not find this red line in cars that are equipped with this revolution limiter feature. over, you would also not find this redline in machines with diesel engines that are equipped with mechanical injector systems that have an integral governor, for this integral governor is designed to prevent the engine from over-speeding.

Most Recommended Tachometers for Small Engine

1) Runleader Digital LED Engine Hour Meter

If you are looking for a multifunctional meter, you can check out the Runleader Hour Meter. This tachometer can function as a TACH/Hour meter, Temp meter gauge, hour meter, and tachometer. First, it can gauge engine temperature, TOT hours, maintenance service timer, and many more.

Second, as a temp meter gauge, you can use its temp sensor to get the engine’s temperature in real-time. You can likewise program it to give you an over-temperature alert. over, you can view the maximum temp value and reset it. As an hour meter, you can use the TOT hours to track the working hours of the engine. Nevertheless, you can’t reset the TOT hours.

As a tachometer, this equipment records the RPM value in real-time. It also enables you to adjust the engine idle time. over, you can program the patterns of engine firing to keep more accurate the RPM value.

You can quickly install its LED display, and a 12V external power supply powers it. It also retains data when you shut it down, and it comes with a two-year warranty.

2) AIMILAR Digital Tach Hour Meter Tachometer

AIMILAR Digital Tach Hour Meter is a popular product that many consumers use. It is popular because it is affordable and of quality. It would not burn your wallet when buying this tach/hour meter. It is easy to install and operate. You only need to activate it when you use it for the first time by pressing S1S2. It will show 00000-99999. Then, it shuts off. In doing so, you successfully activate it.

This unit will function on two-stroke single, two cylinders, two-stroke, four-stroke single-cylinder, four-stroke two-cylinder, and four-stroke four-cylinder engines. It also features a power-saving mode.

Its LCD will automatically shut off if you are not operating it for sixty seconds. It also automatically starts when you start the engine. over, you need to set the firing pattern of the spark plug correctly. Its factory default setup is also once every revolution. (1P1R).

The AIMILAR Meter features a green backlight. It also comes with a sizeable seven-segment LCD with a CR2450 Internal battery.

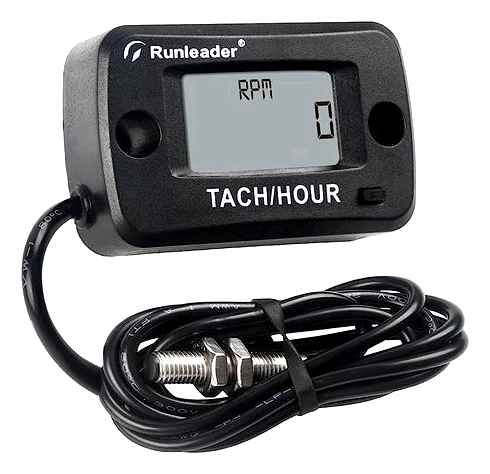

3) Runleader Hour Meter Tachometer

Runleader Hour Meter Tachometer is another excellent option that is easy to program and suits different applications. It is easy to install and works well. over, it comes with features like Tachometer (RPM), Service Timers (SVCSVC2), Hour Meter, Resettable Job Timer (JOB). The data is easy to view, and you can manage with ease the health of your engine using this device.

You can program the maintenance interval service timer. It can also remind you about the countdown tracking service. Once the SVC time is reached, you will see a warning icon on its LCD, and its backlight will turn red.

Its JOB timer will also allow you to measure a specific work job like change oil and even the job time for air filter replacement. Besides, you can reset the value and view the SVC and JOB readings by clicking on the related buttons.

4) Searon Store’s Small Engine Tachometer Hour Meter

If you need a tachometer to track your engine’s RPMs as well as its running time, you should consider the Searon Store’s Small Engine Tachometer. A CR2032 battery powers it, so you don’t need to connect it to any external power. With the help of its 5-ft insulated wire, the connection of this Tach/hour meter is made possible. You simply need to wrap the wire five times to the spark plug. The engine’s spark activates this Tach/Hour Meter.

The common usage of this Tach/hour meter includes RC toys, (2/4 stroke) engines, marine engines, motorcycles, tractors, chain saws, marine engines, (gas-powered) tools, and lawnmowers. This (Tach/hour) meter records the operation’s total run time, which is non-resettable. It can also registers job time which you can reset. Besides, you can program its SVC timer from 0 to 200 hours.

5) Foundown’s Engine Hour Meter

If you want something with a powerful timing system as well as an RPM measuring system, you should check the Foundown’s Engine Hour Meter. Its timing system includes accumulating total running time and recording JOB time. It also has a maintenance timer that you can set freely from 0 to 200 hours SVC. It also has an RPM measuring system that includes current engine RPM measurement and allows you to view MAX RPM’s engines.

It also sets an Overspeed Warning function, and you can also set its refresh rate. over, it comes with a unique design that makes it easy to install, with a replaceable CR2032 battery. It can store data automatically after replacing its battery, and comes with a green backlight LCD.

It also comes with a waterproof Rate IP65. Besides, it is the perfect rev counter for ATV, motorcycles, PWC, scooters, chainsaws, and cleaners.

Purposes of Using Tachometers on Small Engines, Tractors, Trucks Other Vehicles

Trucks and tractors are usually equipped with tachometers that have other markings such as that of a green arc that indicates the range of speed wherein the engine can produce maximum torque. Operators of the abovementioned vehicles would surely benefit from this green arc feature of the tachometer. Some tractors that are equipped with a power take-off system are also fitted with tachometers that indicate the necessary engine speed for rotating the PTO. It basically indicates the standardized speed required for most PTO-driven equipment.

Regulations vary from country to country with regards to the requirements for a tachometer. Many countries, for example, require tractors to be fitted with a speedometer. Since it would be superfluous to have another dial that indicates speed, the tachometers are usually fitted with a second scale that indicates the unit of speed, and this second scale is fairly sufficient for practical use on the road. On the other hand, tractors that have multiple gears are usually equipped with multiple speed scales. For aircraft tachometers, however, a green arc is generally fitted into the tachometers that indicates the standard cruising speed range of the aircraft’s engine.

EGO LM2114SP 21-Inch Self-Propelled Lawn Mower

Thinking about a new battery-powered lawn mower for the upcoming season? EGO has one of the most robust lines available with models that serve entry-level customers all the way up to those who want the latest and greatest designs. New for 2023, the EGO LM2114SP self-propelled lawn mower is hitting the shelves and we’re breaking down the core details to see who it’s the best fit for.

EGO LM2114SP Self-Propelled Lawn Mower Performance

Cutting Capability

This EGO mower utilizes a brushless motor that spins a 21-inch blade with some very real gas-replacement power. It churns out 6.0 ft-lbs of cutting torque and up to 2,800 RPMs, giving you the cutting performance equivalent to a 140cc gas mower. Sound familiar? That’s the same performance numbers as the LM2125SP that is launching alongside this model.

For us, this is just fine for performing regular maintenance cuts on St. Augustine grass as well as some of our heartier Florida bahiagrass. Not to mention, it can handle a bit of overgrowth as well. Like most brushless mowers, the motor automatically kicks up the RPMs when it senses a heavier load. We did manage to stall the motor a couple of times in the thickest overgrown areas, just like we expect from a gas engine with similar performance.

Keep in mind that EGO makes stronger mowers such as the Select Cut XP if you have the kind of lawn that needs consistently higher performance.

Cut Quality

If you’re familiar with EGO Select Cut mowers, you’ll notice this model sticks with a single blade rather than the stacked blade system on the premium end of the line. Regardless of that fact, it still produces a very clean cut and leaves very few stragglers in its wake. You may see a few more if you’re mowing at full speed in thick grass so slow down a bit in those areas to keep the cut quality up.

As is typical for EGO’s designs, the mulching and bagging functions are very effective on maintenance cuts (~2 inches off the top). If you’re cutting much more than 4 inches off, consider switching to the rear discharge chute.

If you’re making the switch from a gas mower, you’ll notice the rear discharge doesn’t quite spread the clippings as well as a side discharge. However, by having more uninterrupted airflow under the deck, EGO gets better mulching and bagging characteristics than most, and that’s a trade-off we’re willing to make.

Runtime

EGO estimates your max runtime to be 50 minutes under light cutting conditions. Of course, grass height, species, whether it’s wet, and even environmental factors come into play. We did our normal maintenance cut, removing ~2 inches, and got 50:22 out of the 6.0Ah battery that comes in the kit.

Here’s what you can expect across multiple cutting loads:

The self-propelled drive system on this mower is very similar to that of the EGO LM2102, but with a few helpful tweaks. For the most part, the overall look is the same but the devil is always in the details.

The dual-toggle drive handles are a little slimmer and more ergonomic than past generations which makes them more comfortable during extended use. Our favorite change is that EGO moved the drive speed control lever from the left side of the handle and put it front and center on the drive handle. While it’s not a ground-breaking design, anything that limits the number of extra movements you have to make while mowing is a plus in our book.

Deck Height

We love the single-point deck height adjustment rather than individual wheel adjustments like we see on old-school push mowers. The cut height ranges from 1-1/4 inches all the way up to 4 inches. That should cover any grass species in your lawn.

Josh McGaffigan

Staff Reviewer and Writer

Having worked in the automotive and metalworking trades, Josh has even found himself core drilling commercial properties for purposes of surveying. His knowledge and love of tools are exceeded only by a greater love for his wife and family.

A fan of all things that can stretch him mentally, Josh quickly dives into new products, tools, and product testing with ample amounts of both enthusiasm and precision. We look forward to many years of growth alongside Josh as he settles into his role at Pro Tool Reviews.

How to Measure Engine Rpm with a Multimeter? [Follow The Article]

RPM stands for Revolutions Per Minute and is a great way to know how hard your engine is working.

The most common way to test for RPM is by using a tachometer. However, many of us don’t have this around the house.

How To: Use a Small Engine Tachometer & Set Engine Speed | Reviewing the Cheapest One On Amazon

However, we often have multimeters which we can create a workaround to test for.

What are the best multimeters for this test?

I highly suggest the Fluke brand as they have true RMS, which gives you accurate readings and removes any “noise” or electrical interference.

Below are some of the best ones which also measure Frequency (Hz):

Fluke 87-V Review

Fluke 87-V

Fluke 115 Review

Fluke 115

Fluke 116 Review

Fluke 116

Fluke 179 Review

What you need

Before you get started with measuring an engine’s RPM with a multimeter you have to ensure you have the following items:

- Calculator (Or the phone with a calculator)

- Digital Multimeter which is capable of measuring a frequency

- Access to the engines spark plug wires

- A 4-inch piece of wire

Safety reminder

This is not a standard test done with a multimeter and thus you should use all protective gear including eye cover and electrical gloves.

When doing this test, we are using the multimeters ability to detect the RPM signals via a wire and taking advantage of the high level of electromagnetic interference produced by the ignition systems. With that said, the spark plug wires, in general, have a very high level of voltage so caution is extremely advised.

How to do the test

Follow these steps to complete the test:

- The first thing you need to do is remove both the red and black leads (the cords) from the device and set them aside.

- Next, take the wire and remove about an inch of the rubber insulation from one end of it so that it’s bare. Then take bare wire and bed it halfway so that it is a bit thicker into a U-shape.

- Insert the U-shape bare wire into the red socket. It will stick up straight out of the device.

- On your Multimeter select the setting to “HZ” so that it can measure frequency.

- Start your vehicle’s engine and let it run for a minute.

- After a minute grab your multimeter and with the long wire sticking out from it move the wire close enough to the spark plug wire but do not let them touch.

Checking the results

As you do the test above, your multimeter will show results on the screen. You’ll need to write down these results. They will be shown to you in hertz(frequency) but you still need to convert them to get RPM.

The results shown will show you the pulses per second but RPM will need a simple calculation x60 to get the actual RPM.

- If your Multimeter shows you 21 as the Hz then multiplied by 60 gives you 1260 as the RPM.

- If your Multimeter shows you 25 as the Hz then multiplied by 60 gives you 1500 as the RPM.

Some testing irregularities to watch for

Double the Expected Amount?

There’s a well-known issue in some 2/4 stroke engines which is called a wasted spark which makes the results of any frequency test show twice the amount that’s needed.

While there are ways around this to change it, the best suggested solution is if your results look to be double the expected, then just divide by 2.

Play around with the wire

If the test does not seem to be working, sometimes the length of the wire has been an issue in which I was able to shorten or lengthen it a bit.

Also, the thickness of the wire often became an issue which trying a thinner metal wire worked better depending on the engine.

Give it some time and play around with it a bit and you’ll get it to work out in the end.

Frequently Asked Questions

How to measure car engine rpm (Best way to measure engine rpm)?

You can measure car engine RPM in two ways.

The first one is with a tachometer.

It is the easiest way, but there is also room for mistake when doing this because tachometers can sometimes be not so reliable.

If your tachometer is broken or you suspect that it gives out false readings, you can replace the tachometer with a new one and use the new one to measure rotations per minute. However, this can be an unreliable method because the source of the false readings could be in something else.

In the case that the first two tests prove inconclusive, this will definitely help you to pinpoint the cause of the problem and to repair it, or if that proves to be impossible, to replace it. Measuring car RPM with a multimeter does require a bit of knowledge, but you can find everything you need in the article above.

Automotive multimeters are accurate, and even the cheaper models will give you readings that are more accurate than an average tachometer. Even if your tachometer proves to be in order, it would be a good thing to test the RPM with a multimeter from time to time.

How to measure motorcycle engine rpm?

You could measure motorcycle engine RPM with a multimeter, or with a tachometer.

Some motorcycles come with a plug that makes it possible for the user to add a high accuracy tachometer.

If your motorcycle doesn’t have that plug, don’t attempt to install the tachometer by yourself because you risk serious injury if are not exactly sure what are you doing, both while doing that and when driving a vehicle that was modified in that way.

You can use an automotive multimeter to measure motorcycle engine RPM.

Basically, the whole process is almost entirely the same as with car engines. The article above can provide you with excellent information on that subject.

Since motorcycle drivers need more accuracy when it comes to tachometers, tachometers made for use on motorcycles are designed and built to be more accurate than those built for cars. It is easier to measure motorcycle engine RPM with a tachometer, but tachometers on motorcycles can become inaccurate too, so that leaves you the possibility to do this with a multimeter.

Other than that, motorcycle engines operate in the same way as car engines do, and the entire process should be the same. If you get confused, you can always contact a car mechanic.

What does engine RPM actually measure?

To measure RPM means to measure rotations per minute. Every internal combustion engine works by injecting small amounts of gas into a cylinder.

The inside of the cylinder is a vacuumed space. When gas is injected, it is lit up by a spark, and since gas is usually supplemented with small amounts of oxidizer, it explodes. When a drop of gas explodes in a cylinder, large amounts of force are released.

The cylinder is built so that force has nowhere to move, except up, and in an upper (or lower part, depending on the engine) part is another movable cylinder.

The force from the explosion moves that cylinder up, and that force the moves the crankshaft. Crankshaft rotates and translates the force to the wheels, and that makes it possible for the car move.

Rotations that the crankshaft produces (all vehicles have more than one crankshaft) are measured because they are an indicator of any problems, and there could be a variety of them.

A difference in rotations per minute can mean that gas is not oxidized enough, or of good quality, that the cylinder isn’t lubricated, that a screw has loosened up on the crankshaft, literally, a million things could be the problem.

Since rotations per minute are an excellent indicator of the state of the vehicle, it is important to monitor them yourself, or at a licensed car mechanic.

How does rpm affect car performance?

For a detailed explanation of the term rotations per minute, and to get some context on how an internal combustion engine works, please check out the paragraph under the’ What does engine RPM actually measure?’ question. If you have read that, let’s continue on.

RPM can affect car performance in a variety of ways. The most important, and most common vehicle feature affected by rotations per minute is the acceleration of the vehicle. Basically, if RPM is too low, the vehicle won’t move. And that’s about it when it comes to low RPM.

In cases where the RPM is too high, a lot of things could happen. The vehicle could become overresponsive, there’s even a slight chance that the engine could explode, but don’t worry, in most cases, it will overheat, and smoke will start to come out from under the hood of your car. I will use the example of the smoke to explain this in greater detail.

The smoke won’t come from too many rotations, but from the cause of too many rotations and the cause can be overpotent fuel, or more commonly, an old engine that lost the state of vacuum in the cylinder.

Since additional oxygen from the outside comes in, it causes more potent explosions, the cylinder can’t handle that, and the smoke has to come out because it has nowhere else to go.

How to measure engine rpm without a tachometer?

It is easiest to measure rotations per minute with the tachometer, but if your tachometer is broken, or you think that there is a problem in regards to the tachometer’s accuracy originating from somewhere in between the tachometer and the engine, you can always use a multimeter.

The article entitled ‘How to measure engine RPM with a multimeter’ will help you in regards to that.

Automotive multimeters are truly an excellent choice when it comes to measuring engine RPM, be it on your car on your motorcycle, if you know how to do it right, the results will be better than if you had seen the result on a tachometer, especially if you have had one of those tachometers that didn’t show the precise value, but had the rotating dial instead.

If you are concerned about your safety, you don’t have to be. When it comes to the danger of electric shock, in most cases, there isn’t any, but you check for your model online, just to be certain.

If you are thinking that there could maybe damage your engine, that’s a possibility, especially if you don’t have any experience.

Follow the article describing that in the letter, and if you are still not certain, it would be better if you would contact a professional than cause a car crash.

Lawn Mower RPM Too High (Why What to Do)

So you started up your lawn mower, and it sounds like it’s over-revving. If your lawn mower RMP is too high, your mower will create an unusually high engine sound. There are a few common causes of this problem and luckily, they can usually be fixed quickly and easily. So, let’s dive in.

Why is My Lawn Mower Revving High? (The Short Answer)

High RMP stems back to the governor. A build-up of grass, bad springs, poor adjustment, and a damaged governor lever can all lead to high revving.

What is a Governor?

The governor controls the engine speed as loads are applied, such as when engaging blades or going up a hill. The governor will cause increased throttle by introducing additional fuel and airflow to the carburetor to maintain a steady RPM. The governor is controlled by the movement of the throttle, a set of springs, and link arms. So, how does the governor malfunction?

Common Causes of a Lawn Mower with RPM That’s Too High

Any time the governor is obstructed or damaged, the engine cannot adjust itself. A high RPM results from the governor’s inability to adjust the throttle. Let’s look to see what could cause this.

Debris on the Governor

You first want to check for a build-up of debris around the governor. In my experience, grass loves to collect in this area. As a result, you’ll need to get to the governor, which may require removing the air filter, fuel tank, or engine cover if the mechanism is hidden behind them.

With these removed, you should have easy access and be able to see any build-up of grass and junk. Next, you can check to see how the governor is working by moving the throttle from fully closed to fully open. If the governor is blocked, then the mechanism will not move correctly.

Checking the Two Springs

Different lawn mowers use different setups, but they all achieve the same job. Your spring could have worn, or it could have been damaged by debris. If the governor opens the throttle but can’t close it, the RPM will stay high.

To check this, you can see if the springs are under tension. If the springs are slack, they will not recall the throttle and the governor. If you have access to the springs with the mower fully assembled, then it’s best to check with the lawn mower running. This will show you exactly how the springs react.

Adjustment of the Governor Lever

The governor lever connects to the throttle linkage and the governor shaft, and controls the air-fuel flow and engine speed. The lever is mounted to the governor shaft, usually using a small bolted clamp. If the lever is loose or damaged, it will be unable to provide the correct adjustment to the engine, causing your lawn mower to rev too high. Inspect the lever to see if it has moved on the shaft or if it looks damaged.

How to Fix a Lawn Mower That is Over Revving

Before starting any fix on the governor, you’ll need to know what over-revving is. Your ears are a good gauge to identify a problem, but they’re not reliable enough to accurately carry out a repair.

For example, if you make a repair to solve a high RPM, you could accidentally end up setting it too low. As a result, you’ll be causing more problems because the lawn mower won’t have enough power.

Typical lawn mower engines have a range of around 2700-3000 RPM. You can confirm this with your specific engine. However, since your lawn mower doesn’t have an RPM counter, you’ll need to have an alternative solution to gauge it.

Inductive Tachometer Gauge

This inexpensive gauge connects to the spark plug lead and provides an accurate reading of engine RMP. It removes any guesswork when making adjustments to the governor. I’ll explain when to use a tachometer gauge on the specific fixes below.

Gaining Access to the Governor

With any repair to the governor, you’ll need unobstructed access first. Next, check if an engine cover, air filter, or fuel tank is getting in your way. If they are, then they’ll have to be removed. A small socket wrench or screwdriver should work fine, depending on your situation. Once the obstruction is removed, you can set them aside and move on to the fixes.

Tools to Remove Obstructions

Cleaning out the Governor

Removing debris from the governor isn’t tricky, but it’s best to be gentle and not cause a new problem. If you had to remove the air filter, the carburetor’s inside will be exposed, and you’ll need to prevent debris from getting in. Let’s cover this in more detail.

Steps to Cleaning Out a Governor

First, start by removing the debris with your hands. I suggest you wear gloves since you might find something like a mouse nest that appeared over winter.

Be careful with the mechanism; remove what you can, making sure what you’re pulling out isn’t wrapped around a spring. The springs are delicate, and you want to avoid damaging them.

When you have the bulk removed, you can move on to using an air compressor or leaf blower to get the remaining junk out. Just be extra mindful if you have an exposed carburetor. Placing your hand over the carburetor opening should keep any debris out. Finally, once it is all cleaned out, give the mechanism a good coat of spray lubricant, making sure it doesn’t get into any exposed engine parts.

With this done, you can go ahead and put the lawn mower back together and test the RPM. Connect the tachometer gauge as per the instruction and start your engine. With the engine set to FULL, check the reading. It should be reading in line with the engine recommendations.

Tools Required to Clean out the Governor

Repositioning the Springs

You’ll notice that the governor lever has several small holes where you can attach the springs at different intervals. These allow you to adjust the tension of the various springs. By repositioning the springs, you will adjust the governor lever’s movement and, consequently, the engine’s RPM. Let’s go over how to adjust the springs to reduce the engine RPM.

Reducing the RPMs Using the Spring Adjustment

Start by attaching your tachometer gauge to the lawn mower, and start your engine. Take note of the RPM with the engine on full throttle. Once you have this reading, you can go ahead and turn off the lawn mower.

Next, take your needle-nose pliers, move the spring to the next hole, and take a new reading by starting your engine. Continue this process until you can get the RPM into the desired range. If you cannot achieve the desired RPM, you will need to move on to replacing the springs and checking the lever.

Tools Required to Adjust the Springs

Replacing the Governor Springs

I strongly recommend using new springs if you have identified that the governor springs need to be replaced. Any little fixes you do with your old springs may or may not last. Let’s look at the steps you’ll need to follow to get your governor working as it should.

Steps to Replacing Springs

Start by taking a pair of needle-nose pliers and removing the springs. Make a mental note of which spring goes where and its orientation. You’ll want to get the new springs back on the same way the old ones came off. They may get caught up if they go on backward.

Next, take your new springs and hook them into position using your needle-nose pliers. It’s that simple. With this done, give the governor area a good clean and spray it with a coat of lubricant.

Finish the fix by putting the lawn mower back together and testing the RPM. Take your tachometer gauge and check the RPM the same way you did after the cleaning process above. With the new springs properly in place, you should no longer have a lawn mower over-revving.

Tools Parts to Replace Springs

Governor Lever Adjustment

The governor lever adjustment is the final fix to try if your lawn mower’s RPM is too high. Now, this isn’t adjusting the lever plus or minus. It’s simply adjusting the lever to be in the correct position. The governor shaft is usually square or half-round; this means the governor lever can only fit in one position. So, if yours isn’t in the correct position on the shaft, you’ll need to carry out a fix.

Positioning the Governor Lever Correctly

Start by using your needle-nose pliers to remove the attached springs and throttle arm. This will keep them out of the way, so they are not damaged. Then, use your wrench to loosen off the nut and bolt on the lever.

Once loosened, you can remove the lever from the lawn mower and inspect it for any damage. If you find that some damage looks beyond repair, I recommend using a new part. If you find the lever is bent, you’ll probably be able to straighten it by hand since it is made of thin metal.

Take either your new or repaired governor lever and place it back onto the governor shaft, ensuring it’s lined up correctly. Continue by fastening the lever’s nut and bolt and reattaching the springs and throttle arm.

To finish, clean and lubricate the area and reinstall the obstructed parts you removed from the lawn mower. Finally, take your tachometer gauge and check the RPM, as explained earlier.

Riding Mower Revs Too High: Causes Solutions Specific to Ride-Ons

You may be asking, what about a riding mower that revs too high? Well, the fixes are just the same. The only real differences are that the engine is usually covered, such as with a tractor hood, and the size of the engine is larger in terms of horsepower. When it comes to governors, they tend to all work the same and follow the same principles. So, the next time you hear your lawn mower revving high, you’ll have four very quick and easy fixes for it.

About Tom Greene

I’ve always had a keen interest in lawn care as long as I can remember. Friends used to call me the lawn mower guru (hence the site name), but I’m anything but. I just enjoy cutting my lawn and spending time outdoors. I also love the well-deserved doughnuts and coffee afterward!

Leave a Reply Cancel reply

Copyright © 2010. 2023 LawnMowerGuru.com, All Rights Reserved.

Affiliate disclosure: As an Amazon Associate, we may earn commissions from qualifying purchases from Amazon.com. You can learn more about this here.