Ohv meaning lawn mower. Lawn Mower Only Runs with Choke On (Why How to Fix)

What is the difference between OHV, OHC, SOHC and DOHC engines?

The main difference is in the placement of the camshaft. OHV means Over Head Valve. Although almost all modern car engines have valves placed in the cylinder head, the term OHV is used to describe a pushrod engine, with the camshaft placed in the cylinder block. OHC stands for Over Head Cam, or the camshaft is installed in the cylinder head. SOHC means Single Overhead Cam, while DOHC means Double Overhead Cam.

Which one is better? It’s always a heated argument. Muscle car fans will swear by an old-school pushrod, while younger car enthusiasts will say that nothing beats the twin-cam (DOHC). Each design has its pluses and minuses. Let’s start with the good old Pushrod:

OHV or Pushrod engine

In an OHV engine, the camshaft is placed inside the block and the valves are operated through lifters, pushrods and rocker arms. This mechanism is called a valvetrain. An OHV design has been successfully used for many years. Most early American cars had OHV engines and they are still used in trucks and sports cars.

How To FIX A SURGING ENGINE On A Lawn Mower, Pressure Washer, etc.

The downside of an OHV design is that it requires many moving components to operate the valves. Each component adds weight. This results in higher valvetrain inertia, making it difficult to control the valve timing at higher RPMs.

This means that a small OHV engine will not be very efficient. The OHV design is more suitable for larger V6 and V8 engines; you won’t find an OHV engine in a modern compact car.

Advantages of an OHV engine include a lower cost, higher low-end torque and more compact size. For example, the 2018 Chevrolet Corvette Z06 is 4.4 inches shorter than 2018 Honda Civic sedan. Yet, thanks to its compact 6.2L OHV V8, the Corvette Z06 can go from 0 to 60 mph in 2.9 seconds. The Corvette’s supercharged aluminum 650-HP OHV LT4 engine pumps out a crazy 650 pound-feet of torque at 3,600 rpm.

OHV engines are also famous for their durability and longevity. It’s not uncommon to see older trucks with an OHV V8 engine with over 300K miles still running strong. Maintenance costs are low too. A typical OHV engine has a small timing chain that is not very difficult to replace. See examples of OHV engines:

OHC or SOHC engine

OHC simply means Over Head Cam, while SOHC means Single Over Head Cam or Single Cam. In a SOHC engine the camshaft is installed in the cylinder head, and valves are operated either by the rocker arms or directly through the lifters (as in this animation). See this photo of a Mitsubishi SOHC engine.

The advantage of the OHC design is that valves are operated almost directly by the camshaft, which makes it easier to maintain precise timing at higher rpms. It’s also possible to install three or four valves per cylinder.

Honda successfully uses the SOHC design in its late V6 engines where four valves per cylinder are operated by a single camshaft.

The downside of an OHC engine is that it requires a timing belt or chain with a tensioner and other related components. A timing belt must also be replaced at regular intervals. The timing chain lasts longer, but it too might need to be replaced if stretched. Another downside is that it’s more difficult to implement variable valve timing separately for exhaust and intake valves; something that can be easily done in a DOHC engine.

DOHC or Twin-Cam engine

DOHC means Double Over Head Cam. A DOHC engine design is often called Twin Cam or Dual Cam. It’s the most widely used engine today. The majority of today’s cars have a DOHC engine, see the photo of a modern DOHC engine.

A typical DOHC engine has two camshafts and four valves per cylinder, like the one in this animation. One camshaft operates intake valves, while another camshaft controls exhaust valves on the opposite side.

This allows the intake valves to be at a larger angle from the exhaust valves, which results in a more direct air flow through the engine. In other words, a DOHC engine can breathe better, which means it can produce more horsepower out of a smaller engine volume. Compare: The 5.0-Liter V8 DOHC Coyote engine with 4 valves per cylinder of the 2018 Ford Mustang GT is rated at 460 HP @ 7,000 rpm. The 6.2-Liter OHV (pushrod) V8 GM L86 engine has two valves per cylinder and produces 420 horsepower at 5,600 rpm.

DOHC engine, click to see a larger image.

Technologies like Variable Valve Timing and Variable Valve Lift can be easily implemented in a DOHC engine on both camshafts further improving efficiency.

Downsides of a DOHC engine include a larger size and more complex design with a timing belt or chain and related components. A timing belt needs to be replaced at recommended intervals, adding to maintenance costs. Replacing a timing chain is only necessary if it’s stretched, or there is another related problem, but it could be expensive.

Conclusion: Currently, the DOHC engine design is the most fuel-efficient, but an old-school OHV engine will last longer in similar conditions and is cheaper to maintain.

Lawn Mower Only Runs with Choke On (Why How to Fix)

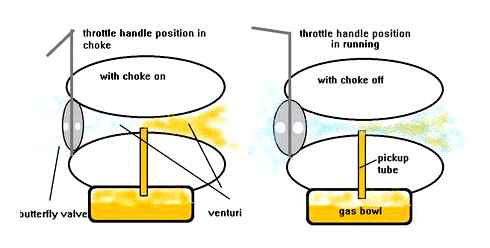

Known by some as the magic lever that helps get an engine started, the choke is actually a pretty simple but essential mechanism. Though it may seem a little bit mysterious at first, the choke on an engine works just as the name suggests. Most people know that setting a choke fully on gives the engine “more gas” but this only explains half of what really happens. The way that choking an engine supplies more gas is by restricting the airflow into the carburetor (which is why it is called a choke). Using the choke to get an engine started or warmed up is normal but if the lawn mower dies when the choke is off, something is probably wrong.

Why Does My Lawn Mower Only Run on Full Choke? (Short Answer)

Working on the fuel and air supply end of things, if your lawn mower only runs with the choke on, there is probably a fuel delivery or carburetor problem. The main carburetor issues that cause this are air leaks, and clogging. Bad fuel or fuel with too high of an alcohol content can also require excessive choke use. If you need to choke your engine for any longer than 5 minutes, you’ll know that something isn’t right. This is true in any case whether you have a Kohler engine that only runs with the choke on or a Honda lawn mower that only runs with the choke on.

Possible Reasons Your Lawn Mower Dies When the Choke is Off

“Why does my lawn mower only run on full choke?!” is something many people find themselves muttering at some point or another. What using the choke really does is enrich the fuel and air mixture that the engine uses to operate. If your lawn mower dies when the choke is off, you’ll need to figure out why the engine isn’t getting the right ratio of fuel and air by itself. I’ll describe the three most common reasons why this happens below.

Carburetor Problems

Carburetor clogging is probably the most common issue, especially when it comes to a 2 stroke engine that only runs with the choke on. From gas turned to varnish, rusting, or debris in the fuel, carburetors can get clogged for any number of reasons. Inside of a carburetor, there are small jets with tiny holes that help deliver gas to the combustion chamber. Because they’re so small, they are easily blocked.

Probably the most common reason carburetors get gummed up is gas deterioration. Over time, gas that just sits will break down and coat the interior of the carburetor. Carburetors work in a very precise way and if something is off they cannot supply a correct mixture of fuel and air alone. This would create a situation where an engine or lawn mower only runs while choked, basically turning the choke into a clutch.

Air Supply Issues

When it comes to the fuel delivery system, air supply is super important. A choke works by restricting the air supply, increasing suction, and enriching the fuel and air mixture that enters the engine. In other words, the choke forces more gas into the combustion chamber, helping engines start when cold.

While there are a few things that can throw off the amount of air that enters the engine, the main issues are: cracks or leaks in the fuel line or primer bulb, loose hardware or a carburetor air screw that is set wrong, and a gasket that isn’t seated right or is deteriorating. What these things have in common is that they can lead to excess air delivery and a weaker vacuum system. In all of these cases, the mower might be extra dependent on the choke to run.

Bad Fuel

Sometimes the problem is just that your fuel isn’t any good. This is usually due to using old gas or using the wrong type of gas. Without any stabilizers, gasoline starts to break down pretty quickly (I wrote a separate post on how long gas lasts typically). If your lawn mower has been sitting for more than a year without use, there is a possibility that the gas has gone bad. If you’re not sure how to tell, read about the symptoms of bad gas in a lawn mower. They’re fairly easy to spot.

Also, you might have a type of gas in your tank that doesn’t agree with your mower’s engine. Fuel with a high alcohol content like those with an ethanol blend will carry moisture and can lead to rust or a gunked-up carburetor. In the United States, all regular gasoline is blended with ten percent ethanol. In larger engines, regular gas works great, but in smaller engines, it isn’t always the best choice. Knowing which fuel you should use in your lawn mower is important if you want to avoid mechanical problems down the road.

How to Fix a Lawn Mower that Only Runs with the Choke On

Well, now that you have a good idea of why your lawn mower dies when the choke is off, let’s talk about how to fix it. I’ll start with the most common fix and end with the rarest.

Clean or Replace the Carburetor

When deciding between these two options it really comes down to a couple of things: your experience with small engine work, and the price and availability of a new carburetor. Being aware of the symptoms of a bad lawn mower carburetor can also come in handy too and help you understand whether a new carb is really necessary.

If you’re comfortable doing work on your lawn mower it actually isn’t too difficult to clean a carburetor. You’ll need to remove the carburetor and disassemble it. Just be sure to remember how it goes back together. Sometimes you only need to spray carb cleaner through the jets and around the inside of the bowl. But, if your carburetor has a ton of varnished gas residue, you may need to soak the parts in the carburetor cleaner for a few hours. Afterward, you just have to put the carburetor back together and reinstall it into the mower.

With that being said, if you have a carburetor that has rusted or is extremely gummed up, and you find an affordable new carburetor, you may be saving yourself a ton of time by going with a new part. If you have any doubts, you can get some good advice at your local small engine mechanic’s shop.

Seal Air Leaks

The process of sealing air leaks looks different for every lawn mower. However, figuring out where the air supply has been disrupted is pretty straightforward.

How to Fix a Surging Lawn Mower

Start by checking your fuel line for any cracks or connections that are loose. All of the vibration of a running lawn mower can be enough to wiggle a hose clamp off its seat. If everything looks good, check your primer bulb. As these rubber bulbs age, they can get brittle and crack as well.

After making sure these rubber components are good, give your carburetor a once-over and make sure all the hardware is tightened down. Also, when you’re checking out your carburetor try and see if anything looks off with the mounting gasket. If you see any edges of the gasket sticking out or it looks dried or cracked you’ll want to replace it.

Lastly, take a look at your fuel cap and make sure that it has a good seal on it still.

Use Different Fuel

Whether you have gas from the last season in your lawn mower, or you have used regular-grade gasoline, it might make all the difference to try premium or non-oxygenated gas.

If you aren’t sure if your gas has gone bad, take a look at its color. Gas that has gone bad usually has a darker color and sometimes even a sour smell. If you have bad gas or just want to give new fuel a try, you’ll want to siphon or drain out the rest of the fuel in your tank (here’s how to drain gas from your mower without a siphon). If you drain it out by tipping the mower over just make sure you keep your carburetor and air filter facing up when doing so.

Using high-quality fuel can help extend your mower’s life and a riding lawn mower that only runs with the choke on might benefit from premium gas in particular. If you’ve made the investment in a riding mower, do yourself a favor and do everything you can to keep its engine happy.

About Tom Greene

I’ve always had a keen interest in lawn care as long as I can remember. Friends used to call me the lawn mower guru (hence the site name), but I’m anything but. I just enjoy cutting my lawn and spending time outdoors. I also love the well-deserved doughnuts and coffee afterward!

Комментарии и мнения владельцев

Hello, I noticed that you mentioned to check gas cap for good seal. My Husqvarna will only run choked, however the gas tank itself has crack in the top of it. After gas sloshed inside tank a bit I noticed leaked gas on top of tank under the seat. Could this be the cause. Already replaced/checked fuel lines, filter, pump, and a couple gaskets. The other thing I’m suspicious about is where the governer assembly is there appears to be a piece of plastic that’s dangling off the rod or arm that seems like it might be something that broke, not sure (very little engine experience). Would appreciate your thoughts. Thanks, Jared.

Hello Jared! Whether or not your cracked fuel tank is the source of your problems, it is something that you should fix right away. Gas fumes leaking up underneath your seat can be a pretty serious fire hazard. Luckily it isn’t a super hard fix. However you do it, it helps to start by drilling tiny holes on either end of the crack so that the crack won’t get any bigger. As far as your mower only running with the choke on goes, I think you’ve made some steps in the right direction. The remaining boxes to check would be trying fresh fuel, and cleaning out your carburetor. I think that carburetor issues are some of the most common. Regarding that piece of plastic dangling, it sounds to me like you could be describing a pneumatic governor. A pneumatic governor should have a piece of plastic that dangles and also two springs: one attached to the throttle, and one to the carburetor. If the governor assembly is messed up, that could definitely affect how the choke is used. Hope this clears things up a little bit. I would probably investigate your carburetor first. Tom.

You are a clear teacher. Thank you. My Honda Inverter doesn’t get used very often. I live near the ocean and everything than can rust does rust. Like within the hour. Recently the engine started but died immediately, with or without choke. After draining gas and putting in a cup of “fixit gas” the engine started and ran smoothly ON THE FIRST PULL. I had also drained carburetor bowl and checked spark plug. While plug was out I pulled cord a few times. My manuals says there’s a fuel pump and that would clear gas from it. I didn’t notice any gas come out. Kinda weird. As I stood there congratulating myself for “fixing” the generator (even though I had no idea how it got fixed) I noticed the choke was on. Opening the choke caused the engine to die immediately. But it runs beautifully w choke on, in regular mode and “eco mode”. ♂️

My John Deere x500 only runs with choke on and is hard to start. It shuts down while cutting grass. I installed a new fuel pump and new carb. Still the same problem. I’m going to check fuel line from the tank, but there is gas in the filter. What do you think of this?

Hi Jim, Have you tried to run the tractor on low RPM? Usually, if the engine is being starved of gas, it’s a bigger problem when the demand is higher (high RPM). So, if the mower keeps running on low RPM and then stalls when you increase the RPM and add load, it could definitely be starved of fuel. The engine can be starved of fuel in the following ways: Blockage in the fuel tank Clogged fuel line Blocked fuel filter Incorrect fuel filter Poor fuel pressure (check the pipe from the OHV to the fuel pump) Clogged fuel cap Pinched fuel lines If you have just installed a new carb, then we can only hope that the factory’s air-to-fuel mixture setting is correct. If you have to play with the choke, then you’re manually adjusting the mixture. Choking is giving more fuel, so there’s not enough fuel or too much air. I’m guessing you already looked at the air filter. I hope this gives you a few ideas. Cheers, Tom.

Have a 46” XLT cub cadet that has been used regularly, but has been set out, year round, uncovered for 5 years. Stopped running and the owner bought a new replacement zero turn. He gave me the cadet. I cleaned the carb, changed the oil, air filters, plugs and inline fuel filter. One of the two coils was bad and I replaced both with new ones. Before doing all this, it would crank good, run 1.5-2 minutes, and cutoff. Could prolong the running, by working the choke. Obviously, the hotter it got, the more difficult it was to keep it running. The mower is tight and I think would be quite serviceable if I could keep it running. Do you have suggestions on what else I need to try to solve my problems? Thanks in advance.

Hi Dan, Well, it looks like you have covered most of the bases and serviced everything that you can. So, I’d be looking back at the carburetor. If you can keep the engine running with the choke, then you’re changing the air-to-fuel mixture and giving the engine a little more fuel. This means there is either an issue with the fuel coming in, the air coming in, or the way the fuel is being mixed and then ejected out of the carburetor’s jet. These are items I would want to inspect. Fuel Filter Fuel Lines Fuel Pump Air Filter Carburetor Jet Float Carburetor Settings I’d try running the engine on idle to see if it stalls. If it only stalls at high speed, it looks like the engine is being starved of fuel. I hope you find where the problem lies and get the cub running again. Good luck! Cheers, Tom.

My Toro backpack leaf blower is 14 years old. I just replaced the carb and spark plug but it still only runs with choke 1/2 on. After replacing the carb it now only runs for awhile then bogs down and dies. Could it be as simple as a bad fuel filter ? I only run fresh, 90 octane, ethenol free gas.

Hi Marty, 14 years, impressive! I have an old STIHL blower that belongs in a museum. I had a similar problem with it like the one you seem to be having. I would make sure that the in-tank fuel filter is replaced and take a look at the fuel lines. It doesn’t take much to give them a problem as they are so tiny. Also, I had to replace the washer on the fuel cap as the tank couldn’t pressurize and push fuel to the carb. One trick I found was to put my hand over the end of the pipe the air of the blow comes out of for a few seconds. This forces the RPM to increase and keeps the engine running. I’m guessing that you have changed out the air filter and that the new carb is already pre-set with air-to-fuel mix. Finally, the piston rings and pistons can wear causing a loss of compression in the engine. If this is the case then it could be time to finally retire the blower. I hope this gives you a few ideas! Cheers, Tom.

I have a 19hp Kohler zero turn which was hard starting. I replaced the carb with off-brand, new plug, new air and fuel filter, and all new gas lines. It starts great now but I have to let it run at low rpm for a minute then increase rpm for a couple of minutes before engaging the blades or it will stall. It didn’t do this before the new carb. Could be air and fuel mixture or maybe the governer. I tried adjusting the air and fuel mixture screw but not sure where to set it. Or could it be the way the new carb is as it runs great after it warms up?

Hi Ed, It sounds like your Kohler is struggling with the initial load at low RPM. This would make me think that the Idle RPM is set too low or that the carb-low setting/screw needs to be increased. Your comment about the fact it’s not an OEM part also could be a factor. Maybe have a read of the reviews on the part. Other people could be having the same problem with that particular part. Another thing you mentioned was the governor. I would check the old carb with the new one. If the link bar between the carb and the governor is different on the two carbs, then you may need to compensate and make some small adjustments. I hope this gives you a few ideas! Cheers, Tom.

Hi Tom, I have a sears snow blower four stroke. It starts right up and run perfect till I take the choke off. I installed a factory carburetor for second time. I verify the carburetor is not the issue unless Briggs and Stratton are having issues. It does not come with a new o ring and I see no issues with original. What do u think? I will definitely check the primer. Never was aware this would affect the engine. No mixture adjustment.

Hi Lou, So, a correctly installed new non-adjustable carburetor with a manual choke. Well, I would want to look at fuel delivery and air delivery. For example, you want to make sure that there is no kind of blockage preventing fuel from flowing through the fuel lines, fuel filter, fuel pump, and any air restriction through the air filter. Also, I would want to make sure that the pulse pressure from the OHV is working. That’s if your snow blower uses a pulse fuel pump. If you have some kind of blockage or a split in one of your hoses (including the primer), then air could be getting sucked into the fuel throwing off the air/fuel mixture. I would be interested to know if the engine struggles on low RPMS as well as high RMPS. If it’s just high RPMS, then it is likely the engine isn’t getting enough fuel. I hope this gives you a few ideas of what to look at. Thanks for the question. Tom.

Mowing Slopes Safely – Let’s Get Real About Hills.

Updated March 2018. I read many reviews complaining about lawn tractors not being able to mow on a hill. “They don’t have enough traction.” “I have to use tire chains.” “I have some fairly steep hills on the property and the tractor stands so tall that it is not safe at all on hills over 15 degrees. So I couldn’t mow half of my lawn.”

It’s time to stop complaining and get real. You will not be able to mow all of your lawn with a lawn tractor or zero-turn if there are slopes.

Thank You Toro For This Photo

The truth: Residential Lawn Tractors and Zero-Turns are not designed to mow on slopes steeper than 15 degrees. They all tell you that in the manual. There are mowers designed to mow hills but the cheapest one on the market is over 10,000. The good ones are in the 20,000 to 50,000 range.

Making myself more comfortable on a slope is not my goal. Not rolling the tractor or zero-turn is my goal. Rolling the tractor is not worth cutting an extra bit of grass. It is just grass.

If it is too steep to mow, turn it into a landscape bed or wildlife area.

Be Safe:

Can a tractor mow this hill? NO!

Zero-Turns are not weighted to mow up a hill. Especially older zero-turn mowers. They will tip over backward.

- If you cannot back up the slope or if you feel uneasy on it, do not mow it with a ride-on machine.

- Mow up and down slopes with a lawn tractor, not across.

- Watch for holes, ruts, bumps, rocks or other hidden objects. Uneven terrain could overturn the machine.

- Choose a low ground speed so you will not have to stop or shift while on a slope.

- Do not mow on wet or damp grass. Tires may lose traction.

- Do not mow on drought-dry grass. Tires will lose traction.

- Always keep the machine in gear when going down slopes. Do not shift to neutral and coast downhill.

- Avoid starting, stopping or turning on a slope.

- Keep all movement on slopes slow and gradual.

- Use extra care while operating the machine with grass catchers or other attachments; they affect the stability of the machine. Do not use them on steep slopes.

- Do not try to stabilize the machine by putting your foot on the ground.

- Do not mow near drop-offs, ditches or embankments.

46 inch 2 blade decks on lawn tractors do not have the clearance between the rear of the deck and the rear tires to install tire chains.

If you have a Walk Out Basement the angle is too steep to mow side to side or up the hill. Mow down the hill, drive around to the top of the slope and mow down. Yes, you may have to drive around the house a dozen times to do this, but it is the only way. Never attempt to mow or drive up the hill

Don’t even consider using a rear mounted bagger on hills. On both tractors and zero-turns that makes them too heavy in the rear.

Don’t even consider a leaf/lawn vac on slopes. The transmissions in lawn tractors are not heavy enough and you will destroy the trans. On garden tractor, there may be too much weight on the rear hitch. Blow the leaves to the bottom of the hill with a handheld blower or backpack blower, then pick them up with your vac.

Tip-over from water logged turf

Do not mow near drop-offs, ditches or embankments. Don’t mow near a pond. The first 6 to 10 feet of turf by the water’s edge is water-logged and your mower will sink in and tip over.

Follow the rules in your operator’s manual. But remember, an unseen hole on the down-slope or a bump or stick of wood on the uphill side can increase your slope quickly and cause an accident.

Seatbelts and ROPs won’t save you if there is water

What is available today For the Homeowner:

Notice the dual wheels on the ATV?

The ATV is out of the water logged turf

There are very few residential mowers specifically designed to mow slopes. Here are a few that work:

Acrease Wing and Rough-Cut Mowers: Acrease Mowers are able to mow slopes. They use full pressure engines on the commercial models that won’t blow up on slopes greater than 15 degrees. Be aware these mowers are heavy and you will need a heavy tractor to pull them. I actually used 2 in tandem to mow a 10-foot road ditch (Swisher T-60 Trailmower 14.5hp. is only designed for 15-degree slopes. The engines are splash lubricated and will blow up on slopes greater than 15 degrees.)

Craftsman 4WD walk-behind.

There are a few tractors with a rear differential lock from Craftsman Pro, Cub Cadet and Husqvarna that give you better traction going up and down slopes, but they are still only rated for 15 degrees.

There are other mowers that will handle slopes but all of them are commercially rated. Standon Mowers, 60 inches and larger like the Wright Stander are capable of mowing greater than 15 degrees. Toro Walk-Behind commercial mowers with the T-Bar steering also work well. Of course, there are the dedicated slope mowers like the KutKwick and the new robotic mowers.

Final Thoughts

Many people don’t read the operator’s manual or feel these warning statements are “just guidelines.” Even staying under 15 degrees there are still ways to tip your lawn tractor or zero-turn mower over. Mowing commercially for many years I have had too many close calls and I still use my “Pucker-meter” all the time. The seat of your pants is the best gauge – really. It is a long, slow, careful learning experience. You have to get to know your machine and how to best approach various terrain. Going slow and low is always good.

If is feels wrong, if the hill feels too steep, if the tractor doesn’t feel right, I don’t mow it.

(This Last From Consumer Reports)

What we tested, what we found. We compared several zero-turn-radius riding mowers marketed to consumers with a lawn tractor on slopes ranging from roughly 5 to 20 degrees. We used a typical 4.5 mph mowing speed over both dry and wet grass, going up and down as you should with most ride-on machines. So far, so good.

The trouble began when we made a hard turn down 10- to 15-degree slopes. The zero-turn riders lost most of their steering control, skidding straight into our simulated hazards. All could stop in time when the brake was applied, though stopping entails manipulating two levers that also do the steering. That’s less intuitive than a tractor’s foot brake. And while the zero-turn models steered controllably at slower speeds, time savings is a major selling point for zero-turn machines.

The rollover risk

Rollovers are another concern with all ride-on mowers, contributing to the more than 15,000 injuries and 61 deaths associated with those machines for 2007, according to estimates based on CPSC data. Commercial tractors and riding mowers often include a roll bar, called a rollover protective structure (ROPS), and a safety belt. Both are supposed to work together to protect and confine the operator if there’s a rollover. But even that approach leaves lots of room for error.

- Choose a front-steering tractor over a zero-turn-radius rider if you’re mowing slopes 10 to 15 degrees or greater. (A 10-degree slope rises roughly 20 inches over every 10 feet.) If you already own a zero-turn-radius riding mower, be sure to mow slowly on hills. And mow only on dry grass to maximize traction.

- Give yourself time to learn the controls on any ride-on mower, especially a zero-turn mower’s levers for steering and speed.

- Mow straight up and down slopes with a tractor or rider unless the manual says otherwise. And mow side-to-side with walk-behind mowers, start at the bottom and work up-hill. Always turn uphill.

OHV vs. OHC Engines: What Is the Difference and Which Is Better?

An eternal battle wages in the hallowed halls of muscle car glory. A vicious war that’s almost as bloody as that of Chevy vs. Ford. We’re talking, of course, about OHV vs. OHC, or pushrod vs. OHC, engines. Whether you’re looking for information or just want to see what side of the battle we’re fighting on, join us as we dig through the trenches on everything you need to know about the OHC and OHV engine. If you already have an opinion on the matter, we’re probably not going to change it — and if you don’t, well, maybe you’ll learn something.

What Is the Difference Between an OHV and OHC Engine?

The difference between an OHV and OHC engine is all about the configuration of the cylinder heads. OHV stands for overhead valve, whereas OHC means overhead cam. An OHV engine has a camshaft placed between the engine’s cylinder heads, also known as cam-in-block. The crankshaft connects to the cam, so they turn in tandem. As the camshaft turns, a pushrod causes the valves on top of the engine to open and close.

On the other hand, on OHC engines, the camshaft (or camshafts) are on top of the cylinder heads, controlling the intake and exhaust valves.

What Is a Pushrod Engine?

A pushrod engine is simply another name for an OHV engine, named so because of the engine’s use of a pushrod for operations. OHC engines can be referred to as modular engines because of their setup.

Pros and Cons of an OHV or Pushrod Engine

Introduced in the 40s, some drivers think of the OHV engine as being outdated. That said, it certainly has its defenders. Let’s take a look at some of the advantages and disadvantages of installing a pushrod engine in your ride.

OHV Engine Pros

Putting in a pushrod engine is worth consideration, especially for the following reasons:

- Classic Style — When you think of classic American muscle, an OHV engine is a big part of it. While this will be subjective from driver to driver, the cam-in-block style just screams old school, and for some folks, that’s enough to give it the thumbs up.

- Size — OHC engines are bigger and heavier because of the placement of the camshaft (and addition of more camshafts in most cases).

- Cost — OHV engines are more cost-effective upfront and generally cost less to maintain. They’re also known for lasting a long time.

- Low-End Torque — While the tides may be shifting, the pushrod engine is still known for having better low-end torque because of the way its valves work, creating a better air and fuel mixture.

OHV Engine Cons

You might think twice about using OHV engines for these factors:

- Potential for Failure — Even though they tend to be durable, OHV engines have many moving parts, which means they have more potential points of failure. Additionally, the pushrods tend to warp and flex over time.

- Less Control over Valve Timing — At higher RPMs, it’s way harder to control the valve timing because there are so many components. Pushrod flex also decreases accuracy. While modern OHC engines often have built-in variable cam timing, OHVs simply don’t naturally have that level of control.

Pros and Cons of OHC Engines

First of all, it is crucial to note that there are two types of OHC engines: SOHC and DOHC, with both utilizing a design that puts the camshaft(s) at the height of the cylinder heads rather than in-block. SOHC stands for Single Overhead Cam, meaning there is one camshaft for the intake and exhaust valves, while DOHC means Double (or Dual) Overhead Cam, using two separate camshafts to control the intake and exhaust valves separately. We’ll compare pushrod vs. DOHC and SOHC below.

SOHC vs. OHV

While DOHC might be more common, it’s still worth comparing SOHC vs. OHV.

- Pro: OHC engines allow for more precise timing, especially at high RPMs, because the valves are operated directly by the camshaft.

- Con: A timing belt or chain is required, and this has to be replaced periodically.

- Con: Separate variable valve timing for exhaust and intake valves is complicated (a problem solved with DOHC engines).

DOHC vs. OHV

Most new cars off the line today are equipped with DOHC engines. When comparing pushrod vs. DOHC for your ride, you’ll want to keep these factors in mind.

- Pro: DOHC engines can achieve more direct airflow because the dual camshafts allow for a larger angle between the intake and exhaust valves.

- Pro: breathing room means more horsepower and more high-end torque (though pushrod engines still have better low-end torque).

- Pro: Variable valve timing can easily improve power and fuel efficiency.

- Pro: DOHCs can hit way higher redlines than OHV engines due to a higher rev ceiling.

- Con: All OHC engines are heavier because of additional components, especially those with dual overhead cams.

- Con: These also need a timing belt or chain.

Pushrod vs. OHC: Which One Wins

To be frank, it really comes down to personal preference and what you’re trying to get out of a specific build. We’ll give you our final breakdown to help you decide where your loyalty lies in the battle of OHV vs. OHC.

OHVs are known for durability, longevity and ease of maintenance. While OHC engines are generally reliable, if they do have problems, they’re usually much bigger problems. With more moving parts that are all connected (particularly the timing chain tying together the camshafts, pistons and crankshaft), if one thing goes wrong with an OHC, it can all go wrong. However, a pushrod engine can’t beat the rev range, smoothness and fuel efficiency of a modular engine, no question.

Let’s face it — in modern cars, you really only see OHV engines in Chevys, so you know where we stand.

“Aerodynamics are for people who can’t build engines.”

Find Parts and Accessories for DOHC and SOHC Engines

Comparing OHV vs. OHC, it doesn’t matter which side you’re on — Lethal Performance can help you get the killer ride of your dreams. While we specialize in modern Mustang OHC engines, you’ll find OHV parts in our store as well. Browse our selection today!

Related Articles

Let’s get this straight right off the bat: The internal combustion engine is man’s greatest invention yet (although we got some votes in for the miniskirt and deep dish pizza as well). And, understanding how your car’s engine works is a fundamental.

Let’s get right to the point — there have been a lot of Mustang engines throughout the car’s history. And sure, not every single one of them is notable. But there are A LOT, and many of them are pretty important to our precious pony’s development.

You ever wolf down a humongous meal and stuff yourself to the point where you think you’re going to burst? You’re as full as full can get but somehow you can’t stop thinking about the dessert. That chocolate cake looks so good, how can you say no.