Pull behind mower diy. 17 Creative Lawn Mower Storage Ideas to DIY or Buy

CRAFTSMAN

Find the CRAFTSMAN original equipment parts and accessories you need to keep your lawn mower, snow blower and other outdoor power equipment performing strong. These parts and accessories are designed and engineered to exact standards to provide reliability and optimal performance. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment parts and accessories.

Can’t find your part? Customer Service can help. 1-855-971-2271 Monday. Friday, 8:30 am. 5:00 pm EST CHAT WITH US

FIND PARTS BY DIAGRAM

Find the original equipment parts and accessories for your CRAFTSMAN outdoor power equipment on our Parts Diagrams. The Parts Diagram helps visualize components found on your equipment. If you can’t find what you’re looking for or need assistance installing the new part, call 1-855-971-2271.

FIND PARTS BY MACHINE TYPE

CRAFTSMAN original equipment parts can help you maintain your CRAFTSMAN outdoor power equipment long-term. Find parts by machine type: Riding Lawn Mower, Walk Behind Lawn Mower, Garden Tiller and Snow Blower to repair your machine.

Help keep your CRAFTSMAN riding lawn mower running strong year after year with original equipment parts. SHOP PARTS

Find the parts you need to keep your CRAFTSMAN push mower operating in peak condition. SHOP PARTS

Pull behind mower

Whether you’re cultivating your entire lawn or just a small garden, find the CRAFTSMAN garden tiller parts you’ll need to get the job done. SHOP PARTS

Avoid waking up to that fresh snowfall with a snow blower that doesn’t work! Regular maintenance and replacement of your CRAFTSMAN snow blower parts will keep you ready all winter long. SHOP PARTS

FIND PARTS BY PART TYPE

Find parts by part type: Blades, Belts, Tires and Wheels, Engine Parts, Cables, Attachments and Accessories, Pulleys and Spindles.

When you need blades to deliver a clean cut and a healthier-looking lawn, look no further than CRAFTSMAN original equipment blades. CRAFTSMAN blades are designed to provide a precise fit with every blade change. Heat dipped for durability and flexibility, these blades have been tested for thousands of hours to meet equipment standards. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment blades. SHOP PARTS

CRAFTSMAN original equipment belts are manufactured to equipment specifications so you can attain a precise fit with every belt change. These belts have been designed to combat conditions. Made with durable, high strength materials, they’re designed to be flexible enough to withstand continuous bending around pulleys. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment belts. SHOP PARTS

CRAFTSMAN original equipment engine parts are specifically designed for your outdoor power equipment’s engine. Shop air filters, oil filters, fuel filters, spark plugs and more. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment engine parts. SHOP PARTS

When it’s time to replace the cable in your CRAFTSMAN outdoor power equipment, you’ll find the exact part you need. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment cables. SHOP PARTS

A properly working pulley helps your machine perform with maximum power. You can find the exact part you need when it’s time to replace a pulley on your CRAFTSMAN riding lawn mower or snow blower. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment pulleys. SHOP PARTS

A proper-fitting tire will help your CRAFTSMAN riding mower, walk-behind mower and snow blower to have a smooth and sturdy ride. Replace tires and wheels as they wear to help make sure your CRAFTSMAN outdoor power equipment runs at optimal performance. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment tires and wheels. SHOP PARTS

Find the spindle assembly parts you need to help maintain your CRAFTSMAN lawn mower’s performance so your lawn looks pristine. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment spindles. SHOP PARTS

Do more with your CRAFTSMAN outdoor power equipment with a wide variety of attachments and accessories including baggers, mulch kits, sun shades and more. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment attachments and accessories. SHOP PARTS

SUPPORT RESOURCES

Enter the product code shown on the product serial number. Then select your language, click “Search,” and download your manual. FIND OPERATOR’S MANUALS

With our easy-to-use online Service Locator, you will get information on your current location and closest service locations, as well as their contact information and driving directions. You can choose to view the service points either conveniently on a map, or a list. FIND SERVICE LOCATIONS

Have your CRAFTSMAN equipment registered Online now. If you don’t know your model and product serial number, call 1-855-971-2271 and we will be glad to assist you. REGISTER YOUR PRODUCT

Creative Lawn Mower Storage Ideas [to DIY or Buy]

Outdoor Happens is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Click to learn more.

Are you tired of tripping over the lawn mower in your cluttered garage? Perhaps your riding mower spends its off-days outdoors? Then you need some creative lawn mower storage ideas that will free up floor space and protect your push or riding mower from the elements!

You can buy a prefabricated storage solution or create a bespoke DIY space for your lawn mower. Either way, we’ve compiled a selection of creative lawn mower storage ideas to suit any budget. Let’s shed some light!

What’s Inside

- 1. DIY a Rustic Wood Shed for Your Riding Lawn Mower

- 2. Lawn Mower Storage using a DIY Electric Garage Lift

- 3. DIY Lean-To Carport for a Riding Mower

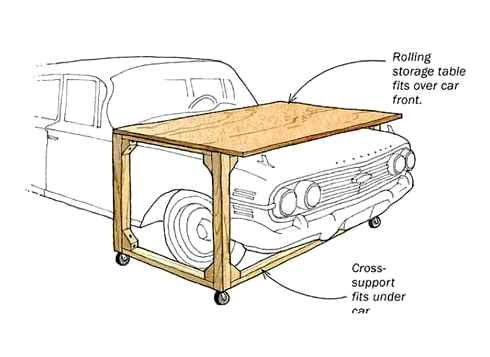

- 4. DIY Over-Car Trolley Table for a Push Lawn Mower

- 5. DIY a Manual Lift Platform for a Push Mower

- 6. DIY Pallet Goat Shed for a Riding Mower

- 7. DIY Three-Wall Mower Shed on Trolley Wheels

- 8. Make a Tarp Cover for Your Lawn Mower

- 9. Buy a Small Yard Tent for a Push Lawn Mower

- 10. Hang an Electric Lawn Mower on Hooks

- 11. Buy a Lawn Mower Cover

- 12. Buy a Resin Shed for a Small Riding Mower

- 13. Buy a Large Tarp Storage Box for a Push Mower

- 14. Buy an Overhead Garage Mower Storage Rack

- 15. Buy an Overhead Pulley Hoist

- 16. Buy a Large Tent Shed for a Riding Mower

- 17. DIY Pallet Barn for a Riding Mower

Creative Lawn Mower Storage Ideas [to DIY or Buy]

A riding or push lawn mower can be safely stored using a creative DIY storage idea or a store-bought product. Lawnmowers vary in size, but all require protection from UV rays, rain, snow, and dust while in storage to ensure component longevity and engine health when mowing season returns.

The cool thing about lawnmowers is they’re rugged machines requiring only crude servicing and storage when not used.

And better yet, all materials get employed when creating the ideal storage solution for your lawn mower. No matter the space limitations of your garage or yard!

- You can use wood and repurposed materials to make a lawn mower storage shed, DIY a clever garage space-saver, or fashion a suitably sized waterproof cover to pull over your grass cutter.

- If a factory-produced mower storage solution is what you’re looking for, there are several products you can buyfrom a store that enables you to house your lawn mower in safety and style, indoors or outdoors.

But which lawnmower storage ideas are best for you? We have 17 bright lawn mower storage ideas for you to consider.

DIY a Rustic Wood Shed for Your Riding Lawn Mower

Here’s a sassy idea for a small garage and a lightweight lawn mower – a wooden table on castor wheels that acts as a storage table above the hood of your automobile!

You can construct this versatile piece of garage furniture. You only need DIY woodwork skills, four-by-four timber, plywood, and castor wheels with brakes. It can safely store your mower (you will have to lift the lawnmower onto the tabletop), plus other gardening and DIY equipment.

DIY a Manual Lift Platform for a Push Mower

Getting your push mower off the garage floor using a manual pulley-operated lift platform will bring a touch of ingenuity to your garage ergonomics. And save your toes from those annoying mower stubs!

- The lift design is ideal for a wee push lawn mower, using a simple timber platform and a traditional rope and pulley setup.

- A trailer winch does the heavy lifting while heavy-duty hooks keep the lawn mower lift securely level and safely aloft.

The design from instructibles.com is a perfect educationalDIY project for parents and kids.

DIY Pallet Goat Shed for a Riding Mower

Here’s a clever, low-budget, easy-to-DIY storage solution that combines your existing bricks and mortar structures (walls and driveway). It’s a three-walled wooden shed on castor wheels with a roof, perfect for riding and pushing lawnmowers. The original design is to shelter a motorcycle, but the proportions can get tweaked to suit your lawn mower.

- Pallet wood and two-by-two lumber will make the frame and wall.

- The roof could get made from various materials. Consider weatherproofed wood pieces, tin, plastic, or polycarbonate sheets.

The castor wheels on the base of the shed allow you to move the shed away from the fourth wall (house or garage), making the mower parking procedure a breeze!

Make a Tarp Cover for Your Lawn Mower

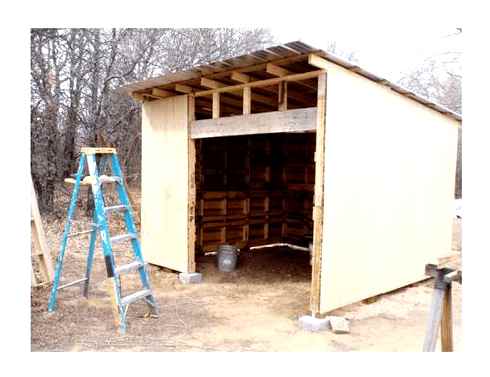

A budget-friendly barn idea is a homesteader’s dream! Here’s one using pallets – a proper high-roof home for lawnmowers of all sizes. And then some!

This wood shed can get constructed for less than 500 using free pallets for the frame, plywood for the cladding, two-by-six boards for the double doors, and corrugated iron sheets for the roof.

- The shed is secured to the earth at each corner using concrete footers, with rebar and steel bands embedded in concretedholes tied to the corner posts of the 10’ x 10’ structure.

A lick of paint and a gravel floor round off a surprisingly aesthetic shed – perfect for horsepower!

Creative Lawn Mower Storage Ideas – FAQs

Choosing the best place to store your lawn mower is more work than garden enthusiasts think!

We also know you may have further questions. So – we amassed a list of the most critical lawn mower storage FAQs. We hope they help!

Hanging a gas-powered lawn mower upright is not advisable. Fuel and oil could leak onto the storeroom floor or contaminate parts of the mower engine that should be free of gas and oil.

You can safely store a lawn mower outdoors by covering the machine with a tarp or structure to prevent water, dust, and insects from entering the engine and UV rays from perishing the bodywork.

Leaving gas in a lawn mower over winter will result in the gas gumming up, posing a risk to engine components when the mower restarts. Adding a fuel stabilizer to the gas in the lawn mower will prevent gumming.

Do not drain the oil out of the lawn mower for winter. Components inside the engine require lubrication even when the mower is in storage. However, we advise changing the oil as old oil can corrode your lawn mower engine.

Do not leave a lawn mower out in the rain. Moisture entering the air and fuel system will compromise engine lubricity and combustion efficiency. Always cover the mower with waterproof material in wet weather.

A lawn mower can safely store in a basement if the basement is well-ventilated and the mower fuel tank is empty.

It is advisable to run the mower with a fuel stabilizer additive in the fuel tank to coat the engine components with a stabilized fuel coating before draining the remaining fuel from the gas tank. Component longevity will be optimized when the mower engine gets blanketed with stabilized fuel.

A lawn mower battery should be removed from the lawn mower during winter and be connected to a trickle charger to ensure battery health. Sub-zero temperatures destroy lawn mower batteries if uncharged for six weeks or more.

Lawnmowers should get winterized to ensure ongoing engine reliability and component longevity. The key to winterization is keeping the engine components lubricated with oil and a coating of stabilized gas. Ensure the gas tank is empty and the oil tank gets filled to the specified level. Store the mower in a weatherproof but well-ventilated area.

The Best Shed for Lawn Mower Storage!

You’ve now scoped our 17 creative lawn mower storage ideas. But now comes the tricky part! You must decide whether to DIY or buy! Building a mower shed yourself or with friends can save you some cash.

And it can make for a fun outdoor project. If you prefer shopping for a ready-made storage solution for your lawn mower, you’ll reap the benefits a well-made product gives you – peace of mind. And, more important, more time to make hay! (And play in the flower garden!)

Which lawn mower storage idea do you like most?

Or maybe you use a top-secret lawn mower storage method you can share with us?

We’d love to hear from you either way.

Author

Paul writes for a living, about trucks mostly. He lives away from the city and off the road, nurturing his love for all things outdoors –- like tiny house construction, country cooking, bushcraft, woodwork and power tools, alternative energy, and minimalist living. If there’s a way to Do It Yourself, Paul wants to hear about it, and try it out. Then he’ll write about it, and share his story with blog readers around the world. Paul was raised on a South African homestead where he tended two horses, a Jersey cow, and half a mile of split pole fencing. At age 16, he bought a dirt bike, pirated a punk rock compilation, and commenced a blind-rise adventure that continues to this day where words, Wabi-Sabi, cooking, all-terrain tires, and all things to do with canvas and wood are his fodder. His overarching existential question is – “What more does a man need than a cast iron pot and a pair of loose-fitting trousers?” View all posts

DIY Aerators That Will Make Your Lawn Lush And Beautiful

Do you aerate your lawn? I recently started looking into ways of making my lawn more lush and healthy and what I learned is that aerating your lawn if really good for it.

Aeration helps to create openings in the turf and soil that allows water and air to penetrate the roots of your grass and makes them healthier.

This in turn, turns your lawn into a lush, beautiful green blanket that would rival any golf course.

So, when I found out how good aeration is for my lawn, I started looking into aerators.

Let me tell you, a lawn aerator is not cheap. Even the seemingly cheaper ones are pretty costly, so what did I do?

I started looking for DIY lawn aerators. I found seven great DIY aerators that all work perfectly to make your lawn lush and beautiful.

Repurposed Oil Drum Aerator

This DIY aerator is made from a five gallon oil drum and it’s pretty simple to put together. Once the spikes are in place, you add a handle and wheels and then just push the aerator through your yard to keep your soil and grass healthy. This one is so simple and can be really cheap if you have an old oil drum that you can use as the base.

Cheap And Easy DIY Concrete Aerator

This DIY lawn aerator is very cheap and easy to make. The spikes are made from nails, which are perfect for creating the aeration that your lawn needs to make it grow lush and healthy. This one is also a push aerator so you add a handle and then just push it throughout your lawn to help it to grow. It will only take you a couple of hours to put together and begin using it. I really love creative DIY concrete projects!

Why spend hours pushing a lawn aerator when you can simply walk around your lawn and get the same result? These DIY lawn aerator shoes are honestly the easiest things you will ever see. You just need a couple of pretty thick boards and some nails as well as something to secure your aerators to your shoes. You could do a few of these in different sizes and have the entire family walking through the yard to aerate it.

DIY Plexiglass Lawn Aerator Sandals

Here is another quick and easy take on lawn aerator shoes. These little sandals are made from plexiglass and they are super easy to put together. They work just like you would imagine…you strap them to your feet and then walk your way to a beautiful lawn. Make a few pairs and let your family or friends help you to make your lawn healthy and lush. These are also really cheap to DIY.

DIY Repurposed Rake Lawn Aerator

You don’t need any fancy equipment to aerate your lawn. You can make a simple DIY lawn aerator out of an old garden rake and a 2X4. I do love good 2X4 DIY projects and this one is fabulous. You just use the rake to steady your aerator and give yourself a brace for pushing it into the ground. This one honestly will only take you an hour or so to make and it is really easy to use, too. What a great way to make use of old gardening tools!

Upcycled Five Gallon Plastic Bucket Lawn Aerator

This homemade lawn aerator is made from an empty five gallon bucket and it is really simple to put together. This is a great upcycling project for those empty buckets. You just need the bucket, a few nails and something to use as a handle – an old handle from a push lawn mower would be perfect. You just assemble and then push the aerator around your lawn to give it that great lush look.

Reclaimed Wood Lawn Aerator

You can make this simple DIY lawn aerator with strips of reclaimed wood. You just have to find a base – PVC pipe filled with sand or concrete works well – and then add your strips of wood. The wood houses the nails that you use to aerate the lawn.

You can add a handle from an old lawn mower or something similar to make pushing it through the yard simple. This one only takes a couple of hours to make and it works like a charm.

Hi, I’m Leah! I started DIYnCrafts long ago to spread crafts and happiness. Currently, we have thousands of easy crafts and tutorials, making us the biggest crafty site on the internet.

There are a number of reasons, mechanical and otherwise, why a mower won’t run. The good news is that fixing most all of the issues is easy enough for a DIYer to handle.

By Tony Carrick and Manasa Reddigari | Updated Aug 8, 2022 4:03 PM

We may earn revenue from the products available on this page and participate in affiliate programs.

Lawn care can be tedious, but once the grass starts growing in the spring, mowing becomes a fact of life in most neighborhoods. When you finally muster the strength to tackle that first cut of the season, there are few sounds as disheartening as that of a lawn mower engine that turns over but doesn’t start.

Before you drag the mower in for repairs or invest in costly replacement parts, first make sure that a clogged air filter, soiled spark plug, damaged safety cable, clogged mowing deck, or contaminated gas isn’t to blame. Work through the following steps, and you may be able to get your puttering grass guzzler up and running again in no time.

A lawn mower repair professional can help. Get free, no-commitment repair estimates from pros near you.

Change the lawn mower carburetor filter.

Your lawn mower’s air filter guards the carburetor and engine from debris like grass clippings and dirt. When the air filter becomes clogged or too dirty, it can prevent the engine from starting. To keep this from happening, replace paper filters—or clean or replace foam filters—after every 25 hours of engine use.

The process for removing the filter depends on whether you are operating a riding or walk-behind lawn mower. For a riding mower, turn off the engine and engage the parking brake; for a walk-behind mower, pull the spark plug wire from the plug. Then, lift the filter from its housing.

How to store your lawn mower with the Trimyxs #storage #novios #lawncare #trimyxs

The only choice for paper filters is replacement. If you’re cleaning a foam filter, wash it in a solution of hot water and detergent to loosen grime. Allow it to dry completely, and then wipe fresh motor oil over the filter, replace it in its housing, and power up the mower—this time to the pleasant whirring of an engine in tip-top condition.

Check the spark plug.

Is your lawn mower still being stubborn? The culprit may be the spark plug, which is responsible for creating the spark that ignites the fuel in the engine. If it’s loosened, disconnected, or coated in water or carbon residue, the spark plug may be the cause of your machine’s malfunction.

Locate the spark plug, often found on the front of the mower, and disconnect the spark plug wire, revealing the plug beneath. Use a socket wrench to unscrew the spark plug and remove it.

Check the electrode and insulator. If you see buildup, spray brake cleaner onto the plug, and let it soak for several minutes before wiping it with a clean cloth. Reinstall the spark plug, first by hand, and then with a socket wrench for a final tightening. If the problem persists, consider changing the spark plug.

Clear the mower deck of debris.

The mower’s deck prevents grass clippings from showering into the air like confetti, but it also creates a place for them to collect. Grass clippings can clog the mower deck, especially while mowing a wet lawn, preventing the blade from turning.

If the starter rope seems stuck or is difficult to pull, then it’s probably due to a clogged deck. With the mower safely turned off, tip it over onto its side and examine the underbelly. If there are large clumps of cut grass caught between the blade and deck, use a trowel to scrape these clippings free. When the deck is clean again, set the mower back on its feet and start it up.

Clear the vent in the lawn mower fuel cap.

The mower started just fine, you’ve made the first few passes, then all of a sudden the mower quits. You pull the cord a few times, but the engine just sputters and dies. What’s happening? It could have something to do with the fuel cap. Most mowers have a vented fuel cap. This vent is intended to release pressure, allowing fuel to flow from the tank to the carburetor. Without the vent, the gas fumes inside the tank begin to build up, creating a vacuum that eventually becomes so strong that it stops the flow of fuel.

To find out if this is the problem, remove the gas cap to break the vacuum, then reattach it. The mower should start right up. But if the lawn mower won’t stay running and cuts off again after 10 minutes or so, you’ll need to get a new gas cap.

Clean and refill the lawn mower fuel tank.

An obvious—and often overlooked—reason your mower may not be starting is that the tank is empty or contains gas that is either old or contaminated with excess moisture and dirt. If your gas is more than a month old, use an oil siphon pump to drain it from the tank.

(It’s important to be careful as spilled oil can cause smoking, but there are other reasons this might happen. Read more about what to do when your lawn mower is smoking.)

Add fuel stabilizer to the tank.

Fill the tank with fresh fuel and a fuel stabilizer to extend the life of the gas and prevent future buildup. A clogged fuel filter is another possible reason for a lawn mower not to start. When the filter is clogged, the engine can’t access the gas that makes the system go. If your mower has a fuel filter (not all do), check to make sure it’s functioning properly.

First, remove the fuel line at the carburetor. Gas should flow out. If it doesn’t, confirm that the fuel shutoff valve isn’t accidentally closed. Then remove the fuel line that’s ahead of the fuel filter inlet. If gas runs out freely, there’s a problem with the fuel filter. Consult your owner’s manual for instructions on replacing the filter and reassembling the mower.

Inspect the safety release mechanism cable.

Your lawn mower’s reluctance to start may have nothing to do with the engine at all but rather with one of the mower’s safety features: the dead man’s control. This colorfully named safety bar must be held in place by the operator for the engine to start or run. When the bar is released, the engine stops. While this mechanism cuts down on the likelihood of horrific lawn mower accidents, it also can be the reason the mower won’t start.

The safety bar of a dead man’s control is attached to a metal cable that connects to the engine’s ignition coil, which is responsible for sending current to the spark plug. If your lawn mower’s engine won’t start, check to see if that cable is damaged or broken. If it is, you’ll need to replace it before the mower will start.

Fortunately, replacing a broken control cable is an easy job. You may, however, have to wait a few days to get the part. Jot down the serial number of your lawn mower, then head to the manufacturer’s website to order a new cable.

Check to see if the flywheel brake is fully engaged.

The flywheel helps to make the engine work smoothly through inertia. When it isn’t working properly, it will prevent the mower’s engine from working.

If it is fully engaged, it can make a mower’s pull cord hard to pull. Check the brake pad to see if it makes full contact with the flywheel and that there isn’t anything jamming the blade so the control lever can move freely.

If the flywheel brake’s key sheared, the mower may have run over something that got tangled in the blade. It is possible to replace a flywheel key, but it does require taking apart the mower.

Look out for signs that the mower needs professional repairs.

While repairing lawn mowers can be a DIY job, there are times when it can be best to ask a professional to help repair a lawn mower. If you’ve done all of the proper mower maintenance that is recommended by the manufacturer, and gone through all of the possible ways to fix the mower from the steps above, then it may be best to call a pro. Here are a few signs that indicate when a pro’s help is a good idea.

- You see black smoke. The engine will benefit from a technician’s evaluation, as it could be cracked or something else might be worn out.

- Excessive oil or gas usage. If you’ve changed the spark plugs, and done all of the other maintenance tasks, and the mower is consuming more than its usual amount of oil or gas, consult a professional for an evaluation.

- The lawn mower is making a knocking sound. When a lawn mower starts making a knocking sound, something could be bent or out of alignment. It may be tough to figure this out on your own, so a pro could help.

- A vibrating or shaking lawn mower can be a sign of a problem beyond a DIY fix. Usually something is loose or not aligning properly.

Dad’s lawn dethatcher tips and tricks (Best Lawn Series)

This post may contain affiliate links. Please see our disclosure here.

Today I am sharing my dad’s lawn dethatcher tips and tricks that won’t break the bank, which is part of our Best Lawn Series. What is a lawn dethatcher? It’s basically a tool that you add to the back of your lawn mower and it digs up all the dead grass, allowing new grass to grow once seeded. You can purchase an inexpensive tag along detacher like we have below and fix your grass quickly and easily.

Is your lawn soil really hard, full of weeds and just overall tired looking? Want to learn how to dethatch a large lawn?

Check out our DIY lawn dethatching ideas:

My Dad’s Lawn Dethatcher Tips

Our lawn seems to be in desperate need of dethatching every Spring. This is where a yard dethatcher and aerator that hooks onto your lawn mower (tow behind) comes in handy.

You can rent power dethatchers (dethatcher rental vary) or hire a professional but the good old fashioned way (kind of a homemade way) has always worked for us. My dad’s lawn dethatcher that attaches to the back of our lawn mower and is older than dirt. If you do not want to do this yourself, search dethatcher rentals in your area. If you are looking to purchase a dethatcher attachment, I suggest checking out the links I provide here in this post.

It pulls behind the lawn mower (tow behind dethatcher) and digs up all the dead grass. Call me crazy but I love watching all the dead grass get dug up.

A lawn dethatcher and aerator (this is a great aerator) are the two must have yard tools if you want a lush green lawn. A tow behind lawn dethatcher or aerator will make your life so much easier vs renting one. Plus, if you purchase a tow behind, you will have it year after year.

This image above is from previous year (check out this post where I talked about the yard project killing me and the budget). We removed all the dead trees and brush and you can see the dead lawn. It was thick yellow dead grass and weeds.

From far away it didn’t look that bad (like really far away) but up close, totally disgusting.

If you remember, we hired a company to remove the dead trees (see below) and overgrowth.

The yard excavation was extensive and ate up all of our time and budget so the existing lawn took a backseat to being repaired.

Want to dethatch your lawn this weekend? Follow my dad’s lawn dethatcher tips and you will have a beautiful lawn in no time.

How to dethatch a lawn with a mower attachment

Once we picked up all the limbs and sticks from the lawn, my dad started to dethatch the lawn with the lawn mower. You will need to hand rake any areas where the dethatcher cannot physically fit. For example, near flower beds, walkways and along the driveway.

The lawn dethatcher tines (the metal pointy things that dig into the ground) are very sharp and will scratch any hard surface and destroy your flower bed edge, so don’t get too close!

You simple attach the lawn dethatcher to the mower (your mower should have a small hole for a hitch attachment on the back). Note the hitch pin above that attaches to the mower.

How to Dethatch A Lawn

When to dethatch lawn

The lawn dethatcher metal tines essentially dig up the dead grass. You could never hand rake a large yard and loosen the soil to the extent of a dethatcher. Typically the end of summer and fall is a good time if live in the northern part of the country. I’ll be honest, we have done it in the spring as well and it still helps our grass regardless.

I absolutely love this picture above. You can see the thatched lawn on the right (the part my dad already dug up) and the gross lawn that isn’t dethatched on the left.

You will need to weigh down the dethatcher with cement blocks.

My Dad’s dethatcher Tips:

- We use a bungee cord to keep the blocks in place.

- You must raise the lawn dethatcher (dethatcher rake) using the adjustable bar before crossing a patio or driveway. The sharp tines will scratch your driveway!

- When to dethatch your lawn? Early Spring or Fall is the perfect time to dethatch your lawn.

Where to buy a lawn dethatcher

The best lawn dethatcher will have metal tines that are sturdy with sharp ends. You can see how the metal tines dig into the ground and loosen up the soil.

I found this affordable lawn mower dethatcher below on Amazon. It’s very similar to the one we have. Most lawn and garden centers will also carry them for sale.

If you are interested our lawn mower dethatcher attachment shown above, this one very similar to the one we have. I have also linked a couple others here. Just be sure you get the correct length based on the size you want. Find several more dethatcher options here that I have rounded up.

Once my dad was done dethatching the lawn, we removed the dethatcher and attached the lawn mower bagger in order to pick up all the dead grass.

Can you imagine hand raking all the dead grass? A lawn dethatcher rake attachment will save your arms!

I’m thinking no way. My dad sucked up all the dead grass with the lawn mower and I removed and emptied the full bags.

New Lawn Care tips

There were many areas of the lawn my dad could not dethatch.

The newer lawn installed last year is still very thin in areas and you do not want to tear it up so we gently hand raked it in preparation for overseeding.

Now that the lawn is dethatched in the front yard (the backyard is happening this weekend) it is ready for grass seed in certain areas.

I snapped this picture right before we started working in the yard. I had just picked my parents up from their trip to St. Lucia. While many would get home from a vacation and “rest,” my dad was ready to get working in the yard.

Lawn Dethatcher Yard Update 2023!

Updated: Fast forward to the end of the summer and check out how our yard (see below) is doing sporting lush green grass (click here) thanks to the on-going lawn thatching process and aeration.

We recently installed driveway entrance columns (picture above) and I am sharing how to plant planters on top of the driveway columns so come take a look.

I promise, the yard looks so much better than these lawn dethatching pictures!

Getting your grass seed down in early Spring is best. This way the grass has time to grow before the hot dry weather arrives. My dad’s lawn dethatcher fixed our gross lawn in about 2 hours total. An hour to dethatch the lawn and an hour to suck up the dead grass with the bagger. The Best Lawn Series part 2 happens this weekend so stay tuned for more tips and tricks.

recent posts

This is an amazing before and after transformation. Gorgeous white cabinets, harmon pendants, quartzite super white counters and backsplash. width=600 height=397 /