What disk to saw slate with a circular saw. Ways to cut the slate

Than to saw the slate of the wave which disk

So, how to cut a flat slate, if you still have to cut it?

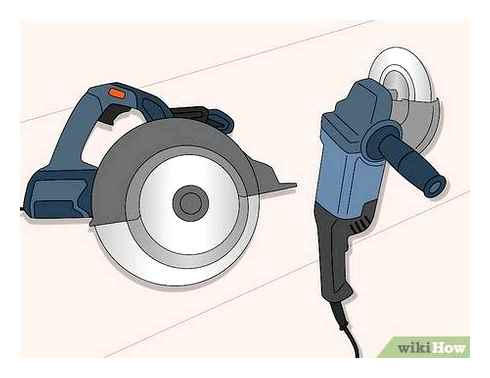

Cut the corner grinder: select the disk

So, to cut a large amount of flat slate, take an angular grinder with a diamond disk. Cut the slate will be quickly, neatly, evenly and safe. The only negative when working with this tool is a lot of dust. But a relatively cheap angular grinder easily copes with such a task.

When working with a corner grinder, take it by one handle and drag it on yourself. under your own weight of the instrument, everything will be good:

Diamond circle cuts flat slate easily and quickly. As for the speed of the disc, 2000-3000 allow you to work easily and the tool does not heat up. By the way, with the help of a corner grinder and a diamond disk, you can grind the edges of the slate right away. Tip: When working with a corner grinding, we also put on protective headphones. the sound will not be pleasant.

One of the most affordable and practical options is a cutting circle on stone, which can be inserted into the cheapest simple corner grinder.

Another good way that is often practiced today is to make only an incision on the cipher with a corner grinder, and then break the sheet.

Cut with a saw: select the coating and teeth

Perfectly cuts slate saw with a special Teflon coating, which on the one hand protects the saw blade, and on the other, significantly reduces friction with the material. And less friction. less dust and easier work. Such a saw is not much more expensive than usual.

Secondly, you should pay attention to the teeth of the saw: the larger they are, the faster the slate will saw. And already definitely faster than a simple hacksaw

Cut with an electric saw and chisel

This slate is cut traditionally with a bite and a disk electric saw:

We take a ruler, a sharp chisel and on both sides of the future section we make notches. We place the slate on a flat base with a sharp bar or a line so that the lines coincide. Carefully break the slate. If the slate could not break, we cut with a disk electric saw, from time to time cooling it with water.

Cut with a gearbox

Another suitable instrument is a breeze. He has a built.in diamond disk that is able to reach a high speed speed. But, t.to. This “toy” costs is expensive (because professional), and therefore home craftsmen do something like it themselves: connect a parquet and small-toothed circle on wood. Cutting the slate with this tool is quite convenient.

Cut an electrician

But the worst of all, the usual cheap electric one copes with such a task. wears out too quickly. Most of all for such work is an electrician with a HCS saw of high.carbon steel, which is designed to work with soft materials.

Electrolobesik with a saw also copes with a sharp flat slate, for each tooth of which a winning tip is soldered. With such a tool, it is convenient not only to cut the sheets according to certain parameters, as well as make roundings and arcs.

Another good option, especially if you have to work often and professionally with slate, it is an electrician with a BIM saw. Such a tool when cutting sheets will never break even thin corners in a flat slate.

Of the incisors, it will be easiest for you to work with carbide, which can be found in any store. You can use an electrician for this purpose, if you purchase it with a special file with diamond spraying. True, but it will not work to cut it quickly.

Cut on a home circus

Cutting flat slate is also not difficult also on a conventional circular, 2 kW. Put a circle with carbide wood attacks so that there is more teeth. It turns out everything quickly and without any problems. Put on protective glasses, clothes without wide sleeves and durable gloves

It is only important that the sheet itself is fixed

If you use a manual circular, then set the speed within 3500-4000. So the slate will be spread evenly and much cleaner than with maximum turnover 5500.

Features of the slate and the scope of application

This material is in demand and popular, it is often used by home craftsmen in the construction of objects of various purposes: residential and industrial buildings; summer cottages; garages and other buildings. It is customary to call products with a wavy profile with slate, in the production of which asbestos cement is used. In recent years, you can find varieties of this material without asbestos on sale. for example, Euro.shifer.

Since today for buyers the issue of environmental friendliness of the material is of no small importance to prevent the allocation of dust containing asbestos particles, it is painted. Also covered with paint, the sheets have greater strength and a long period of operation.

Why is it difficult to cut slate sheets

Asbestos.cement material is based on mineral asbestos mineral fibers. Asbest itself is quite soft and suppressed, threads, cords and even fabric are made from the fiber. Being fastened with cement grains and compressed in dense mass, the slate in its properties becomes like a viscous and solid structure. If we draw an analogy, the structure of the slate can be compared with individual stories of solid wood. The material is easily cut and crumbled with a knife or chisel, but can hardly lend itself to a high.speed tool.

At home, the slate has to cut:

Note! Do not try to cut the sheets of slate using the thermal method, heated steel rods, hot wire and other ineffective techniques. When the temperature drops, the slate does not prick along the heating line, but according to the internal voltage grid formed during its production.

How easier and safer to cut a sheet of slate

The more cement contains cement, the more difficult it is to cut a slate of slate using an electric tool. Most often, sheets of flat slate have to be cut into smaller fragments, everyone who has come across a similar occupation knows that it is very difficult to cut or drill a sheet with high.speed tools.

The cutting edge of the disc saw instantly heats up and loses its sharpness. The same thing happens with a drill or cutting disk of a corner machine. Therefore, the following conditions must be observed during the cutter of the slate:

- The speed of rotation or movement of the cutting edge of the tool should be minimal;

- The force attached to the cutting tool should be higher than average, but not maximum. When cutting slate, it is very important to ensure the stable position of the tool, any flooding or skew leads to the splitting of the slate leaf;

- For productive and efficient cutting, it will be necessary to provide a support of wood or metal, which prevents a skew or displacement of a sheet under load.

Important! The most important condition for safe slate cutting is protection against dust and asbestos fiber separated by the cutting edge from asbestos.cement mass.

Basic Rules

Despite the emergence of new materials to create a roof, the slate continues to be actively used in construction. When installing it, there is a need to trim individual elements. This operation is specific: in the composition of gray roofing material there are asbestos fibers. They are carcinogenic. Asbestos dust inhalation can provoke the development of lung cancer

Therefore, you need to cut the sheets very carefully, observing safety rules. They are extremely simple:

Before work, you need to put dense clothes on the body, completely closing the case, gloves, protective glasses and respirator

Cutting is always accompanied by a strong noise, if you refuse to use anti-noise headphones, you can deaf for some time. It is important to thoroughly moisten the surface of the roofing material before starting, then less dust will form. Experienced roofers, talking about how to cut the slate, advise watering it right during the saw

This is the most effective way that allows you to protect yourself as much as possible from inhalation of the strongest carcinogens.

Slate when cutting should be moistened with water from the Maja-Dachsource.ru

The operation needs to be carried out on the street, preferably in a well.blown place. If you sit on it so that the wind will immediately take the dust as part of which there are particles of asbestos, it will be possible to protect not only yourself, but also passers.by.

Sometimes it becomes necessary to cut the slate inside the closed room. In this case, all employees must be removed from the room and leave only the operator in overalls. Before the sharp, he should tightly close the windows and doors, hang them with an old rag, after cutting to collect the dust formed by an industrial vacuum cleaner. The same technologies are used for cutting flat and wavy slate. But in the process of its implementation there are some nuances.

Cutting flat slate source STROYCHIK.ru

How to reduce the amount of asbestos dust as much as possible?

Opinions on the harmfulness of inhaled asbestos fibers today are very different, and even completely opposite. Our compatriots, for example, have worked all their lives in factories with slate without any masks, have no health problems in terms of respiratory tract.

But British doctors claim that it is only one day to breathe asbestos dust in order to find lung cancer in 20 years. over, with one sigh in the body, up to 700 thousand harmful fibers enters the body at the same time!

Take one thing for yourself: asbestos dust is really harmful in the process of active actions with slate. and this is, first of all, its sawing

A little about asbestophobia

So, let’s start from the beginning. The most ordinary slate, which covers the roofs of houses for several decades, consists of such components:

In addition, some experts have an opinion that only the dust from amphibol-aspes is carcinogenic, which is mined in Africa and in the domestic flat slate (here only chrysotype-asbestos).

For example, amphibol-asper was banned several years ago in large countries such as Germany and the USA. Billions were spent on the search for artificial substitutes and the struggle for markets for new materials has become especially fierce.

Chrysotil-Assbest is a different type of roof slate. Durable and refractory material is produced and used to today, and 50% of it is exported to other countries. The price of it is low, and therefore it is difficult to talk about competition. Why are world reports of the world media about the unexpected carcinogenicity of all materials containing not only amphibol asbestos, but also chrysotil-Assobes by most scientists are perceived critically-as a regular competitive attack in the international market. Although it is worth noting that the question of the ban on the use of this raw material is now raised quite high.

The whole problem is that the fibers of asbestos tend to irritate the tissues of the lungs-and constantly, which is why the body first produces benign tumors in such places, and they can degenerate over time. On the other hand, the same problems can cause both glass and cement. T.e. Almost every person can have micropholes in the lungs, but they are reborn into malignant only in people predisposed to cancer. Therefore, be that as it may, the respiratory tract all participants in the process must be closed.

How harmful the asbestos.cement slate is harmful

Many heard that asbestos, respectively, asbestos.cement slate, but almost no one knows what. So, it is not harmful to slate, but a mucous membrane, to be precise, inhalation of asbestos dust. Small particles can provoke tumors.

If you put on a good respirator and glasses, and even water the place of cut with water, then the risk of such dust entering the mucous membrane is negligible. And a swollen hysteria about the harm of asbestos as such is just one of the ways of unfair competition and nothing more. After all, even in the manufacture of money, asbestos is used.

An elementary vacuum cleaner for an angular grinder collects up to 70% of the dust.

Electric tools

So that the slate is less dusty, you need to moisten the cutting place with water

Use a cutting saw, with a stone cutting disk. Preparation includes the marking of the line on the slate sheet, wetting the place of the cut. When working, you cannot allow displacement from the intended line, conducting exactly along it.

At a time, the part will not work out at a time, so after wetting, additionally outline the fishing line for the trimmer, simultaneously deepening it with core. So the wheel wheel will not be lost from the rut of the mark. In the case of using a disk saw, several approaches you need to make.

Use an electric drill with a drill that has a winning tip.

The sheet is placed on the aligned surface, on it across the waves or along them marks the line of separation; On the marked line, holes are drilled, as close as possible one to the other, drilled to the end of the sheet, while trying not to move away from the line; take a hammer and tap on the line of holes every 6. 10 centimeters; one half of the panel is lifted, carefully separated from the second side of the sheet.

Common Types of Diamond Saw Blades and Their Uses

Some roofers additionally cut a fishing line for a trimmer along the holes using an acute ax blade. This procedure is optional, t. to. The stove will split in the direction of drilled holes. Do not take a drill with a shock effect (peorator) for work. such sharp efforts will lead to the appearance of a oblique crack not along the planned line.

Cutting sheets of asbestoscene with corner grinding or jigsaw

A circle of stone or diamond disk is put on an angle grinding machine to saw slate.

In the first case, organize a continuous supply of a water jet to the place of touching the circle to the surface of the slate to cool the work edge of the disk and prevent dust. For convenience, work is performed with an assistant who uses a hose or a plastic bottle with holes in the lid. When single work, the hose is fixed in a convenient position.

- The sheet is laid on the floor, if you need to cut off the narrow edge, then a wooden bar or board is placed under it.

- Make the first cut along the intended line on the ledge of the wave from beginning to end the panel.

- The stove is turned over, the cut place is obtained in the concave area of the sheet.

- Cut along the line, if everything is correct, then the profile will be divided into two parts;.

- The dust on the side surface of the disk is removed with a wet rag at once, if it froze, the circle will have to be thrown away.

In the case of the use of a diamond disk, a sheet can be cut into two directions on an angular grinder and it is not necessary to turn the panel overlap. In winter, it is recommended to lay asbestoscene slabs directly on the snow. so the allocated dust for the most part is absorbed into it. The diamond circles are polished by the edges of the material in Pesta cutting to increase resistance to negative factors. The disk is used to cut the corners of the profile if the sheet does not move half during installation.

Electric tools

For processing wave.shaped sheets, angular grinder is most suitable. It’s easier to cut them, choosing a disk for cutting stone or a diamond circle.

The first nozzle is more suitable for cutting in a longitudinal position. To facilitate the process, a fishing line for a trimmer is carried out. She lies on top of the wave. Then the sheet is installed on a rigid base. According to the safety rules, a permanent stream of water is organized. She must drain to where the cutting disk touches the slate. So it is possible to simultaneously cool the metal, and prevent the formation of dust that is dangerous to human health.

The easiest way to organize the desired process is to put an assistant, hand him in his hands a garden hose and ask him to hold him over the cut line. When there is no one nearby, you will have to come up with a device that will allow you to fix the hose in the right position.

Everyone should know how and how to cut the wavy slate in the direction across the location of the waves. In this case, cutting is carried out according to the following algorithm: first, an incision of protruding ridges is made, then the sheet is turned over, and the operation is repeated.

Schipher is better to cut a diamond disk source of KrySha-Expert.ru

The preference for the choice of a diamond circle is given when it is necessary to cut the workpiece and at the same time sanding the edges of the cut. Such a procedure, experts assure, helps to renew the life of the roofing material. For its implementation, the sheets are previously abundantly moistened. This increases the elasticity of the slate, makes it more pliable cutting. If the operation is carried out in winter, it is advisable to carry it out by putting the blank over snow flooring. Then most of the dangerous dust will remain on the wet cover.

There are other electric tools that can replace the corner grinder. This is a detachment machine. But work with her will not allow to cut the material at once in one approach. The procedure will have to be repeated again and again, each time deepening more and more fishing line for the trimmer of the cut. To achieve the result, you will have to make three, four approaches. After each you need to soak the material well.

Cutting flat slate with an electrician source of NEVACROSSFIT.ru

Another electric tool is an electrician with a file in a small tooth

Using it, it is important to set a reduced transmission mode, and then smoothly conduct a tool, avoiding strong pressure. It is difficult to work with an electrician, so its choice is justified only when you need to cut one, two pieces

Safety precautions

Safety precautions in any business are important. When working with slate, it should be remembered that the asbestos contained in it, a dangerous mineral of silicate class, irritates the respiratory tract, eyes. Many do not attach the proper importance to compliance with the simple rules, make smokers, inhaling air contaminated with dust, neglecting a real danger. And in vain.

It is not difficult to protect yourself from the traumatic effects of asbestos dust, it is important to follow the following rules:

- Cut only outdoors;

- Wear a respirator moistened in water;

- Protect your eyes with glasses;

- Become from the leeward side so that the dust does not fall on you.

Working with power tools, corner grinders, circular saw and other devices that make piercing sharp sounds, use headphones.

Types, features, characteristics

The slate seemed to have lost its relevance in modern construction. Gray, dull appearance, dull associations with poverty of Soviet life. However, the technical and operational characteristics of the material do not allow him to go into the past irrevocably. In addition, modern manufacturers have learned to overcome its aesthetic shortcomings

Shifer painting in green, red, gray-blue colors allows manufacturers to skillfully use its operational virtues, attracting the attention of customers. Slavifa is in advance in demand because:

In addition, this material has high characteristics:

The material is easy to install, it is easy to process. The practicality of the slate is also well known to the people. Even the old, the sheets removed from the roof can be used to arrange a poultry pen, home.made, fence, vegetable beds, flower beds, some of the auxiliary structures.

This roofing material is distinguished in the shape of a sheet, it is flat and wavy. The wave view is available in three types:

The disadvantages include a composition that includes asbestos, fragility, and the complexity of transportation. Over time, mossy formations appear on the surface, reducing the aesthetics of its appearance. But this can be avoided by treating the surface with a primer.

This is interesting: calculating the load of the foundation on screw stilts. we understand in detail

Features of the slate and the area of its application

One of the most common materials, due to its cheapness, strength and accessibility, is roofing slate. It is used in the construction of summer houses, and in the construction of high.rise urban buildings, and other buildings, such as composenia and greenhouses.

Hearing the word “slate“, everyone imagines material with a wavy profile, which is made on the basis of asbestos cement. Although today there are different options for this coating, which contains asbestos, for example, Euro.shifer.

Traditional slate is made of the following components:

There is an opinion that slate is a non.elected building material, since it allocates dust with particles of asbestos into the air. However, this problem can be easily solved by painting the coating. over, the painted slate is stronger than the non.painted and has a longer service life.

Asbestos.cement slate can be covered with a roof with an angle of inclination of more than 12 degrees. Distinguish the profiled wavy type of slate and flat. The latter is often used in the decoration of the walls of structures of various light structures.

Other slate cutting tools

You can apply an electric jigsaw with low speeds or the most ordinary hacksaw. In any case, the main criterion of the work is accuracy and the correct use of force in order to avoid breaks and splitting of the sheet.

You can very simply cut flat slate with an ordinary cutter. To do this, lay the sheet on a flat even surface and outline a fishing line for a cutting trimmer. Then, using a ruler, risk on the intended mowing fishing line. Having done two or three passes, deepen the risk. Then break the sheet on the intended mowing fishing line, after laying the rail under it. In the same way, you can cut the wavy slate when the fishing line for the cutting trimmer runs along the wave. Using a cutter, cut a slate of slate in two minutes. over, working as a cutter, you can significantly reduce the amount of asbestos dust compared to the use of corner grind.

Sleeper sawing off the angular grinder with a stone disk

In this way it is more convenient to cut the slate together. One person cuts a corner grinding sheet of the material, the second at this time pours a cut place with a thin stream of water. You need to pour water with a hose or just from a plastic bottle. Such a simple and at the same time cunning method will avoid plenty of dust ejection, which scatters through the air and stains the tool. Using water, asbestos dust simply flows to the ground.

How and how to cut the slate?

Today, slate is one of the most common roofing materials. Its laying is carried out in a run, which implies the use of sheets of non.standard length. This feature requires solving the following issue: how and how to cut slate?

Ways to cut the material

In the production of this type of roofing, asbestos, cement, chrysolite, water are used. Asbestos fibers give the material stiffness throughout the volume.

The question of how to cut the slate, arises precisely due to the high rigidity and strength of the material. The cutting tool is quickly stupid and wear out, and in the process of work, asbestos dust is rising to human health.

Therefore, before getting down to business, you should wear protective equipment. glasses, respirator and gloves.

The main methods of cutting:

- Work with flat slate. For these purposes, you can use a corner grinder equipped with a stone disk. It is better to cut the material together. One master will cut a sheet of slate, the second. shed a fishing line for a trimmer cut with water. You can pour water from a plastic bottle or hose. On a moistened line, draw a disk, almost without clicking on it. In this case, risk is formed. At risk is carried out 3-4 times, deepening the incision. In this case, the risk of cracking of the slate will be minimal, while the cut will be made clearly along the planned line. At the final stage, slightly break the material along the intended line. What else can you cut flat slate? The cut is perfect for these purposes.

We put a sheet of material on a flat surface and draw a cut on the marked line.

Then we deepen the section, re.drawing along it with a tool, after which we break along the line.

- Cutting wavy slate. For these purposes, you will need an angular grinder with a diamond circle. Using this tool, you can quickly cut the material in the right direction and grind the edges. When choosing how to saw slate, you can dwell on tools such as an electric electrician, cutter or manual hacksaw. It is recommended to moisten the planned fishing line for a trimmer with water. If work is carried out in winter, you can put a layer of snow on the sheet. After getting wet, asbestos cement becomes more elastic.

How to cut the slate using nails and hammer?

To begin with, a fishing line for a cutting trimmer is marked on the sheet. With the help of a slate nail and a hammer, openings are created along the marked line. The more often the holes are located, the easier it will be to break the sheet. Under the slate, put a long wooden rail and make a breakdown. The evenness of the cut line depends on the accuracy of the master and the number of holes.

For this, holes are drilled in a wooden bar and nails are inserted at a distance of 2 cm from each other. Using such a tool will significantly accelerate the process. Only slate nails should be used in creating a ridge. Thanks to the special structure of the head and the rod, such a nail is quite simply penetrated into the asbestos.cement sheet, without damaging it.

Regardless of what method of cutting the slate will be chosen, the main thing is slow and accuracy.

Learning to cut the slate

Slate of wave or flat used to be cut quite problematic. Today, when the tool is richer, you can perform this operation very quickly. There are several ways and each of them is good in its own way. You just have to choose how to cut the slate.

Legends are already going on about the dangers of asbestos slate. Indeed, is the slate harmful? You can find out the answer if you look at the photograph of asbestos fibers:

- The slate itself is harmless, but we are talking about how to cut the slate, which means there will be dust. It is logical to assume that such fibers hundreds of thousands of particles will be shot into the air and can fall into the respiratory tract. Therefore, slafers should be cut with caution for yourself. It is advisable to use a respirator or try to be on the leeward side when cutting.

- The dust of asbestos is a carcinogenic substance and many countries have long abandoned the use of asbestos in construction.

- The International Agency for the Study of Cancer Diseases included asbestos in the list of the most dangerous and causing cancer. At the same time, it should be noted that the number of asbestos in this list is the first.

- So it’s not worth joking with him: the respirator helps a lot, and additional wetting of the cut place allows dust to quickly settle on the ground.

- Also, the eye protection should not be neglected. Some cutting methods are associated with high speeds and if even a grain of sand flows into the eye, then there is little pleasant here.

How to cut the slate of the wave

The first method: cutting corner grinding

Special stone circles allow you to cut the wave slate (it is also called wavy) in a very short time. It is advisable to use a circle of large diameter (230 mm) so that the cut can be made in one pass.

If only a small or medium corner grinder and circles at hand, you will have to mark the slate on both sides and perform the operation on both sides.

On the one hand it will only work out to cut the wave, but not reach the hollow between them.

Second way: Electric

A wave slate can be cut with an electrician, but it will be very inconvenient. If there is no corner grinder at hand and there is no desire to seek another way, then you can do with an electrician. For a transverse cut, the inconvenience is that the slate is hungry, which means you have to cut and constantly turn the sheet.

One wave is cut, the sheet is turned over and the wave is cut on the other side. And so the whole sheet, so this method is convenient only for those who do not have the opportunity to use other existing ways.

It’s how to light a bonfire with meals or a magnifying glass. the difference in time is enormous and in convenience too.

Cutting wood with an Makita angle grinder and saw blade

Third Method: Disco’s saw

Similarly, as in the case of a corner grinder: put the disk on the stone and forward. A good way, although, like all previous, dusty.

Fourth method: hacksaw

If there is nothing from the aforementioned tool, but you need to work, the hacksaw will come to the rescue. The work is long, almost without dust, the tool will become unusable, but the sheet will be cut. It is better to use a hacksaw with an average or small tooth and one that is not a pity to spoil.

Fifth method: hammer and nails

A fishing line for a trimmer is planned and holes are broken every 1.5-2 cm every 1.5-2 cm. When the penet is ready, you can break off. It is possible that it will have to help the mild beats of the hammer.

There are several disadvantages at once: uneven edges, prolonged work, the probability of damage (the sheet can give a crack along a completely different path), but it was this way that cut the slate even during its occurrence.

Hammer and nails are perfectly replaced by a drill. Then all the shortcomings are removed, except for the first. an uneven fishing line for a trimmer cut in any case remains.

Before cutting the slate of wavy or flat, we advise you to recall your tool. Choosing a specific of them, you can know what to expect from the operation. In most cases, a lot of dust awaits you, so protection and protection again. Safety precautions should be fully observed, since your precious health at the stake.

How to cut a cement-stove at home is most effective

The finish master Sergei Konovalov rated five cutting tools at once and compiled his own rating on the Stroyvelikan website. The main selection criterion is the effectiveness of the work. The list will begin the worst option for the saw and end with the best.

Location: Khosuovka on wood for stubborn

If physical labor does not scare, and the upcoming volumes of work are small, begin to cut the cement-brown stove with a hand hacksaw on wood. Many tools are always at hand, connecting to an electric network is not required. You can clearly control the accuracy of the cut without any experience.

I propose to choose a hacksaw with hot teeth and a trihedral sharpening for high performance for cutting cement-brown stoves. I count the optimal length 450 mm. In case of high requirements for the quality of the cut, I recommend applying a canvas with a pitch of teeth 7-8 per inch.

Place: Corner grinder for self.confident

Not entirely suitable for cutting hard sheet materials due to the lack of sole, but exceeds manual hacksaw in effectiveness. Who confidently holds in their hands an angular grinder, not without difficulty and a large amount of dust, but saw the sheets in the given sizes. The quality of the saw will have to try hard.

I would prefer to cut the cement-brown plate with a corner grinder using the winning or diamond discs by concrete or stone. Work safer than with wood discs. With the right approach, a more accurate cut is obtained.

Location: electric jigsaw for pragmatic

This tool combines the performance and quality of the saw. It is easy to make curly cuts with different radius of rounding. The stable metal sole simplifies the work and allows you to control the blade relative to the planned line.

I tried to cut a cement-brown plate with an electric lobe with a carbide-melting file T341NM, which is intended for a quick cut of cement-brown plates and slate. It turns out a neat cut without loss in speed. The canvas withstood large volumes of work, did not break and did not bent, but it also depends on the correct handling of the tool.

Location: Sable saw (electric wire) for modern

Not a very popular tool in the arsenal of the master, but in performance wins the corner grinder. Sable saw cuts quickly, but not too accurately. You have to pay for effectiveness. But narrow files allow you to make rounded saws.

I recommend cutting the stove with an electric tile with a special file on a cement-stove and slate and slate. A canvas from a solid metal alloy withstands prolonged loads. A 225 mm blade with attacks from tungsten carbide provides high speed and the most clean slice.

Place: Circular saw for hasty

If the maximum performance is required, it is better to cut the cement-brown plate with a circular saw. Cuts the slabs in a straight line not only quickly, but also for sure. To obtain a flat cut, set the guide. To do this, measure the distance from the cutting disk to the edge of the sole, then mark the sheet.

What disks to cut a cement-brown plate when using a circular saw:

Recommendation! For a clean cut, saw the sheets without stopping. Try to cut the stove in one pass. Make the power cable does not interfere when working with the tool.

How to drill holes in a cement-brown slab for cables and pipes

For the communication systems of the house, you often have to make holes in the cement-brown plate of different diameters. At this stage, it is important to choose the right consumable elements for an electric drill.

- Concrete drill or ceramics. Suitable when drilling holes for cables and pipes with a small diameter. Easily enter plates of any thickness, while leaving even edges around the perimeter.

- Bimetallic or diamond crowns. Suitable when drilling holes for pipes with a large diameter. Cut through the sheets well, do not leave chips at the edges.

Note! For thick plates when attaching with conventional wood screws, through openings are preliminarily made. Special fasteners with a pointed tip do not require drilling.

General recommendations for the opening of the material

In order to work safety and better cuts of slate sheets, follow general recommendations.

- Work in a respirator and goggles. When cutting the material, protect the respiratory tract. During the work, a large amount of asbestos dust is formed, which can penetrate the lungs, and over time to cause various diseases. Also protect your eyes from the effects of fine dust.

- Moisten the place of cutting water. Wet slate is easier to cut, the amount of dust decreases. Small particles when contacting water are connected to pastoral gruel. Water is neatly poured from a container with a narrow throat or use a wet rag immediately in front of a sharp, but not during.

- Consider the wind direction when cutting on the street. Try to be located so that it is blown from the back. Then dust particles will fly from the body. This will allow you to get down less and clearly see the fishing line for the trimmer of the marking on the surface of the sheet.

- Do not make sharp movements to the side. Regardless of the tool used, try not to direct the strength to the left or right to avoid chips and the appearance of cracks at the edges. The tool should move easily and smoothly.

Users are expressed about other methods

Eugene, learned to cut slate at home without corner grinding and other power tools. Wavy sheets remained from the old roof, and in good condition. I decided to use it to arrange beds. There was no power tool in the country, and it was a pity to spoil the new hacksaw. Therefore, he took the blade from a large cutter and carefully beat it with a hammer, moving systematically along the line. The edges turned out not very even, but it does not matter, all the same, the lower part will be in the ground.

Anton, tried to break through the slate along the line with a nail. If the requirements for the evenness of the cut place are not too large, then you can use the old method. Strictly on the line we make holes with a nail. Then we just break. It is advisable to squeeze the material from above and below. It is better to take on the edges of the sheet so that there are less chips. In the middle, the material usually does not go away from the intended line.

Peter, I had to cut the slate for the beds with a nozzle for a drill. I purchased narrow sheets for the garden with a width of 200 mm and 8 mm thick. It is not necessary to saw the strip along the length, only in width. From the tools there was a drill with a disk metal nozzle. It doesn’t work out very quickly, but it turns out to cut small slabs.