What spark plugs for lawnmowers. How to visually assess the condition of a spark plug

What spark plug for a lawn mower

Spark plug. it is the engine component that determines by 90% how easy it can be started. Therefore, before the first start of any device with a gasoline engine, it is advisable to use a new clean spark plug. Then the first start will not cause you a storm of emotions, memories of the mother and you will not pull out with the “meat” starter motor. The same situation occurs after winter storage of the power tool in a cold, damp place like a garage, basement, or shed. Again, do not overdo it with too much oil (better a little less than normal, at least at the first start). Excess oil will immediately flood the spark plug and you won’t be able to start your engine. But if there is no new candle, then read on.

For DP200 engine KIORITS. DP270 KIORITS, for GX240 engines Honda , GX270 Honda Motoblock MTZ-05 on the passport recommended spark plugs:

Candle glazing chainsaw, gasoline trimmer

I’ve read a lot of “recommendations” on the Internet. It is clear, the sellers of plugs are interested in buying new ones, frightening by the grave consequences of attempts to resuscitate the plugs. There were several reports that the spark plug cools by air-droplet laughter during operation almost to room temperature. But here is a colorful picture of NGK (company producing it), where you can see that when the engine is running normally, the temperature of the spark plug skirt is 450. 850 ° C. At these temperatures, the color of the skirt glow. from dark red (680 ° C) to cherry (780 ° C). So either with a burner, or under a gas stove flame heat the skirt of the candle to a cherry glow, and then leave to cool naturally to room temperature. Of course, you have to be careful about overheating the upper part of the plug. of the enameled insulator, this part of the candle really shouldn’t overheat. Therefore, during burning, you can put the candle in a tube of the appropriate diameter, I used a “Chinese” socket wrench, which was included with a gasoline torimeter.

Next, with a brush, carefully clean the center electrode. And you can use. But cleaning with a steel brush or sandblaster will really lead to physical deformation of the candle electrode, which subsequently worsens its performance. this is clearly understandable. Again, it is clear that before starting a chainsaw or weed trimmer, you will not fire the spark plug every time, but you will find out the reason why the spark plug is in bad condition. But when you have to start the gasoline engine for the first time, and you don’t know where and in what conditions it was stored and how it was preserved, glowing plugs may well help.

Cleaning spark plugs with solvents

Searching on the Internet I found another good method of cleaning plugs from sludge.

The thing is that nowadays you can easily find the gel for cleaning electric stoves, exactly the kind that cleans the fouling. In the kitchen I found Sanita gel, took an old toothbrush, smeared this gel on the sooty electrode, left for about 10-15 minutes, rinsed under running cold water, repeated the procedure three times and got almost a white electrode. If such a quick therapy did not help, you can cover the spark plug with gel and leave it for the night.

First, it is recommended not to tighten too much (torque 12. 15 nm, as I wrote above), then there will be less problems with unscrewing. It is necessary to unscrew it counterclockwise ;). I liked the advice to unscrew the plugs on a hot engine. Oddly enough, the need to unscrew it occurs most of the time when it won’t start! And the engine is cold!? I understand. In a car, when one of the 4 spark plugs does not work, the engine can be warmed up on three. It does not unscrew. You need to pour WD40, “liquid key”, kerosene, wait and try to unscrew.

The gap and other parameters of the plug

The main parameters that the buyer needs to know:

- The diameter of the thread that screws into the cylinder;

- the length of this thread (in common parlance skirt or jacket);

- the gap between the central current-carrying core and the side electrode (mass), between which a spark is formed.

The exact gap for each chainsaw model is in the instruction manual. It varies from model to model in the approximate range of 0.45 to 0.55 mm.

There are other parameters. For example, the thread pitch. But it is standard for all the plugs of this type (M10x1) and they don’t think about it when buying.

A90 SUPRA SPARK PLUG UPGRADE FOR MAX POWER ������ (AND TO PREVENT MISFIRES ��)

There are parameters of voltage on the plug. These are huge, from 10,000 to 20,000 volts and higher. They are taken into account by manufacturers to calculate insulators and t.д. The user does not need to know the exact voltage.

It is important to remember that if you touch the spark plug contact or electrode when you jerk the starter, you can get a very tangible shock of electric current. It can’t kill you because at high voltage, the ignition current has a small ampere rating, which is measured in microamperes. But it hits pretty hard.

Replace car spark plugs, How to easy replace sparks plug. Honda Jazz, a woman replace spark plugs

What will be needed

- Flathead screwdriver

- A #19 spark plug wrench or pliers

- Spark plug (refer to manual for selection)

Find the black plastic shroud with the protrusions on the body of the grass trimmer. Your fingers should be enough to remove the plastic, but you can use a flathead screwdriver instead.

Lift up and separate the black plastic trim of the comb from the spark plug.

Using a spark plug wrench, turn the spark plug counterclockwise until it loosens and take it out. You can use pliers to remove the spark plug if you don’t have a spark plug wrench.

Insert the new spark plug and turn it clockwise by hand until it stops.

Use a spark plug wrench or pliers to turn the spark plug clockwise to ensure a snug fit.

Attach the bottom of the plastic cover to the top of the spark plug. Press down on the cap. Light pressure is enough.

Grass trimmer spark plug replacement is over.

Subscribe to our Telegram. To be the first to know about new articles on the site.

How to choose a spark plug for brushcutter (grass trimmer), chain saw.

You’ll also like the later ignition on the trimmer: the piston goes down after compressing the fuel that hasn’t ignited, and that’s when the spark occurs. This is where the engine either does not start or looses power significantly and does not rev up as quickly.

Alas such problems with early or late ignition on two-stroke ICE are rare enough, as the flywheel with the magnets is already set in the correct position, which is perfectly synchronized with the movement of the piston. Among other things, the flywheel is secured to the shaft with a key and a nut. Therefore, it is not possible to install it incorrectly.

In the main, the adjustment of ignition is to align the correct gap between the magneto and the flywheel.

Magneto is the main part in the ignition system of the engine and is a coil with the primary and secondary windings located around the core. Often, due to a faulty magneto the spark is lost on the spark plug, and the ignition of fuel does not happen. To check the coil, you will need to use a tester, and perform the following acts.

- Set the resistance measurement mode on the tester to 200 ohms. The primary coil will be checked with this method.

- Connect one electrode of the tester to the coil “ground” and the second electrode to the contact coming out of the magneto. Normally, the resistance will be from 0.4 to 4 ohms.

- To check the secondary winding it will be necessary to set the device switch to 20 com. Next, one probe of the device is inserted into the cap of the spark plug and the 2nd probe is connected to the “ground”. Normally, the resistance characteristics should be in the range of 4 to 6 kohms and above (depending on the model).

The device will display infinity when the circuit is open and zero (zero) when shorted.

If you do not have a tester, then use the following method, showing great care that the electrode does not touch the cylinder, otherwise the coil will burn out.

- Remove the cap from the spark plug. You will not unscrew it to save the compression.

- In the cap you need to stick a nail without a cap. The nail is of such cross size that it will perfectly stay in the cap.

- Tie the cap with a nail to the cylinder, using a dielectric, so that the gap between the electrode and the cylinder body was at a time of 5.5 to 7 mm (but did not touch the “mass”).

- Use the starter a couple of times to simulate the start of the engine. The ignition button may be on.

- Observe whether the spark arises and what color it is.

Normally, the spark may be strong, snow-white, or have a bluish tint. If the spark is weak and its color is orange or yellowish, it indicates a defective magneto.

Also consider the fact that from time to time the magneto in a cool state can give a good spark. But after heating up due to internal defects it stops making current. When the coil cools down, the grass trimmer starts up again and runs for a couple of months until the magneto heats up again. It’s a coil that needs to be replaced.

At a similar problem with the heating may cause the spark plug, if the coil is serviceable, so it is necessary to inspect both parts.

Trimmer ignition is simple to adjust.

-

Remove the cover from the motor by unscrewing the screws that hold it in place. For example, on the Patriot (Patriot) PT 2540, to remove the cover, you will need to unscrew the air filter housing, and a flat screwdriver to remove it from the latches. After that the plastic case is simply removed.

What spark plug to choose for a brushcutter (grass trimmer), chainsaw.

You will also like the later ignition on the trimmer: the piston, after compression of the fuel, which has not ignited, goes down, and in this case there is a spark. Here, the engine will not start or significantly lose power and will poorly gain speed.

Alas, such problems with early or late ignition on two-stroke internal combustion engines occur quite seldom, because the flywheel with magnets is already set in the correct position, which is perfectly synchronized with the movement of the piston. Among other things, the flywheel is fixed to the shaft using a key and a nut. That is why a faulty setting of the part is impossible.

In the main, the adjustment of ignition is to align the correct gap between the magneto and flywheel.

The magneto is the main part in the motor’s ignition system and is a coil with primary and secondary windings arranged around the core. Often, due to a faulty magneto spark is lost on the spark plug, and the ignition of fuel does not happen. To check the coil, you will need to use a tester, and perform the following acts.

- On the tester, having switched to resistance measurement mode, it is necessary to set the switch to 200 ohms. The primary winding will be checked by this method.

- Connect one probe of the tester to the coil’s ground and the second to the terminal that comes out of the magneto. Under normal conditions, the resistance will be from 0.4 to 4 ohms.

- To test the secondary winding it will be necessary to set the switch of the device to 20 kohms. Next, one probe of the device is inserted into the cap of the spark plug, and the second is connected to the “ground”. Normally, the resistance characteristics should be in the range of 4-6 com and higher (it depends on the model).

At an open circuit the device will demonstrate infinity, and at short circuit. 0 (zero).

If you do not have a tester, use the following method, being very careful not to let the electrode touch the cylinder, otherwise the coil will burn out.

- Remove the cap from the spark plug. You will not unscrew the spark plug to save compression.

- You need to stick a nail without a cap in the cap. The nail comes in a diameter so that it can be perfectly seated in the cap.

- Tie the cap with a nail to the cylinder using dielectric in such a manner that the clearance between the electrode and the cylinder body is 5.5 to 7 mm (but does not touch the “mass”).

- Use the starter a couple of times to simulate the start of the engine. The ignition button can be turned on.

- Watch whether the spark appears and what color it is.

Normally, the spark should be strong, snow-white in color or a bluish color. If the spark is weak and its color is orange or yellowish, it indicates a defective magneto.

Also consider the fact that from time to time a magneto in a cool state can give a good spark. However, after heating due to internal defects, it stops generating current. When the coil cools, the grass trimmer starts up again and runs for a couple of months until the magneto heats up again. Such a coil needs to be replaced.

A spark plug can cause a similar heating issue if the coil is serviceable, so both parts need to be inspected.

The ignition on the trimmer is simple to adjust.

-

Remove the hood from the motor by unscrewing the bolts that hold it in place. For example, on бензосе Patriot (Patriot) PT 2540, to remove the cover, will need to unscrew the housing air filter, and a flat screwdriver to remove it from the latches. After that the plastic case will be simply taken off.

Replace a spark plug brushcutter BC-43E

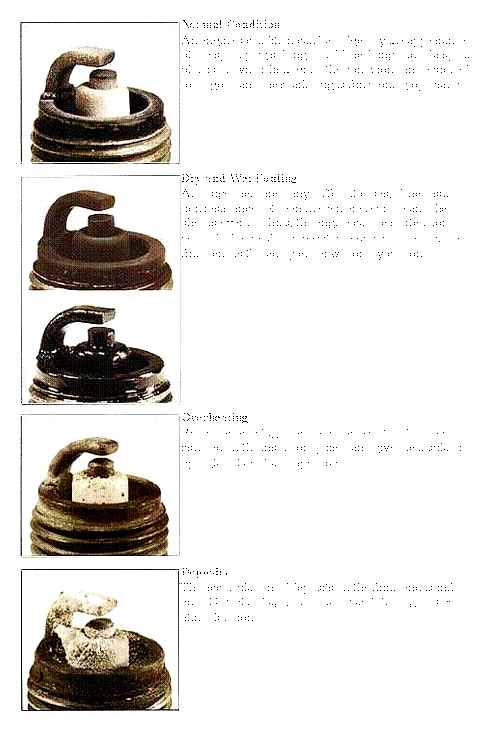

Spark plugs and malfunctions associated with the appearance:

- Wear and tear, more often the side electrode.

- Cracked insulator housing.

- Melting of both electrodes.

- Erosion. thinning of the side element.

- Deposition of carbon deposits.

Not timely replacement of plugs leads to a distortion of the gap and as a result, spark formation with the consequences of a nasty car start. Wear of the side electrode is caused by the additives in the gasoline. The result is spark gaps, engine detonation. Products are changed.

The reason for changing even unnoticeable cracks or visually visible chips on the body of the insulator.

When using spark plugs with cracks, there is leakage of current through the insulator on the body of the plug

The defects appear because of:

- Wear (natural).

- Detonation due to early ignition angle.

- Fuel with low octane number.

- Low quality insulator.

- Improperly set clearance.

A bad insulator is the reason of current leakage. This leads to a decrease in the discharge between the electrodes. It is already difficult to start the engine, the low injectivity, when driving from a place, unbalanced idling.

micro cracks are easy to find in the dark or in the darkness of the garage.

Electrode melting is a manifestation of serious overheating

Rough, porous soot appearance. Is caused by thermal stress, low octane gasoline, early ignition cycle. Not exclude distributor (tramler) or valve deficiencies. Check the mixture, ignition, change the plugs.

Why do you need a good spark?

The quality of the spark determines its ability to ignite a correctly formed air-fuel mixture under operating criteria. A weak spark under the criteria of high pressure and temperature in the combustion chamber can not do it. Ignition occurs later or not at all. How to check the ignition coil on the trimmer yourself. There is a bulge in the work of the motor, the motor does not pick up speed, there is vibration, detonation, in the starter may show the effect of “revolving shock”.

Lack of spark on the lawnmower repair with their own hands.

Why do you need ignition adjustment

In some cases, when the engine does not start, ignition adjustment will be required. Of course you first need to check if the spark plug and the high-voltage cable with the cap are in good working order.

Adjust the ignition on the two-stroke engine is needed to ensure timely ignition of fuel in the engine combustion chamber. Here is a diagram, from which you can understand how an internal combustion engine works.

a spark in the plug should appear at the moment of fuel compression by the piston, when it just slightly reaches the top dead center (TDC). When the piston reaches TDC, the fuel mixture ignites, and the piston moves downwards as a result of the explosive energy.

Therefore, if for any reason (mainly due to displacement of the flywheel on the shaft relative to its original position) fuel ignition occurs before the piston passes TDC, it goes back and the crankshaft is cranked in the opposite direction. Such movement can damage the starter assembly, break the starter cord, etc.д. In this case there is an early ignition of the fuel.

There can also be late ignition on the trimmer: the piston goes down after compression of the fuel, which is not ignited, and at this moment a spark appears. In this case, the engine will either not start, or will lose power significantly and will not pick up speed well.

But such problems with early or late ignition on two-stroke engines are quite rare, because the flywheel with magnets is already set in the correct position, which is perfectly synchronized with the movement of the piston. In addition, the flywheel is fixed to the shaft by means of a key and a nut. Therefore, incorrect installation of the part is ruled out.

Basically, the adjustment of ignition is to set the correct gap between the magneto and the flywheel.

How to start the grass trimmer

The question of how to start the trimmer for grass, if the grass trimmer does not start or starts badly will arise if the engine gasoline trimmer for grass is worn, not regulated, or when, because of violations of the sequence of operations during engine start-up in the combustion chamber got a lot of fuel (when the engine is “sucked”). To help the engine start, a little fuel can be poured into the cylinder through the spark plug hole. To do this, it is best to use a special starting fluid, but you can also use regular fuel from the tank of the starting grass trimmer or lawnmower.

How to start the trimmer for grass, pouring 20 g. fuel in the spark plug hole

To start the grass trimmer (if the grass trimmer does not start) you should first check if there is fuel in the tank and if its level is sufficient (whether the fuel reaches the intake hose. is the fuel filter immersed in fuel). It does not take long. open the cap of the tank and look inside.

Remove the cap and unscrew the spark plug with a spark plug wrench.

Next, you need to check and, if necessary, clean the electrodes from sludge or other deposits, using a metal brush or a thin screwdriver. Keep the electrodes clean. When cleaning the electrodes, you must be careful not to damage the white ceramic insulator of the center electrode.4. Preferably ignite the electrodes of the plug on the gas burner or with a lighter (observing the fire safety rules). You can check the serviceability of the spark plug by inserting the plug into the cap and ensuring contact of the housing with the engine “mass”, and then rotating the grass trimmer engine with the starter and evaluating the presence and quality of the spark between the electrodes of the spark plug.

Pour about 20 grams into the spark plug hole. Use a tablespoon, a cup or a medical syringe to pour the fuel. After that, immediately install the spark plug in place and tighten it.

Close the choke shutter (turn on the starter gas) and press the manual pump button 3 times with a pause of 4 seconds. Between each pull.

Pull the starter grip several times and start the grass trimmer engine (lawnmower). As soon as the engine of the grass trimmer is running, close the choke.

If the engine does not start even after that, then it is necessary to replace the spark plug with a new one, as the cause is most likely in it (buy a spark plug with the marking indicated in the Grass Trimmer / Lawnmower User’s Manual).9. If the engine still fails to start, you should clean the carburettor with a carburettor cleaner.

For a quick cleaning of the grass trimmer carburetor with a carburetor cleaner, you must remove the plastic covers and air filter to get access to the carburetor (preferably remove the carburetor from the engine and disassemble). squirt a few times with a jet of carburettor cleaner in the central nozzle and other accessible channels of the carburettor (through). This can be repeated several times and make sure that the channels are clean and free of debris.

It is necessary to check the spark arrester in the gasoline grass trimmer / lawnmower’s muffler for contamination. If it is clogged with sludge, it may be the main reason for poor engine starting and the screen should be cleaned with a metal brush. the spark arrester in the weed trimmer’s muffler is intended to prevent hot particles from flying out of the muffler that could cause a fire if they fall onto hay or other easily combustible materials.

How to start the trimmer for grass, if after all this work the engine still does not start. you need to analyze if pouring 20 g. If you can’t get enough fuel in the cylinder, the engine will start working for a short time, or it will start, work and then choke again. In this case, you must either buy a new carburetor (it can be clogged), or take to repair the carburetor trimmer for grass, or make adjustments to the carburetor itself. If, after pouring 20 g. fuel in the cylinder trimmer for grass / lawnmower engine at all does not give signs of life, then the reason for the spark plug, which should be replaced with a new one (buy a spark plug trimmer for grass) or clean the old spark plug.

At the end of the season you must always drain the fuel from the tank of both your trimmer (gasoline mower) and any other machine with two-stroke engines. Pour fuel from the tank into a bottle through a funnel, then start the grass trimmer to work out the remaining fuel from the carburetor until the engine stalls. If this is not done, if stored for more than 1 month, the fuel will begin to stratify into light and heavy fractions and oil mixed with fuel will precipitate, leading to corking of channels in the carburetor and, consequently, to the failure of the grass trimmer.

Tips

You should regularly check for contamination and change the fuel filter in the fuel tank of the grass trimmer (lawnmower) on time. The fuel filter can be easily removed from the tank with a wire hook to change it. The fuel filter is easily clogged with sediment in the fuel tank, which leads to deterioration or termination of the fuel supply from the tank to the carburetor of the gasoline grass trimmer.

You should not use ethanol gasoline to fill up the grass trimmer, because in small two- and four-stroke engines that are not used every day or at least every other day, it is a big problem. Ethanol from gasoline precipitates and turns into tar or varnish, clogging the microscopic jets and carburetor passages.

To keep the carburetor clean and in good technical condition, you can buy a special fuel additive for two-stroke engines, which cleans the carburetor from tarry deposits. The price of additive is comparatively low and it (additive) is not dangerous.

Also, you should give up all old metal canisters, which rust inside over time. Particles of this rust will cause clogged filters, jets and channels in the carburetor and, consequently, inoperability of the gasoline grass trimmer (or lawnmower). over, as a rule, right away, the owner of grass trimmer can not determine where this blockage comes from.

How to start a Husqvarna 333R grass trimmer

(Procedure):

- To pull the suction on the motor (to close the air flap).

- Pump the fuel 6 to 8 times.

- Hold with left hand (not foot)!) by the engine covers.

- Lightly pull the cord handle to select the starter’s free stroke.

- Pull the pull handle of the starter cord once or several times quickly to start the engine (but pull it to such a height and with such force that the starter cord is not torn out!).

- Pull the recoil starter gently down (don’t drop it)!).

- Push in the choke (open the choke).

- The grass trimmer motor is running. You’re smiling. Everyone else has a puppy’s delight!

- After a few seconds, lightly throttle to release the starting throttle, which is switched on by the choke.

- Warm up if the engine is cold, 3. 7 min., depending on the air temperature and you’re ready to mow.