What tools are needed for woodcarving

Tool kit

Cutters

Cutters are one of the basic tools for wood carving. And there should be several of them. with different angles of inclination of the blade and its size, which will ensure the convenience when performing various operations.

As a rule, there are six cutters in the cutter set, and one of them is the main one, which is the most convenient to work with. The choice of such a cutter is a strictly individual matter.

However, there are some basic requirements that all cutters must meet:

When choosing a tool, you should hold it in your hands to make sure the handle is sufficiently ergonomic.

Chisels

Chisels come in different types and are characterized by the following parameters:

For example, the chisel number 3 is practically flat, while tool number 11 is U-shaped. As can be easily guessed, chisel 11 can cut deeper into the wood than a chisel with a chisel and the latter is more convenient to work with when finishing a piece.

It should also be noted that there are chisels number 12 that have a V-shaped profile. They are characterized by a wide range of angles. 24 to 90 degrees. However, the most common is a V-shaped chisel with an angle between 60-70 degrees.

Tip! When choosing a chisel, you should pay attention to the handle of the tool. It should not be round so that it does not roll off the table and onto the floor. Otherwise you would have to repair the blade very often.

To carve the wood with your own hands you should buy chisels the size of your palm. Even smaller tools are needed for finer carving. But for relief and sculpture carving, standard-sized tools with large handles are used.

You need a good knife to make a carving.

According to the type of construction, knives are divided into three types:

Advice! In specialized stores there are special kits that include all the necessary tools for woodcarving for beginners.

They are also differentiated according to the following characteristics:

- Type of steel the best option are knives made of high-carbon steel 55. 60 RC. Such a tool stays sharp longer than knives made of stainless steel or mild steel.

- Blade size. to create a finish and shape the workpiece, it is better to use a knife with a blade length of 4 to 5 cm and a thickness of about 4 mm.

It should be said that some carvers prefer knives with interchangeable blades. Their advantage is that you can simply replace the blade instead of sharpening it. Chisels can also be used with the handle of such a knife.

Tip! If you are a beginner, you can put a steel wire glove on your hand before you work to avoid injury.

A variety of saws can be used in carving, but the most common is the archer saw, also called a “serpentine” saw. It consists of a replaceable blade made of high-carbon steel and a frame with a handle.

It can be used for making narrow and curved lines. This saw is also often used for removing surplus wood.

Please note! Be careful when working with a bow saw because it can easily deform and break.

Special tools

Special wood carving tools are used in special cases. For removing bark, for example, you would usually use a scraper. It is also often used for rough trimming excess wood.

A spoon knife, which has a rounded, double-edged blade, is also a fairly widespread tool. Such a tool is used in the manufacture of wooden cups, spoons and other wooden products.

Abrasives

Abrasives include files and rasp files. They can be used to smoothly remove excessive wood. The main difference between files is the following points:

Abrasives also include:

- Sanding flexible tape. used in the processing of curved surfaces.

- Sanding cylinders (hand drill attachments). are an indispensable tool for finishing the product.

Please note! Sandpaper can be used only for the final treatment of the wooden product, otherwise the wood carving tool will quickly blunt the abrasive particles stuck in the wood.

Power tools

Various power tools for woodcarving allow to simplify considerably and at the same time to accelerate the process.

Below we will consider the most common types of it:

- Circular saws, thanks to the large selection of blades, make it possible to perform even those operations that cannot be performed with an archer saw allow you to quickly finish your workpieces. They can also be used to remove bark and perform some other operations.

- Rotating tools with a large selection of heads (milling cutters). make it possible to perform grooves, profiles and many other operations.

Note! Even electric tools, such as reciprocating chisels, are available. They are designed primarily for people suffering from arthritis and other joint conditions.

Locking devices

As a fixing device is usually used a vice, which is attached to the workbench. In order not to leave marks on the product, it is necessary to use spacers when clamping it in a vice. It can be pieces of thick leather or plywood.

Wood carving tools

Carving in wood is carried out with the use of special tools. High machinability, which is inherent in wood, allows to obtain products of different shapes and sizes. It is necessary to choose the right tool for carving, because of their certain qualities depend on the features and complexity of the work carried out.

What kinds of knives are used

Each type of wood for carving has its pros and cons. It is easy to work with soft wood, but there can also be many defects. It is aspen, linden, birch. For beginners, this wood is best suited.

Oak, boxwood, mahogany are more expensive and difficult woods. It is hard and resistant, so it is difficult to carve from such wood. Very often there are problems when working with such wood species. Either the tool or the craftsman can be damaged.

An experienced carver can easily work with different wood, including juniper. But for beginners it’s better to use inexpensive materials like spruce, pine, pear, or birch.

Whatever tools have not been chosen for woodcarving, it is necessary to strictly observe the safety technique!

Tools for woodcarving

Carving wood requires not only skills, but also special tools. Some of them are familiar to everyone, but there are specific ones, used exclusively for this kind of folk art. Let’s try to understand and present you the main types of tools you will need if you want to try your hand at woodcarving.

As noted by the masters themselves, a clear and unified classification of tools does not exist. Not only that, in different descriptions there are different names of the same type of tool.

The main type of tool that is actively used during wood carving is a knife. However, there are several kinds of them, which differ markedly in both purpose and appearance.

Shoal knives. Characterized by a beveled blade, the cutting angle reaches 60 degrees. Shoals are used in the process of flat-relief carving, to cut straight long mowing lines. You can also use the jambs to work the side walls of existing grooves and to fillet the contour.

Cutter knives. They are also called cutters or simply knives. They all have a cutting angle of 35 degrees, but the shape and size may vary. Carvers consider such knives as the basic tool, each master has his favorite knife, which he may invariably use for many years.

There are also bogorod knives and tatianka knives. The name comes from the village of Bogorodskoe, known for its wooden toys of the same name. Bogorodsky knives can have different size of the blade, which varies depending on the subtlety of the work. Tatianka is simply a variation of the Bogorodsky knife with a longer handle, which provides the maximum transfer of the master’s efforts to the cutting edge. It is used for power carving.

For beginners amateur carving in wood, according to experts, a ready-made set of knives will do. You should try your forces, in practice to figure out which knife will be more convenient for you to work with, so such a set at the first stage is the best choice.

- Through-carving, which involves sawing and slashing a wooden workpiece:

- Sawing carving is implemented with a jigsaw or hacksaw;

- a slotting variant is a through percussive piercing of the workpiece with chisels or special wood cutters. Also apply the processing of woodworking machines.

- contour carving is a groove-deepening, which is formed by a special chisel, angular or semicircular chisel or a carpenter’s knife;

- The result of a staple carving is a staple notch in the wood, which is made with a semicircular chisel.

Basic, auxiliary, joinery and carpentry tools for wood carving are used to implement the above options.

- Cutter. it is a universal tool for cutting in wood. It is used in shaping the main part of the object. Such wood tools have an elongated, straight or bent blade, a bent shoe. Cutting angle of cutter blade 35 0. Such knives are also designed for fine operations. Modern cutter can have interchangeable blades.

- The jamb cutter has a cutting blade angle of 60 0. Blade itself is beveled. Such cutters are used for cutting geometry lines, roughing and finishing wood.

- The Bogorodsky knife is similar to the European knife-cutter, but with a longer blade and a shorter handle. It is designed to perform rough and fine finishing work. Cutting part of the blade, 30-90 mm long, is evenly partially ground. The cutter owes its name to Bogorod carving (a wood-carving art direction).

Chisels

- Straight chisel used in conventional recess carving.

- An oblique chisel has a cutting edge angle of 45 0. Used for cutting long grooves.

- Angular chisel is used to cut V-shaped recesses.

- Semicircular chisel is designed for complicated patterns and serifs. Available in round, medium and chamfered.

- Clucarza differs from the previous variant by the fact that the blade is rounded both on the face and on the shank. Can be rounded, angled, or straight.

- Caesaric differs from the variant in that it has a narrow cutting edge. Caesar chisels narrow grooves and fine patterns.

- A chisel is used for cutting grooves.

- A pincer (mini-pincer) has a narrow cutting edge that resembles a pointed leaf. Used for creating precise ornaments.

- A nail file is equipped with a narrow rounded end.

Special tools

- Gravers (electric and manual) are equipped with woodworking nozzles and a flexible shaft.

- Flexible shaft for wood carving.

- The laser engraver can grind and polish surfaces in addition to its cutting function.

Abrasives

- Files and rasp files to remove excess wood. tool surface: rough, medium rough, smooth. Abrasive tool shape: flat, semi-circular or circular.

- Flexible sanding band used for sanding bent surfaces.

- Sanding cylinder nozzle for a drill or electric screwdriver.

Wood scraping, sanding and polishing tools have different roughness and texture surfaces for working with different types of wood.

Electric tools

- Cordless or 200 volt electric drill.

- Jigsaw can operate as a hand held, jigsaw or arbor craftsman. Quick accessory change and low vibration level are advantages over hand jigsaws.

- The circular saw can safely cut wood along or across the grain.

- Electro planer used for trimming or trimming to size.

- Electric disc or belt grinders for polishing, sanding or varnishing surfaces.

- A hand-held electric cutter is used instead of a hand planer, scraper, tongue and groove cutter. Used for cutting edges, grooves, quarters, and chamfers.

What you need an electric tool for woodcarving

First, timely and quality sharpening of knives, chisels and other hand tools to be used for threading should be taken care of. It is from these tools that the beauty of the work and the ability to execute the conceived decors depends directly.

The sharpening machine is probably the most important electric tool of the wood carver. It is best to buy a model with a shaft on two sides with about 500 watts of power and a shaft speed of 1500-3000 rpm. Such sharpening machines are usually universal and allow not only sharpening, but also drilling, grinding and polishing operations.

Pay attention to the built-in backlight. this option is very useful when working with small details.

Of supplies for the sharpening machine will require abrasive wheels (with coarse and fine grain, diamond, corundum, felt, felt for finishing polishing with Goya paste), if it is planned to use and as a grinder and polisher.

Grinder is indispensable for almost any carpentry work, including woodcarving. It is best to buy a delta or circular model.

To grinder will also need to purchase attachments of varying grit size. For the beginning of works on wood it is better to take their set, and over time to replenish the failed consumables.

Drill also need to work. As a rule, it is already at any handyman involved from time to time repair, assembling furniture, performing some dacha work. In woodcarving the electric drill will have an auxiliary function and will start in hammerless mode. Therefore, it is not necessary to buy some expensive models, it is enough the most simple battery-operated.

To the drill should also buy a set of drills and drill bits for wood, and then replenish the failed.

Electric jigsaw also belongs to those tools that almost everyone has in the arsenal of a home workshop and even more so in the shop. Since accuracy and calibration are important here, it is better to buy a jigsaw of a higher price, from the middle range and above.

Engraver with a flexible shaft or boron-machine significantly expands the possibilities of woodcarving in various decorative elements. Especially if you plan to perform some small, elegant patterns.

But it can be purchased later, after getting a hand on the performance with hand tools.

Tools for carving

General principles

Wood carving is a fairly popular technique for decorating various items.

As a rule, the process itself takes place according to this scheme:

Please note! Sometimes the undisturbed parts of the tree are carved to decorate the surface. In this case, select a fragment, the form of which has the maximum decorative potential.

A wide variety of tools are used for the carving of figures

- Afterwards the surface is machined with special cutters and a part of the wood is removed. This results in the formation of a decorative relief.

- After finishing the carving the surface is finished: sanding the cut areas, impregnating with protective substances, full or partial painting, varnishing etc.д.

The most important tools in this process are the woodcarving picks. Besides the skill of the carver himself, it is the quality and the right choice of cutter that determines how pure the ornament or subject image on the wood will be.

That’s why we’ll look below at the main varieties of these tools and describe where and how they are used.

Main kinds of cutters

To create three-dimensional images masters use a variety of types of wood cutters. In principle, if you have the skill, you can do without some of the products listed below, but for best results it is better to assemble as extensive a set as possible and use each tool for its intended purpose.

The main varieties of cutters are shown in the table below:

- These are knives with short, triangular-shaped blades with different bevel angles.

- Are a universal tool, because they can be used to form a variety of relief objects, ranging from straight lines and ending with shallow recesses.

- Three functional areas are used when working with a jamb cutter: the toe, the blade and the heel.

Depending on the shape of the edge of the chisels are:

- Flat. used to form smooth lines and recesses. Flat chisels with wide blade are also used for roughing in order to cut or edge out surface imperfections.

- Angular. used for cutting V-grooves and notches, and for forming shaped elements. The smaller is the angle of closure of the planes of such a chisel, the deeper will be the relief formed by it.

- Semicircular. one of the most common in figural carving. Rounded shape of the end blade allows effective extraction of wood from a solid block by creating a recess. Small semicircular chisels are also used for texturing and notching on a flat surface.

- Beveled. similar to semi-circular, but creates a groove with distinct inner edges when extracting wood.

- Reversed (rounded and stapled). used to form semicircular and rectangular protruding parts, as well as for drawing parallel lines.

Blunt-cut chisels are usually used for fine carving with a strong penetration, which enables the formation of a clear relief.

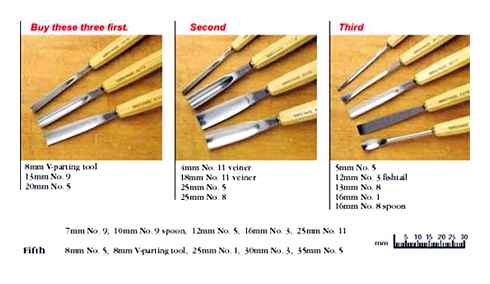

Basic Tools to Get Started.Intro To Woodcarving

As a rule, these tools are classified according to the shape of the blade:

- Straight.

- Semicircular.

- Bevels (distinguish between left and right-handed cutters).

- “Dovetails.

- Dovetails.

- Reversible.

- Corner.

Auxiliary tools

However, the master carver, in addition to chisels and knives of various shapes and sizes, requires other tools.

The required minimum of additional equipment includes:

- Wood saws (hacksaw or sabre saw for roughing, onion saw for finishing).

- Jigsaws.

- Drills and grinders.

- Planing planes for leveling.

- A set of wood files (rasp files).

- A mallet for working with hardwood cutters.

- Wood sanding tools.

If the master is working with quite large constructions, in addition to simple cutters, he may also need shaped axes. the so-called tesla. Similar in principle to picks (naturally with adjustments for scale and finish).

Selection tips

If you plan to master the technique of wood carving with your own hands, then you need to start with the selection of the appropriate tool. And here we stop before the dilemma: really high quality cutters are quite expensive, but if you buy a set for beginners “for cheap”, then work with uncomfortable and constantly losing the sharpness of the device for a long time will remove the desire to engage in this type of art.

The optimal solution would be to buy a few good cutters, and then expand your toolbox as needed. To begin with, we need at least one medium-sized jamb knife, as well as four or five chisels: one flat, several angle chisels and semi-circular chisels with different bending of the blade.

Quality products from a foreign manufacturer

With regard to specific instances, you should pay attention to the following features:

- The blade should be strong and well hardened, without rust or other defects.

- Cutting part should be firmly, without play, fixed in the handle.

Notice! It does not concern knives with replaceable blades. they in any case will have a minimum backlash, which you have to put up with.

- Handle material. wood or firm plastic. However, the second option is a little worse, because the wooden handle does not fit very comfortably in the sweaty hand.

- Naturally, the handle should be flat and smooth, with no burrs and cracks.

- If we talk about the shape of the handle, the most common are cylindrical variants (suitable for percussion carving with a mallet), cone-shaped and mushroom-shaped models.

- Some manufacturers produce chisels and jambs with handles of anatomic shape, equipped with a recess under the fingers, but many novice masters have some complaints about their convenience.

- The manufacturing company also plays an important role: today you can find both domestic and foreign molds, producing quite decent quality products. And that is worth to give up, so it from the blatantly cheap Chinese and some domestic cutters: yes, the purchase you will save, but these products will cut, if and will not last long.

Wood carving for beginners

People who prefer to create their own decorative objects can learn the art of cutting. Wood is the material that allows you to create genre paintings and decorative compositions. Such products can become a decoration for your own home, and they can also be given as a gift to friends. Today wood products are at the height of their popularity. There are plenty of woodcarving tutorials on the Internet.

Carving chisels. Classification

The wood chisel is a professional carpenter’s or joiner’s tool to prepare wood for further processing. It can help chamfer, carve ornaments by removing extra layers of wood. The design of the chisels is very simple. a plastic or wooden handle and a sharpened blade of various shapes.

There are the following types of chisels:

- Straight chisel is needed for processing wooden workpieces and cutting simple hollows

- An oblique chisel has a blade that is beveled at an angle of 450. It is used for cutting longitudinal grooves, and work associated with the primary processing of the workpiece

- Angular chisel, which resembles the English letter V, with 2 closed planes of the blade at different angles. It is necessary for making V-shaped notches. the sharper and smaller the angle of the cutter, the deeper the notch the craftsman gets

- The half-circular wood chisel is probably the most important type. It is a semi-circular tool for the preparation of the product, as well as cutting ornaments of varying complexity, apply serifs. The semi-circular wood chisel can be round, medium, or chamfered

- huckleberry is very similar to a semi-circular chisel. The main difference is that its working surface has a rounding not only on the edge of the blade, but also on the rod. This shape guarantees a sharper tool movement in the wood. The snow blower comes in a variety of styles. Their cutting part can be rounded, carbonized or straight

- cesariqs can also be called a kind of semicircular chisel, but they have a narrower working part, only 3 mm wide. Their main purpose. cutting of fine grooves and elaboration of the smallest details of the ornament

- Pliers have a mushroom-shaped handle and an oblique chisel. They are mainly used for cutting grooves. As the master’s pressure increases, the carving becomes clearer and deeper

- A dagger is a mini wood chisel that has a thinly sharpened, narrow blade that resembles a sharp leaf. they are used when ordinary chisels cannot create the pattern required

- nail is also a type of miniature chisel. It is intended for cutting thin pieces, but is more rounded than a rivet

- reverse chisel, like a cleaver, has a convex outward notch to create a protruding pattern above the plane of the main blade.

Almost all of their listed jigsaws can have different modifications. Plane chisels are wide or narrow, the angle chisels are wide or narrow, and the round chisel has a flattened or radial curve.