Basin vibration plate does not go forward. The vibration plate overheats or smoke

The vibration plate does not trim the earth

The likely cause of the breakdown

Debugg

The ignition switch is switched to the “OKL” position

Transfer the switch to the working position

The air damper is in the wrong position

Translate the damper to the necessary position. Details of the operation, see the operating instructions in the section Preparation for the launch

The fuel ended or it does not enter the engine cylinder

Check the presence of gasoline in the fuel tank, if necessary, season. Check the fuel filter, transfer the fuel tap to the working position. If the actions described above did not help, contact the service center.

Check the candle and other system elements or contact the service center

The engine works unstable at idle, stalls or does not develop full power

Gasoline of inadequate quality, inappropriate octane number or long storage

Drain improper gasoline, pour a new

Perform work on the service of the ignition system

Air pollution or fuel filter

Clean or replace the air or fuel filter

Great wear of the details of the piston group

Contact the service center for repair and replacement

Low.quality surface tamping, insufficient depth of sealing

See recommendations for eliminating malfunctions “The engine works unstable at idle, stalls or does not develop full power”

Reduced revolutions of the vibrator due to slippage of the clutch coupling pads

Inspect the pads, check their cleanliness and integrity. If necessary, replace

Reduced vibrator speed due to slipping of a drive belt

Check the belt tension, its cleanliness from pollution and integrity. If necessary, replace

Inappropriate product for a compacted coating (asphalt for a soil product)

The vibration plate stopped and does not move

Turning off the product due to a critically low oil level or its absence

Overheating of equipment: low lubricating properties of oil; clogging or overlapping of air intake holes

Let the vibrating plate cool and eliminate the reasons for overheating

The vibration plate does not work, does not go, does not trim, stalls, smokes

The vibration plate is a building mechanism for performing tamping work. To understand the breakdowns and malfunctions of the vibration plate, you need to know a little about its device. Vibroopers are used when it is required to compact a fresh coating of crushed stone, concrete or sand.

There are two types of vibration stages:

We are repairing vibro.fuels of the following manufacturers: Atlas Copco, Champion, DDE, DIAM, Elitech, Grost, Helmut, Makita, Masalta, Patriot, TSS, ENKOR, VEKTOR, CBU, CALIBER, KRETON, Ammann, Wacker, Bomag, Weber, Dynapac, Termag. Splitstone, Oskar, Enar, Euro Shatal, Batmatic, Mikasa, Dinamic, Masalta.

Vibration stations are operated in difficult conditions and experience heavy loads. This leads to a large wear of parts and mechanisms and the need to carry out repairs. Our service center produces high.quality repair of vibration fuels and other construction equipment in all our specialists constantly undergo training in order to improve their qualifications.

We will analyze the most common breakdowns and malfunctions of vibration fuels.

Далее приводим неисправности виброплит: ATLAS COPCO, Champion, DDE, DIAM, ELITECH, GROST, HELMUT, Makita, MASALTA, PATRIOT, ТСС, ЭНКОР, VEKTOR, Зубр, Калибр, КРАТОН, AMMANN, WACKER, BOMAG, WEBER, DYNAPAC, TREMIX, Splitstone, Oskar, Enar, Euro Shatal, Batmatic, Mikasa, Dinamic, Masalta.

Advantages of a home.made tamping machine

The main advantage of a do.it.yourself vibration plaque is in its low cost and the possibility of high.quality and effective work. Simple design ensures the reliability and durability of the mechanism. In addition, a home.made vibration plate allows:

- Safely perform tamping of any surfaces;

- reduce manual labor when performing work;

- improve the quality of the foundations of pedestrian paths and sites;

- well densify dry cement and semi.dry concrete mixtures when laying them.

The presence of a mechanism for compaction of loose soils and bulk materials will allow you to perform any volume of improvement and external design.

Review of purchased options.

Homemade vibration plate

Factory installations for tamping are a lot. Therefore, some masters prefer to make a vibro.accumulator on their own. This process will require welding skills and a small set of tools.

The advantages of homemade

- Full compliance with the working conditions for which it is made allows you to qualitatively perform the assigned functions.

- The owner chooses what kind of vibrating plate to make: with an electric motor or ICE.

- Everyone is also worried about their own security on their own. Therefore, all the necessary protection systems will be provided and installed.

- The presence of your own device will choose the time and place of work for your circumstances.

Repair of the Vibro.fuel Honda, Masalta, Wacker, Weber and other manufacturers

Engine malfunctions. Basically, engine malfunctions occur due to the incorrect operation of the equipment by workers somehow low qualification of personnel, or insufficient briefing on the rules of operation of the equipment entrusted to him.

The malfunction is not the correct start of the engine. The engine is not correct to “throw” the spark plugs, which leads to its replacement and fuel entering the oil crankcase.

The malfunction is not the correct stop of the engine. The incorrect engine stop leads to fuel entering the oil crankcase. When mixing fuel and oil in the crankcase, oil loses its functions laid down by the manufacturer, which leads to a strong wear of the CPH and KSHM, output of the engine.

Malfunction for the use of oil not intended for a given engine. As if on vibro-stalks there is an air-cooled engine, it is not advisable to use oil with water cooling engines. When using conventional oil in air cooling engines, leads to overheating of the engine and the hair of the piston rings, which leads to increased fuel consumption and oil.

Malfunction of the stove split. Often occurs due to non-careful transportation and loading and loading work, which leads to the replacement of this unit.

Malfunction lack of lubricating fluid in the vibrator or the use of oil not intended for this unit.

Vibration Machine Review | 4 Thing You NEED to Know Before BUYING!

ETO (daily maintenance) is a visual inspection of the vibrating plate for the presence of oil subtexts, checking the oil level in the engine, the condition of the air filter, the condition of shock absorbers, clutch couplings and a drive belt. also checking and broaching all threaded joints.

Then after a long lease: 1. Replacing all lubricating liquids. 2. Replacing the spark plug. 3. Replacing the air filter. four. Replacing drive belts. 5. Clutch replacement (if necessary). 6. Replacement of shock absorbers (if necessary).

Operating recommendations: 1. Oil control. 2. Fuel control in the tank (AI-92). 3. Turn on the ignition. four. Open the fuel valve. 5. Close the fuel damper. 6. Engine start by manual or electric starter. 7. Open the air damper. eight. Move the throttle to the desired engine speed.

Work in mode. 40 minutes. Rest. 20 minutes.

Engine stop: 1. Move the throttle to minimum turnover. 2. Close the fuel valve. 3. Turn off the ignition.

Why is the vibrating plate smoke?

During operation, the vibro.fuel can be encountered with the appearance of smoke from the exhaust system of the vibro.plate engine, which was not previously. Smoke can occur both when the vibration plate is turned on, and during use. Uncharacteristic smoke is an alarming sign that cannot be ignored, because it is most likely a consequence of a particular malfunction in the engine. To answer the question of why the vibro.plate smokes, it is worth considering the types of smoke, t.To the color and nature of the smoke is an indicator of the malfunction.

You should diagnose a breakdown not only by evaluating the color of the smoke, but also parallel phenomena, such as: weather conditions, the moment of smoke, non.standard oil cargo, increased fuel consumption, etc.D. The color of the smoke can be: white, blue, black.

White smoke made of vibro.plate

If white smoke appears while turning on the vibration plate at a low air temperature, then there is no reason for concern. this is a normal phenomenon when warming up a cold engine. This smoke is a steam that is always present in the engine is a standard fuel combustion process. At cold air temperatures, the pair is condensed and becomes visible. The lower the air temperature, the brighter and denser steam. When warming up the engine, pairs gradually disappears, t.Conditions are reduced. Also, steam saturation is affected by air humidity, steam becomes thicker at high humidity.

If the vibration plate smoke with white smoke to heated, it is worth checking whether the moisture on the air filter of the vibrating plate of the engine is in any way. Also, as an option, you can completely drain and pour new fuel, it was possible an increased level of gasoline humidity.

Black smoke of vibro.plate

When black smoke appears, first of all, it is necessary to check whether the air damper is open and whether it is in principle working. Maybe you just forgot to open the air damper after starting.

If everything is in order with the damper, this type of smoke is actually micro particles of soot, which indicates a malfunction of the fuel supply system. This phenomenon is accompanied by increased fuel consumption, unstable engine operation, poor launch.

This situation may occur due to the deterioration of the conditions of combustion of fuel or oversaturation of the fuel-air mixture. There are a number of reasons:

In order to understand why the vibro.plate engine smokes in this color, its complete diagnosis is necessary.

If you do not find the cause in time and do not repair, then serious consequences may occur. Due to the oversaturation of the mixture in the engine, soot in motor oil occurs, the engine is quickly polluted from this, the shift of the piston rings is accelerated. As a result, the filter and the oil channel are polluted, there is also the possibility of burning the valve and piston, soot can get into the oil, thereby increasing its viscosity. These malfunctions complicate the engine operation and accelerate wear, moreover, the engine operation becomes dangerous, and if defects do not eliminate, more serious breakdowns may occur.

Blue or gray

The main reason why the vibro.block or a walk.behind engine is smoke in a blue or blue color is oil entering the cylinder. The color of smoke can vary from thick white to transparent blue.

First of all, you need to check the type of oil, which was poured into a vibro.fuel. Perhaps the oil for two.stroke engines was flooded, which caused increased smoke. Please note that the oil level should not exceed the maximum level, it can also be the reason for the oil entering the cylinder. It is also necessary to recall whether you accidentally tilted a vibrating plate to any side (for example, in the process of incorrect transportation)-it could get into the air filter.

The difference between white smoke and steam is that the steam disperses much faster than smoke. Also, with oil smoke, oil consumption increases. There are several more reasons for the oil in the engine:

The most common reason. There is a wear of piston rings, cylinder sleeves, piston grooves. Due to gaps in the grooves of the piston, a pump effect occurs, which pumps oil into a cylinder. Also, a change in the shape of the rings worsens their properties, forming the gaps. These malfunctions are added to compression loss.

Damage of the jumpers between the grooves of the piston, the “occurrence” of the piston rings

The cause of this malfunction is the detonation or overheating of the engine. As a rule, engines installed on vibration stations are ordinary four.stroke single.cylinder engines with air cooling. In the process of working with a vibration plate, it is imperative to take small breaks, for example, after each hour of work, in order for the engine to cool down. The need for breaks is especially relevant in hot weather, when the air temperature is more than 25 degrees from. The key to the durable work of the vibration plate is the proper run.in the new engine. If you start using a vibration pound without running at full power, you can ruin the engine.

Use of poor.quality oil and untimely maintenance

Is a fairly common cause of oil entering the cylinder. Old oil is burning, from this rings in the grooves lie, losing elasticity.

Acting of the valve rod, oil cap and bushings

These defects are the reason for the engine smoke after warming up, because the heated oil becomes more liquid and easier to penetrates through the gaps.

If there is such a defect, then it is very easy to recognize. Smoke acquires a white. blue hue and occurs during operation. There is practically no compression in the cylinder, a strong black fog can be observed on the candle, possibly in the form of growths.

In any case, when the blue smoke appears from the vibration plate, it is necessary to measure the compression in the engine. If the compression is normal, the chief tractor recommends:

-check the purity of gasoline, if foreign particles are detected, drain the old fuel and season.

Polluted air filter

The contaminated air cleaner limits the flow of air entering the carburetor, which leads to interruptions in the engine operation. To continue the full operation of the engine, the air cleaner must be regularly cleaned.

- Unscrew the nut and remove the air cleaner cover. Unscrew the second nut and remove the filter elements.

- Rinse the spongy filter element using a solution of domestic detergent in warm water. After thoroughly dry it. Drink the filter element with clean engine oil and squeeze its excess.

- Clean the paper filter element with compressed air (directing it from the inside out), or simply knock it several times on a solid surface.

- Collect the air cleaner in the reverse order.

Checking the spark plug

One of the frequent reasons for the impossibility of starting the engine is pollution on the spark plug, or an incorrect gap between its electrodes. To check this, you need:

- Remove the tip of the spark plugs

- Remove the candle with the end key and carefully examine it for the presence of chips and traces of wear.

- Measure the gap between the electrodes and compare it with the nominal (0.7. 0.8 mm). Adjust the gap if necessary, carefully bending the side electrode.

Checking the spark plug

One of the frequent reasons for the impossibility of starting the engine is pollution on the spark plug, or an incorrect gap between its electrodes. To check this, you need:

- Remove the tip of the spark plugs

- Remove the candle with the end key and carefully examine it for the presence of chips and traces of wear.

- Measure the gap between the electrodes and compare it with the nominal (0.7. 0.8 mm). Adjust the gap if necessary, carefully bending the side electrode.

Cleaning the flame arrester

The exhaust system of the engine must also be periodically served. A long absence of service can bring to the burning of the muffler, which will greatly worsen the operational characteristics of the vibration plate.

- Remove the protective casing of the muffler by turning the screws m5.

- Disconnect the flame arrester from the silencer by turning the screw M4.

- Remove carbon deposits from the flame arrester with a wire brush.

- Collect the muffler in the reverse order.

Here are the main repair procedures that require a minimum of the tool and can be conducted outside the service workshop.

Repair of a gasoline unit

Starting the repair of the gasoline internal combustion engine, you must first make sure that the fuel is enough in the non.functioning unit tank, the ignition switch was in the position on the on the side and the air damper was correct. This must be done so as not to disassemble the equipment once again and not waste time in vain.

Most often, ICE problems are caused by the following reasons:

- low oil level or its poor quality, while the engine does not start at all or stops during operation;

- pollution of the air filter, which leads to unstable operation of the motor, loss of power or completely to the impossibility of starting it;

- malfunction of a candle, which causes problems with the start of a gasoline unit or leads to an unstable functioning;

- strong pollution of the elements of the exhaust system (or the burning of the muffler), which affects a number of operational characteristics of the equipment;

- wear of the piston or the lack of proper adjustment of the carburetor, which leads to unstable operation without load or drop in power.

Oil check

If the oil level is lower than the norm, then the engine starts in many modern seal models are blocked by built.in sensors. To check this, they do this:

- Install equipment on an even platform (in a horizontal plane);

- unscrew the lid of the pouring hole;

- insert the probe;

- determine the sufficiency of oil by it.

Vibration fuel oil must be periodically changed due to its pollution: the first time after 20 hours, and all subsequent ones-every 100 hours of continuous operation of the equipment. Lubricants are better to use high quality. The oil should be stored in clean containers.

Cleaning air filter

The air filter is cleaned as follows:

- Remove, unscrewing the nut, the cover of the air cleaner;

- unscrew the next nut and take out the filter elements;

- With warm water with a conventional detergent, the sponge filter is washed, and then it is dried and wetted with engine oil, the excess of which is squeezed;

- With the help of compressed air, clean the filter element of paper;

- Collect an air filter.

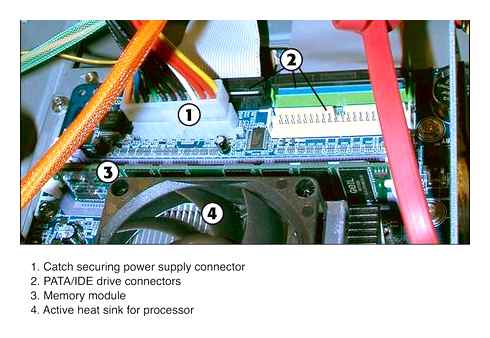

The figure below shows the air filter diagram and its elements.

Checking the spark plug

To check the condition of the spark plug (its pollution, wear, the distance between the electrodes) act as follows:

- Using the end key, remove the candle;

- determine the degree of its wear, as well as the presence of defects, for example, chips;

- compare the size of the gap between the two electrodes with a nominal value of 0.7-0.8 mm, adjusting the distance if necessary;

- If the twisted candle cannot be used further, then they put a new.

Service of the exhaust system

The device of the exhaust system is shown in the diagram below.

The service of the exhaust system is carried out as follows:

- Having promoted the M5 screws, remove the casing;

- To disconnect the silencer and flame arrester, unscrew the M4 screw;

- Using a metal brush, remove carbon pollution;

- If the muffler has not burned out, then the entire knot is assembled.

To reduce the likelihood of damage to gasoline units to a minimum, you need to properly take care of the technique: change oil, filters, candles in time. Before operation, the vibro.fuel with any type of engine should be inspected for external defects, it is also necessary to check the reliability of bolt compounds, the belt stretch. After the work, it is required to clean the unit from various pollutants, for example, soot, dirt, butter. When operating equipment, it is necessary to follow the recommendations set forth in the instructions for it. Simple rules will allow to extend the life of the equipment as much as possible.

In early spring, when the temperature rises above the zero mark, summer cottages and personal plots begin to come to life. Someone is engaged in garden work and preparation for landings, and some started repairs or construction. As a rule, it does not do without excavation: then tamp the path under the tile, then strengthen the bottom in the ditch. Here, a vibrating plate made by yourself and in its own drawing will come to the rescue.

DIY tamping repair

It would be difficult to imagine modern road construction without vibration fuels. They help when laying asphalt and floors, repairing the roadway, are used for soil tamping (from sand to crushed stone), compaction of pits and trenches, and so on. The question arises: how such a small machine is controlled with such a large layer of work? And here is the whole thing, of course, in the device of vibration placers

Road rink (taking into account all its significance for utilities and road services), it cannot always justify certain repair hopes. And this is mainly due to its bulky design and clumsy, while the vibration plate is maneuverable, light and compact. The principle of operation of the vibration plate is also extremely simple

The principle of operation of the vibration plate is also extremely simple.

The market today offers a huge variety of these road assistants and provides the opportunity to choose models for different volumes of work. One.time or reversible, self.propelled or installed on pneumatic drift tractors. unites their common goal, reduced to one word. a seal.

Device and repair of gasoline and electrical vibration fracturing malfunctions

The main malfunctions of the vibration fuel

Vibroophytles. equipment designed for tamping of soil and other bulk substances before laying paving slabs, during the repair and construction of roads, arranging pillows when laying pipelines. Repair of single.extent and reversing vibration stages usually trust professionals, since often the cause of breakdowns can be determined only using diagnostic equipment.

The most frequent breakdowns of vibro.fuel engines

The main element of this equipment is an electric, gasoline or diesel engine, and most of the breakdowns are connected with it. The most popular gasoline and diesel models are due to independence from the power source. Engine repair is recommended to trust professionals.

- Low oil level or its poor quality. It may cause why the vibration plate is not started, the engine is heated, the equipment will start and immediately stalls.

- Polluted air filter. Leads to power loss, unstable engine operation, and even to stop it.

- Fast of candles. Leads to difficulties when starting a gasoline unit or unstable operation.

- Incorrect carburetor adjustment. Leads to unstable functioning without load.

Damage of the vibration node

There are situations when the equipment is turned on, but the vibration node does not work. There are several reasons why the vibrating plate does not trim:

- The leakage of an omentum located on the shaft. The flow of oil leads to the rapid abrasion of the gears and the failure of the entire node. If you do not notice the flow of the oil seal in time, you will have to replace not only the gears, but also the details associated with them.

- Low engine speed. To launch the vibro.bore, it is necessary to increase the number of revolutions.

- Weakening of the drive belt. If the belt is slightly worn, then you can strengthen its stretch. A strongly worn belt is replaced.

- Engine malfunction. With the help of diagnostic tools, they determine the cause and eliminate it.

Why is the vibrating plate smoke?

During operation, uncharacteristic smoke can come out of the exhaust system, the color and type of which will help determine the type of malfunction.

The best total body workout on a vibration plate HANDS DOWN!

- White smoke. If it appears when the equipment is launched at low temperatures, then there are no reasons for concern. it just warms up the cold engine. precisely, this is not smoke, but the steam that disappears when the motor is warmed up. White smoke that appears with a heated engine indicates a moisture entering an air filter or too high fuel humidity.

- Gray (blue, blue) smoke. Indicates the entry of oil into the cylinder. The second reason is to get oil into an air filter with a strong tilt of the unit.

- Black smoke. When such a smoke appears, you should check if the air damper is open. If it is open, then the problem may be in the fuel system.

Other frequent breakdowns

Steel bases usually work several seasons without defects. If small cracks appear, then they are eliminated using a welding machine. In the same way, defects are removed on the handle and engine frame. If the base has cracked and a large crack appeared, then the element is replaced with a new. As a rule, the replacement of the base is accompanied by the replacement of vibro shutters, which are installed between the engine and the working surface.

Another question that may arise during the operation of the unit: “Why is the clutt of vibration plate warm?””. The reason for this may be the excess of engine speed, compared with the value specified in the instructions, or other violations of the operating rules.

The reasons why the direct.flowing plate does not move forward, and models with reverse do not make movements forward/back, can be:

- Lack of fuel;

- absence, low level or poor oil quality;

- belt break;

- overheating that arose due to clogging of air holes, poor quality oil.

Users often ask the question of why the belt is torn. Unfortunately, for rubber belts, this is a common occurrence. The most functional are models in which a steel synchronizing circuit is installed instead of the belt.

The masters of the service center equipped with modern diagnostic and repair equipment will be able to accurately determine the place and causes of the malfunction of a direct.flowing or reverse vibro.plate and qualitatively eliminate the problem.

Vibro.fuel characteristics

Vibroophytes are characterized by the following indicators:

The mass, effort and size of the vibro.fuel characterize the quality of the seal, which is issued by it as a result. The ease of work depends on the power of the motor. the lower the power, the greater the force needs to be applied for ramers.

By mass of the mechanism, all models are divided into:

For different types of work, a mechanism with different mass is suitable. The efficiency of the use of vibro.stalks by 70% depends on the correctness of the selection of its weight. The remaining 30% determines the vibration force, surface size and engine type.

Vibration force. indicator of the power of the shocks transmitted from the vibrator to the plate. The larger this indicator, the more dense materials it will be able to tamp. The size of the working surface is an indicator of pressure per unit of the processed plane. The smaller the working surface, the greater the pressure per unit will create a vibration plate during operation. This ratio coefficient should not exceed the indicator of 0.3. Therefore. the smaller the working surface, the more efficiently the mechanism copes with its task.

It should be noted that working surfaces are also characterized by the type of material used. cast iron or steel. In this context, vibration fuel with a cast.iron base is much more effective, since the area of their working surface is less than that of models with a steel base.

The engine power is no less important. This indicator determines the ability to move on a viscous surface located under the slope. When starting a vibration plate, she herself pulls herself forward, without requiring additional effort. If the power indicator is low, the plate will be buried in the ground and explodes on the lifts. Conclusion: the greater the power of the vibro.fuel engine, the better it will cope with its task and the less effort will make it a person controlled for this.

Repair of an electric motor

Before checking the equipment equipped with an electric engine, the power supply voltage should first check:

- If the electric motor is single-phase, then it should be 220 V, / permissible instructions for deviations from this parameter;

- When a three.phase engine is installed on the unit, a voltage of 380 V is necessary (plus or minus, but within the specified limits).

Check the voltage in the outlet using a multimeter, having previously determined using the instructions on what value its equipment electric motor is designed. The device switch is installed in the desired range. The probes are inserted into the corresponding nests.

Multimeter and similar measuring devices are indispensable when checking electrical equipment. With their help, the presence of breaks in the circuit, as well as regulatory indicators of the resistance of the windings of the electric motor are installed.

The reasons for the problems with the electric motor are presented in the table below, which also contains recommendations for the repair of problems.

| Problems | The reasons | Instructions for correcting problems |

| The electric motor will not start | The start button has broken | It should be replaced |

| Gap of power cord | It is necessary to find the place of the cliff and connect the broken wires, you can also replace the cable | |

| The fork broke | You need to put a new fork | |

| Rupture or burning of windings | You should replace the electric motor | |

| Poor contact or breakthrough of the internal electric circuit | It is required to set the breakdown site, and then tighten the connection or combine the wiring | |

| The electric engine is warming | Overload | You need to make regular pauses in work |

| Bad contact in barn | You need to check the connection, tighten the contacts | |

| The pavers are burned | Replacement of the electric motor | |

| The electric motor suddenly stops (works with jerks) | The presence of poor contact in the electrical circuit | It is required to determine the place of poor conductivity, and then restore it (for example, pulling up bolted contacts) |

| The engine works and the belt does not rotate | Cut the shaft | You need to replace the engine itself or only the rotor |

| The pulley is turning on the shaft | It is necessary to remove the pulley from the engine from the vibrating plate, then check the seats, and then replace the part (or just fix it well) or repair the shaft | |

| The electric motor does not stop the start button | Closing in the control circuit | You should find a closed area and disconnect the wiring |

| The button broke | It is necessary to replace it |

In very rare cases, the electric motor jam. Often the reason for this is associated with bearings. Therefore, they must be periodically lubricated, according to the operational instructions, and with strong wear. replace new ones with new ones.

Repair of a gasoline unit

Starting the repair of the gasoline internal combustion engine, you must first make sure that the fuel is enough in the non.functioning unit tank, the ignition switch was in the position on the on the side and the air damper was correct. This must be done so as not to disassemble the equipment once again and not waste time in vain.

Most often, ICE problems are caused by the following reasons:

- low oil level or its poor quality, while the engine does not start at all or stops during operation;

- pollution of the air filter, which leads to unstable operation of the motor, loss of power or completely to the impossibility of starting it;

- malfunction of a candle, which causes problems with the start of a gasoline unit or leads to an unstable functioning;

- strong pollution of the elements of the exhaust system (or the burning of the muffler), which affects a number of operational characteristics of the equipment;

- wear of the piston or the lack of proper adjustment of the carburetor, which leads to unstable operation without load or drop in power.

To eliminate the problems given in the last paragraph, it is better to contact the specialists of the service center.

Oil check

If the oil level is lower than the norm, then the engine starts in many modern seal models are blocked by built.in sensors. To check this, they do this:

- Install equipment on an even platform (in a horizontal plane);

- unscrew the lid of the pouring hole;

- insert the probe;

- determine the sufficiency of oil by it.

Vibration fuel oil must be periodically changed due to its pollution: the first time after 20 hours, and all subsequent ones-every 100 hours of continuous operation of the equipment. Lubricants are better to use high quality. The oil should be stored in clean containers.

Cleaning air filter

The air filter is cleaned as follows:

- Remove, unscrewing the nut, the cover of the air cleaner;

- unscrew the next nut and take out the filter elements;

- With warm water with a conventional detergent, the sponge filter is washed, and then it is dried and wetted with engine oil, the excess of which is squeezed;

- With the help of compressed air, clean the filter element of paper;

- Collect an air filter.

The figure below shows the air filter diagram and its elements.

Checking the spark plug

To check the condition of the spark plug (its pollution, wear, the distance between the electrodes) act as follows:

- Using the end key, remove the candle;

- determine the degree of its wear, as well as the presence of defects, for example, chips;

- compare the size of the gap between the two electrodes with a nominal value of 0.7-0.8 mm, adjusting the distance if necessary;

- If the twisted candle cannot be used further, then they put a new.

Service of the exhaust system

The device of the exhaust system is shown in the diagram below.

The service of the exhaust system is carried out as follows:

- Having promoted the M5 screws, remove the casing;

- To disconnect the silencer and flame arrester, unscrew the M4 screw;

- Using a metal brush, remove carbon pollution;

- If the muffler has not burned out, then the entire knot is assembled.

If, after checking the probable causes of breakdowns, the equipment works, but does not go forward, then it is better to contact the service center.

To reduce the likelihood of damage to gasoline units to a minimum, you need to properly take care of the technique: change oil, filters, candles in time. Before operation, the vibro.fuel with any type of engine should be inspected for external defects, it is also necessary to check the reliability of bolt compounds, the belt stretch. After the work, it is required to clean the unit from various pollutants, for example, soot, dirt, oil. When operating equipment, it is necessary to follow the recommendations set forth in the instructions for it. Simple rules will allow to extend the life of the equipment as much as possible.

By repairing vibrors, we take into account powerful and other individual features of the repair equipment. In the designs working on the vibrational principle of the action of tamping, both electric and gasoline engines can be involved. This difference involves the use of different workers of algorithms in repair work. The rigidity of the requirements for the work of the employees of our Center service is explained by a high load on the vibroon when performing tamping work.

The device and principle of operation of the vibration focus

The rapid development of the construction sector required a new innovative equipment that could accelerate the implementation of work processes. At the same time, if powerful heavy equipment is used at solid facilities, then on small construction sites or in conditions of limited space its use is unprofitable, and in some cases it is impossible.

Among the large nomenclature of modern construction vehicles and units, a special place is occupied by such a universal and at the same time quite small.sized tools as a vibrational sealing plate (vibration plate).

Purpose and principle of work of vibration pins

In the general case, the tamping vibroopropels are designed for layer-by-layer stabilization of different types of soil by surface vibration-trammeling on the sealing coating. Their use is advisable in hard.to.reach places or in small areas, the area of which does not exceed 1000 m².

As intended, vibro.plate for tamping soils or asphalt are distinguished. The latter equip the irrigation system, the water in which is designed to prevent the stove to stick to asphalt.

Need for soil compaction

The loosen of bulk materials and soils at the beginning of construction greatly facilitates the conduct of earthwork. However, later these qualities begin to play a negative role. This is due to the fact that the structure of the soil, as well as other bulk materials (sand, gravel, crushed stone, clay) consists of fractions, that is, of small solid particles of various sizes, between which water and air gradually accumulate. If the latter are not forcibly removed, then gradually, under the influence of the constructed structures, they themselves “leave” themselves. In this case, the so.called drawdown occurs. the foundation of the structure, walls or road surface are covered with cracks, in trenches, pipes are bursting and t. D. In order to prevent this, soil and/or bulk materials compact, displacing air and moisture from them until the poured materials become evenly dense. In this case, the latter has increased strength and filtration abilities decrease.

Note: The seal is considered to be high.quality if in the structure of the bulk of the air does not exceed 5%.

The sealing of bulk materials can be carried out in different ways, and one of the most effective is considered to roll and tamp. A special massive skating rink or a tram car is used to roll up the soil in large areas, but to obtain the same result, a vibration plate or vibration is used on small sites, which are much smaller in size.

The use of the latter will make it possible to tamp the surface where heavy construction equipment will not be able to drive up or turn around.

The device of the vibration plate

The layout of the vibration plate is not of high complexity and in general it includes in its composition:

In practice, there are a large number of models equipped with additional equipment (transport wheels, a rug for laying paving slabs, protective gloves for the operator, etc.), with the help of which the operation of the vibration plate becomes more comfortable.

Note: If the vibration plate serves for interpretation of asphalt, then the design is supplemented by a water tank.

The main element of this construction machine, it is also its working surface. is a heavy slab with rounded edges, around which the rest of the structure is built. The workplace is made of cast iron or shockproof steel. These materials are less than others as a result of exposure to high loads. The plate has the shape of a rectangle, a length of order 0.3. 0.5 m and width 0.4. 0.7 m. Its mass, as a rule, is in the range from 60 to 150 kg.

The vibrator (vibration engine) consists of one or two debalanced shafts installed in the bearing supports and enclosed in a cylindrical case.

IMPORTANT! The vibration plate with a one vibration engine moves in only one direction. If a double.sized vibrator is provided in the design of the unit, then it has a reverse function.

To the main plate (sole) through the shock absorbers, a motor frame with a motor installed on it is screwed with bolts. The centrifugal clutch is fixed on its shaft, which works at the speed of rotation of the shaft of more than 2000 rpm. A vibrator is installed in the center or on the “nose” of the sole. The rotation from the engine shaft to the executive mechanism of the vibration engine is transmitted using a wedge.shaped belt. Rotating, the shaft of the vibrator’s executive mechanism causes the appearance of centrifugal force, as a result of which the main plate begins to vibrate. In this case, vibration not only increases the parameters of the surface compaction, but also makes the entire car move. It is interesting that the presence of vibration allows one operator to manage even the most difficult aggregate without much difficult.

The working surface of the slab intended for the interpretation of asphalt is smooth. This differs from the slabs designed for tamping gravel and crushed stone. their working surface has special rifting.

As a rule, vibro.plate management is carried out manually. For this, a special pen is provided, which is folded in half during transportation. For the security of the operator, it is equipped with a vibration protection pad.

How the device works?

The principle of action of the vibrating plate is to provide strong pressure of the working stove on the sealing surface. It provides its vibrating massive sole, due to the fact that the kinetic energy of the working mechanisms installed on it is converted into other types of energy. At the same time, vibration leads to an instant increase in the pressure in the contact zone of the working stove with the sealing surface, followed by its rapid decline. Thus, the seal occurs not only due to the force pressure of the heavy slab, but also from the vibration frequency, as well as the speed of the last strike on the processed surface.

Types of vibration fuels and recommendations for their choice

The construction uses a wide variety of vibration stations that may differ from each other:

Gasoline vibration plate. Device, application and characteristics

The durability and reliability of the road surface or the built building, especially the high.altitude, depends on the qualitative preparation of the base. Examples of soil deformation, with the unfair preparation of substrates experiencing long loads, is enough to recall the historical incident. the Pisa tower. One of the criteria for the reliability of the base is a sufficient density of the substrate, the standard values of this condition are achieved by soil compaction with special construction machines. rollers or gasoline vibration places.

Device and design features of gasoline vibration plate

As follows from the name of the machine, the seal is carried out by shock vibration.

The binding of bulk mass is carried out by the vibrations of the eccentric in the debalance driven by the engine. The vibrational energy of the unbalanced part is transmitted to the massive sole of the machine and then to the trim surface.

Supporting plate

The sole of the gasoline vibration plate, as the main working element of the machine, must satisfy the following requirements:

Sufficient mass and sole area allow you to produce high.quality seal, at the same time, these parameters increase the total weight of the mechanism.

The material for the working platform is cast iron or steel. Cast iron with the addition of spherical graphite has a higher degree of elasticity compared to the basic material, and for a longer operation of the highway platform. Steel is used in the form of sheets, with a thickness of 8 mm, or specialized rental.

In case of paving slabs or paving stones on the sole of the gasoline vibration plate, a rubber or polyurethane rug is put on. Such measures will avoid shock loads on the material subject to compaction.

The workplace of the vibration plate has rounded edges that contribute to the smooth movement, and is enhanced by the ribs of stiffness.

Cylindrical vibrator

The main element creating vibration is an eccentric, the principle of its action is like a flywheel. Constructively is a shaft with a shifted center of gravity.

The movement of the flywheel around the circumference creates vertical movements of the tamber shoe up and down. The passage of the flywheel along the lower part of the circle creates the pressure effect, the movement along the upper semicircle forms the movement up and additionally gives the mechanism a small horizontal movement forward.

The movements of the eccentric on the shaft create the main noise effects when operating the machine.

Engine

The engine is driven by the engine. Depending on the power of the engine, the manual vibro can be:

Electric devices are rigidly attached to the energy source, although they have low noise levels and do not pollute the air. The electric vibration plate is more suitable for work in rooms or for landscape work. Can be used in the preparation of cable trenches or road works. Powerful tamping consumes a significant amount of electricity, which is also little acceptable.

Diesel vibrational machines are very powerful, massive and are used in professional construction work related to large areas that are subjected to tamping and requiring significant depth of the material compaction. In heavy winter conditions, the use of diesel fuel can bring inconvenience.

Gasoline vibration plate is a universal and widespread machine in the production of tamping work. Hand gasoline vibration plate is positioned as an inexpensive, mobile and unpretentious car in maintenance. Finds application in landscaping, road construction, laying cables, in the construction of buildings and parking parking lots.

The gasoline engine that is equipped with the unit is 4-stroke, one- or two-cylinder. The most common brands of gasoline, for gas refueling, AI-92 or AI-95. Adding oils to fuel is not required, cooling air. All this together, makes a gasoline vibro.plate the most attractive tool for a wide spectra work on the compaction of bulk materials.

Work characteristics of gasoline vibration pages

The main parameters characterizing the optimal operation of the unit are:

The weight of the unit

The depth of rampant material is directly dependent on the weight of the machine. The larger the weight of the vibration plant, the deeper the compacted layer and higher the productivity of the device. This indicator reduces the number of passes to achieve the design values of the seal.

For laying sidewalks from paving stones or tiles, the weight of the machine, on the contrary, can have a negative effect and lead to coating defects.

Vibrationia

In fact, this parameter shows the value of compressive force (KN), the sole plate. For effective work with large volumes of bulk substances, the high value of the pressure force is welcome. However, for intra.house work or when laying tile sidewalks, this value is limited to one ton of absolute weight (1000 kN).

The area of the base of the vibration plate

The force affecting the processed surface depends on the total area of the shoe of the plate. Vibrations spread throughout the plane, and the larger it is, the less effort per unit area. The optimal ratio of these parameters, the main task of the manufacturer.

Device engine

In difficult conditions of operation of sealing equipment, the most in demand is a reliable and non.capricious engine that does not require exceptional conditions of service. Basin ICE meets these requirements quite well.