How does a tile cutter for mosaics look like?.

Tile cutter. Types, characteristics and features

Work on laying tiles is almost always accompanied by the need to cut this material, cutting shapes with straight and curved lines, round and oval holes.

Taking into consideration that ceramic tile is a hard product, but at the same time it is very fragile and can be compared only to glass, for cutting ceramic tiles the special tools with the appropriate name. tile cutter.

Among its many types, it is difficult to single out any of the best.

We can only talk about the most effective options in any given situation.

Each type of tile cutter is important and deserves its right to exist.

THE TOOL FOR A MOSAIC. MONTOLIT. SIGMA

Disc cutters for mosaics, creating classic and designer panels. The force of the effective leverage of the cutters is concentrated at the points of contact with the material. it guarantees an extremely high cutting force and therefore a precise cut.

MOSAKIT mat in vulcanized rubber for glass and ceramic mosaic, on paper and grid. Placed on the working table of the hand-held tile cutter. The scale supports the tile. Two-sided scale with 0.5 cm increments, centered on the edge of the slab.table. 1 cm grid spacing for precise placement of material in straight and diagonal cuts.

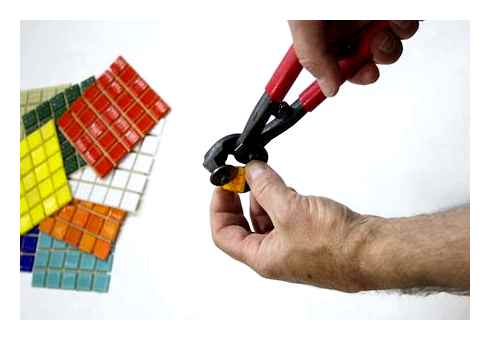

Pliers specifically for ceramic and glass mosaics. The tungsten carbide blade is hard and precise.

Cutting roller Ø 12 mm for vitreous materials. Glass, glazed, enamel mosaic tiles. Suitable for all SIGMA self-cutting tile cutters.

Mosaic cutter set: exchangeable cutting platform for 3L SIGMA block cutters (freehand, 55 cm cutting length, power 1050 kg) and cutting wheel Ø 12 mm for vitrified materials. glass, glazed, enameled mosaic.

Discs for angle grinders CM series ‘SILVER LINE TOP. solid, 10 mm high diamond segment. Maximum clean cut when working with mosaics. Cutting of natural stone, porcelain stoneware, glazed stoneware and glass, as well as slabs of thin porcelain stoneware. Very long lifetime. Low cutting speed, no need to push to speed up!

CPV series ‘SILVER LINE TOP’ machine discs. solid, special shape of the cutting edge. Very clean cut for glass mosaics, glass tiles, glass panels up to 3 cm thick; perfect results for natural stone mosaics. Very long lifetime. Low cutting speed. No pushing to speed up!

Disc cutters 55W2 (improved version of the 55W). Especially designed for professional work with mosaics. Create classic and designer mosaic panels. Also can be very helpful in shaping the right edge line of any extra-hard, stoneware or ka.

special pliers for ceramics in thicknesses up to 15 mm the tungsten carbide blade is extra hard and precise the design of the pliers prevents the blades from touching. This significantly extends the service life of the pliers, maintaining the original precision l.

Special cutters for mosaic tiles. glass and glazed. up to 15 mm thick. Designed for safer cuts and cleaner cuts in fragile materials than ceramic tile cutters Tungsten carbide blade is particularly hard and precise.

Heat-treated forged steel. PVC-coated handles. Designed for enlarging holes, e.g. for plumbing and pipes. Small head for working with small holes. Special design for adjusting the grip to the material thickness. Nickelier.

Why cut tiles

Tile is laid in a variety of ways: vertically, diagonally, with an alternation of tiles of different sizes, and even with the creation of images or ornaments.

The more difficult the laying, the more often the craftsman has to cut the tile to get what he wants.

Well, and to halve the tiles in a diagonal laying is necessary in any case.

TILE NIPPERS FOR MOSAICS | How to Use, Materials to Cut, 5 Tips on Safety, Maintenance

Most often performed with an angle grinder.

For small amounts of work, the cut is done manually with wire cutters.

At home, such work requires a combination of hand and power tools, and the result is not guaranteed.

With what to start laying a mosaic image

Mosaic canvases are not only a fascinating creative process, but also an original way to save. On the background of the steady rise in price of construction materials there is an opportunity to show ingenuity, collecting elements for a picturesque panel from improvised materials. Shards of broken colored tiles helped Gaudi not only to discover new facets of his talent, but also to create famous masterpieces in the Guell Park!

There are several options for choosing a theme for the panel:

Try to see in the colored shards of his theme and color solution, then add a little missing material.

Choose a ready-made broken tile mosaic scheme based on personal preference.

It’s better to create a mosaic of broken tiles on your own sketch, but on the basis of getting acquainted with highly artistic samples.

The picture that inspired it, you can dare to recreate it in a mosaic version, using magnification of images.

Try to repeat the ready-made mosaic masterpiece with your own color solution.

Review the offers for sale of ready-made mosaic tiles, and choose the material that most impressed.

Using ready-made broken material, lay out on any smooth surface an abstract pattern that the imagination prompts.

It is important to have an idea of artistic principles:

- symmetrical paintings are more difficult to lay, but they are better perceived;

- in asymmetry, the larger fragment is placed on the left, and the right-hand placement of large fragments weighs down the image;

- When laying out recognizable outlines and portraits without a stencil, it is important to respect the proportions;

- if there is no artistic taste and creative experience, it is better not to experiment on a prepared surface, but to use a good sketch.

Fragments of broken tiles are also laid in the form of abstract canvases, using color contrasts. But abstraction also lines up with the principle:

However, the most spectacular in a mosaic paintings look large natural elements:

- Birds and animals or fantasy images of them;

- Flowers. sunflowers, daffodils, poppies, irises;

- fish. aquarium, marine, or animated;

- portrait elements. profile of a girl in a hat, carnival mask, languid gaze, recognizable images;

- Landscapes. schematic or highly artistic.

Before you start laying out the mosaic canvas on its permanent place, try to work out the layout on another surface, such as the floor or table. It is important to commensurate the size of the finished work with the surface where the mosaic will be. Try to imagine the finished result with grout between the fragments, you may need to add a pigment of the right shade for a solid pattern. Black filler between large pieces of colored broken tiles will resemble a stained glass window, and white will give a clean and fresh.

In the picture of the future work is better to think through all options, so as not to regret the rush. to remake a mosaic is extremely difficult. If a mosaic with a recognizable image causes difficulty, it is better to start with a simple abstract composition.

Tip: When choosing pieces of tile it is important to make a sorting. better quality fragments are suitable for the central elements and semantic accents, the rest of the battle goes to the edges. Cut pieces on the front side, chipped and defective pieces with cracks in the enamel are good for edges and breaking off missing pieces (filling voids). In the case of tiles for mosaics, adjust the size with cutters. When the finished panel is dry, refresh it with a glass cleaner and wipe it down with a fluffy rag.

Frame strength

Remember that a weak frame will not be able to handle even an average amount of work, and will fail very quickly. Pay attention to the thickness of the metal bed. The stiffness of the base is the first sign of a quality tile cutter. Otherwise, it is possible the appearance of vibration when splitting tiles, and it simply will be spoiled. The sturdier the handle, the more powerful the lever. This is especially important if you work with porcelain tiles.

Length of the tool

The length seems to be the most innocuous part. But it also has its own nuances. You shouldn’t buy a short tile cutter. If you buy it for yourself, don’t save money. Overpay a little, and you’ll have a universal tile cutter, which is suitable for both wall and floor tiles. Also, a roomy tile cutter will be very helpful when laying tiles on the diagonal. There is another way. to cut with an angle grinder. But a lot of dust will be in the room. If the repair is in a new building, it’s okay, but if it’s in a residential house, then it’s not so bad? Think about it in advance.

Smooth action

Almost all high-quality tile cutters have special bearings, which set the necessary smoothness of movement. But if you buy a tile cutter without bearings, be careful, because you can check it only in work or by trusting a famous brand.

Be sure to test the tile cutter, cut a couple of tiles. The sliding must be smooth, the tile must only break along the marked line.

If the tile cutter has proven itself well. feel free to buy. The costs will be recouped during the first work. then the net profit will go.

The main part of the handheld tile cutter is the carbide steel cutting roller. When it becomes blunt, the quality of cutting drops significantly. The roller cannot be resharpened, it can only be replaced. Many tile cutters are equipped with a rotary ruler, with which you can cut tiles at an angle.

Quality branded tile cutters have additional settings that are needed to adjust the thickness of the material. this limits the stroke of the shear key and therefore prevents the bevel from crumbling even in diagonal cuts. However, a good handheld tile cutter is very expensive, so we will not consider how much is a handheld tile cutter of famous brands.

Accessories

Accessories are either built-in or detachable.

- Connecting a vacuum cleaner. this option is most often provided in portable electric models, but also found in stationary ones. Vacuum cleaner attachment is necessary during dry cutting.

The tool is equipped with a screw hole or grooves for connection. In most cases, a domestic vacuum cleaner will not fit. the size of the hole and the shape of mounts are adapted to the technique of a particular manufacturer.

- Angle stop. allows you to cut the tile at a given angle without marking. The common variant is adapted to a 45-degree angle, but in stationary models this range varies from 0 to 45 degrees.

Threshold stop with scale. In addition to the angle fence, electric models have a parallel stop of similar functionality.

- Side platform. creates additional support for wide tiles. Mostly found in electric stationary models, it is attached to the side. Without this accessory, the tile is unstable.

When you need to cut a thin piece, you have to support it with your hands for maximum stability. No need for manual support with the platform.

Optional accessories: transport rollers, folding legs or carrying bags.

Tips for using a tile cutter

When working with a construction tool such as a tile cutter, you need to follow some rules to avoid the possibility of injury.

Splinters that form during work can damage the eyes, so protective goggles should be used. You should not bring your hands too close to the cutting tool. Be especially careful when using electric power tools.

Electric tile cutters do not tolerate high humidity. It is important not to overload the tile cutter by trying to cut very quickly or very thick tiles. Through this motor can overheat or split tiles.

Particular attention should be paid to the cable of electrical equipment. it must not interfere underfoot, twist or kink.

Pliers for mosaic

The mosaic cutter, or the mosaic pliers, are used for straight cutting of mosaic tiles. Hold the cutter in your cutting hand, with the other hand hold the mosaic as still as possible with your thumb, index finger and middle finger. Place the mosaic between the cutting surfaces of the cutters. The tile and the cutter should not overlap completely, the pliers should protrude about halfway up the tile.

The direction of the break is set by turning the head of the cutters. To increase the cutting force, hold the cutters closer to the ends of the handles. Some practice is required to obtain a quality cut.

Handheld tile cutter

Manual tile cutters have the shape of pliers, on one edge of which is fixed a sharp tip, made in the form of a sharpened roller of hard metal. Sometimes there are models with artificial diamond. The principle of working with such a tool is quite simple. It is applied almost like an ordinary glass cutter. This tiler’s equipment is the cheapest and requires a certain skill to work.

To cut an even piece of tile it is necessary to draw a line on it for the trimmer of the future cut. A ruler, rule, level or other tile is then applied to the line. The main thing is that it should be an even object that can serve as a guide. Then a manual tile cutter is taken and a cutting edge is drawn along the line with strong pressure from one edge to the second. The movement is on itself. This is done on the face of the tile. After that it is necessary to put a metal bar under the tile along the line and press the edges to be separated. As a result the tile will break off on the contour of the depression made by the tile cutter.

The tool has jaws similar to those on pliers. They are necessary if a narrow strip of tile edge needs to be cut, or if corners need to be rounded. As a result, it is possible to adjust the shape of the line for the trimmer to fit the pipe. In this case, the jaws grab a part of the tile and the tool is turned out, breaking off the pieces. Take literally 3-5 mm of tile and tear off. The desired shape can be created as a result. Please note that when working with sponges, the edge of the tile is uneven and looks sloppy. This will require additional sanding if it is noticeable. If the surface is concealed, for example, under a bath or behind a toilet bowl, it can be left as is.

Such a tool can work only with fairly thin tiles. It can be chosen in those cases where the laying is carried out on the walls. The porcelain flooring is rather thick, that’s why the cutting line left by such a tool sometimes isn’t enough for the accurate breakage. As a result, the porcelain tile breaks off incorrectly. Cutting range of the hand-held tool is up to 8 mm. Thicker material will be rejected.

If we consider the advantages that the manual tile cutter has, we can note:

- Low price.

- Compact and lightweight.

- The ability to create rounded cuts.

- No noise and dust.

- The ability to work with tiles of any area.

This tool also has disadvantages. These can include:

- Required skill.

- Uneven edges when processing roundings.

- High reject rate.

- High time consumption for each cut.

- Impossible to work with thick material.

Mechanical tile cutters

Mechanical tile cutters are more advanced. They are already classified as manual machine tools. Such installation is a platform for laying tiles with a carriage and lever. The same wheel on the end of the lever as in a hand-held tool. Tiles are laid at the place of the cut under the line for the trimmer of the lever stroke. After that, the operator takes hold of the lever and leads it towards himself. At the same time, the cutting part of the tool fits tightly to the surface and makes a rather deep plunge. To ensure a neat cut of the material it is necessary to lay the tile with the face upwards, so that the roller moves along the glaze. After drawing the line, when the handle with the roller reaches the end, it is necessary to push it, which creates a mechanical impact and breaks the tile into two parts.

Mosaics 101: How To Cut Tiles For Mosaics

This equipment does not create noise and dust, as well as a manual tile cutter. Thanks to this, it can be used to make repairs really quiet. For ease of operation, such machines are usually screwed to a normal table or stool with self-tapping screws. For this purpose, manufacturers provide special holes on the legs.

The weight of such equipment can range from 2 to 9 kg. There is also a difference in the maximum thickness of tiles that can be processed with it. These machines are versatile because they can work with most materials, whether they are thin wall tiles or thick floor tiles. The only limitations are in terms of width and height. This is limited by the design features of the tool. For really big tiles you need a big, heavy tile cutter, because it just won’t fit on a small one. Do not buy big models right away, either. They are expensive, heavy, and bulky, and will be less convenient when working with the bulk of materials.

Considering the positive aspects of mechanical tile cutters can be noted:

- No noise and dust.

- High quality of cut.

- Low defect rate.

- A wide range of material thicknesses.

- High throughput.

- Practically perfect precision.

- No need to draw the cutting line.

There are also disadvantages with this tool:

- The possibility of creating only an even cut.

- Limitation in terms of tile size.

- The appearance of backlash over time.

- The need for periodic maintenance.

Periodically, such tile cutters need to replace the cutting roller. They can be found on sale, so there are no problems with it, although it is necessary to devote some time to search and installation. When choosing such a tool, you should keep in mind that it can only cut a straight line for the trimmer from one end of the tile to the other. If the material needs to be L-shaped, to make a round hole for a pipe or to round an angle, then mechanical tile cutters are powerless in this case.