How to connect a screwdriver from charging

with power supply inside

The popularity of these units is due to the low price. For domestic use, a unit with less functionality is suitable. The charger must meet the requirement for fast current load and charge rate.

Note. To start charging the screwdriver, you need to create a charging voltage of the screwdriver of the power supply at the output greater than the battery indicator of the device.

The operation of analog chargers with a power supply is extremely simple. The use of such a device is carried out as a stabilizer. In practice, it is not at all important what type of battery is used.

Cordless screwdrivers are popular with those who plan to use them only for household chores. A very important point is knowledge of the features of repairing units in the event of a breakdown. A power supply of this type can be assembled with your own hands. The screwdriver charging circuits are soldered on a universal board. The best device for dissipating heat is a 20 cm² copper radiator.

Note. The stabilizer is used in the work on the principle of compensation. Excess energy is removed in the form of heat.

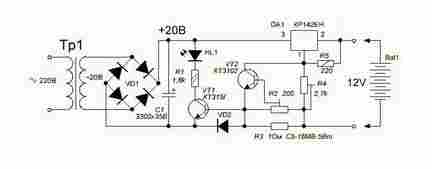

The output transformer provides the generation of an alternating voltage for charging the screwdriver to decrease from 220 V to 20 V. The calculation of the power of the transformer takes place according to the voltage current at the output of the charger. The diode bridge organizes the rectification of the alternating electric current, after which it becomes pulsating. Such a nuance, however, has a negative impact on the operation of the circuits. The ripple is smoothed by a filter capacitor. Chip KR 142EN is used as a stabilizer. To create a voltage of 12 V, you need to use a microcircuit with an index of 8B. also, resistors are used. These types of units operate without a process automation mode. To control the charge, you can assemble a simple circuit on the VT1 transistor. The circuit has a VD2 diode. When the charge voltage is reached, the charging indicator of the screwdriver goes out.

Power Supply

Situations when the drill is working and the charger is broken are not uncommon. There are plenty of ways to solve the problem, but due to the fact that the parts are toxic, not everyone wants to deal with them. To continue the work of the screwdriver, you must connect

To continue working with the screwdriver, you must connect the outdoor screwdriver charging unit.

14.4V batteries in Chinese models allow the use of a car battery. Another option for solving the problem would be a transformer with an output voltage of 15-17 V. All the necessary parts are quite affordable. You will need a diode bridge and a thermostat. There is no need to purchase a stabilizer.

Analog chargers for the screwdriver

Pulse charging for screwdriver

Professional use requires the use of tools that are ready to work for a long period of time without recharging. High functionality determines the corresponding cost of devices, they cannot be cheap. The complete set of such units provides for the presence of 2 batteries.

The impulse circuit of the screwdriver charging unit has an intelligent control circuit, which in turn provides one hundred percent charging in just 1 hour. Among the positive qualities of these devices, it should be noted their small size, high charge current, and the presence of a protection system. Considering these points, the circuit of such a charger is rather complicated. Those who cannot afford such devices can build a charger on their own. Thus, you can save 2 times.

Chargers for cordless nickel-cadmium screwdrivers are equipped with a third signaling contact. The assembly diagram of the unit on the MAX713 is the most commonly used. The output voltage is 25 V at constant current.

The charging has several smart functions. After checking the voltage level, the charge acceleration mode is started, which makes it possible to prevent the memory effect. A full charge is completed after 1.5 hours. Such a scheme makes it possible to select the type of battery and the charging force.

with external power supply

The circuit of such a charger is simple. The complete set includes a power supply unit and a charger. The screwdriver charging unit circuit has a standard package: transformer, diode bridge, capacitor filter, rectifier. Outputs 18 V.

It is controlled by a small board that is the size of a matchbox. Such devices do not have a heat sink system, which affects the service life. This unit becomes unusable very quickly.

- Get a power source. If the factory unit is in working order, you can organize an elementary control scheme. In the event of a malfunction of the entire kit, you can use a laptop charger. At the output you will get the required 18 V.

- Collect wiring diagrams. Parts can be removed from old household appliances.

- Install an 18 V stabilizer at the input. The control circuit for charging the battery of a screwdriver drill, operates on a KT817 transistor. To enhance the work, install the KT818 transistor, which is equipped with a heat sink for heat dissipation. Depending on the charging current, it can dissipate up to 10 watts. The radiator power must have an area of 30. 40 cm².

Important! Analog units have one significant drawback. a long period of full charge. This moment is not critical for home use screwdrivers.

Charging for a screwdriver: device, types and how to do it yourself. features of the charging unit circuits. Video and Photo

Drill and cordless screwdriver. an indispensable tool in repair work. This electric tool is powered by an AC outlet or a battery. Battery-powered drill type requires the purchase of a charging device.

Often, manufacturers produce such units in a set.

Charging for a screwdriver, like any other technique, fails over time, in order to extend the service life and prevent troubles in its operation, you should study the instructions for use.

Inverter chargers for screwdriver

They work according to a different principle. They use the conversion of the input voltage into an electric high-frequency charging current of the screwdriver. This method of operation makes it possible to use small transformers that operate with high power ratings. Inverter chargers, being much smaller, produce significant amounts of electric current for charging. The time taken to recharge the battery is reduced to 1 hour or less.

Types of chargers for a screwdriver

Convenient screwdriver from the network: features of use

The cordless cordless screwdriver is a great companion in your home. Almost everyone who he has never let down can agree with this. Those who stopped working halfway have a completely different opinion. This tool will help you always and everywhere, but exactly until the time the battery is discharged. over, the quantity in it is limited. In moments of idleness, the battery can also deteriorate. Batteries usually last no more than three years. When this time expires, it has to be changed or sent to the museum of obsolete things. The situation is possible if you convert the screwdriver into a network one. There are enough ways to do this.

The power supply unit of the device provides the function of changing alternating current with a voltage of 220 V. Standard screwdrivers consume a constant current, with a nominal value in the range of 9-18V. In this regard, connection to the network is carried out subject to the use of an electronic transformer. For these purposes, products of the Toshibra and Feron brands are most suitable.

In order for the screwdriver to be comfortable and practical, it must be carefully looked after.

Mains transformers of these brands are of high quality and reliable in operation. In addition, they are quite compact, lightweight, and do not complicate the work with the tool. Their load characteristics are close to those required for a standard screwdriver. In their design there are 2 input and output wires, which allows you to supply power to halogen lamps and other types of electricity consumers with a voltage of 12V. However, to use the converted device, you need to adhere to some rules.

Here they are:

- Let the appliance rest for 5 minutes every 20;

- Fix the cable at the elbow with your hand so that it does not interfere with the work;

- Clean the power supply from dust;

- Do not use too many extension cords;

- Do not use the device without grounding;

- It is forbidden to use a converted device for work at height.

Before each start of work with the converted device, make sure that it is working properly.

How to convert a battery device to a screwdriver from a 220 volt network

Today the screwdriver belongs to the devices that we very often use in everyday life. It is also irreplaceable in production. This device is suitable for a variety of electrical and construction work. With its help, furniture and other items are assembled, the design of which requires threaded connections.

The cordless screwdriver is compact and portable. But not everyone is happy with these advantages, because the device quickly runs out of battery, and you have to interrupt work halfway. Therefore, many owners of this tool are interested in the question of how you can convert a screwdriver with a battery to a network.

In order to convert the battery device to a cordless screwdriver, it is necessary to prepare materials and tools for work in advance.

The reason for this decision is also the fact that when the device is not used for a long time, the battery is discharged on its own, which leads to a breakdown of the screwdriver due to the destruction of some elements. It is impossible to repair a failed battery, and it is not always possible to purchase a new one. Often, component parts can only be purchased from the official representatives of the manufacturer. Accordingly, the cost of a new battery will be almost equal to the cost of a new screwdriver. Therefore, some craftsmen come to the decision to turn the screwdriver into a network.

Materials and tools required for this:

- Charger from this screwdriver;

- His native battery;

- Soft stranded electrical cable;

- Soldering iron and solder;

- Insulating tape;

- Acid.

First, you need to solder the loose ends of the cable to the terminals of the charger. You need to know that copper wires of a cable with brass contacts can only be soldered after they have been treated with acid. Experts recommend using special solder, but sometimes the simplest methods are used in the form of acid treatment.

Converting a screwdriver to a network using laptop charging

In the event of a battery failure, a household screwdriver can be switched to mains power by making some changes to its design. This does not require a lot of expenditure of finance, time and effort. The positive nuances of this transformation are obvious: you do not need to constantly charge the battery, and at the same time, the forced downtime will go away. After all, the shortest duration for charging the device is more than 3 hours.

However, when deciding to perform such a transformation with your screwdriver, you should understand that from now on you will need an alternating current to work with it. You will no longer be able to use it away from communications.

If you need to connect the screwdriver to the network, you can use the charger from an old laptop. It has similar characteristics to a screwdriver, and it can be easily found in every home or workshop. But, nevertheless, check what output voltage is shown for your charging. In this case, chargers for 12-19V are suitable.

Using a laptop charger, you can convert a screwdriver to a network

Scheme of your actions:

- We take out unusable batteries from a failed battery pack.

- We take charge from the laptop.

- Cut off the connector and strip the wires from insulation.

- We solder the bare wires or wrap them with electrical tape.

- We make an outlet for the wire in the case.

- Assembling the structure.

This manipulation will allow you to use the screwdriver at any moment, and without stopping for charging.

How to convert a cordless screwdriver to a network: powered from a 220 volt network, DIY alteration

You can extend the life of a cordless screwdriver if you convert it to a network one. Those who have used a cordless screwdriver at least once could not help but appreciate its convenience. Without getting tangled in the wires, at any time you can penetrate the device into hard-to-reach niches, bring it to the country house, or take it out into the street and patch up the playground. But all the advantages of such a device are good until the battery is discharged.

How to convert a cordless screwdriver to a network: powered from a 220 volt network, DIY alteration

Home »How to convert a cordless screwdriver to the mains: powered from a 220 volt network, DIY alteration

- How to convert a battery device to a screwdriver from a 220 volt network

- Why do you need to remodel a mains-powered screwdriver

- Converting a screwdriver to a network using laptop charging

- Convenient screwdriver from the network: features of use

- How to make a screwdriver from the network

Why do you need to remodel a mains-powered screwdriver

In order for you to be able to use a screwdriver even in the most inaccessible places without unnecessary wires, at any time, the mobile screwdriver is converted to a network.

To carry out such a procedure is not so difficult as it seems at first glance. With the appropriate skills and all the necessary components, this process will take a little time.

It is difficult to remake a cordless screwdriver, so you can ask a professional for help

Methods for converting a cordless screwdriver into a network vary in complexity. One of them. powering the charging from a laptop practically does not require knowledge and skills. To mount a computer power supply, you need to know how to handle a soldering iron, and to repurpose a Chinese adapter, you need to know how to handle a measuring device. In addition, there are several other methods for converting a cordless screwdriver directly into a network.

Namely:

- Using a power supply device from a personal computer instead of a battery;

- Giving new life to the car battery;

- Using, as source, a power supply from halogen lamps;

- By connecting the Chinese 24V power supply board.

For brainy craftsmen, it is not difficult to perform such manipulations. If you are not confident in your abilities, then it is better not to risk it and seek the help of a knowledgeable specialist.

How to make a screwdriver from the network

When the batteries stop working due to the fact that they have simply outlived their life, many begin to wonder how they can fix the situation and remake their old cordless screwdriver into the network with their own hands. After all, it is no longer possible to repair a battery with a destroyed element, and the cost of a new one is almost equal to the purchase of a new screwdriver. But zealous and skillful owners came up with a way out. to power the screwdriver from the mains. Some were even able to invent a device that works simultaneously from the mains and from the battery. But it’s better not to do it.

The kitchen is one of the most popular and visited rooms in an apartment and house. She is the place where the whole family, all her generations, gathers. Can…

In interior design, LED backlighting has become widespread, because with its help certain zones and decor elements are highlighted, as well as.

When planning repair work in an apartment or at one of the stages of their implementation, the question arises of the installation of electrical wiring. If you decide that.

DIY screwdriver alteration

There are enough craftsmen in everyday life of the household, there are many ways how to convert a screwdriver to mains power. It is enough to provide the required voltage for the electric drive of the device.

Disassembled cordless screwdriver

In some cases, for alteration, it is enough to use the charger from the kit, it is available, because supplied complete with a screwdriver. It is quite simple to remake such a structure, it is enough to disassemble the screwdriver, connect the output contacts on the charger with the drive wires. The voltage produced by the charger after the alteration corresponds to the technical characteristics of the drive, there is no need to worry about the safety of the electrical part. It is also worth noting that there is no need to disassemble the device completely. only the wires designated for use need to be connected. A significant drawback is the size of the charger, it is not convenient to constantly move it during work and causes discomfort.

The power supply of the screwdriver can be achieved by several types of blocks. The case accommodates some of them, the rest are outside.

There are many ways to alter a cordless screwdriver, all have pros and cons.

- In the case of the old battery, a place is organized for the finished power supply unit. The alteration is simple, no intervention in the electrical circuit is required, it is enough to carefully perform the work, to achieve a perfect appearance. The disadvantages are the time spent looking for a block with the appropriate voltage and size. Also, small devices usually heat up in an enclosed space, it is necessary to provide the device with ventilation by making holes in the case.

- Installing a homemade energy source is a more complex solution, it requires finding the necessary radio parts and understanding the circuit. The advantages of this method of alteration are low financial costs, no losses when using a low voltage cable, no changes in the appearance of the device.

- An external power supply unit can be used when working in one place, since the device’s mobility and compactness are lost. There are also costs associated with finding a suitable voltage for the electric drive of the screwdriver.

- The most common external type device is a computer power supply. The advantages are that it is easy to find it on disassembly for a reasonable price, there are no complicated rework processes. However, the bulky design will not be to everyone’s taste.

Replacing old elements

When purchasing new battery cells in radio components, it is necessary to check their capacity and voltage on the spot.

In case of improper storage, the batteries lose their capacity, do not meet the declared characteristics.

- Unscrew the screws securing the case, remove the cover and the old battery cells.

- Place new cells, soldered together, into the battery case.

- Assemble in the reverse order, after alteration try the work.

When soldering, you must act quickly, otherwise overheating of the battery can cause an unusable condition due to temperature changes.

Homemade power supply

When working with a soldering iron, it is necessary to check the connection to the network of the battery cells and the self-made unit, if there is a connection, all power sources must be disconnected for safe operation.

Alteration work is carried out step by step, to obtain the result you need a little experience when soldering and installing boards:

- Dismantling and dismantling the old battery case;

- In accordance with the diagram, install the elements on the circuit board, solder the contacts and connections.

- After soldering, check the output voltage with a multimeter.

- Assemble the board to the battery case.

- Connect appropriate wires to the instrument’s low voltage outputs.

- Check operation by connecting the converted device to the network.

Connecting to an external battery

An external battery source can be of increased capacity, it is necessary to select a cell suitable for voltage. The battery is mainly used from an uninterruptible power supply. Alteration is not difficult, does not require large financial costs.

For alteration, you need a wire with a cross section of at least 2.5 mm, up to 2 meters long. It is necessary to disassemble the tool, remove the old battery cells, connect the wire to the terminals. Make a neat hole for the power cord, assemble a converted screwdriver and try it out at work.

How to remake a cordless screwdriver

The cordless screwdriver is used everywhere, both in the household and in small industries. Mobility and autonomy allow you to perform work away from the electrical network for a certain time. The battery has a certain number of charge cycles, after which it is not suitable for further use. There are several reasons, the battery is a very capricious element that breaks down even if not properly stored and inactive. The high price of a screwdriver prompts you to learn how to convert a cordless screwdriver into a network.

Connecting the screwdriver to the charger

It is necessary to understand that at low voltage there are losses in the cable, therefore, it must have a cross-section of at least 2.5 mm, and a length of no more than 1.5 meters. In order to figure out whether it is possible to connect a screwdriver to the charger, you need to perform a number of actions.

The sequence of alteration for power supply from the charger:

- Solder and redo the wires to the charger, usually the contacts are located in a conspicuous place, one is responsible for the plus, the second for the mass. When working, the charger must be disconnected from the network.

- Then you need to disassemble the unusable battery, dismantle the old elements;

- A hole is drilled in the case for the cable, for a tight connection, the cable is wrapped with electrical tape or fixed with a shrink tape.

- For a balanced weight, a piece of dense wood or rubber must be placed in the remaining space, this will contribute to a competent weight distribution and the hand will not get tired during work.

- The final step is to solder the wires to the power supply of the electric drive, assemble the body of the power tool after alteration.

How to power a screwdriver while maintaining its autonomy

There are situations when you have to work in the absence of electricity. Powering a screwdriver without a 220 network is possible in several available ways. In such cases, if the battery of the device is faulty, and alteration from the mains is impossible, there are several ways to activate the wrench:

- Replace the battery cells inside the battery with new ones purchased from radio parts.

- Using an external rechargeable power source such as a UPS battery.

- Connected and powered by car battery.

Ryobi 12V Cordless Drill Review Ryobi Cordless Screwdriver

It is important to remember that any alteration requires technical skills and safety.

Advantages and disadvantages

By supplying AC power to the instrument, you will get the following benefits:

- You will not need to constantly charge the batteries, which is important during long working hours.

- You don’t have to think about battery self-discharge, which is important for long-term storage.

- You will provide constant torque, which is important when working for a long time.

However, by turning your instrument into a networked one, you are “tied” to the mains, which may be critical in the future.

How to connect a screwdriver from a charger with your own hands

The versatility and autonomy of the screwdriver determine its popularity among professional finishers and home craftsmen. However, the autonomy of this tool also has a serious drawback. As soon as the battery breaks down or is discharged, it becomes impossible to continue working. In order for you to solve this problem, we will tell you how to connect the screwdriver from the charger.

Materials and accessories

To convert the instrument to the network, you will need:

- The screwdriver charger you used to charge the battery.

- Stranded electrical cable.

- Broken down battery.

- Soldering iron.

- Solder.

- Soldering acid.

- Insulating tape.

Procedure

To turn an autonomous screwdriver into a network one, you need to adhere to the following algorithm of actions:

- It is necessary to solder the stranded electrical wire to the charging contacts. This requires soldering acid to serve as a connector. Treat the terminals of the charger with acid, then solder the wires of the electric wire to the contacts. Not only the functioning of the tool, but also its reliability in operation depends on the quality performance of this stage.

- Redesign the old battery. It is necessary to disassemble it and delete its contents. When disassembling batteries, use protective equipment and do not throw batteries in the trash. To disassemble, follow these steps:

- Unscrew the screws on the bottom battery cover.

- Remove the defective Nickel-Cadmium batteries.

- Separate them from the connector pins by snapping off the plastic latch.

- Place a weight in the battery housing to act as a counterweight and facilitate further operation of the tool.

When reworking a screwdriver, it is important to observe the polarity, as a mistake will cause the tool spindle to turn in the opposite direction. If this happens, then you can not redo all the actions from the beginning, but solve the problem using the switch.

How long does it take to charge the screwdriver

The indicator is individual. It varies from 30 minutes to 7 hours and depends on the capacity. Usually the time is written in the manuals for use.

Most chargers are equipped with an indication, so you can see how many percent are left until the end of the charge.

Checking the battery status with a multimeter

A device like STHT0-77364 can help you troubleshoot various electrical components, including screwdriver batteries. It is best paired with other testers to achieve validity. This allows you to check the indicators and calculate the error.

Note: Before you start measuring, you need to make sure that the multimeter itself is working. To do this, you just need to connect it to an outlet along with another similar device and check the readings.

Screwdriver battery device

The main components of power tool batteries:

- the case on which the contacts are located;

- thermistor, which is needed to protect against overheating (not all models have);

- battery.

The main types of batteries and their features:

- Nickel-cadmium. they are cheaper than others, they are lightweight. The downside is the memory effect. They need to be discharged to zero and charged to the end. If this is not done, the capacity will decrease.

- Nickel metal hydride. This type has a less pronounced memory effect, therefore, such devices are more expensive. If the Ni-MH battery is idle for more than 30 days, a full recharge is required.

- Lithium-ion. One of the most popular types. They do not work well in the cold: they discharge faster, and with regular use and storage at subzero temperatures, their service life is reduced. But otherwise, such batteries are better than others. The high cost of Li-Ion is fully justified by the speed of charging and impressive capacity, as well as the absence of the aforementioned memory effect.

Car charger

It is not necessary to use this method all the time due to the mismatch of the parameters. A car charger is suitable if it is equipped with voltage and voltage regulation elements. You just need to set the indicators correctly: the current is set as 0.5-0.1 of the total capacity of the battery.

How to properly charge a screwdriver battery: 3 best ways to charge

This article explains how best to handle the cordless screwdriver in terms of charging and storage. The manual also tells you how you can recharge your power tool without the supplied charger.

The nuances of charging various types of batteries

Most of the features that need to be taken into account are described in the first section. Here. about how long the power tool should be kept on charge.

Battery Storage Tips

In order for the battery to serve for a long time, it is necessary to store it correctly:

- Do not leave the battery in the instrument.

- The place must be dry. Dampness negatively affects battery components.

- Avoid sudden changes in temperature.

These were general requirements, details are in the table.

Connecting Power Bank to laptop via USB

Many powerbank users think that this device can be connected to a laptop via a USB cable. This is indeed possible, provided that you have the latest USB 3.1 port on your laptop. This type of connection also has another name. Type C.

If your laptop does not have the above connection type on board, but only USB 2.0 and 3.0, then you will not be able to charge the laptop through the “USB cable” under any circumstances. The reason for this is quite simple: ports 2.0 / 3.0 have a voltage transfer of only 4.5 volts, for a tablet and a smartphone this power can be suitable, and to charge a laptop at least 30, and best of all. 50 volts and above.

Charge from a universal portable battery

To charge a laptop from a Power Bank, you need to know how to properly “interact” with a portable device. This is quite an important point to consider before charging your laptop. So, the power bank must be charged up to 100 percent before using it on a laptop. If your device was recently purchased, it is worth fully charging and discharging it for optimal battery performance in the future.

If the device has not been charged to 100 percent, then there is no particular point in trying to charge the laptop, because it will be discharged much earlier than the laptop battery is full. An exception to this rule will be power banks with a battery capacity of 20,000 mAh and above.

How to choose a Power Bank to charge your laptop

To understand the question of whether it is possible to charge a laptop from Power Bank, you should make the right choice when buying it. When buying a mobile charger, pay attention to original devices with high-quality rechargeable batteries from popular manufacturers.

As a rule, low quality batteries are found on Chinese counterfeits. At the same time, the manufacturers of such devices promise the consumer a capacity of 20,000 mAh, but in reality, the promised volume available to the user is not observed. Accordingly, the output current on such a device will be low and will definitely not be enough to charge the laptop. By the way, connecting such a Power Bank to a PC will be very problematic.

The average laptop has a battery with a capacity of 10,000 milliampere-hours, so for the effective use of a portable charger either the same capacity or slightly less is necessary. This will charge your laptop, if not 100 percent, then at least 70-80 percent, which is a fairly good result.

Efficient laptop charging with Power Bank

Considering the efficiency of charging a laptop from a portable battery, we can confidently say that this method is very good. It makes it easier to use a laptop without access to the mains electricity.

Just imagine how pleasant it is to use a laptop at work or when moving to another city without a power supply. The battery of your laptop plus the capacity of the portable battery is very convenient. This approach will provide you in the process of using a laptop PC about 5-8 hours of operating the device without being connected to a power source.

Is it possible to charge a laptop from Power Bank

A laptop is a convenient portable device that we can take with us both to work and when traveling. But the problem lies directly in the charge of the battery, the volume of which is enough for 3-4 hours at best. When asked if a laptop can be charged from Power Bank, the unequivocal answer is yes! Technologies are improving every year, and now no one will be surprised at the creation of a portable charger (Power Bank), which can neutralize the lack of a nearby power source, which solves many problems for the laptop user.

It should be noted that not every such device can become your faithful assistant when charging your laptop. To do this, the Power Bank must have the necessary characteristics or be specialized for a laptop charge. Let’s figure out how to charge a laptop via Power Bank.

Can I charge my laptop with Power Bank? Technique for charging a laptop using a power bank device

Power Bank is a universal portable charger with which you can recharge your smartphone or gadget from anywhere. Thanks to this invention, the problem of restoring the charge of a mobile device is easily solved. Can I charge my laptop with Power Bank? This question still arises for many people. The article will discuss in detail the solution to the problem of the possibility of charging a laptop using a portable Power Bank charger.

How to connect a power bank to a laptop correctly

To find out how to connect the Power Bank to a laptop, you should take into account the above requirements for the portable battery accessory and your personal computer, as well as find out what ports for connecting various devices are available on your laptop.

Based on the foregoing, the question arises: how to connect the Power Bank to a laptop if you are not the owner of a laptop with a Type C 3.1 port available on it? The answer to this question is this: subject to the necessary characteristics of your charger, you need an adapter from the power bank to the connector for charging the laptop.

It is unlikely that the adapter you need will be included with the charger. it should be purchased separately. If you have a suitable adapter for a laptop Power Bank, then from port 2A by means of a cable it must be connected to the power connector on the laptop.

Required Power Bank Specifications for Laptop Charging

Often, owners of a portable charger wonder how to charge a laptop using the Power Bank. To do this, he must have the characteristics that will be described below.

To charge, the device must have an output voltage of 18 to 20 volts and a rated current of two amperes. Not all portable chargers have these parameters. As a rule, the exception is made by Chinese fakes of popular models and manufacturers of power banks.

In order to accurately select a device for charging a laptop, you should pay attention to the following things:

- The presence on the case of ports for connecting a USB cable in 1A and 2A. The letter (A) following the number means the amperage that this port gives at the output. They can also be used simultaneously, and the figure, respectively, indicates the number of Amperes.

- For comfortable operation of the charger and laptop, the power bank must have a storage battery capacity of at least 10,000 milliampere-hours (mAh).

- The Power Bank must have a cable for charging a laptop with a certain size, so pay attention to the accessories of the adapters: they must be suitable for the device you want to charge. Otherwise, it will not be possible to connect even a charger that is appropriate in all respects to a laptop.

At the end of the description of the required characteristics of a Power Bank for charging a laptop, it is worth noting that there are specialized chargers with all the above characteristics and the required adapters. When choosing a power bank, pay attention to them.

Is it possible to connect the screwdriver directly to the charger

The screwdriver is convenient for its ubiquity. independence from limiting wires makes it possible to wade into hard-to-reach areas. A set of two power modules allows you to power one of them while working with the other. However, each battery pack has a finite number of charge / discharge periods, failing when they are used up. In inexpensive tools, blocks break faster, and the user receives a gadget with a working motor, but no power. Then the dilemma arises “is it possible to connect the screwdriver directly to the charging”.

You can feed such a screwdriver by connecting it to the network through a power supply unit, because its motor operates at 220 volts.

Other ways to supply power

On their own

For users with special knowledge and skills, there will be no difficult problem “is it possible to power a screwdriver from a charger without special means”, because assembly of the feeding block is possible with your own hands. Instead of damaged elements, a power module assembled according to the scheme is inserted into the case. Outgoing voltage is monitored, the wires are powered, the case is locked.

Tip: the circuit may require additional load, it can be ensured by including a 15W light bulb in the system, which will also provide backlight.

Block inside

The solution to the problem “is it possible to connect a screwdriver through a charger” can be an alternative way to power the screwdriver. installing the power supply into the empty case of the power supply unit of the tool.

Before starting the action, it is necessary to prevent overheating of the unit, for which holes are arranged in the case in advance, which will provide air movement, heat removal. It is advisable to reduce the time of continuous work with a screwdriver with such an improvement to 15 minutes.

A ready-made block is purchased, it is selected according to the size of the case, technical indicators. The most suitable for use is the pulse version of the module, it is small in size, lightweight. The use of modules of domestic production from the times of the last century is not recommended. they have large volumes with low efficiency.

Unsuitable batteries are removed from the bed, and the power supply is placed in their place. The contacts are energized, the case is closed. The assembled hybrid gadget is ready to work from the network.

- Cables can be extended for convenience.

- It is necessary to monitor the quality of the assembly: the structure should not be able to touch the metal elements, otherwise the circuit cannot be avoided. It is best to leave some space between the transformer and the board, which will have a positive effect on cooling.

- If any parts of the structure are very hot, it is possible to install modules that remove excess heat, or to arrange ventilation slots.

A computer module will work too

Another solution to the problem of powering a screwdriver. mounting it to a computer power supply. This option is applicable to those modules that are equipped with a mechanical trigger. The positive aspect is that the unit is cooled by a cooler and is protected from exaggeration of the load by the built-in special system.

Such an assembly is arranged only with the use of power modules for 300-350 W and a current of 12 volts, at least 16 A. For instruments with a voltage of more than 14 volts, this power supply option does not work.

The user may want to hide an unaesthetic unit in a beautiful case, then it is recommended not to forget to arrange ventilation in it.

How to connect to the charging station

Before deciding whether it is possible to charge the battery of a screwdriver with a charger, you need to remember that the charging unit of the screwdriver supplies a low voltage, with a long wire length, the voltage is lost, so it would be rational to connect through a meter cord with a cross section of 2.5 mm2 or more.

- Wires are attached to the contacts of the charging unit of the screwdriver. Spoiled nutrients are removed from the nest.

- A groove is made in the case, a cable is passed through it. It is proposed to seal the entry point with elastic material so that there is no backlash and the wire is held securely in place.

- Since the nest has lost its weight after removing the unusable elements, it is recommended to restore the balance by inserting some kind of load into the vacated space, otherwise the hand will get very tired during work, eventually harming the health of joints and ligaments.

- The cable and previously attached wires are connected together, the body is assembled.

Car charger

In search of a solution to the question “is it possible to connect a screwdriver to a charger”, you can stop at charging with a car AK-block. Modules with manually adjustable current, voltage are applicable. The connection is absolutely not complicated. it is enough to connect the input channels of the tool motor to the contacts of the car charger.

Ways to remake a cordless screwdriver

Alteration of a screwdriver for mains power consists in converting 220V AC voltage to 12 or 18V DC voltage. One of the safest and easiest ways to convert a screwdriver into a network version is to use its standard components.

Alteration of a screwdriver for power from an outlet network

In the economy of a modern person, a screwdriver is not a rare tool, practically this tool is an analogue of an electric drill. The advantage of this type is considered to be autonomous power supply from a portable battery embedded in the lower part of the handle. The battery must be periodically charged from the mains through a special charger, with prolonged use the battery fails, replacement is required, and they are not cheap. Therefore, many users are thinking about how to remake a cordless screwdriver so that it works on 220 volts.

General view of one of the options

Sometimes consumers decide that it is necessary to convert the screwdriver into an ordinary electric drill powered from a wall outlet. The question arises of how to do this with less time and money. If you have certain knowledge in electrical engineering and practical skills, then powering a screwdriver from a 220V network is easy to do. There are several ways using various devices to convert electricity to the appropriate form for rotating the screwdriver motor.

Alteration with a standard battery and charging

Converting a cordless screwdriver to a network one in this case assumes that the circuit is assembled on the basis of a standard charger. The following materials will be required:

- Charger;

- Accumulator battery;

- 2-3 meters of flexible stranded copper wire, with two conductors, section 2.5-4 mm2;

- The usual set of tools and consumables, a soldering iron, solder, electrical tape or heat shrink tubing of the appropriate diameter to the wires. To disassemble the screwdriver, you will need a screwdriver, side cutters and an assembly knife for cutting and stripping wires.

The sequence of operations in the process of converting a screwdriver into a network:

- The cover is removed from the charger case;

- The ends of the wire are soldered to the output contacts of the charger board, which are connected to the battery during charging, observing the polarity. A core with red insulation. to the “” terminal, with blue insulation. to the minus terminal;

Charger board

- Polarities can be determined by the inscriptions on the board or the product case. For reliability, you can turn on the charging and measure the 12V output with a multimeter, and determine the contacts by polarity;

- Galvanic cells are removed from the battery case;

How are galvanic cells removed from the battery compartment?

- A wire from charging is connected to the contacts inside the battery case, observing the polarity.

Thus, the screwdriver is transformed into a network one. When the device is plugged into the socket, the corresponding voltage of 12 or 18 V DC will be supplied to the input circuit of the screwdriver.

Polarity is recommended but not required. When the polarity changes, the motor shaft will rotate in the opposite direction, all modern screwdrivers have a polarity change switch, in fact, the rotation of the screwdriver chuck is reversed.

Important! The terminals on the charger board are usually made of a brass alloy, they must be soldered to copper wires with acid solder or removed altogether, and the wires must be soldered to the tracks of the printed circuit board.

Before soldering, holes are made in the battery and charger cases through which the wire is pulled. For a more rigid fixation, it can be tied into a knot within the body and wound with electrical tape so that the winding diameter exceeds the hole Ø.

Replacing a faulty charging board with a power supply unit from a computer

In the case when the charging board is faulty in the set of the screwdriver control unit, in order to make the network option, a power supply unit with parameters suitable for voltage and power is installed. Sometimes the power supply comes from a personal computer. It should be borne in mind that the mains supply is converted to 12 volts DC, the screwdriver at idle consumes up to 4A current, for a short time at the moment of tightening. more than 40A, then the peak value of power consumption can be up to 480 W.

You can install a PSU from a laptop, they are compact and easy to use, but the maximum power of these models is within 100W, a little more is not always enough.

Laptop power supply

The output voltage is 19V, there are screwdrivers with such a power supply.

Power (P) = 19 A x 6.15 A = 117 W, then you can add a 12V converter, and the screwdriver will idle and tighten the bolts with little effort. When screwing self-tapping screws into a dense wooden surface, such a power supply may not last long. it will burn.

The location of the power supply inside the PC system unit

It is safer to use power supplies from the system units of stationary computers. They are more powerful and in all respects are suitable for connection to screwdrivers.

The peak power of such a power supply is 500W; the nominal load for long-term operation is 460W, this is just what you need for a screwdriver with a 12V power supply.

AX500-A board in a housing

There is a fan on the top cover of the metal case, which is connected via connectors to the board. Ventilated cooling allows the PSU to withstand high peak loads of 500W for a few minutes. Sometimes the fans are located on the side walls, it depends on the PSU model.

To connect such a power supply to a screwdriver, you need to perform just a few operations:

- Disconnect all power supply connectors from the motherboard and other elements of the system unit;

- Unscrew the fastening screws on the power supply unit and the system unit, then remove it from the system unit;

- There are no problems with connecting to a 220V network, a wire with a connector is included in the power supply kit;

- You will have to look for a 12 volt output, there are even two of them in this PSU model, you can find it by the markings on the printed circuit board. On some connectors, the output voltage is written opposite the pins;

Designation of contacts on PSU connectors

For your information. When there are no inscriptions, you can navigate by the color of the conductors; in this series, 12V power supplies are connected from the board to the connector by wires with yellow insulation. The minus connection is done with black wires.

- To check the correctness of the selected pair, you need to turn on the power supply and measure the voltage with a multimeter;

Note! In our case, a pulsed power supply unit is used, which will not start outside the system unit circuit. Without going into the details of the operation of individual semiconductor elements, we will simply accept as an axiom that a refinement is needed, which consists in a simple jumper.

- The green wire, designed to turn on the power supply unit according to the standard scheme, must be connected to the black conductor, this is done directly on the board. An extra piece of green wire is bite off, the remaining end is stripped and soldered to the board track to the black conductor;

Modification in the power supply unit AX500-A, installation of a jumper

- After the completion of the revision, the power supply unit can be connected to the network and check the presence of 12V on the selected pair of wires with a multimeter;

- The yellow and black conductors can be lengthened and the connector soldered to them;

- In the battery case for connecting a screwdriver, as in the previous cases, galvanic cans that have served their life are removed, and the mating part of the connector to the mowing line from the power supply is installed. The options may be different, you can solder the cord to the screwdriver, and the connector can be connected to the power supply, to whom it is convenient;

The conclusions from the 12V power supply are soldered to the connector that goes to the screwdriver

- When soldering connectors and connections, do not forget to first put heat-shrinkable tubes on the wires and shrink them with a hot air gun, isolating the soldering points. As a last resort, do it with ordinary duct tape;

- Unused leads from the power supply unit can be bitten off or rolled up, the ends can be insulated and folded inside the case.

Block AX500-A with fan

Note! Remember to connect the fan when assembling the case. If you unsoldered or bit off it during the installation process, you need to remember the connection contacts. The fan is powered by a 12V mowing line, by this indicator, you can easily find the connection points of the screwdriver.

Transformer circuit for powering the screwdriver

One of the available ways to quickly power the screwdriver from the network is to use the classic circuit with a 220V / 12-15V step-down transformer and a diode bridge, an AC-to-DC converter.

Transformer power supply circuit

All elements are easily placed in any case, the necessary controls, monitoring and indication are displayed on the front panel.

Transformers and diodes with appropriate parameters, withstanding powers of more than 100W, can be taken from old household appliances (TVs, tape recorders), from voltage stabilizers and other power supplies. If necessary, we redo the transformer, wind up the secondary winding or put an output in the winding for a certain number of turns, to achieve 12-15V at the output.

Installation of elements of the transformer power supply in the case

It is recommended to place the diodes on a duralumin heatsink, which effectively removes heat, extending the service life. Having certain practical skills and knowledge in electrical engineering, the transformer can be wound with your own hands.

There are many power supplies on the market with suitable characteristics to power the screwdriver from the mains, but this requires financial costs. If you have an old system unit from a PC, it is easy to remake the power supply, especially since, if necessary, it is easy to restore it to its original state and use it for its intended purpose.

Required materials and tools

Materials and tools when reworking a screwdriver completely depend on the type of tool and the type of power source, as well as its features. But to summarize, there are several main tools:

- screwdrivers;

- pliers;

- knife;

- insulating materials;

- cable for supplying electricity;

- soldering iron and soldering materials;

- any case for the future power supply.

Transformer

common power supplies that have proven to be reliable and efficient in many areas. The device consists of a step-down transformer and a rectifier through which the undervoltage passes. Rectifiers vary depending on the number of diodes used.

Such elements are easy to manufacture, cheap and reliable. Therefore, they are often preferred. They provide stable voltage without interference with high maximum power. But there are also a few downsides. The main disadvantage is bulkiness, with a much lower efficiency than that of pulsed sources. This fact requires the selection of a power supply for the screwdriver with a power greater than the tool needs. Since part of the capacity will go to side processes.

We use laptop charging

An excellent option is to use laptop charging. Such devices usually operate with a voltage of 12 to 19 V. This is quite enough to ensure high-quality operation of the screwdriver. But do not neglect the output current indicators. The closer it is to the required, the better.

In this case, reworking a screwdriver for mains power is reduced to an elementary soldering of wires from the charger to the board in the tool. It is advisable to isolate everything with electrical tape or other similar materials. After that, the wire is brought out and the tool can be used.

Alteration of the power supply unit made in China

Perfect for creating a power supply for a 12 volt screwdriver with your own hands, ordinary Chinese power supplies with an output voltage of 24 V and a current of 9 A. But since the tools use less voltage, you need to lower it first.

To achieve the goal, you need to replace the original resistor R10 with an adjustable resistor, with which you can achieve the desired voltage. This is done in several stages:

- a constant resistor is removed;

- in its place, a previously prepared adjustable resistor is inserted, on which a resistance of 2300 ohms will be set;

- so far, the voltage is still 24 V;

- using the resistor settings, you need to achieve the required voltage on the contacts.

After all the manipulations, you need to check that the output voltage is the required value (12 V, 14 V, etc.), and also that the current exceeds 9 A.

How to do it yourself

Before remaking a screwdriver, it is necessary to clearly determine what power and what voltage the tool needs to work. From this it will be necessary to proceed.

Then the tool body is opened. The two halves of the case can be fastened with screws or with glue. When disassembling, a knife can be very useful.

After opening the case, a power supply or a wire is inserted inside, the contacts of which must be soldered to the charger. Soldering should be as effective as possible, using special solutions.

The other end of the wire must be designed for mains supply. So there should be a fork. It is recommended to make a hole in the housing in advance through which the cable will pass.

A homemade power supply can be obtained in several ways. In any case, you will get a full-fledged tool that can be used to perform work after connecting to the network. It is advisable to pre-prepare a diagram that will help you avoid mistakes when creating a block.

Pulse

The principle of operation of pulse systems is that the voltage is first rectified and then converted into a special pulse signal. In this case, it is important to achieve a stable voltage. This can be helped by a transformer winding or resistors.

Switching power supplies are quite effective and can be used in different conditions. At the same time, they have a high level of protection against short circuits and similar effects. However, in terms of power, impulse systems are clearly inferior to transformer ones. In addition, such units are very capricious to the input voltage. If it is lower than the set, then the element may simply not work.

Computer power supply

You can make a screwdriver from the network using an unnecessary power supply from a computer. There are many types of such devices, but almost all of them are suitable for a screwdriver. The required wires can be found by colors, making inquiries on the manufacturer’s website.

Power supplies from computers are distinguished by their durability, advanced overload protection and a host of other advantages. They may not be very convenient due to their size, but a long wire will help solve this problem.

The procedure for connecting the computer power supply to the screwdriver:

- disassemble the block;

- remove the protection against switching on by disconnecting the green wire from the board;

- this wire must be connected to the black connector on the device;

- separate all wires except yellow and black;

- these two wires are soldered to the extension cable;

- the second end of the cable is directly connected to the screwdriver;

- all open contacts are isolated if possible.

Thus, a power supply unit for a 14 volt screwdriver will turn out from a computer device.

Professional power supplies for screwdrivers

These devices are the most convenient to use, as they are specially made for converting battery models into mains power tools. They are produced for different voltages: 12, 14, 18 and 24 volts.

Professional power supplies for screwdrivers

These devices do not need to be modified. they are already tuned to the specified parameters. Their connection will not be difficult. It consists in connecting the wires to the contact terminals of the screwdriver.

An important condition in all variants is the observance of the polarity and the prevention of operation with a device connected and a working battery at the same time.

Conversion of a screwdriver to mains power

One of the common reasons for the failure of a screwdriver is battery wear, that is, the moment when the battery stops accepting the charge necessary for the tool to operate. This always happens unexpectedly and always causes bewilderment: all units and mechanisms are in good working order, but it is impossible to achieve a result due to lack of power. Repairing a battery, like purchasing a new one, is not the cheapest way out. But, it is possible to convert the portable model into a network model, operating from a 220 V source, and return to working condition. How to do this will be discussed in this article.

- The prospect of the operability of the converted tool, the “pros and cons” of its use

- Various devices used when converting a screwdriver

- Application of a computer power supply

- Using a car battery charger

- Professional power supplies for screwdrivers

- Ability to connect screwdrivers to a 220 V network using various power supplies

The prospect of the operability of the converted tool, the “pros and cons” of its use

The condition for the successful reconstruction of the old screwdriver is the serviceability of its main parts: the motor, the gearbox, the start button, and the clamping fist. Only the feeding element is subject to alteration, so the rest of the “filling” must be in working order.

Of course, as a result of design changes, the tool will lose its main advantage. mobility. It will entirely depend on the presence of a nearby electrical point with a voltage of 220 volts. But it will remain operational for a long period of time and will even receive a number of advantages:

- cost savings;

- no need for periodic recharging;

- complete elimination of the possibility of loss of functionality of the product after prolonged inactivity.

One way to solve the power problem is to use extension cords, but this option is not always available. Nevertheless, the power tool will remain useful and can serve in the home workshop.

Various devices used when converting a screwdriver

The most optimal option for turning a cordless tool into a network tool is to use an external power supply. Its main purpose is to convert 220 Volts into a voltage acceptable for the product (12, 14, 18 Volts). It must correspond to the rated voltage for which the consumer is designed.

Practical tip: The amount of current coming out of the power supply should be approximately the same as the value specified in the performance of the screwdriver. Otherwise, the tool may not reach the required power for work.

Among the devices most often used when reworking screwdrivers, the following can be noted:

- power supplies from laptops or personal computers;

- car chargers;

- professional power supplies for screwdrivers.

The features of using the listed products are described in the following sections of the article.

Using a car battery charger

The best option would be an adjustable analog device. It will act as a converter of 220 V AC voltage to 12-14 Volts DC consumed by the power tool. The advantage of this option is that there is no need to change anything in the design of the “charger”.

The connection is made as follows:

- in the disassembled battery from the screwdriver, it is necessary to cut the wires connecting the batteries to the contact terminals;

- through the hole made in the case, pass a cable 2.5-3 meters long, the ends of which are connected to the wires soldered to the battery terminals;

- switch opposite ends of the cable to the charger output;

- latch the battery, apply voltage. the tool is ready for use.

Appearance of a charger for car batteries

Practical tip: Do not use a cable that is too long to connect the impact wrench. This can affect its power. with a long length, current losses will be noticeable. This can be avoided by increasing the cross-section of the wires, but this will affect the usability.

Application of a computer power supply

These devices can have a power of 250-350 W, and the output voltage is 12 volts for a PC and up to 20 volts for laptops, which is quite enough for the operation of a power tool. First of all, you need to prepare the ends of the wire of the low-voltage part of the unit for connection to the screwdriver terminals.

In the case of an adapter from a laptop, it is enough to cut off the plug, determine the “positive” and “negative” conductors on the wire, mark and strip their ends.

When working with a power supply from a personal computer, the operation will be more difficult, since many wires come out of the low part, connected at the end into connectors.

The voltage of 3.3V, 5V and 12V comes out of the PC power supply via different wires. The main task is to choose the color of the conductors corresponding to the voltage of 12 volts.

The procedure for selecting the required conductors:

- on the largest square connector (power), identify the green wire and connect through the button to any of the black wires of the same connector (the rest of the wires can be removed);

- on a smaller connector called “Molex,” the yellow wire and one of the black wires are selected;

- they are connected to the ends of an extension cable, which will later serve to connect a screwdriver.

Color-coded wires on the connectors of the computer power supply

Further connection of the instrument itself is carried out according to the step-by-step instructions:

- The battery case from the screwdriver is disassembled

- The batteries contained in it can be removed, but it is better to leave it to maintain a comfortable grip.

- A hole is made in the back of the case through which the cable from the adapter is passed

- The wires connecting the batteries to the battery contact terminals are cut and joined with the cable from the adapter

- The joints are carefully insulated

- The battery is assembled and docked with a screwdriver.

The final step is to check the functionality of the upgraded tool.

Ability to connect screwdrivers to a 220 V network using various power supplies

Various devices, sometimes the most unexpected ones, can act as step-down transformers and converters for converting cordless tools into network ones. For example, drivers for LED lamps (12V) have proven themselves positively in this matter. Also, backup batteries of alarm systems are used quite successfully for this purpose.

The option of connecting a screwdriver from a car cigarette lighter is possible. Of course, it will not reach high power, but it will be able to tighten the screws in the garage or in the country.

it is worth noting that not all breakdowns of a power tool force you to put an end to its operation. In the case of a cordless nutrunner that has a failed battery, you can easily find a way to restore its performance.

Conversion of a screwdriver from a battery to a mains supply

- Battery Disadvantages

- There is a way out. reworking the screwdriver in the network

- External power supply

- Battery case power supply

- DIY screwdriver alteration

- Using a power supply from a personal computer

- Using a car battery charger

- Making a homemade power supply

- AC adapter for screwdriver in battery housing

- We build in a ready-made power supply

- Homemade power scheme

Those who have used a cordless screwdriver have appreciated its convenience. At any time, without getting tangled in the wires, you can crawl into hard-to-reach niches. Until the battery runs out.

External power supply

The idea is not as absurd as it might seem. Even a large and heavy buck rectifier can just stand near the outlet.

You are equally tied to the power supply, and to the stuck mains plug. And the low-voltage cord can be made to any length.

IMPORTANT! Ohm’s law says. with the same power, decreasing the voltage. we increase the current strength! Accordingly, the 12-19 volt supply cord should have a larger cross section than 220 volts.

Making a homemade power supply

If you are familiar with the principles of building electrical circuits, you can make your own power supply. Scheme giving general concepts. in the illustration.

The transformer can be picked up from an old tube TV, or other household appliances. Power 220 volts 250-350W. The main thing is the power supply. the donor should not be pulsed.

The voltage on the secondary winding is 24-30 volts. The secondary winding is made from a wire of the corresponding section.

However, if the output winding current is at least 15 amperes (see transformer specification), there is nothing to worry about.

After losses on the diode bridge (1-1.5 V on the diode), you will get the required output value.

If you have an electrical engineering education, make the calculation yourself. Or in a practical way: by connecting a 220 volt 100W incandescent lamp as a load, measure the output voltage. E

If it exceeds the needs of the screwdriver, reduce the number of turns of the secondary winding of the transformer.

Using a car battery charger

The principle is the same as using a computer power supply. It is necessary to purchase an old charger for the starter batteries. The modern fashion for compact impulse chargers has left analog linear devices with manual control of voltage and charge current behind board. Therefore, such a device can be purchased on the automotive market for a symbolic cost.

Charger MAX INTER

It’s good if the voltage can be adjusted smoothly. in this case, your makeshift power supply will fit any screwdriver.

Converting it to a power tool is reduced to connecting the input of the electric motor to the power terminals of the charger.

AC adapter for screwdriver in battery housing

If your tool is not too powerful, you can place the power supply in the handle or case from damaged batteries.

DIY screwdriver alteration

Consider the option with a remote power supply.

We build in a ready-made power supply

To do this, you need to purchase a ready-made block with suitable characteristics and dimensions. There is enough such good on the radio markets.

Take the body with you and go to the fitting. When the desired power source is purchased, carefully separate it from the case.

We place the screwdriver in the battery box. All components must be securely fastened.

If necessary, extend the wires connecting the control board and the transformer. If the circuit touches the metal parts of the transformer during operation, a short circuit will occur.

Since the space in the case allows. separate the board and the transformer for better cooling. Whichever quality power supply you choose, the load will be high and overheating is possible.

It will not be superfluous to fix additional radiators on the power control microcircuits. Operate the screwdriver for a long time, disconnect it from the mains and touch the radio parts on the control board.

You yourself will understand which elements need heat dissipation. Holes can be made in the housing for air circulation.

Do-it-yourself rework of the power supply will not take much time, and the cost of the purchased module is incomparable with restoring the battery.