How to cut concrete pile under the house. Installation of the pile field

Quickly, simple and inexpensive, or how the foundation is replaced with screw piles

Replacing a weakened foundation with supports is a practical and least costly way to extend the operational resource of the entire structure.

So that the house no longer threatens the risk of collapse, it is necessary to re.conduct engineering calculations for the foundation, carry out construction work as carefully as possible, without violating the technology.

About how to replace the foundation with piles (for example, columnar. on screw), we will tell in the article.

When it is required to replace an old base with a new?

Even the most reliable base during operation of the house is gradually destroyed under the influence of loads and the influence of external factors.

With minor deformations, it is possible to reconstruct and strengthen the weakened foundation, but most often such events do not bring decent results, and at the same time are accompanied by significant labor, temporary and financial costs.

Signs by which you can judge the need to replace the entire power structure:

- Numerous cracks appeared in the bearing walls.

- The house gave a sediment, as a result of which the geometry of its structural elements was violated.

- The foundation is visually greatly destroyed.

In such cases, it is impractical to carry out repairs, and it is better to immediately raise structures on a new foundation.

Why choose a pile structure?

At the moment, the installation of piles remains a proven and most reliable way to replace the foundation. At the same time, it must be taken into account that the technology is suitable only for frame and wooden houses, since the walls of brick and other heavy materials will not withstand the loads in the process of lifting from the old foundation and may be destroyed.

The advantages of the pile methodology are as follows:

- great bearing capacity of power elements;

- the possibility of building on almost all types of soil, except for rocky breeds;

- sufficient stability in areas with moisture.saturated soil;

- accessibility and low price of building materials.

What is the advantage of such supports?

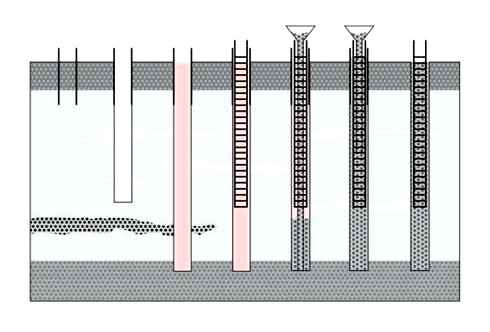

Buronaby, pressed and screw piles are suitable for replacing the foundation, which differ, first of all, by the method of device in soil.

Pros of pile-screw technology:

- economy;

- sufficient carrying capacity;

- high speed of construction;

- lack of earthwork;

- additional soil seal in the process of screwing the blades;

- maintainability;

- the possibility of dismantling for reuse.

In addition to the listed advantages of screw piles, you need to take into account the main disadvantages of other technologies:

- For installation of brownish piles, it is necessary to produce wells and wait 2-4 weeks, while the concrete solution gains strength;

- It is almost impossible to reliably calculate the bearing capacity of brownish supports;

- To press the component screws, it is necessary to use self.propelled special equipment, which is quite problematic to drive to a section with high development density.

Work with various types of foundation

The dismantling of the foundation of various types has its own characteristics. They influence how the work is necessary.

Ribbon

The complexity depends on the presence of the basement, thickness and depth of the structure. For the destruction of the base, scrap, sledgehammer, junk hammer or peorator are used. To cut the reinforcement, an angular grinder equipped with a special disk can be used. When working with more massive and voluminous designs for dismantling, special equipment is used.

From prefabricated reinforced concrete

Such a foundation consists of reinforced concrete blocks. Before removing them, the connection is destroyed using a jack of a hammer. In this case, the mounting loops must bend up. Blocks load on transport and take away. Reinforced concrete structures retain their qualities when dismantling. Therefore, they are often used again.

Pile

If this type of foundation was used, it is rarely dismantled. The use of piles increase the bearing capacity of the soil. The need for complete removal can arise only in special cases, for example, when laying communications.

In most cases, only the upper part of the piles is removed during dismantling. It is convenient to do this with a corner grinder.

Monolithic slab from reinforced concrete

For its destruction, the same methods are used as when removing the strip foundation. However, sometimes instead of dismantling it, they use it again if it corresponds to the features of the new design. over, it can be reduced or increased to comply with a new purpose.

Stages of dismantling

Regardless of who performs the dismantling of the foundation. a do.it.yourself owner or a specialized company. there is a certain sequence of work that needs to be followed:

- First you need to draw up a detailed plan of dismantling. Here you need to fix what and in what sequence to do.

- It is necessary to consider the issue of how the garbage remaining after the destruction of the foundation will be exported.

- We need to familiarize yourself with the rules that relate to the safety of the work.

- We need to think about what mechanisms and tools will be required to dismantle.

It is necessary to determine what work methods will be applied. The following can be used:

- the use of a jack of a hammer, scrap, hammer or other similar tools;

- using specialized technology;

- Destruction can be carried out using certain chemical compounds;

- Dismantling can be based on the use of an explosion;

- Ultrasound may be used for this purpose;

- It is possible to use hydroclin.

When working with the foundations of private houses, the first two ways are usually used. The cheapest is the use of a manual method of work. However, it requires significant expenses of time and effort. It is sometimes more profitable to hire a team of workers or contact a specialized company.

The dismantling of the foundation using an explosion is possible only in cases where there are no other buildings and buildings near the place of work. In order to use special chemicals, holes are drilled in the design. Then a solution is poured into them. This method is relatively costly.

The principle of operation is that the emulsion in a short time increases in volume several times. After destruction by chemicals or ultrasound, the structure breaks up into small pieces.

Hydroclin acts pointily and is completely safe for the environment. It through the spacer frames under high pressure supplies fluid into the wall. She gradually bursts out the structure and destroys it. Before using this tool, a hole is drilled in concrete, into which the tool is then inserted.

For export, you will need to find transport. If large pieces have formed during dismantling, they need to be crushed before loading.

When planning work on your own, you need to evaluate whether there are enough forces and means for this. This can be found out only after detailed planning will be carried out. If your own abilities are not enough, you can contact a specialized company for this.

After the planning is completed, direct work on dismantling occurs. After its end, it is necessary to carry out garbage collection.

Visiting Pikabushnik

So I went to the picabushnik @pyshnyd watch the foundation.

According to Pyshnyd, this is “nothing interesting”

Pine material, diameter from 350mm, brought from the north.

Comuli did not specifically cut for visuals.

Ceilings 3 meters, 8 logs of total. Teremok, in short, and like a bunny inside.

If the paws cope, mount the video (but this is not exactly).

Compare the cost of the walls of the frame and timber

Picabu spores are sometimes useful because truth is born in them. True, it does not reach everyone. Recently, in addition to the arguments of the “grandfathers” and always build like this, in favor of warm winter houses from a beam with a wall thickness of 200 or less than millimeters, another argument has appeared. build from a barbar. Usually I do not enter into disputes with frankly inadequate people, but I could not keep silent here. Let’s just answer in numbers.

PILES construction/installation process step by step.

Take a wall of 6×2.5 meters for example (you get an area of 15 m2) and make it from the beam and in frame technology. All for woods, except for a chamber drying board (there is no necessary thickness) I take on one site, these are average market that are relevant at the time of writing.

In the calculations of energy efficiency, we will proceed from the norms of thermal conductivity for subsequently, which, the thermal conductivity of the enclosing structure should be from 3.2 (m² ° C)/W and above.

Why we count only the walls? The rest in the design of compared houses may be the same. Foundations, overlapping, roofs, windows, there is no point in comparing.

In order not to overtake everything, it is necessary to take a beam of at least transport humidity, I’m not talking about chamber drying, 150x200x6000, well, it is clear that it will need a strict one (otherwise you will have to be polished, so as not to rush about the walls, and this is also money).

3 800 apiece. The wall of 6×2.5 meters will require 17 bars. We will not count the shrinkage. We also do not consider the intensity insulation, as well as all sorts of lotions such as “Strength” nodes and tightening spitters.

Total, purely for the beam. 64 600, let it be the cost of our wall.

Brows 200 mm. Heat transfer resistance: 1.27 (m² ° C)/W (at normal 3.2)

And the overwhelming of a two.hundredth beam of chamber drying? This is what will make the house answering the joint venture? Or it will not need to be caulk? I will take a bass 150×150 from a local sawmill of 15 thousand per cubic meter. 2.25 cube for 15 = 33 750 per beam. Plus thousand and a half for the intervention. it. ALL!

@Stika, #comment_252518356

Bay 150 mm. Heat transfer resistance: 0.99 (m² ° C)/W (three times lower than normal)

So you can reach the bar 50×50. The trouble is that the heat resistance will fall directly proportional to the thickness of the beam.

It will be a little more complicated here. First you need to understand the design of our wall. Let’s take a wall without windows for example, t.to. In the beam we did not take into account windows and casing. It will look like the right wall in the figure below.

Despite the fact that we are drawn with a slogan and could devote it to a simple frame wall, with insulation between the lags, we will make a high.quality wall using MDVP Beltermo as hydraulic protection and cross.insulation of 200 mm thick.

The frame of the wall drying of chamber drying 150x50x6000 costs 1,110 a bit. There are 10 boards on the wall 6×2.5 meters (4 on the lower and upper bindings, 5 by 7 racks and corner boards, 1 on two ugsins). This is 11,110 per frame.

Vapor barrier in the technonic 95 per m2 15 = 1 425

Warming will be crossed, which means that we will need several layers. Between the lags we put a layer of 100 mm 50 mm with a displacement, then across the racks (vertically standing boards of 150×50), we’ll sew a crate from a bar 50x50h6000 and put another layer of 50 mm to cut off the heat leakage through the racks.

We will need Rockwool Scandhy 100 mm. 15 m2 to 335 per m2 = 5 025 rubles the same, but 50 mm. 30 m2 to 173 rubles per m2 = 5 190 rubles a dry string for the crate, we will also write in elements of insulation, 50x50x3000 at a price of 190 apiece, we need 12 pieces = 2 280 rubles 12 495

Hydraulic protection as hydraulic protection, and at the same time soundproofing and additional insulation we will use the downstream Beltermo MDVP 32 mm, per m2.Our 15 square meters we will sew for 11 550.

This expensive option can be replaced with OSB-3 Kalevala (it turns out about 180 per m2 or 2,700 over the entire wall), or generally on a hydraulic protection membrane (then less than a thousand will go throughout the wall), but we will leave it.

Formation of the beam inside and outside, by area 30 m2, 510 per m2 = 15 300. You will also need a 2 20x40x3000 counter for organizing a ventilationzor between Beltermo and a facade imitation of 12 pieces of 125 = 1500.

Durability

If we talk about concrete, then according to the unchanged GOST 27751-2014, if everything is done in accordance with the technology, then such a foundation will stand at least 50 years. In this case, it is necessary to take into account the operating conditions, the quality of materials, the negative effects of the environment, waterproofing and much more. Only with an ideal ratio of all characteristics, the concrete base will last the declared period.

At the same time, 1 mm steel (ST20), which is usually used for the manufacture of piles, will serve at least 40 years without any coatings, even if it is in loam. But the piles are made with wall thickness up to 6.5 mm. But you need to take into account the load and other parameters. But in any case, the piles certainly cannot last less concrete. Even if the piles are installed in the so.called aggressive soil (where there is slag, ash, etc.), then the design will still fully meet the requirements of GOST.

Healthy! Galvanized piles should not be installed. Even in the best conditions, they have been serving for no more than 15-20 years.

Do.it.yourself installation work on the installation of pile foundation

For the installation of reinforced concrete piles, certain materials, tools, completed calculations and project will be needed. If it is difficult to calculate the parameters yourself, you can use online calculators or services of professionals.

Choosing type of piles

In accordance with the method of immersing piles in the ground, several types of supports are distinguished. You need to choose a specific type, taking into account the characteristics of the soil, the depth of the supports, the presence of the desired equipment and the tool. So, for example, if a base for a heavy house is created, the supports will be alone. When designed on stilts, they choose completely different options.

- Clogging. immersion of usually continuous square supports into the soil with different pavers, loaders, hammers

- Shell.in.law. hollow piles that are buried in a vibration loader and then poured with concrete

- Screw. steel supports are screwed into the soil thanks to the special blades available on the surface

- The stuffed ones are the easiest option when in a previous hole in the soil with a reinforcement installed in it (or without it), a concrete solution is poured

Piles can be located in the ground in different ways: separately in important nodes of the base, ribbons around the perimeter of the walls, bushes at points for massive structures, field to support the grillage.

The piles themselves can be made of metal, wood, concrete, reinforced concrete. According to the presence inside the void, the supports are continuous and hollow, in diameter. square, round, complex shape, in terms of support. hanging and supporting.

In private construction, reinforced concrete stuffed, screw steel piles are usually used. The most common are such types of foundation as pile-screw and brownish.

Patch marking

After geological surveys are completed and the project is ready, it is necessary to prepare the object. The construction site is thoroughly cleaned of garbage, aligned, marked. The design position of the piles is carried out on the object using geodetic instruments (leveling, theodolite), marked with wooden stakes and rope (external perimeter, grillage dimensions).

Drilling pits

Trenches dig as you like. you can use a small drill (especially if the supports are installed to a significant depth). The height of the trench should be at least 1.5 meters, diameter. from 15 to 40 centimeters. In order to increase the level of stability of the building to the fusion, the diameter of the well in the process is expanded (the sole is 40-60 centimeters, on the surface-20).

If the foundation is drilled with your own hands, the level is tied to the drill. the vertical must be controlled after each turnover.

Between the supports of the house, the minimum distance is the amount of three sections of the supports: so, if the diameter of the piles is 40 centimeters, the minimum step is 120 centimeters. But these all calculations are performed before drilling is carried out, how the piles are clogged, etc.D.

Installation of formwork

Formwork is made from cement pipes or wooden boards. The design is performed on bulk and weak soils to prevent the destruction of the walls. If the soils are dense, the formwork is enough only above the surface of the earth to make a head. The frame may be a waterproofing asbestos.cement pipe or roof roofing material.

Production of a reinforcing frame

Before pouring piles with concrete, they need to be reinforced. To do this, use steel rods with a section of 12 millimeters. The rods are connected through each meter with transverse rods or knitting wire with a cross section of 8 millimeters. To provide communication with the grillage, the frame is made at least 10 centimeters longer than pile (then the edges are associated with the reinforcing frame of the grillage).

Pouring concrete

Do.it.yourself piles do not make it difficult. The material can also be prepared independently or ordered ready from the factory. The piles are filled with concrete in layers, necessarily vibrated or compacted with a piece of reinforcement. After the concrete froze, the formwork for a monolithic grillage is mounted.

Concrete piles and the foundation created on their basis is a great opportunity to build a strong, reliable, durable building. Subject to the correctly completed project, compliance with technology and certain knowledge, all work can be done independently.

Cutting concrete blocks may be needed when, during construction, you need blocks of non.standard sizes. this often happens during the masonry of the corners, when the cracks form between the material.

You can cut a stone manually. using an angular grinder, a split with wedges or shplints, as well as using a specialized technique. Compliance with the rules of cutting and the nuances of the material will help make a smooth and beautiful cut without further surface correction.

How concrete matures

On the construction forums about the partial filling of the foundation are hot disputes. Some users claim that this will sharply negatively affect the strength of the base of the house and eventually lead to its destruction. Others parry that such a foundation will be no less durable than composed of concrete blocks.

Both sides are given by a lot of other arguments in favor of their point of view. But if you yourself want to understand whether it is possible to fill the foundation in parts, you need to figure out what processes occur in concrete since its preparation and what will happen if they intervene in them.

Concrete is sand and crushed stone, the particles of which are associated with each other with cement glue. The process of formation of ties within the material begins when mixing dry ingredients with water that triggers chemical reactions.

At the first stage, there is an active reaction between water and cement with the formation of crystals. It lasts several hours during which water molecules are gradually binding, and the solution loses mobility. The reaction rate depends on the external environmental conditions, and primarily on air temperature, as well as on humidity, precipitation, wind. In dry and hot weather, it can end after 2-3 hours, and at low temperature and high humidity only after 8-10 hours.

During this period, the solution cannot be mixed, watered with water and generally intervened in the process in order not to violate the formed connections.

The next stage is characterized by the germination of crystalline ties into each other. He goes slowly, but for a long time. Concrete gains design hardness and strength only after a month, it is this period that it is recommended to withstand before starting to load the foundation, erecting the walls of the house on it.

If concrete is not pushed under the weight of a person, this does not mean that it has finally ripened the source of Pol-EXP.com

But we are interested in another question. whether it is possible to fill the strip foundation in parts, how the lower layer will behave when filling fresh solution, how high.quality the clutch of the layers will turn out.

What happens to concrete during layer.laying filling

In the first hours after pouring, while the so.called “liquid” phase of grasping continues, a fresh portion of the solution can be laid on the yet unrelated mobile concrete. Particles in the lower layers perceive the load, they are easily redistributed under the weight of the upper layer, since they are not yet connected with each other. And a fresh solution will easily “germinate” into an already laid mass.

But from the moment when crystals begin to grow together with each other and until a significant strengthening of these connections, it is impossible to load concrete. This will cause deformation in the thickness of a weak concrete and the appearance of cracks interrupting the connections. Such a base will not be durable and will not be able to withstand the weight of the building. it will gradually collapse.

Therefore, the question of the question of whether it is possible to pour the foundation in parts in a few days, experts give only if the next layer is laying no earlier than three days after the previous one. This is the minimum period that is necessary for concrete for hardening and acquiring the stability of the lower layers for loads.

But in this case, you will have to solve the problem of the “cold seam”, the so.called the joint between the layers of concrete of varying degrees of maturation. Fresh solution will harden on its own, without forming connections with already captured concrete. In fact, such a foundation cannot be called monolithic, since each of its layers is a separate supporting element of the structure. And these unrelated elements can move relative to each other.

Installation of Driven Precast Reinforced Concrete Piles

But there are ways in which you can achieve the integrity of a concrete tape or slab and give it the properties of a monolith.

Cutting concrete piles

Cutting concrete piles our company provides professional equipment for cutting concrete piles, as well as equipment for waste removal. The exact cutting of concrete piles covers many advanced technologies, including the technology of column drilling, sawing plates and walls and robotic demolition. Our techniques and engineers have knowledge and experience necessary for processing almost any type of concrete piles. Clients depend on our innovative solutions, as well as advanced equipment and equipment. Our rapid response groups can quickly develop and implement plans for working with almost any commercial or industrial project of pruning concrete piles. often within a few hours. Successfully completed work includes pruning concrete piles for the construction of dams, berths, garages, nuclear power plants, treatment plants, chemical plants, interstate roads and bridges of all sizes. Technology and engineering pruning of concrete piles have come a long way since the time of dusty, inaccurate and sometimes dangerous methods of the past. Today, experienced teams of our experts use the most modern diamond cutting systems to ensure effective and safe completion of pruning concrete piles in even the most difficult working conditions. Diamond spraying of rectangular cutting disk teeth allows the techniques to cut difficult materials. including enhanced reinforced concrete piles. Water is used in the process to compensate for friction and let the blades cool down the use of water also minimizes potentially harmful dust particles and removes the sludge from the cut. The result is a clean, smooth and accurate cut concrete. Our methods of pruning concrete are fast, reliable and economically effective. Remote experts are able to install equipment within 24 hours, regardless of the location of the construction site. Our company is a reliable partner for work with complex pruning of concrete piles. Column drilling methods of column drilling are used when accurate, round cutouts are needed. The holes of almost any diameter is easy to drill, thanks to our equipment. The main drilling is also widely used to create holes when laying cables or placing anchor bolts, installing supporting devices such as dowel, or to analyze mountain structures or soil layers. The hydraulic destroyer of the pile will cut concrete heads for several minutes. The destroyer moves from pile to Swai using an excavator or crane, having a total weight of 2.2 tons. A hydraulic hammer can cut from 100 to 150 piles in just 6 hours. The operator who controls the process from the cab and the man on the ground to control the cutting operation is all the necessary personnel for servicing the destroyer. Firstly, a hydraulic destroyer of concrete piles cuts pile heads up to 1 meter high. At first, the hammer is automatically installed on the pile, depending on the level of the cut. When the hammer is installed in the right position, the operator activates four modules that cut the pile of the pile, receiving a clean, smooth surface along the cut level, without prejudice to steel pile reinforcement. After the operation of the destroyer is completed, the operator transfers the destroyer to a dump truck and turns off the hydraulic system, having previously automatically cleaned the teeth. The whole operation takes about five or less minutes. Now the destroyer can be installed on another pile. This method saves time, money and work, because the car cuts the piles much faster than the jack of a hammer. We argue that our equipment can increase the reduction in the cost of pile work by 70% or more. Based on the release of 100 piles per day, the costs of labor and equipment are estimated, in minimal quality, like 10 for pruning one pile. Cutting the piles with a chipper hammer, finalizing the cut with a saw and the cost of a loader for the disposal of garbage. all this costs from 40 to 60 dollars for pile before knocking down a pile with a junk hammer, workers must prepare the soil, cleaning the place next to the pile. A pile destroyer usually has four working modules with teeth, which eliminate the need for manual revision. Our equipment is able to work on a swampy construction site, our client will not have to wait for the pumping of water by a pump or wait for the site to dry out. If the pile is completely immersed in water, the destroyer is able to work under water. We offer special, technically little equipped equipment. Only chisel and teeth will need to replace after several years of use in such conditions of pile trimming. Cutting concrete piles. A hydraulic pile destroyer is supplied in two types: a 1.2-ton model for 20-35 centimeter round piles and a 2.2-ton model for 10-50 centimeter square piles. In 6 hours, a pile destroyer can cut from 150 to 200 piles, and large piles are in an amount of 100 to 150 piles. We also supply the tested triple incisors for trimming round piles. The hydraulic destroyer installed along the notch line will leave a clean, even cut of pile with intact reinforcement.

In what cases are dismantled?

The structure of the structure get rid of various reasons. They are all quite good:

- The previous base is completely not suitable for the design of a new house;

- laying the missing engineering communications is required;

- in the place that occupies the construction, the owner plans to break the garden (pond, garden);

- Significant shortcomings have been identified during the manufacture of the “backbone” of the new house.

Acceptable methods

Many are sure: you should not think about the methods of destruction. Nevertheless, non.compliance with the long.developed technologies threatens the customer with loss of time and security.

Proper alternatives have been developed that take into account 4 important factors:

Manual (with the help of a drill, peorator and heavy sledgehammer)

The specified species is used when you should get rid of the fine.pounded foundation, in which metal screw piles were not used. only short brownizer or “driving” (zhB).

The former are based on the removal of the soil with the help of a drill and the simultaneous filling of the formed screw with concrete (a large deepening in some situations is problematic and is not required in the construction of a 1-story private house). The second drives the Copernet.

The mentioned type of work is based on the use of the listed tools that destroy the construction solution itself. the material of such supports. It is drilled, drilled and beat with a large hammer.

Mechanical

This method is based on cutting, and on the twisting of metal screw piles that go too deep into the ground (they freely screw into any soil except rock).

The most economically profitable is the second option. Allows you to re.use supports on the farm.

With the involvement of an excavator-destroyer

The last variety is called “rude demolition”. The named special equipment with the help of a heavy iron nucleus eliminates the protruding parts of the support supports along with the building. This method still requires finalization. the use of one of the first methods.

- Dates. Performance of work and the deadline for delivery is stipulated in the contract.

- Reasonable prices. The price includes the delivery of supports to the construction site and the use of the pile. After installing and aligning the supports, you can immediately proceed to the device of the grillage.

- Terms. Work on the preparation of the territory, marking and clogging are carried out by experienced specialists whose work is a guarantee.

A few decades ago, the technology for arranging a pile-risk foundation was an expensive and bulky procedure. For suburban houses, alternative options were used. screw and bored piles, less reliable and durable.

Today, in private construction, a variety of piles on wheeled and caterpillar are used in private construction. They effectively cope with the piles of piles for foundations for suburban country houses and cottages using special hydraulic equipment. Such mechanisms do not deform piles and work on all types of soils.